Page 1

Contents

EC Declaration of Conformity................................2

Operator safety .....................................................3

Description ............................................................4

Operation diagram ................................................5

Connecting the sprayer .........................................6

Roadworthyness ..............................................6

Operating instructions ...........................................7

Operation of the boom .....................................7

Boom height.....................................................7

Pulsation damper .............................................7

Adjustment of the operating unit ......................8

Maintenance..........................................................9

Filters ...............................................................9

Lubrication .....................................................10

Readjustment of the boom.............................12

Changing of valves and diaphragms..............13

Nozzle tubes and fittings................................14

Off-season storage ........................................14

Operational problems..........................................16

Technical specifications ...................................... 18

Pictorial symbols ................................................. 20

Preassembly information.....................................21

Assembly.............................................................22

Spare parts drawings .......................................... 27

BL

Instruction book

673224-GB-04/2002

HARDI INTERNATIONAL A/S reserve the right to make changes in design or to add new features

without any obligation in relation to implements purchased before or after such changes.

1

Page 2

EC Declaration of Conformity

Manufacturer,

HARDI INTERNATIONAL A/S

Helgeshøj Allé 38

DK 2630 Taastrup

DENMARK

Importer,

declare that the following product;

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Adhere extra shipping package labels to inside cover.

A. was manufactured in conformity with the provisions in the COUNCIL

DIRECTIVE of 14 June 1989 on mutual approximation of the laws of the

Member States on the safety of machines (89/392/EEC as amended by

directives 91/368/EEC and 93/368/EEC) with special reference to Annex

1 of the Directive on essential safety and health requirements in relation

to the construction and manufacture of machines.

B. was manufactured in conformity with the standards current at that

time that implements a harmonised standard in accordance with Article 5

(2) and other relevant standards.

Taastrup 03.04.2002

Lars Bentsen

Product Development Manager

HARDI INTERNATIONAL A/S

2

Page 3

Operator safety

Watch for this symbol . It means WARNING, CAUTION,

NOTE. Your safety is involved so be alert!

Note the following recommended precautions and safe operating

practices.

Read and understand this instruction book before using the

equipment. It is equally important that other operators of this

equipment read and understand this book.

Local law may demand that the operator be certified to use spray

equipment. Adhere to the law.

Pressure test with clean water prior to filling with chemicals.

Wear protective clothing.

Rinse and wash equipment after use and before servicing.

Depressurize equipment after use and before servicing.

Never service or repair the equipment whilst it is operating.

Disconnect electrical power before servicing.

Always replace all safety devices or shields immediately after

servicing.

If an arc welder is used on the equipment or anything connected

to the equipment, disconnect power leads before welding. Re-

move all inflammable or explosive material from the area.

Do not eat, drink or smoke whilst spraying or working with contaminated equipment.

Wash and change clothes after spraying.

Wash tools if they have become contaminated.

In case of poisoning, seek doctor or ambulance. Remember to

identify chemicals used.

Keep children away from the equipment.

Do not attempt to enter the tank.

If any portion of this instruction book remains unclear after read-

ing it, contact your HARDI dealer for further explanation before

using the equipment.

3

Page 4

We congratulate you for choosing a HARDI plant protection product. The reliability and efficiency of this product depend on your care.

The first step is to carefully read and pay attention to this instruction

book. It contains essential information for the efficient use and long life

of this quality product.

As the instruction book covers all BL models, please pay attention to

the paragraphs dealing with precisely your model. This book is to be

read in conjunction with the Spray Technique book.

HARDI INTERNATIONAL A/S reserve the right to make changes in

design or to add new features without any obligation in relation to

implements purchased before or after such changes.

Description

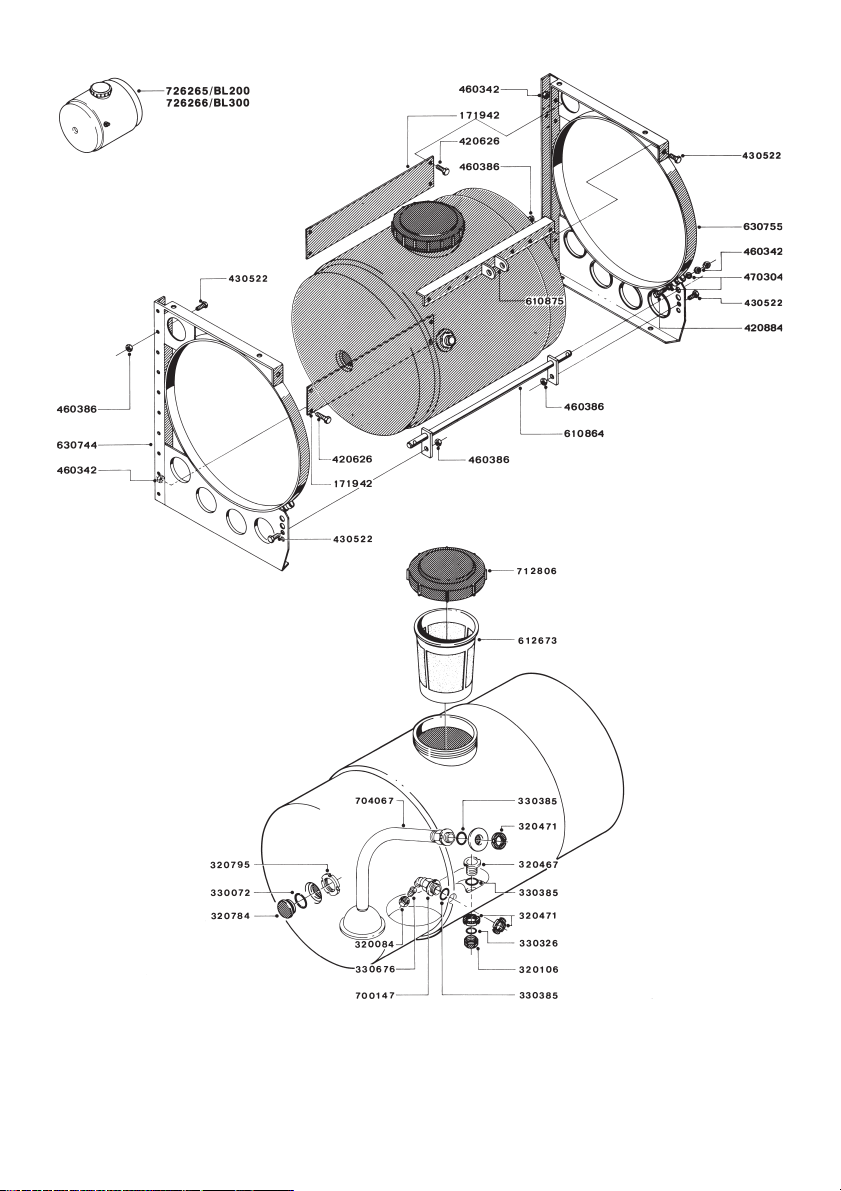

The Hardi BL models consist of a pump, frame with tank of 200 or 300

litre capacity with basket filter, M-70 operating unit and 6 or 8 metre SB

booms.

The design of the diaphragm pump is simple, with easily accessible

diaphragms and valves that ensures liquid does not come in contact

with the vital parts of the pump.

The tank, made of impact-proof and chemical resistant polyethylene,

has a purposeful design with no sharp edges for easy cleaning.

A suction filter is located inside the tank at the sump.

The M-70 operating unit consists of; on/off function, pressure regulation valve with pressure gauge and distribution valves for closing of

spray boom sections.

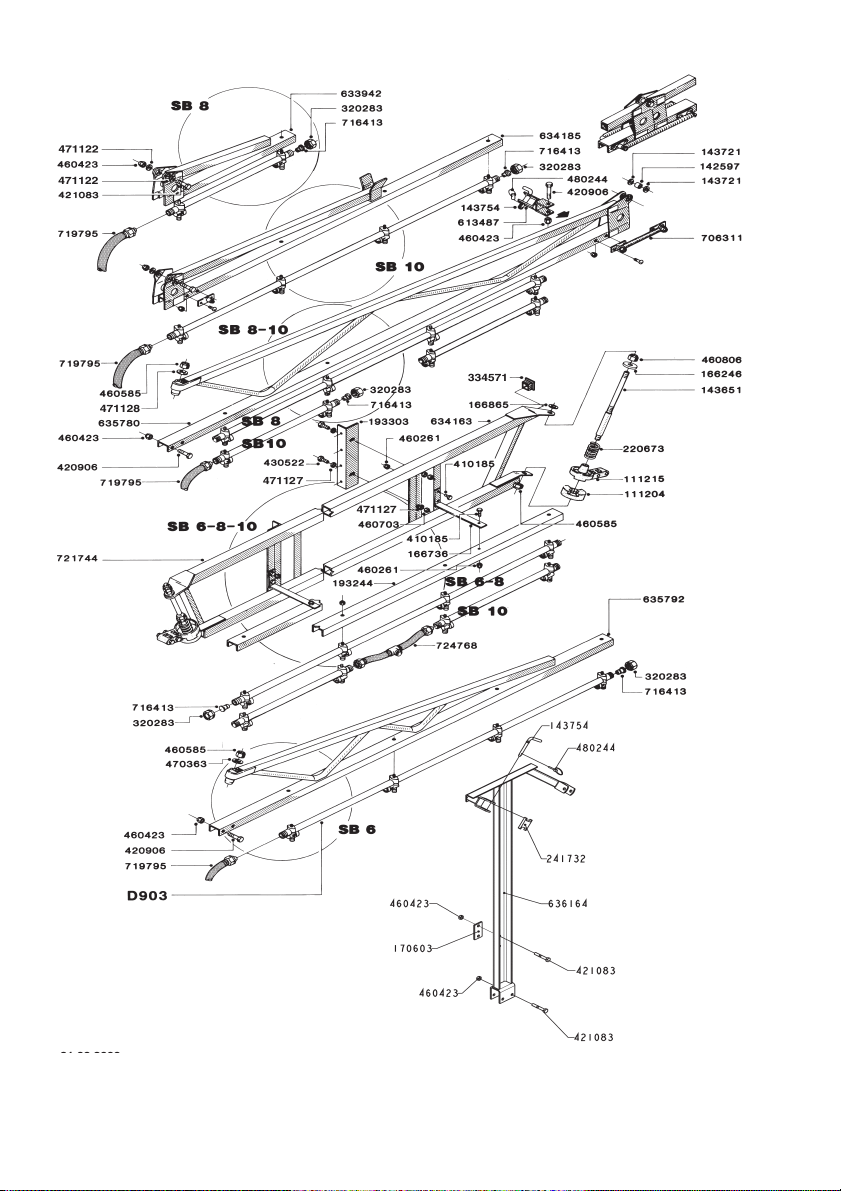

The SB boom is bolted to the tank frame and is fitted with spring

loaded breakaways at the pivots.

An identification plate fitted on the frame indicates model, year of

production and serial number, and country of origin.

4

Page 5

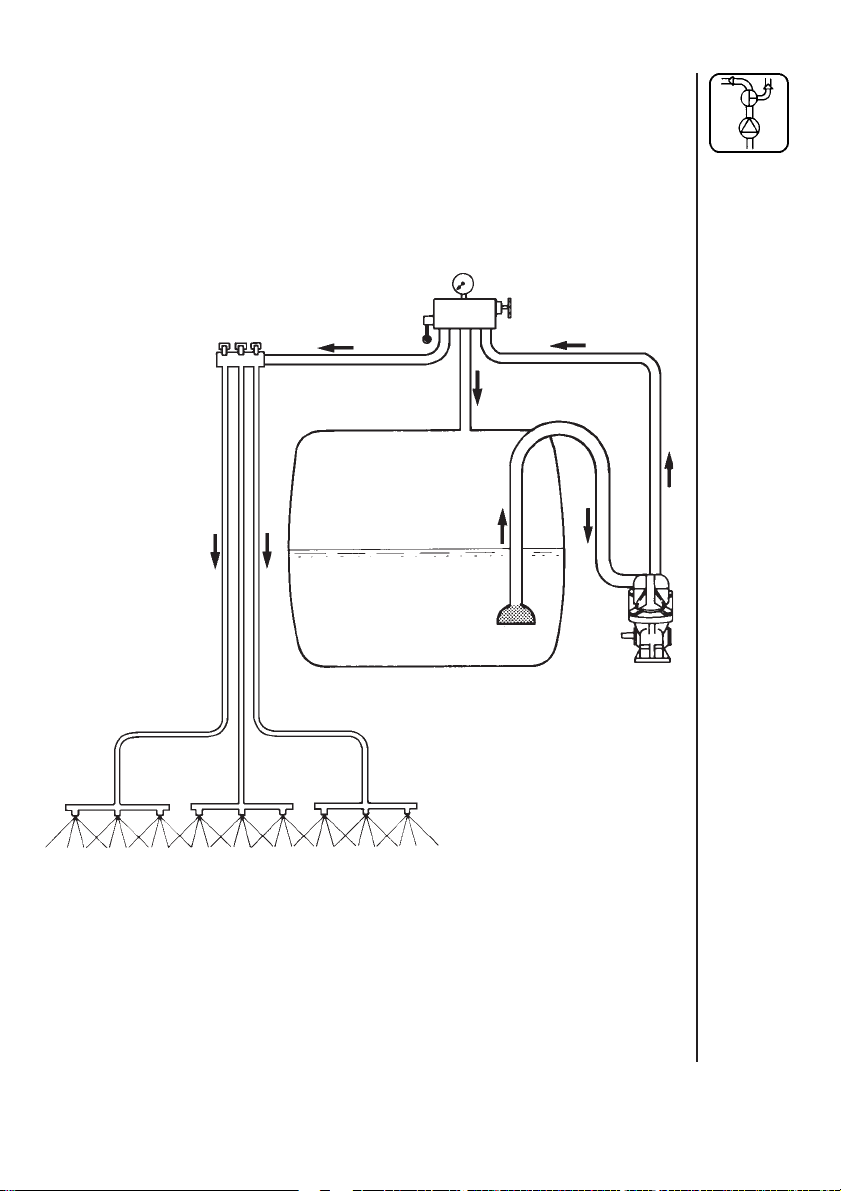

Operation diagram

1. Suction filter

2. Pump

3. On/off and pressure regulation valve

4. Distribution valve

5. Sprayer boom

4

3

1

2

5

5

Page 6

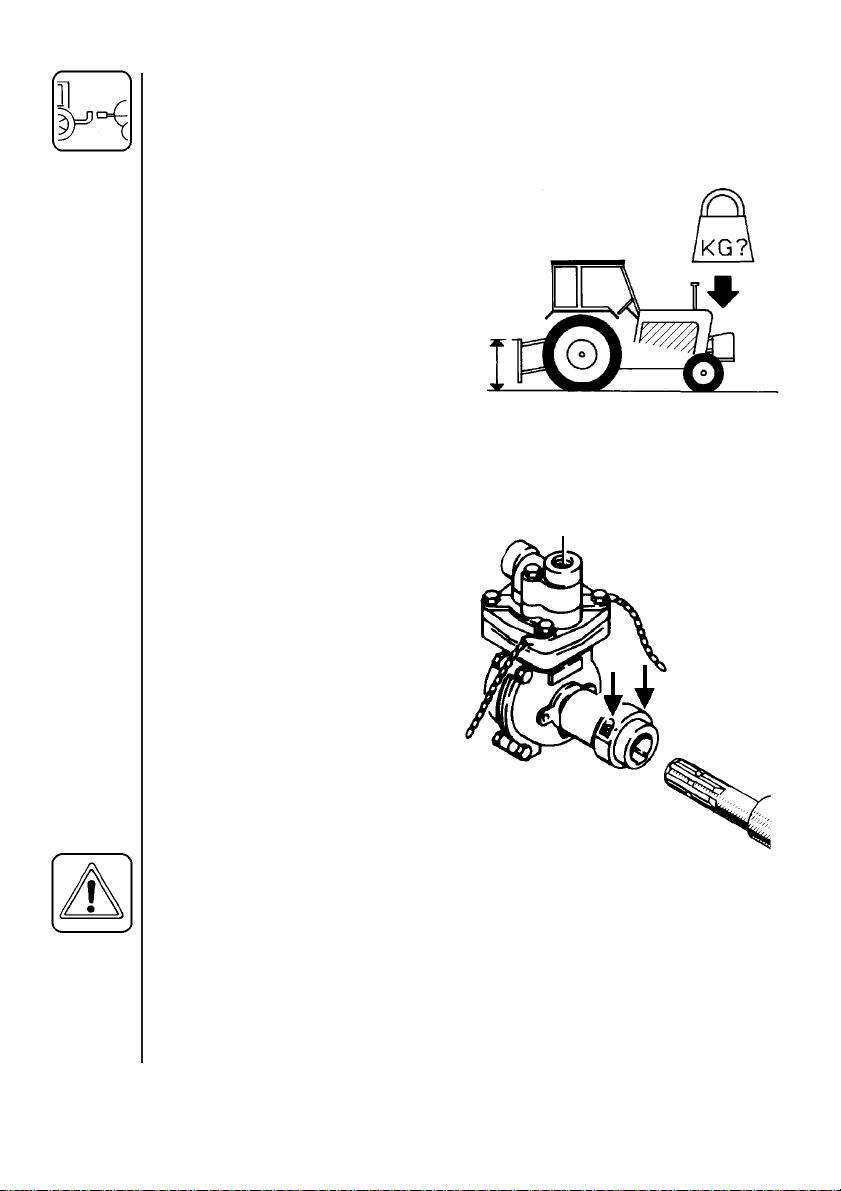

Connecting the sprayer

The sprayer is designed for three point suspension and is equipped

with 22 mm pivots (category I).

WARNING: Note the weight of the sprayer.

See section on Technical specifications.

Generally it is recommended to:

1. Add ballast to front of tractor.

2. Increase tyre pressure (see

tractor instruction book).

3. Travel at slower speeds when

driving with a full tank.

(The tractor will have decreased

braking efficiency.)

4. Be careful when filling/lifting the

sprayer the first time.

The pump is mounted directly

to the tractor P.T.O.

1. Undo the 2 allen screws * on

coupling and remove key.

2. Slide pump onto P.T.O.

shaft.

3. Replace key and tighten

allen screws.

4. Secure pump with supplied

chains to prevent rotation.

*

Roadworthyness

When driving on public roads and other areas where the highway code

applies, or areas where there are special rules and regulations for

marking and lights on implements, you should observe these and

equip implements accordingly.

6

Page 7

Operating instructions

T153-0006

Operation of the boom

Remove boom transport lock pin (8 metre

only). When unfolding (or folding) the initial

force to release the spring loaded breakaways will be higher than the actual unfolding/folding.

CAUTION: The breakaways must be

correctly tensioned and lubricated. (see

section on Re-adjustment of the boom)

Replace boom transport lock pin when

driving with folded boom.

Boom height

Correct boom height is very important in order to achieve the most

optimal spray pattern. (See Spray Technique book).

Small adjustments of the boom height can usually be made with the 3point suspension from the tractor - raising or lowering the sprayer.

In crops where greater adjustments are needed the boom height can

be changed manually by removing the 4 bolts holding the boom to the

frame.

Note: This is best done by 2 persons or with a mechanical hoist.

Pulsation damper

The air pressure in the pulsation damper is

preset at the factory to 2 bar. This covers spray

working pressures between 3 and 15 bar. When

using spray pressures outside this range, the air

pressure should be adjusted as shown in the

diagram. The diagram is also embossed on the

damper.

T020-0032

7

Page 8

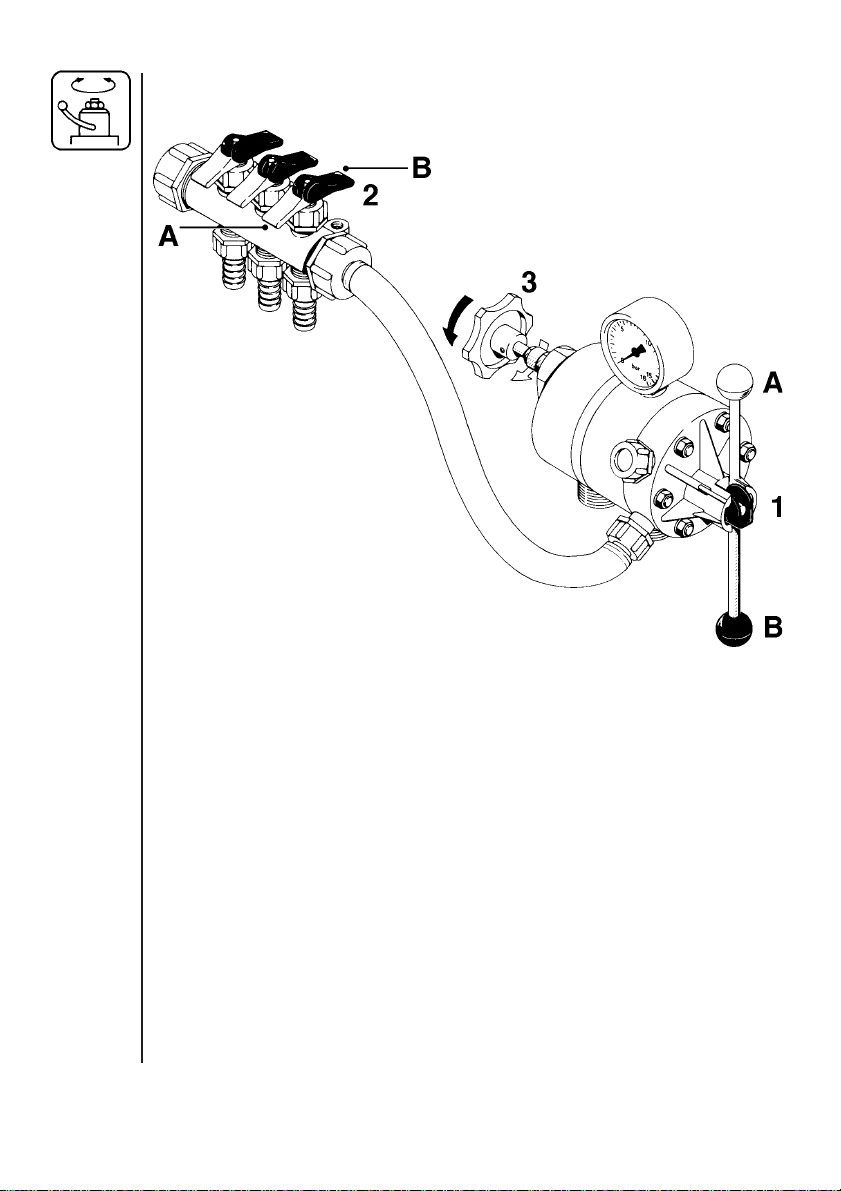

Adjustment of the operating unit

1. Turn main on/off handle (1) to off position A.

2. Set all hand levers on the distribution valve (2) to spraying position A.

3. Put the tractor in neutral and set the engine revolutions and thereby

the number of revolutions of the pump corresponding to the intended

travelling speed. Remember the number of revolutions on the P.T.O.

must be kept between 300-600 r/min.

4. Turn main on/off handle (1) to spraying position B.

5. Now turn the pressure regulating valve (3) to until the required

pressure is indicated on the pressure gauge.

6. Operating the control unit while driving:

To close the entire boom, turn the handle (1) to position A. This takes

the pressure off the pump. The liquid will then return to the tank via the

return system.

8

Page 9

The diaphragm anti-drip valves ensure instantaneous closing of all

nozzles. In order to close part of the boom, move lever (2) of the

distribution valve to position B (off position) for the section or sections

to be closed. Note that the pressure will rise and readjustment will be

necessary.

Drain valve operation

A drain valve cap is located under the tank. Unsrew it to drain tank. Be

careful not to loose the seal.

Maintenance

In order to derive full benefit from the sprayer for many years the

following few but important rules should be kept:

Cleaning the Sprayer - see Spray Technique book.

Filters

Clean filters ensure :

• Sprayer components such as valves, diaphragms and operating

unit are not hindered or damaged during operation.

• Nozzle blockages do not occur whilst spraying.

• Long life of pump. A blocked suction filter will result in pump cavita-

tion.

The main filter protecting sprayer components is the suction filter

inside the tank at the sump. Check it regularly.

Also regularly check nozzle filters.

9

Page 10

Lubrication

Recommended lubrication is shown in following tables. Use ball

bearing grease (lithium grease No.2)

NOTE: If the sprayers are cleaned with a high pressure cleaner or it

has been used to spray fertilizer, we recommend lubrication of the

entire machine.

2

Position on sprayer

Oil

Grease

Operation hours

Page to find

more information

10

Page 11

1X40

T201-0002

11

2X 20

3X 40

4X 40

8m SB

6

10

10

T213-0010

11

Page 12

Re-adjustment of the boom

After having used the sprayer for some days the boom should be

adjusted as follows:

When adjusting the sprayer must be on level ground with unfolded

boom.

Boom breakaway

The function of the breakaway is to prevent or reduce boom damage if

it should strike an object or the ground. If it is over-tight, it will not

function. If it is too loose, it will yawn (forward and back movement)

under spraying.

T103-0009

12

Lubricate coupling before adjusting spring tension. Slacken screw nut

A to decrease breakaway resistance. Do not overtighten; better to

loose than over-tight. Again minor adjustments in the field may be

necessary.

Ensure also channel bolts B are tight.

Outersection (8m SB)

C

The hindge should be firm.

If overtight it is difficult to fold.

To adjust, tighten or loosen nuts C.

T213-0010

Page 13

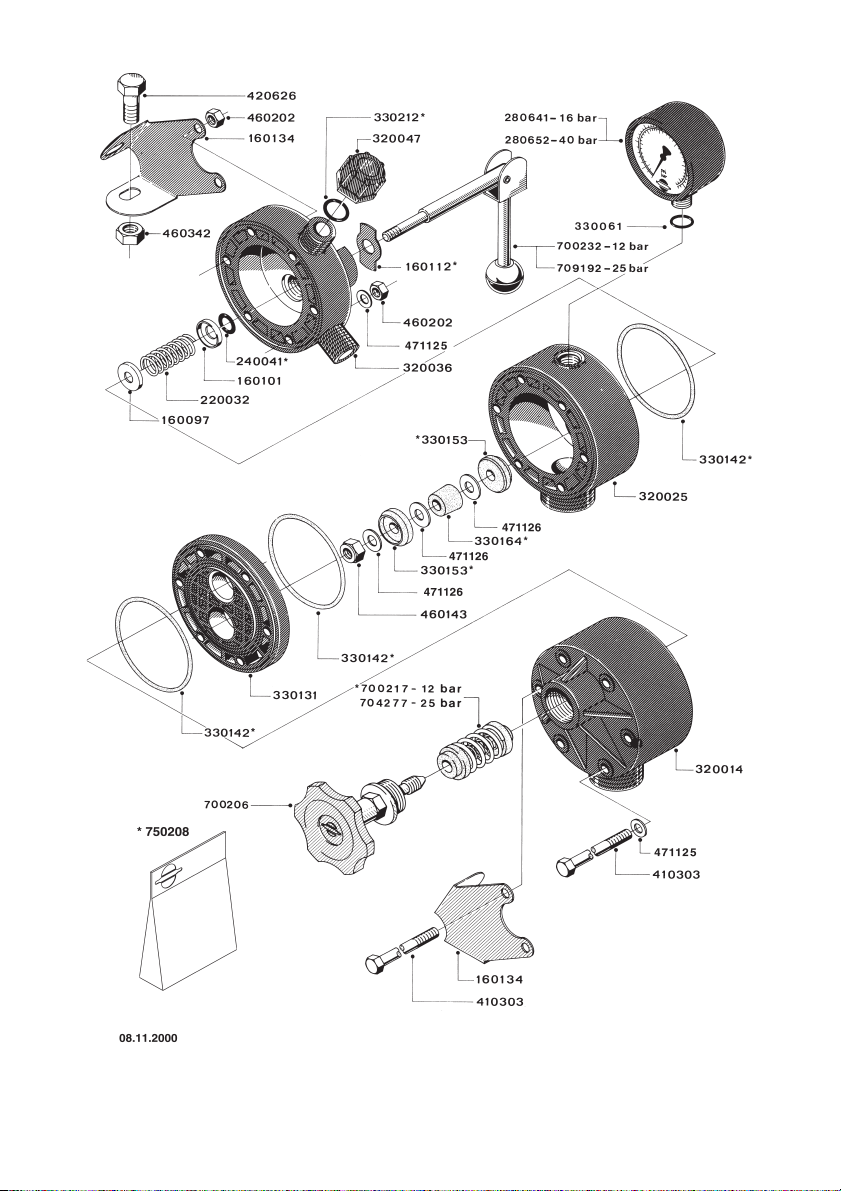

Changing of valves and diaphragms

Valves

Dismantle valve compartment (1). Before changing the valves (2) note

the orientation of the valves so that they may be replaced correctly.

It is recommended to use new gaskets (3) when changing or checking

the valves.

Diaphragms

Remove the diaphragm cover (4) after having dismantled the valve

compartment as indicated above. The diaphragm (5) may then be

changed. If fluids have reached the crankcase, re-grease the pump

thoroughly. Check also the drain hole at the bottom of the pump is not

blocked.

13

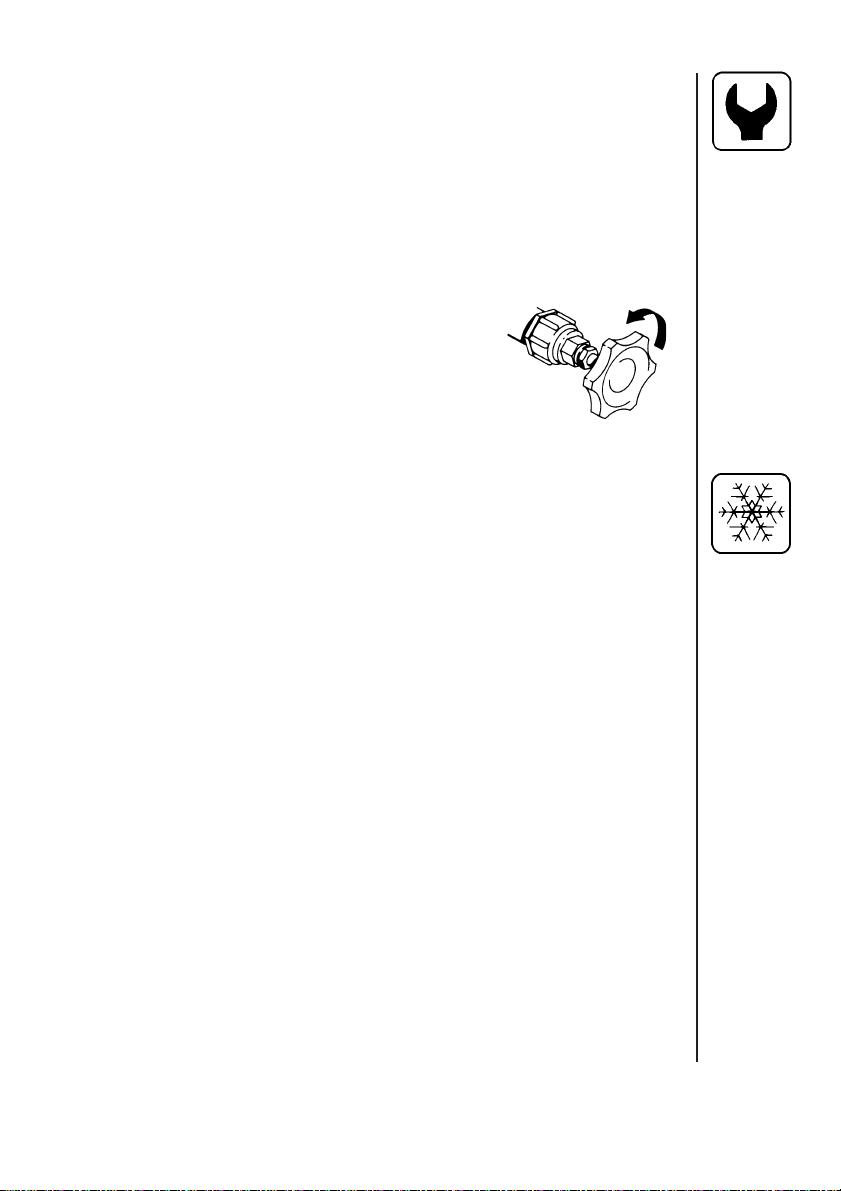

Page 14

Nozzle tubes and fittings

Poor seals are usually caused by;

• missing O-rings or gaskets

• damaged or incorrectly seated O-rings

• dry or deformed O-rings or gaskets

• foreign bodies

Therefore, in case of leaks: DO NOT over-tighten. Disassemble, check

condition and position of O-ring or gasket, clean lubricate and reassemble.

For radial connections only hand tighten them.

The O-ring must be lubricated ALL THE WAY ROUND before refitting.

14

For face connections, a little

mechanical leverage may be

used.

Off-season storage

When the spraying season is over you should devote some extra time

to the sprayer before it is stored.

Hoses

Check that none of the hoses are caught or have sharp bends.

A leaky hose can give an annoying delay in the middle of the spraying

job. Therefore check all the hoses and change if there is any doubt

about the durability.

Page 15

Paint

Some chemicals are very hard on paints. It is therefore well advised to

remove rust, if any, and then touch up the paint.

Tank

Check that no chemical residues are left from the last spraying. Chemical residues must not be left in the tank for a long time. It will reduce

the life of the tank. See Spray Technique book- Cleaning the sprayer.

Operating unit

Take care that the pressure regulation valve is

completely loosened. The spring is thereby

relieved and operation difficulties are avoided at

starting-up next season.

Anti-freeze precaution

If the sprayer is not stored in a frost-proof place you should take the

following precautions: Put at least 5 litres of 33% anti-freeze mixture in

the tank and let the pump run a few minutes so that the entire system

including spray hose are filled. Remove the glycerine filled pressure

gauge and store it frost free in vertical position.

The anti-freeze solution also hinders the O-rings and gaskets from

drying out.

15

Page 16

Operational problems

In cases where breakdowns have occurred the same factors always

seem to come into play:

• Minor leaks on the suction side of the pump will reduce the pump

capacity or stop the suction completely.

• A clogged suction filter will hinder or prevent suction so that the

pump does not operate satisfactorily.

• Clogged up pressure filters will result in increasing pressure at the

pressure gauge but lower pressure at the nozzles.

• Foreign bodies stuck in the pump valves with the result that these

cannot close tightly against the valve seat. This reduces pump

efficiency.

• Poorly reassembled pumps, especially diaphragm covers will allow

the pump to suck air resulting in reduced or no capacity.

Therefore ALWAYS check:

1. Suction and nozzle filters are clean.

2. Hoses for leaks and cracks, paying particular attention to suction

hoses.

3. Gaskets and O-rings are present and in good condition.

4. Pressure gauge is in good working order. Correct dosage depends

on it.

5. Operating unit functions properly. Use clean water to check.

16

Page 17

Fault Probable cause Control / remedy

No spray from

blower when

turned on.

Lack of

pressure.

Pressure

dropping.

Pressure

increasing.

Formation of

foam.

Liquid leaks

from bottom of

pump.

Air leak on suction.

Air in system.

Suction / nozzle

filters clogged.

Incorrect assembly.

Pump valves blocked

or worn.

Defect pressure gauge.

Filters clogging.

Nozzles worn.

Tank is airtight.

Nozzle filters begin-

ning to clog.

Air is being sucked

into system.

Excessive liquid

agitation.

Damaged diaphragm.

Check suction tube and fittings.

Check tightness of pump diaphragm

and valve covers.

Fill suction hose with water for initial

prime.

Clean filters.

Recheck assembly.

Check for obstructions and wear.

Check for dirt at inlet of gauge.

Clean all filters. Fill with cleaner

water.

Check flow rate and replace nozzles

if it exceeds 10%.

Check vent is clear.

Clean all filters.

Check tightness / gaskets / O-rings

of all fittings on suction side.

Use foam damping additive.

Replace. See section Changing

valves and diaphragms.

17

Page 18

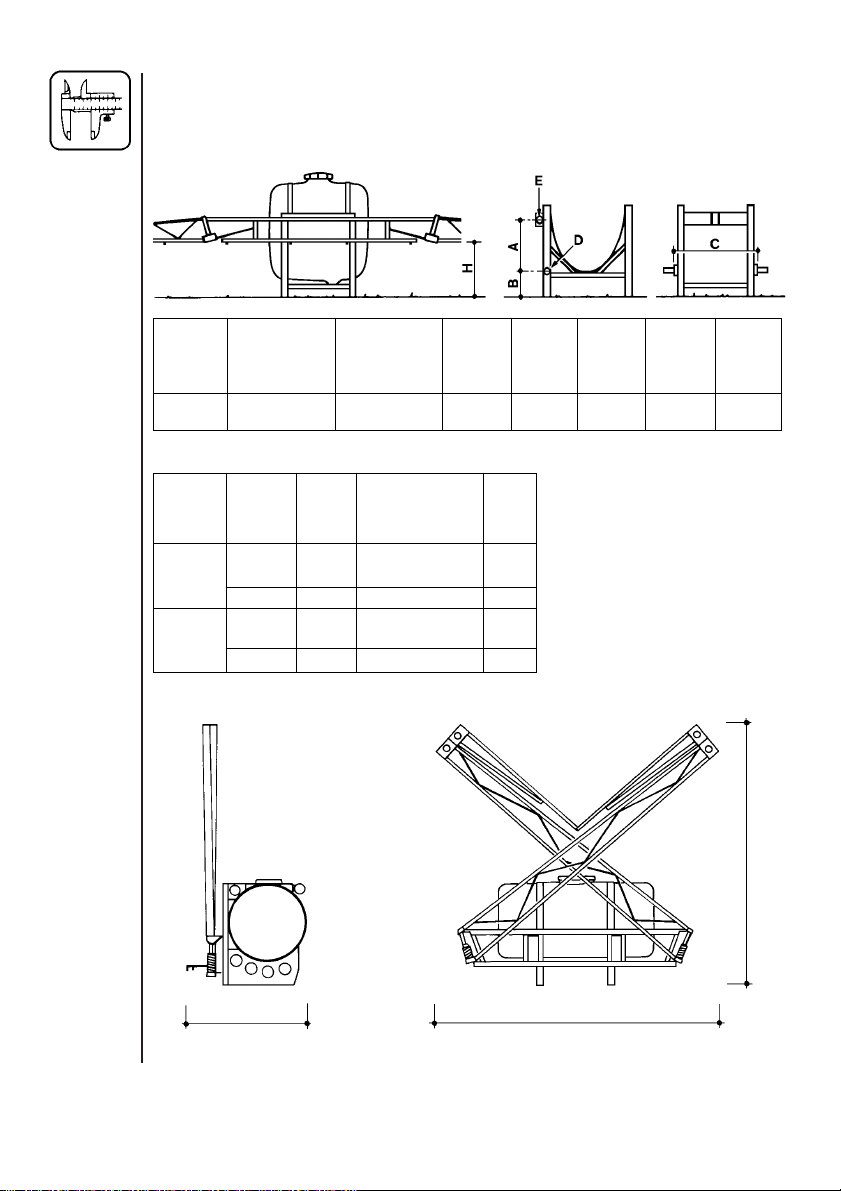

Technical specifications

Measure and weights

Tank Min. Max. ABCDE

size boom height boom height

l H mm H mm mm mm mm mm mm

200/300 20 595 520 210 588 22 26

Tank Spraying Pump Measure Weight

size width model a x b x c

lm cm kg

6 500 100 × 190 × 160 93

200 6 600 100 × 190 × 160 99

300 6 600 100 × 190 × 160 105

8 600 100 × 190 × 200 105

6 500 100 × 190 × 160 99

8 600 100 × 190 × 200 114

18

c

ba

Page 19

Power consumption and capacity

500/7.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 13 0,15 16 0,15 19 0,22 20 0,29 21 0,29

5 10 0,22 12 0,29 15 0,37 16 0,45 18 0,52

10 9 0,29 12 0,45 14 0,52 15 0,59 16 0,67

15

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 9,9 kg

600/7.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 19 0,15 28 0,22 38 0,29 41 0,30 46 0,37

5 17 0,29 23 0,45 28 0,52 30 0,59 34 0,67

10 17 0,45 22 0,59 28 0,82 30 0,89 33 0,97

15 16 21 27 30 33

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 15,6 kg

300 400 500 540 600

300 400 500 540 600

r/min

r/min

Filters and nozzles

Pos. Mesh/ Description/

colour nozzle

1

2 - 3

1 23 Suction filter

2 50 blue Nozzle 4110-16

3 50 blue Nozzle 4110-20

2 50 blue Nozzle 4110-14*

3 50 blue Nozzle 4110-16*

* 6m SB

19

Page 20

Pictorial symbols

Description

Function

Connection

Warning

Operating

Service/adjustment

Liquid flow

Pressure

20

Cleaning

Lubrication

Winter storage

Operational problems

Technical specifications

Page 21

Preassembly information

The sprayer is supplied ex-works in shipping packages (SP). Number

of SP’s per sprayer varies depending on model.

As this covers all BL models, please note the fittings covering exactly

your model.

NOTE:

Removal of the plastic bag covering the tank is easiest done before

assembly.

To verify connection of hoses, a function diagram is included on the

last page.

Packaging information

Materials used for packaging are environmentally compatible. They

can be safely deposited or they can be burnt in an incinerator.

Recycling

Cardboard: Can recycle up to 99% and therefore should be put into

the waste collection system.

Polystyrene foam: Can be recycled. Fluorocarbons (CFC) not used in

foam production.

Polyethylene: Can be recycled.

21

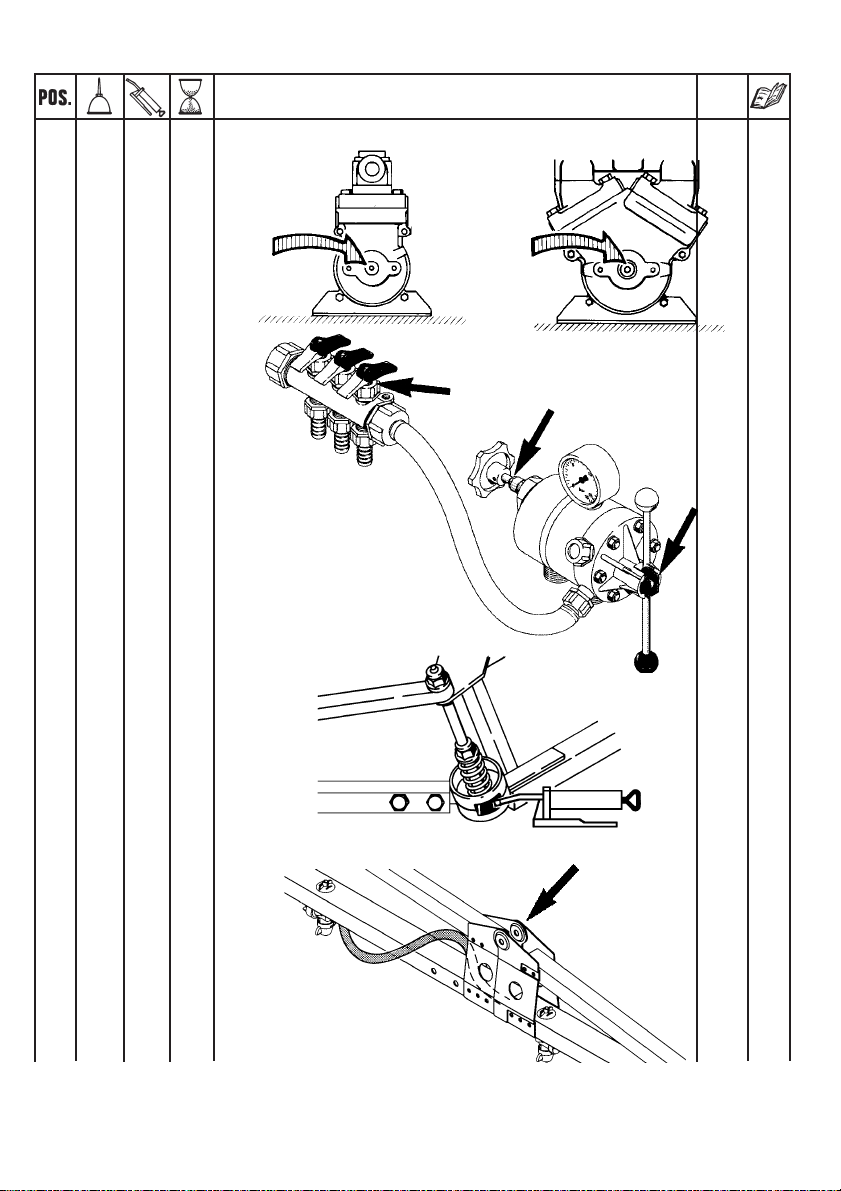

Page 22

Assembly

1. Fit pulsation damper and pressure hose B.

2. Fit suction damper and suction hose A.

NOTE: Use O-rings where indicated.

Lubricate them before assembly.

Where O-rings are not indicated,

use sealing tape.

3. Operating unit

and distribution

valve are assembled and bolted to

rack.

Screw pressure gauge

on to operating unit. Do not

overtighten. See back of

gauge.

Remember to pierce casing

after installation.

22

Page 23

4. Assemble tank and frame.

5. Fit hoses. Remember to lubricate O-rings before fitting.

A = Suction hose to pump.

B = From pump.

C = Return to tank.

F = Feed hoses to boom.

NOTE: For sake of good order, it may be necessary to shorten some hoses

(for example, suction hose A). This is best done when assembly is completed and before hoses are secured with plastic straps.

23

Page 24

6. Bolt angle brackets to

frame.

7. Fit boom centre.

8. Fit U-profile.

9. Fit boom wings. Be

cautious when folding

boom for the first time.

See section on boom

breakaway in instruction book.

T145-0010

6.

•

7.

•

•

9.

10. Nozzle tubes are

supplied with one lock

nozzle saddle per

tube. A. The rest can

slide lengthwise. B

allowing for extension

A B

and contraction.

•

8.

24

Page 25

Placement of nozzle tubes, connecting hoses and feed hoses.

REMEMBER: Lubricate O-rings before fitting.

T145-0011

T145-0011

F

F

11. Fit tubes using synthetic nut.

Press down 1, turn 2.

Do not overtighten.

12. Mount filter and COLOR TIPS.

8m SB

6m SB

T145-0012

13. For 8 metre SB - fit boom

transport lock. Arrow indicates forward direction of

travel.

25

Page 26

14. Check hose connections are

C

F

A

B

in accordance with diagram.

15. Organise hoses; it may be

necessary to shorten some of

them. Secure with straps.

26

Page 27

500 4-9.95 A1

27

Page 28

28

600 4.9.95 A5

Page 29

B5 15-5-79

29

Page 30

B6 18-2-91

30

Page 31

Dampers HJ73 30-9-93 B300

31

Page 32

32

SB 6/8/10m 18-2-91 D2

Page 33

33

Page 34

BL 200/300 18-2-91 E2

34

Page 35

Notes:

35

Page 36

Notes:

36

Loading...

Loading...