Page 1

HARDI

AutoHeight

Original

Instruction book - SW 7(x)

67020400-110 - Version 1.10

GB - 01.2011

www.hardi-international.com

Page 2

We congratulate you for choosing a HARDI plant protection product. The reliability and

efficiency of this product depend upon your care. The first step is to carefully read and pay

attention to this instruction book. It contains essential information for the efficient use

and long life of this quality product.

Acknowledgements:

UC4+ and Roll Control are trademarks of NORAC Systems International Inc., Canada

NORAC® is a registered trademark of NORAC Systems International Inc., Canada

The original instruction book is approved and published in English. All other languages are translations of the

original. In the event of any conflicts, inaccuracies or deviations between the English original and other languages

the English version shall prevail.

Illustrations, technical information and data in this book are to the best of our belief correct at the time of printing.

As it is HARDI INTERNATIONAL A/S policy permanently to improve our products, we reserve the right to make

changes in design, features, accessories, specifications and maintenance instructions at any time and without

notice.

HARDI INTERNATIONAL A/S is without any obligation in relation to implements purchased before or after such

changes.

HARDI INTERNATIONAL A/S cannot undertake any responsibility for possible omissions or inaccuracies in this

publication, although everything possible has been done to make it complete and correct.

As this instruction book covers more models and features or equipment, which are available in certain countries

only, please pay attention to paragraphs dealing with precisely your model.

Published and printed by HARDI INTERNATIONAL A/S

Page 3

Table of Contents

1 - Declaration

This page is intentionally left blank ............................................................................................................................................................ 5

2 - Safety notes

Operator safety .....................................................................................................................................7

Precautions ................................................................................................................................................................................................................ 7

3 - Description

General info ...........................................................................................................................................9

Introduction .............................................................................................................................................................................................................. 9

Key features ............................................................................................................................................................................................................... 9

General description ........................................................................................................................................................................................... 10

Software .................................................................................................................................................................................................................... 10

Hardware components ................................................................................................................................................................................... 11

Understanding Your AutoHeight System ............................................................................................14

Understanding Performance Issues ........................................................................................................................................................ 14

Sensitivity (Sensi) Setting ............................................................................................................................................................................... 14

Boom Reaction Time ......................................................................................................................................................................................... 14

AutoHeight over Ditches, Waterways and Outside Rounds .................................................................................................... 14

Driving Through Ditches and Over Terraces ...................................................................................................................................... 15

Sensor Capabilities ............................................................................................................................................................................................. 15

Understanding Crop Mode And Soil Mode ........................................................................................................................................ 15

Areas of "No Crop" in CROP Mode ........................................................................................................................................................... 16

Thin Crop .................................................................................................................................................................................................................. 16

Boom Lift Sensor in Wheel Track ............................................................................................................................................................... 16

Sensing Further Ahead of the Boom ...................................................................................................................................................... 16

AutoHeight Sensor Capabilities and Limitations ............................................................................................................................ 17

Optional kits ........................................................................................................................................18

General info ............................................................................................................................................................................................................ 18

Severe Terrain Kit ................................................................................................................................................................................................. 18

Enhanced Stability Kit ....................................................................................................................................................................................... 18

Menu Structure .................................................................................................................................................................................................... 19

Full Menu Structure ........................................................................................................................................................................................... 20

Glossary ..................................................................................................................................................................................................................... 21

4 - System setup

System preparation .............................................................................................................................23

General info ............................................................................................................................................................................................................ 23

Automatic System Setup ............................................................................................................................................................................... 24

Retune ........................................................................................................................................................................................................................ 27

Manual System Setup ....................................................................................................................................................................................... 28

Setting Up Hydraulic Valves ......................................................................................................................................................................... 29

Quick Install ............................................................................................................................................................................................................. 34

Options ................................................................................................................................................35

HeadlandAssist ..................................................................................................................................................................................................... 35

5 - Operation

System operation ................................................................................................................................37

General info ............................................................................................................................................................................................................ 37

Power Up Sequence ......................................................................................................................................................................................... 37

Typical Operation ................................................................................................................................38

Basic operation ..................................................................................................................................................................................................... 38

Run screen ............................................................................................................................................................................................................... 38

Press & Hold Functions .................................................................................................................................................................................... 39

Changing between AUTOMATIC or MANUAL Mode ................................................................................................................... 39

Adjusting the Target Height (Setpoint) ................................................................................................................................................. 40

Viewing the Actual Boom Height ............................................................................................................................................................. 40

Sprayer switches .................................................................................................................................................................................................. 40

Changing the Sensitivity of the System ................................................................................................................................................ 40

3

Page 4

Table of Contents

Changing Between SOIL and CROP Mode .......................................................................................................................................... 41

Severe Terrain Mode ......................................................................................................................................................................................... 41

Changing the units ............................................................................................................................................................................................ 41

Options ................................................................................................................................................42

HeadlandAssist ..................................................................................................................................................................................................... 42

Remote Switches ................................................................................................................................................................................................. 43

Crop filter toggle ................................................................................................................................................................................................. 43

High Oil Temperature Alarm ........................................................................................................................................................................ 43

Sensor Reading Alarm ...................................................................................................................................................................................... 43

Minimum Height Mode .................................................................................................................................................................................. 44

Valve and Air Temperature ........................................................................................................................................................................... 44

Operational Messages ...................................................................................................................................................................................... 45

6 - Maintenance

Service info ..........................................................................................................................................47

General info ............................................................................................................................................................................................................ 47

Before each day of operation ...................................................................................................................................................................... 47

Sensor preparation and maintenance ................................................................................................................................................... 47

At the end of a season .................................................................................................................................................................................... 48

Lubrication of the sprayer .............................................................................................................................................................................. 49

7 - Fault finding

Operational problems .........................................................................................................................51

General info ............................................................................................................................................................................................................ 51

General operation ............................................................................................................................................................................................... 51

Setup Messages ................................................................................................................................................................................................... 52

Sensor Related Issues ........................................................................................................................................................................................ 53

Different cases of Sensor related issues are discussed below: ................................................................................................ 53

Sensor Swapping ................................................................................................................................................................................................ 53

Sensor Alignment ............................................................................................................................................................................................... 54

Hydraulic Related Issues ................................................................................................................................................................................. 55

Boom Stability ....................................................................................................................................................................................................... 56

8 - Technical specifications

Specifications ......................................................................................................................................57

Sprayer types ......................................................................................................................................................................................................... 57

9 - Index

Index ....................................................................................................................................................59

4

Page 5

This page is intentionally left blank

1 - Declaration

5

Page 6

1 - Declaration

6

Page 7

2 - Safety notes

Operator safety

This symbol means DANGER. Be very alert as your safety is involved!

€

This symbol means WARNING. Be alert as your safety can be involved!

±

This symbol means ATTENTION. This guides to better, easier and more safe operation of your sprayer!

μ

This symbol means NOTE.

÷

Precautions

Note the following recommended precautions and safe operating practices before using the sprayer and AutoHeight

system.

General info

Note the following recommended precautions and safe operating practices.

€

Read and understand this instruction book before using the equipment. It is equally important that other operators

€

of this equipment read and understand this book.

Keep children away from the equipment.

€

If any portion of this instruction book remains unclear after reading it, contact your HARDI dealer for further

€

explanation before using the equipment.

Turn electrical power off before connecting and disconnecting the display and transducers, servicing or using a

€

battery charger.

If an arc welder is used on the equipment or anything connected to the equipment, disconnect power leads before

€

welding.

Test sprayer with clean water prior to filling with chemicals.

€

Do not use a high pressure cleaner to clean the electronic components.

€

Operating AutoHeight

WARNING! Always ensure that the AutoHeight system is powered down or in MANUAL mode:

±

• Before leaving the operator's seat

• While the machine is not moving

• When transporting the machine

WARNING! Under no circumstances should any service work be performed on the machinery while the AutoHeight

±

system is in the AUTOMATIC mode.

WARNING! Before working on any part of the booms:

±

• Set the AutoHeight system to MANUAL mode

• Turn the sprayer engine off

7

Page 8

2 - Safety notes

ATTENTION! Do not operate this system before:

μ

• Reading and understanding the Operator’s Manual

• Thoroughly understanding your machine operation

NOTE! The AutoHeight system will greatly improve your spraying height accuracy and protect the boom against

÷

damage in a wide variety of field conditions. However, under some circumstances performance may be limited. The

OPERATOR of the sprayer must remain ALERT at all times and override the automatic control when necessary.

8

Page 9

3 - Description

General info

Introduction

Congratulations on your purchase of the HARDI AutoHeight system (UC4+ version). The system is manufactured with top

quality components and is engineered using the latest technology to provide operating features and reliability unmatched

for years to come.

When properly used, the AutoHeight system can provide protection from sprayer boom damage, improve sprayer

efficiency, and ensure chemicals are applied correctly.

This manual is intended to be used in conjunction with the:

• AutoHeight Installation Manual

• Sprayer Instruction Book

The manual provides a general description of the spray height control system, a section regarding system operation, and

discussion related to understanding performance issues. Also provided are instructions for the use of the control panel,

information regarding system setup, regular maintenance and troubleshooting.

Please take the time to read the complete instruction book before attempting to use the system. Although the AutoHeight

system has been designed for easy set-up and use, a thorough understanding of the information provided will ensure that

you receive the maximum benefit from the system.

Key features

The key features of the HARDI AutoHeight is:

Non-contact Sensing

• Sensing is done using ultrasonic sensors which means no parts of the HARDI AutoHeight system come in contact with

the ground.

• Using a non-contact system means there will be no additional forces put on the boom, which could cause damage to

the sprayer boom.

Automatic Software Setup

• The system completes an automatic system setup, which calibrates the software specifically for the sprayer.

• This provides the maximum performance for the height control system.

Individual Boom Overrides

• When necessary one boom section can be put into manual mode to avoid an obstacle, while the other boom sections

stay in automatic.

• This can take the stress out of spraying along obstacles such as fences because you only have to watch the boom along

the obstacle, knowing that the HARDI AutoHeight system is maintaining the height on the rest of the boom sections.

Smart Sensor Technology

• All sensors are designed specifically for the agricultural industry.

9

Page 10

3 - Description

General description

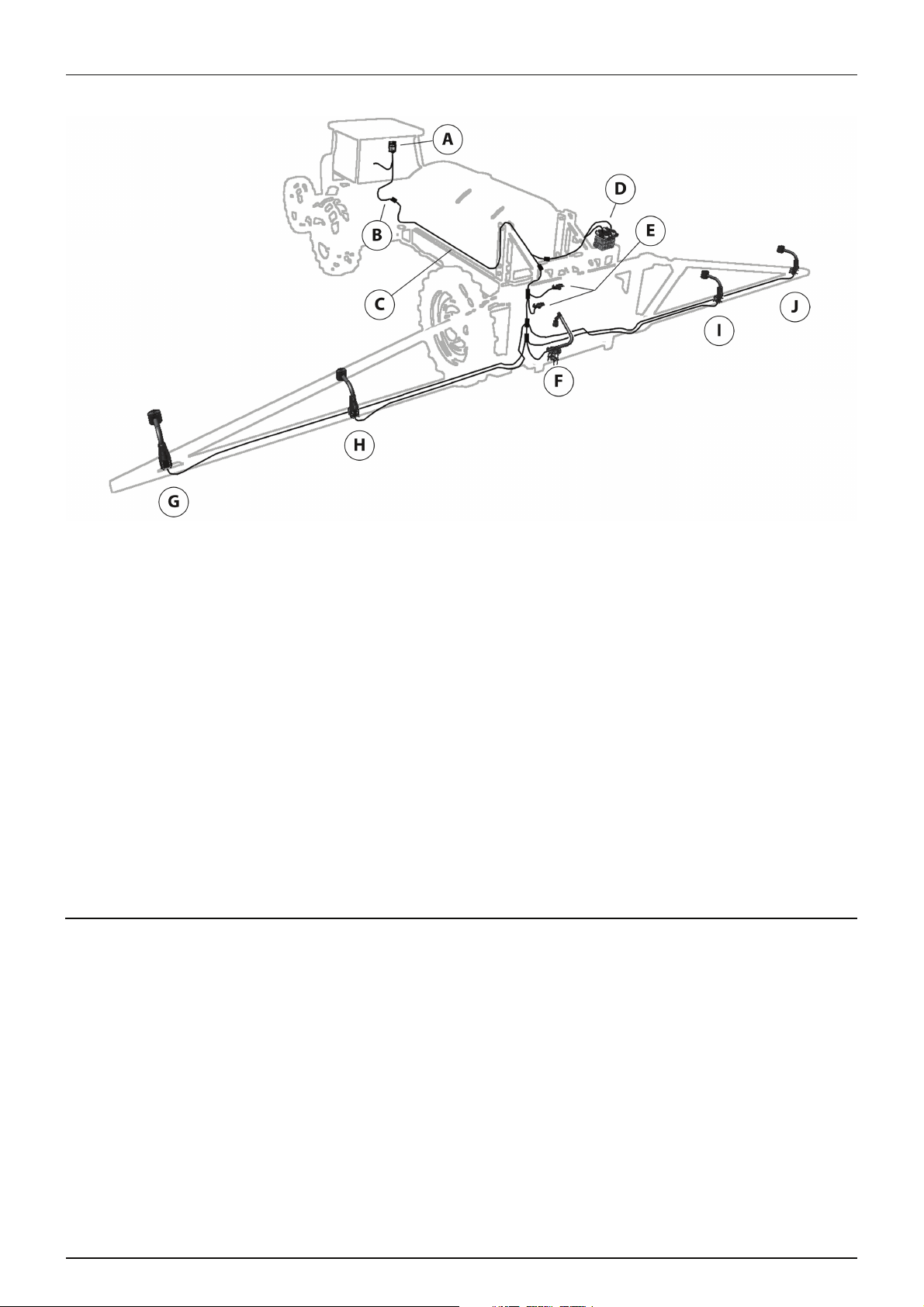

Figure 1 - System Components and General Location

A. Control Panel

B. Power Cable

C. Extension and Trunk Cables

D. AutoHeight Valve

E. Roll Sensors

F. Boom lift Sensor

G. Left Outer Sensor

H. Optional Left Inner Sensor

I. Optional Right Inner Sensor

J. Right Outer Sensor

NOTE! Some kits may not include all of the components shown.

÷

For more information on each component, please refer to the AutoHeight Installation Manual.

μ

Software

The information in this manual applies to systems with Version 7 AutoHeight panel software. When the panel is turned on,

the software version and revision will be displayed for a few seconds as described in “Power Up Sequence” on page 37.

All AutoHeight panels can have their software upgraded. It is recommended that all panels with earlier software are updated

to the current software version. Contact your local dealer or HARDI for more information.

10

Page 11

3 - Description

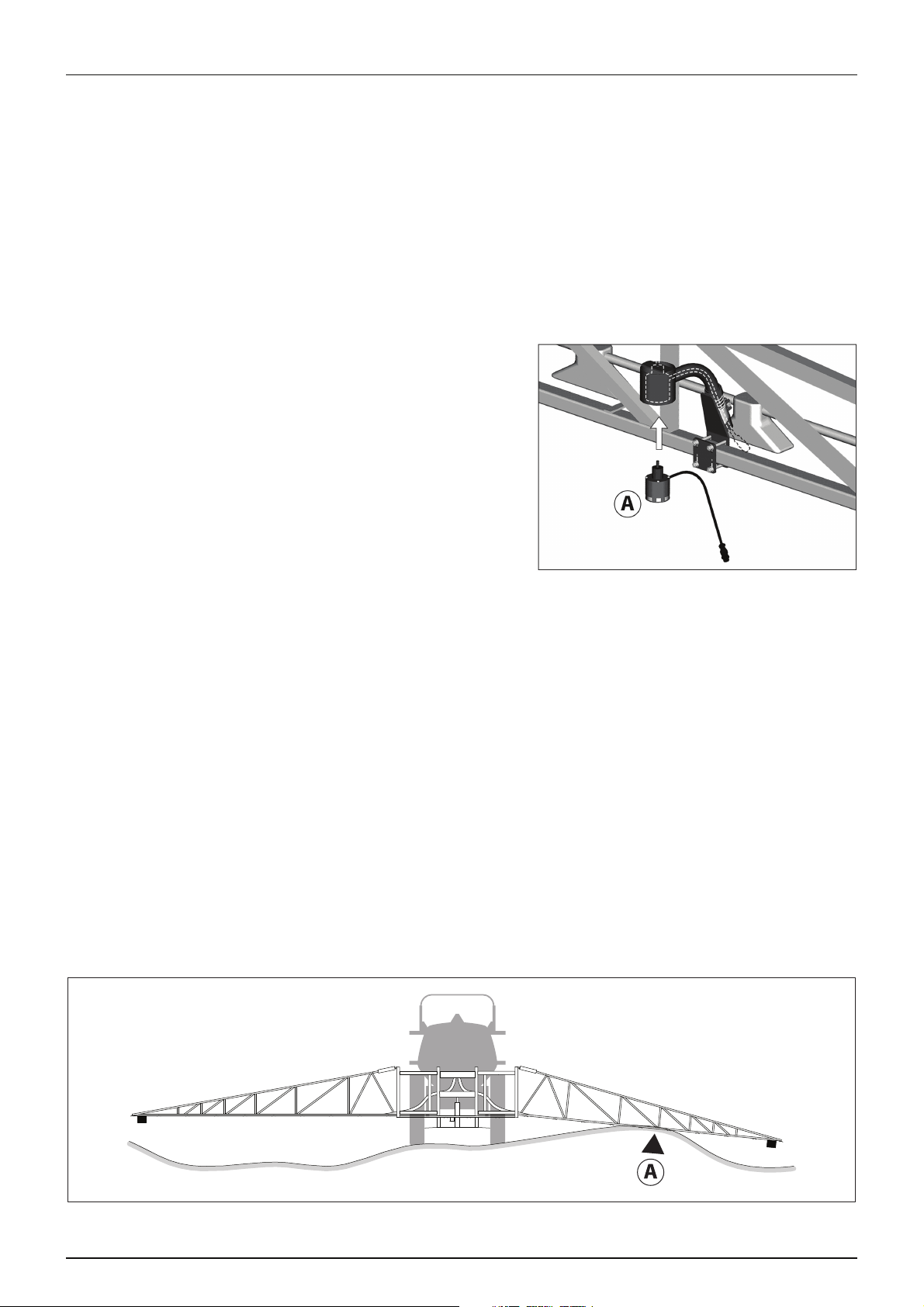

Figure 2 - AutoHeight Sensor and Mounting Bracket

Hardware components

The components of the HARDI AutoHeight are:

Cables

The system will function properly with a power supply between 12 and 28 volts and may draw up to 10 amperes during

normal operation.

The AutoHeight panel contains intelligent valve drive circuitry that helps to protect the sprayer's system against short

circuits and other wiring problems. However, it is still recommended to connect the AutoHeight power cable to a fused

supply that turns on and off with the ignition key of the sprayer/tractor. For more information on cables, please see the

AutoHeight Installation Manual.

Sensors

Three sensors are provided with your AutoHeight boom control kit. The

sensors use an ultrasonic signal to measure the distance to the ground,

or the top of the crop. Three sensors are required to provide good

overall height management of the boom. Two sensors are mounted on

the outer sections of each wing (Figure 2). These sensors maintain each

wing at the set target height independently.

The third sensor is mounted on the centre section. The boom lift sensor

is useful for setting your initial spray height when you begin spraying in

a field.

It is true that the centre section height will not change much, in

consistent soil conditions, since both ends of the centre section follow

the height of the power unit. However, it is extremely difficult to judge

the boom's actual height accurately from the cab. It is also very difficult

for the operator to see the main section nozzles. It is common for

operators to be in error from 20 to 30 cm or more. The AutoHeight panel will give you an actual height reading in the cab

and allow active control to the desired height.

The reason for the centre section sensor is that soil conditions change along with the weight of the machine. As the sprayer

tank fluid level changes throughout the day and soil conditions vary, the centre section height will change because of the

amount the tires sink into the soil.

Special attention must be taken into consideration when mounting the centre section sensor, as explained in the

AutoHeight Installation Manual for your sprayer.

The ultrasonic sensors are designed to work best in the brackets provided (Figure 2). If you decide to use a different style of

sensor mount, you may limit the performance of the sensor and/or void your warranty. Further, it is important to follow the

guidelines in the AutoHeight Installation Manual for mounting the sensors. The sensors should be at least 25 cm above and

25 cm in front of the spray nozzles.

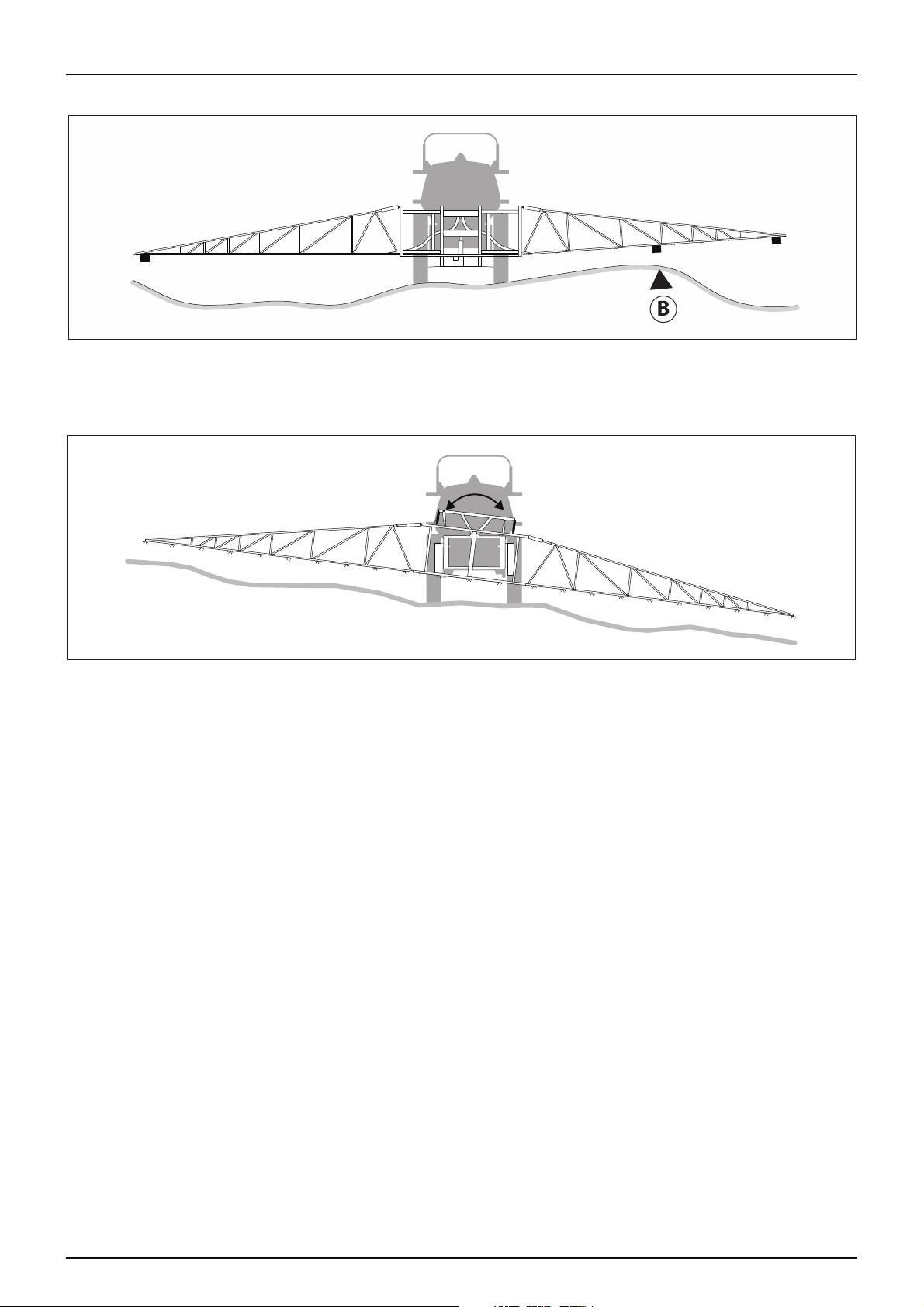

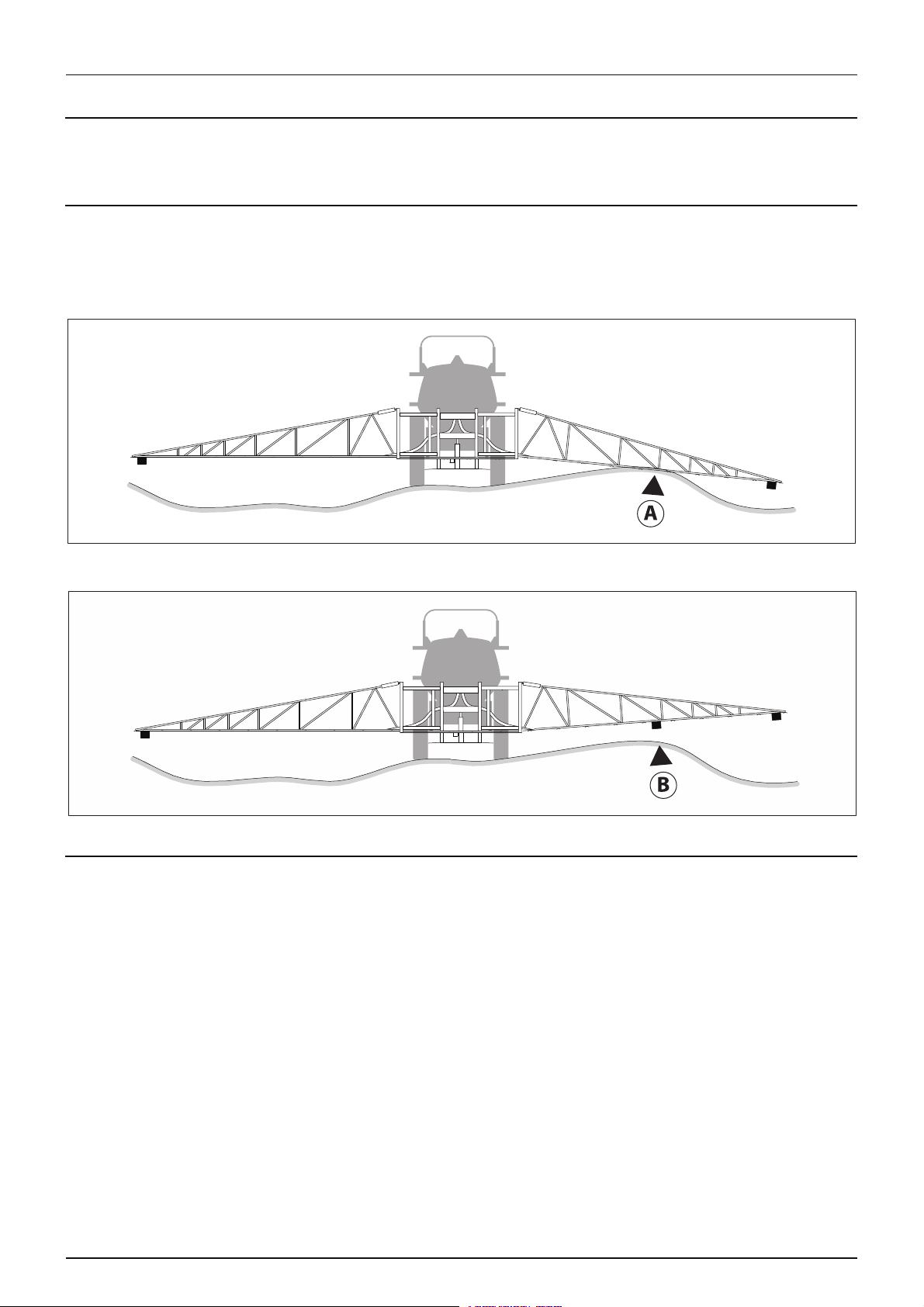

For large boom or severe terrain applications, an additional sensor may be mounted near the midpoint of each boom to

obtain an average height reading. The average height reading will provide improved height control over the length of the

boom and protect the boom in severe terrain conditions. See “Figure 3 - Severe Terrain - Additional Sensors Required” on

page 12.

A. Possible crash without additional sensors

11

Page 12

3 - Description

B. Crash avoided with additional sensors

Figure 3 - Severe Terrain - Additional Sensors Required

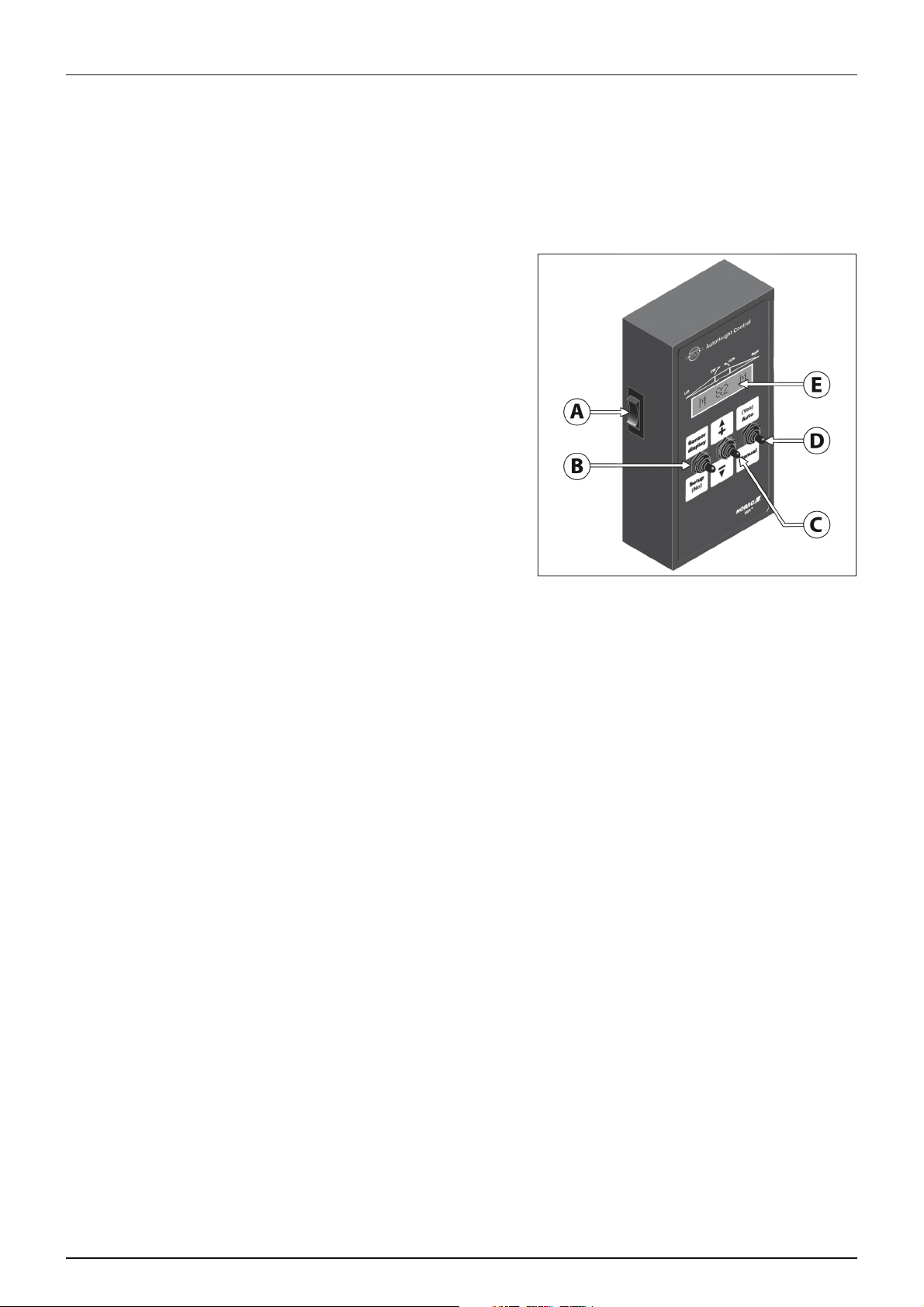

The centre section sensor can also be used to adjust the slant angle of the entire boom. Alternatively, slant sensors can also

be used to adjust the main slant angle of the entire boom. Addition of this sensor to the AutoHeight system can greatly

improve the speed and stability of the automatic control actions.

Figure 4 - Slant Control of the Main Frame

Height Sensors

• Height sensors use an ultrasonic signal to measure distance to the ground or crop canopy.

• Normally there are three height sensors used, but a system may have as many as 6 sensors. A sensor is mounted to the

outer part of each boom tip, and another sensor is mounted to the centre section.

Roll Sensors

• Roll sensors are important for measuring boom and sprayer roll dynamics.

• Two roll sensors are normally used for a UC4+ Spray Height Control System.

• The mounting position of the roll sensors varies from sprayer to sprayer depending on boom geometry and

suspension.

12

Page 13

3 - Description

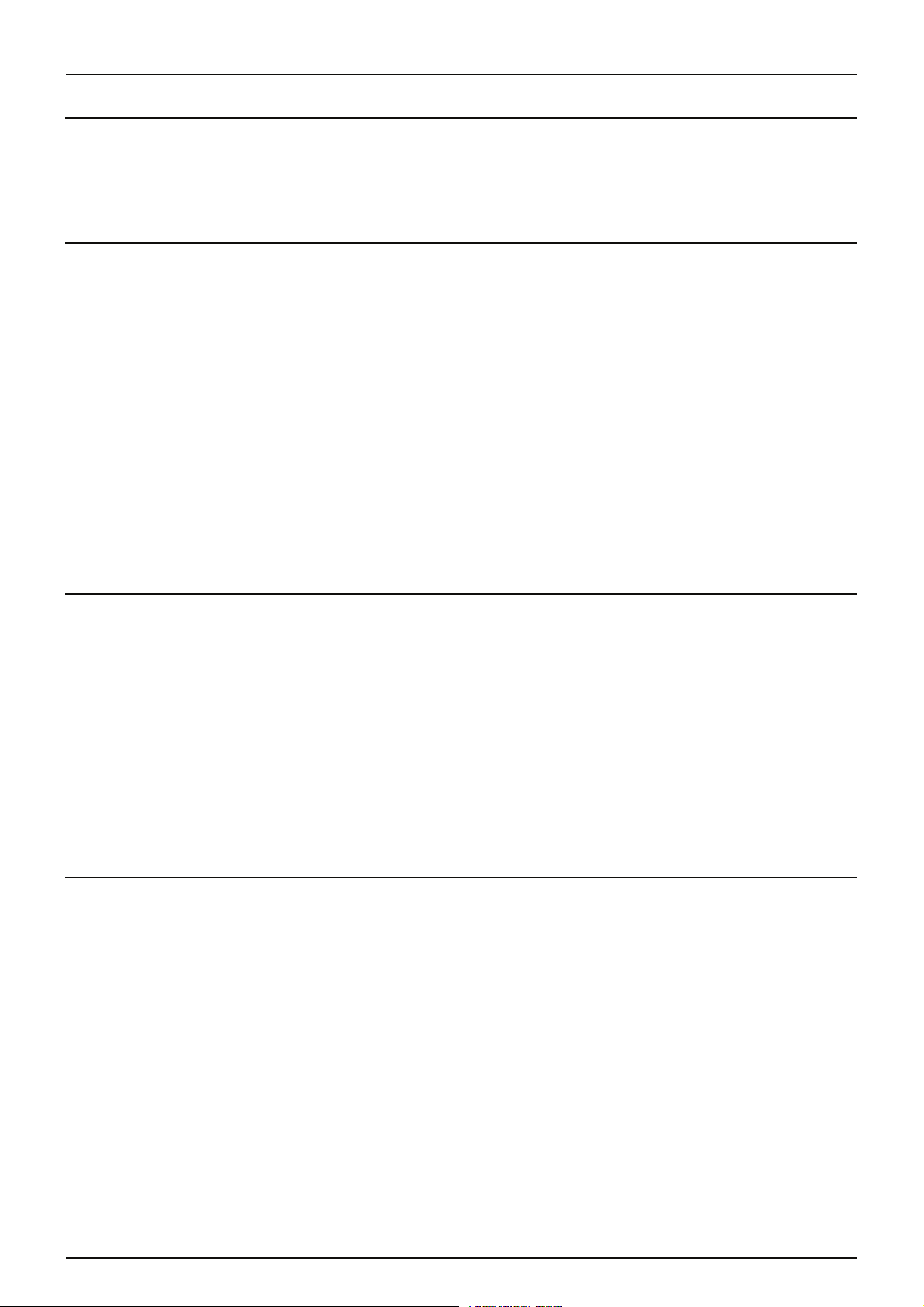

Figure 5 - AutoHeight Panel

Control Panel

The AutoHeight panel (Figure 5) is the main component of the AutoHeight system. The control panel uses the readings from

the ultrasonic sensors to control solenoid operated valves that in turn adjust the boom height. The control panel will:

• Indicate when the system is in AUTOMATIC or MANUAL mode.

• Indicate any hydraulic action which is underway.

• Accept input to adjust all control system settings.

Control panel functions are:

A. Power Switch

B. Sensor Display/Setup Switch (No)

C. +/- Switch (Up/Down)

D. Auto/Manual Switch (Yes)

E. LCD Screen

13

Page 14

3 - Description

Understanding Your AutoHeight System

Understanding Performance Issues

Your AutoHeight will work well in most situations. However, as with any equipment, it is important that the operator remains

alert at all times. There may be some field and terrain situations where performance is diminished. In these situations the

operator must resume height control of the booms manually. A discussion of performance issues is given below to help

clarify these situations.

Sensitivity (Sensi) Setting

The AutoHeight system is configured to work well in most conditions, with warm hydraulic oil, at a sensitivity (Sensi)

setting of five. When you first begin operation at the start of a day, it may be necessary to operate at a higher sensitivity until

the oil has reached normal temperature. After warmup, keep decreasing the Sensi setting until the performance is

optimized, to avoid overheating of the hydraulic oil.

Different types of terrain may require different Sensi settings. The Sensi setting controls more than just response

time. It also determines how accurately the AutoHeight system will try to correct for height errors. The higher the sensitivity

the higher the accuracy. At low sensitivity, a few cm of error will be tolerated. At high sensitivity, virtually no error will be

tolerated. Therefore, the system will be much more active at high sensitivity than at low sensitivity.

NOTE! Running AutoHeight at high sensitivity will increase heat build-up of the oil. Specially when AutoHeight

÷

system is used with tractors that have an open centre system without load sensing, it may require lower sensitivity

settings to avoid overheating of hydraulic oil. See “Hydraulic hook-up” on page 23.

NOTE! Field conditions and operator preferences determine the appropriate Sensi setting.

÷

Boom Reaction Time

There are two key factors that determine how quickly your boom can react to changes in terrain. The first factor is the

available hydraulic speed. The maximum hydraulic speed of your boom was designed by the sprayer manufacturer and is

not improved or diminished with the addition of the AutoHeight height control system.

The second factor is the mechanical design of the sprayer. The Sensi setting does affect the reaction time of your boom

- the higher the number the quicker the response. However, how high you can run the Sensi setting is determined to a

large extent by mechanical issues related to the boom and sprayer.

Important design issues include the style of boom mount (for example, centre pivot or nonparallel links), the amount of

mechanical damping and spring centring on the boom lift mount, and whether a boom slant system is available on the

sprayer. All of these factors together determine the maximum Sensi setting you can run on your AutoHeight system.

This, in turn, will set the reaction time of the boom in a given situation.

The AutoHeight electronics are rarely the limiting factor in determining overall automatic height control performance.

AutoHeight over Ditches, Waterways and Outside Rounds

Many situations exist where one sensor may be reading over terrain that does not accurately reflect the situation for the rest

of the boom. For example, if you are spraying along a waterway, it may be necessary to run the outer boom sensor out into

the waterway itself. This situation is similar to the picture in “Figure 3 - Severe Terrain - Additional Sensors Required” on

page 12. In this example, the outer sensor will bring the boom lower than desired and may put the mid-point of the boom

at risk. Outside rounds adjacent to very weedy areas or tall thick grass are examples of the opposite situation.

In these situations the operator must remain alert and override A UTO m ode when nece ssa ry. A ddit ion of th e opt ion al se vere

terrain (inner) sensors will greatly improve performance in these situations.

WARNING! In most countries spraying over ditches and waterways is strictly prohibited! Always follow local

±

legislation!

14

Page 15

3 - Description

Driving Through Ditches and Over Terraces

Changes in terrain that include driving over terraces or through ditches are special performance cases. This type of terrain

can cause the sprayer to pitch and roll significantly. Sprayer operation at speeds of 15-30 km/h in severe terrain may result

in rapid changes in boom tip height. In these situations, typical sprayer hydraulic systems are not capable of tip speeds high

enough to correct for the induced error.

The sprayer’s roll control system will compensate for the sprayer roll in this situation and also add stability to your boom in

normal operating conditions.

Alternative solution is for the operator to recognize these situations before they occur and manually raise the boom

section(s) to a safe height. To return to AUTO mode, use the "AUTO (YES)" switch.

Sensor Capabilities

In order for the AutoHeight system to work at its maximum level of performance, the AutoHeight sensors must be returning

accurate height readings at the designed frequency. Under typical conditions, the sensors can provide accurate height

readings from 0.2 to over 3.0 m and return many height readings in one second. The target in SOIL mode can be identified

through stubble, young crops, row crops, and normal trash. The target in CROP mode can be identified over cereal grains,

specialty crops, and row crops. See the next section for more information on CROP and SOIL mode guidelines.

There are two main steps to ensure sensor performance. The first step is proper mounting. See “Hardware components” on

page 11 for more information on sensor mounting. The second step is to ensure that the protective foam covers on the

sensors are kept clean, and that the ultrasonic transducer behind the foam does not become corroded or excessively dirty.

Extra foam pieces are shipped with your kit. The transducer is a maintenance item and can be replaced at HARDI service

locations. Transducers can last up to ten years, depending on conditions. Refer to “6 - Maintenance” on page 47 for more

maintenance information.

If the mouth of the sensor becomes wet, it is normal for the sensor to return error messages until the transducer has dried

off. This could include rain or excessive overspray. Material ca n build up on the transducer if the s ensor is mo unted to o close

to the spray nozzles. This is the reason that the sensor must be mounted at least 25 cm in front of the nozzles. It keeps the

sensor housing out of the normal region of overspray.

In the sprayer boom application, the sensors ignore any target that is closer than 25 cm from the bottom of the sensor

housing. This region is called the blanking range. Operating the sensor at heights near the blanking range is dangerous and

will affect performance because height readings can be very intermittent. This is the reason that each sensor must be

mounted at least 25 cm above the spray nozzles.

Understanding Crop Mode And Soil Mode

A unique feature of AutoHeight sensors is their ability to operate in CROP mode. In this mode the sensor will track the first

available sonic target. That is, when positioned over standing crop, the sensor will return the average height of the heads in

a circular area below the sensor. In the same situation in SOIL mode, the sensor will track the last available sonic target. That

is, signals from the heads, leaves, and trash will be ignored in favor of the ground.

It is important to note that the targets must be available and of sufficient strength for the sensor to "see" them. There may

be some crop and terrain situations that do not work well for CROP mode or SOIL mode. In these situations the operator

must resume height control of the booms manually.

In general, the addition of the severe terrain kit will improve performance in CROP mode. All of the situations discussed

below are lessened by the addition of the extra sensors on the wings.

15

Page 16

3 - Description

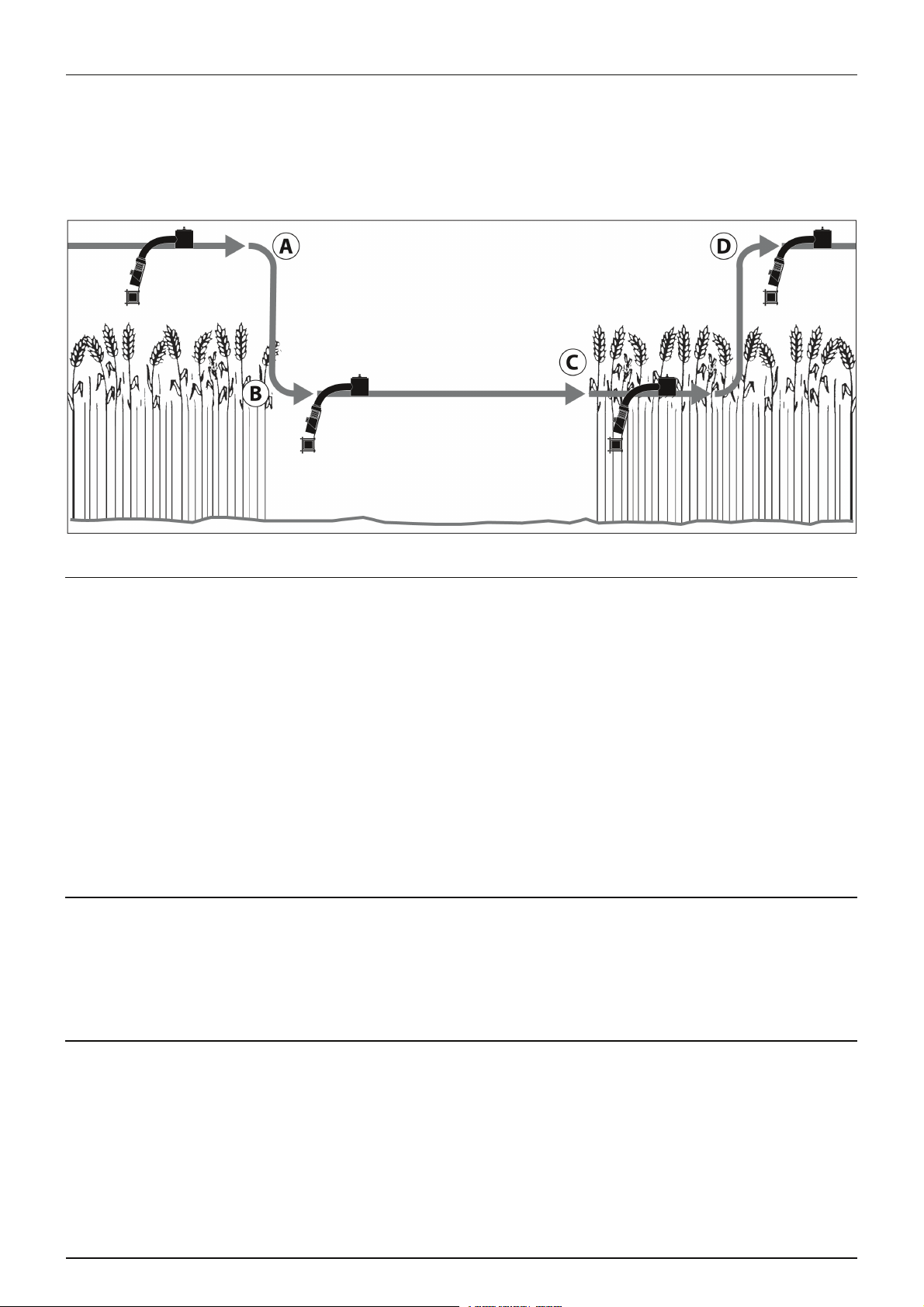

Areas of "No Crop" in CROP Mode

If, while operating in CROP mode, the sensor encounters an area where there is no crop, the system will behave as follows.

The sensor will track the soil (A) because only one target is available. The boom will lower (B) as no crop is detected. Areas

like this may include missed areas during seeding, alkaline areas, and so on. When the problem area ends (C), it may not be

possible for the sensor to see the crop again unless the operator raises the boom manually. The sensor may be closer than

required 25 cm from heads of the crop (D), thus blanking out the desired target.

Figure 8 - Area of "No Crop" When Operating CROP Mode

Thin Crop

The AutoHeight ultrasonic sensors operate by bouncing sound waves off the desired target. A minimum signal level is

required from the crop in order to use it for control purposes. This is no different than the fact that your radio must be at a

certain minimum volume level before you can physically hear it. Different types of crop and crops at different stages of

development return varying levels of sound. The following are some general guidelines.

• Crops in growing stages are relatively good sonic targets.

• Bearded crops are relatively poor sonic targets.

• In row crops, the sensor must be positioned over the row to use the crop signal, or between the rows to use the

ground signal.

• The desired target must cover roughly 60 percent of the area to be tracked consistently. That is, when looking at the

ground, the heads should cover about 60 percent of the ground. Otherwise, you can use SOIL mode.

• If the sensor runs too close to the heads, they may not return enough signal to be seen, or they may be blanked out.

The nozzles must be at least 55 cm from the crop. Slightly higher target height settings will work better in thin crop.

Boom Lift Sensor in Wheel Track

The required location for the centre section sensor is determined by the AutoHeight Installation Manual for your sprayer and

by the options you have installed. Special attention is necessary when mounting the centre section sensor. Mounting the

centre section sensor directly behind a sprayer tire may impair boom lift control when operating in CROP mode. Height

readings from crop that is flattened by the sprayer wheel do not provide an accurate measurement of canopy height,

resulting in poor performance.

Sensing Further Ahead of the Boom

A common misconception is moving the sensor further ahead of the boom will increase performance. Moving the sensor

further ahead of the boom increases the distance between the nozzle and sensor. This puts the sensor at a different location

within the field than the nozzles, which introduces a height error at the nozzles. In severe terrain this height error can bring

the nozzles close to the ground as the sensor reads over the crest of the hill or down a ditch.

Similarly, aiming the sensors ahead (rather than pointing straight down) will reduce sensor performance by providing

inaccurate height readings.

16

Page 17

3 - Description

AutoHeight Sensor Capabilities and Limitations

The AutoHeight sensors are designed and built specifically for agricultural purposes. However, the ultrasonic transducer

must be clean and dry for optimal performance. The foam disc fitted into the bottom of the sensor protects the transducer

from dust. If the protective foams become wet (from rain, drift from the spray nozzles etc.) the sensors may have trouble

reading.

The height sensors will provide height readings from 22 to 300 cm, under typical conditions. In order to optimize sensor

performance, the AutoHeight sensor has a minimum distance that it will read (also known as the blanking range). As a result,

the AutoHeight sensor is designed to ignore targets closer than 20 cm from the bottom of the sensor housing.

17

Page 18

3 - Description

Optional kits

General info

The kits shown below are optional add on kits for the UC4+ Spray Height Controller. These kits will help improve the

performance for certain situations described below.

Severe Terrain Kit

• Additional sensors may be added to improve boom protection and system performance.

• More suitable for larger booms and in severe terrain conditions.

A. Possible chrash without additional sensors.

B. Chrash avoided with additional sensor.

Enhanced Stability Kit

• This kit is designed to provide enhanced boom stability for sprayers which are loosely coupled between the

intermediate frame (paralift arms) and the sprayer chassis.

• The roll sensor included in this kit will provide an additional measurement of the sprayer dynamics to allow for greater

stability of the boom.

18

Page 19

Menu Structure

Navigating past the end of the menu will return the control panel to the run screen

More?

88 () 67

56

55 55

55 55

M

55

Sensi 5

Soil ON

ReTune?

More?

Navigating past the end of the menu will return the control panel to the run screen

Toggle the "AUTO (YES)" switch to edit or view more sensor settings.

Displays diagnostics information used by technical staff.

Displays the current boom lift height, in the selected units.

Displays the current right boom heights, in the selected units, from left to right.

Displays the current left boom heights, in the selected units, from left to right.

SENSOR DISPLAY Menu

M

Displays the current control sensitivity (Sensi) setting. A higher number results in a quicker response. Range is from 1 to 10.

Use the "+/-" switch to set the sensor target to SOIL or CROP mode.

The ReTune will optimize your system for the best performance possible. This will take from one to three minutes. (Section 6.2). The

menu retunes Dead Zone (DZ) and Valve Gain (KP) - not for sensor problems.

Toggle the "AUTO (YES) " switch to edit or view more control settings.

SENSOR DISPLAY / SETUP (NO) Switch

SETUP Menu

3 - Description

The run screen is usually displayed. If no switch is toggled for 30

seconds, the LCD will revert to this screen. Also, from any menu

prompt, if you toggle and hold the "SETUP (NO)" switch for two

seconds, the control panel will return to this screen. The heigh ts are

adjusted for the offset between the sensor and nozzles.

Table 1 - Main Menu Structure

19

Page 20

3 - Description

MHM SP

MHS 18

MHC 25

Units cm

“Adjusting the

Target Height

(Setpoint)” on

page 40

RF off

IF off

BFh- 215

BF 2080

MLht 27

ML 3567

“Setting Up

Sensors” on

page 28

RIht 30

RI 3571

ROht 32

RO 11070

“Setting Up

Sensors” on

page 28

LIht 28

LI 3569

LOht31

LO 11069

“Setting Up

Sensors” on

page 28

Other ?

Roll ?

Main ?

Right ?

Left ?

More ?

66 () 58

55 “Viewing the Actual Boom Height” on page 40

55 56

55 55

Left ?

Right ?

Rems On

Install?

“Au to ma tic

System Setup”

on page 24

Roll Off

DZ 20

KP 175

DZ 20

KP 150

“Setting Up

Hydraulic

Valves” on

page 29

Main On

DZ 10

KP 50

DZ 5

KP 50

“Setting Up

Hydraulic

Valves” on

page 29

Rght On

-DZ 103

-KP 49

-DZ 99

-KP 35

“Setting Up

Hydraulic

Valves” on

page 29

Left On

DZ- 100

KP- 50

DZ- 105

KP- 37

“Setting Up

Hydraulic

Valves” on

page 29

M 55 M “Power Up Sequence” on page 37

Sensi 5 “Changing the Sensitivity of the System” on page 40

Soil On “Changing Between SOIL and CROP Mode” on page 41

ReTune “Retune” on page 27

More ?

Main ?

Roll ?

Other ?

Full Menu Structure

Tab le 2

20

Page 21

3 - Description

Glossary

The following is a list of abbreviations used in the HARDI AutoHeight. Some abbreviations are combined in different display

views.

Abbreviation Explanation

AAutomatic

Absent Failure message

Alrm Alarm

AT Ai r Tem per at ure

BF Boom Frame

Dfalting Resetting the panel

DZ Valve Dead Zone

h = ht Height

IF Intermediate Frame

KP Valve Gain

LEV Levelling

LftDft Left Detection

LI Left Inner (sensor)

LO Left Outer (sensor)

MManual

MHC Minimum Height Crop Mode

MHM Minimum Height Mode

MHS Minimum Height Soil Mode

ML Boom Lift sensor (Main Lift sensor)

MlfDet Boom lift Detection

Mot’n Dly Motion Delay

NC No Communication

NoRdg = NR No Reading

Rems Remote Switches

RF Reference Frame

Rght Right

RI Right Inner (sensor)

RO Right Outer (sensor)

Sensi Sensitivity

SN Serial Number

SNR Sensor

SP Set Point

Stp Step

VT Valve Block Temperature

21

Page 22

3 - Description

22

Page 23

4 - System setup

System preparation

General info

Before the AutoHeight boom height control system will function properly, some information about the sprayer, tractor and

connected sensors is necessary.

Hydraulic hook-up

Tractors vary in design regarding the hydraulic system - either constant flow (open centre) systems or variable flow (closed

centre) systems. The open centre hydraulics block needs to be set for the system the tractor uses, whether open centre

hydraulics or closed centre variable system with load sensing will be used.

NOTE! It is strongly recommended to use a tractor with a closed center or load sensing variable hydraulic system in

÷

combination with the AutoHeight boom height control system, as an open centre system without load sensing may

heat the oil excessively.

NOTE! Running AutoHeight at high sensitivity will increase heat build-up of the oil. Specially when AutoHeight

÷

system is used with tractors that has an open centre system without load sensing, it may require lower sensitivity

settings to avoid overheating of hydraulic oil.

The valve (1) on the side of the block is factory set for open centre

hydraulics, but if closed centre hydraulics will be used (also in

combination with load sensing) then screw in the valve.

Certain tractor models are able to use Load Sensing without connecting

an external sensing line. But if optimal sensing control pressure cannot

be obtained, an external sensing line needs to be mounted (3). Please

consult your tractor dealer for correct setup and correct connection.

Before operating the hydraulics, the valve should be adjusted according

to the specific tractor model. If you are unsure of the type of hydraulic

system of your tractor, please consult your tractor dealer.

Schedule with combinations of settings for flow element and circuit

value:

Valve no. 1 2 3 ( LS port)

Open centre Out Out Not connected

Closed centre In In Not connected

Load sensing (LS) In Out* Connected

*if tractor requires pressure relief, contact your tractor dealer for further advice.

WARNING! Always be sure to fully extract or retract the open/closed centre selection valve (1). Failure to do so may

±

cause damage to vital pump parts.

WARNING! It is of essential importance that connectors on the sensing line are kept totally clean. Failure to do so may

±

result in impurities entering the pump and thereby causing damage to vital pump parts.

Control panel

When the control panel is turned on for the first time, the AutoHeight panel guides the operator through the Automatic

System Setup (This is normally done by your HARDI dealer). This procedure is described in “Automatic System Setup” on

page 24. Normally the AutoHeight system will automatically configure and calibrate itself to the sprayer. If this process does

not produce the desired results, perform Manual System Setup described in “Manual System Setup” on page 28. From time

to time it may be necessary to ReTune the AutoHeight electronics to your sprayer's hydraulics. This procedure is described

in “Retune” on page 27.

23

Page 24

4 - System setup

Automatic System Setup

The first time the AutoHeight system is powered up, it will guide you through the Automatic System Setup to customize the

AutoHeight settings to your sprayer (This is normally done by your HARDI dealer). The entire procedure should take

approximately two to seven minutes.

At any point during the setup procedure, you can exit by toggling the "SETUP (NO)" switch. However, if you exit without

completing the System Setup, you may not be able to use the AutoHeight in AUTO mode.

If you wish to restart/rerun this procedure after an initial setup has been completed, navigate to the "Install?" prompt

in the SETUP menu and confirm the action with the "AUTO (YES)" switch.

DANGER! At points during the system setup (retune) all boom sections need to move. Personnel and equipment

€

must be clear of all boom sections, and unless instructed, do NOT leave the tractor’s seat while performing a system

setup. Keep an eye to the control panel and prepare to toggle the "SETUP (NO)" switch to stop setup procedure, if

persons get into of the boom!

WARNING! Make sure all booms have room to lift fully and are clear of power lines.

±

NOTE! If you confirm the "Install?" menu prompt by accident, you can exit by toggling "SETUP (NO)" before

÷

confirming a sprayer type. No settings will be lost. However, if you confirm a sprayer type and the "Dfalting"

message (STEP 4 in “STEP 5: Select the Sprayer Type” on page 25) appears, all previous system settings will be lost.

You may need to perform Automatic System Setup again.

STEP 1: Prepare the Equipment

• Unfold the sprayer in a location that is relatively level, and where the sensors are over bare soil or gravel.

NOTE! Do not conduct the System Setup or ReTune procedure over standing crop or tall weeds/grass. Avoid concrete

÷

or asphalt surfaces.

STEP 2: Prepare the Equipment

Properly tuned suspension systems will optimize AutoHeight performance, especially on roll-bias (active roll) systems.

• Ensure all hydraulic boom functions are operating properly:

• All fold functions.

• Main lift function.

• Wing tilt function.

•Slant function.

• Ensure the boom guide-rods are set to the “tapered” position, i.e. more stable.

• Check the pads between the sprayer boom and the boom carrier frame to ensure no friction because of wear. Use

grease or other lubricants, if necessary. This is important and will increase the AutoHeight system performance

significantly.

• Ensure boom suspension is critically damped, which is illustrated

as tip height (H) movement over time (T ) when doing following:

A. Unlock the pendulum, and push boom tip down

approximately 75 cm.

B. Hold the boom steady for a moment, and release.

C. Ensure the boom returns to its relaxed state as quickly as

possible, with little to no overshoot.

Adjust the boom damper accordingly.

STEP 3: Prepare the Equipment

• Start the tractor hydraulic oil supply and run the sprayer's engine

at a normal working RPM for the entire setup.

Make sure that you can manually adjust the height of all your boom sections. If your manual controls do not work

normally, check the AutoHeight Installation Manual that came with your kit for troubleshooting information.

24

Page 25

4 - System setup

Type +/-Select

HD4?

Dfalting

3 Sensrs

booms atLevel height90 cm Proceed?

AUTOHold Doneuntil

SwitchRelease

ATTENTION! For best results, the hydraulic system should be under a normal load and at a normal working

μ

temperature. An effective way to warm the oil is to cycle all boom sections up and down manually for 5 minutes.

Longer warm up times may be required in cold weather. Ensure any hydraulic flow controls are adjusted for normal

field operation.

NOTE! Changing the flow controls during or after System Setup will affect AutoHeight operation.

÷

STEP 4: Turn On the AutoHeight Panel

• If this is the first setup for the panel, this process will begin automatically. If the panel was previously setup, you need

to select "Install?" from the SETUP menu to initiate Automatic System Setup.

NOTE! If other messages appear on the LCD screen during the following steps, refer to “Retune” on page 27 for more

÷

information.

STEP 5: Select the Sprayer Type

• Use the "+/-" switch to toggle through a list of available sprayer

types. The types are listed in “Specifications” on page 57.

• When the desired type is shown, confirm the selection with the

"AUTO (YES)" switch.

• If you wish to exit the install now before changing any settings,

toggle the "SETUP (NO)" switch.

• The control panel is loading all the settings for your sprayer.

STEP 6: Sensor Detect

• The control panel reads the serial numbers of all connected sensors.

• Number of sensors found is displayed. This should match the

number of sensors on your system. If it does not, turn off the

control panel and ensure that all sensors are plugged in and

operating.

• If you have boom slant control, manually level the boom.

• Position all other boom sections such that the nozzles are 90 cm from the ground.

NOTE! If you cannot get all the booms set to exactly 90 cm, you can adjust the sensor height after you have finished

÷

the install. Refer to “Calibrating the Sensor's Height Reading (Zero Height)” on page 29 for more details.

• Toggle "AUTO (YES)" to continue.

• Hold the "AUTO (YES)" switch to begin the sensor detect sequence. During the procedure you must hold the "AUTO

(YES)" switch. If "AUTO (YES)" is released, simply toggle and hold again to continue the procedure.

• The control panel will automatically slot in the sensors to the correct locations and indicate the progress.

• Release the "AUTO (YES)" switch to continue.

25

Page 26

4 - System setup

boom tippush

& let goground

Exit cab

near to

AUTOHold Doneuntil

Done

M 84 M

A 115 A

STEP 7: Boom Geometry Tuning

NOTE! Do not activate any hydraulic functions during this step.

÷

• Exit the cab of the machine and manually

push either boom tip near to the ground

or at least 40 cm for a moment and then

let go.

WARNING! Do not walk near the sensors when approaching the boom. Stay at least 1 metre from the sensor in order

±

not to induce measurement error.

STEP 8: Hydraulic Tuning

• Hold the "AUTO (YES)" switch to continue the hydraulic tuning. If "AUTO (YES)" is released before "Done" is displayed,

simply toggle and hold again to continue the procedure.

• The panel will display various messages as it is working. The messages are displayed for informational purposes only.

• Release the "AUTO (YES)" switch, the hydraulic tuning is complete.

STEP 9: Control System Test

• Run screen shown. It shows the system in manual mode with an

average height reading of 84 cm.

WARNING! In the following procedure, switch the control panel

±

to manual mode immediately if the boom movements are

erratic.

• Toggle "AUTO (YES)" to start AUTO mode. Observe the behaviour of the booms while correcting to the target height.

• The operating screen shows the system is in AUTO mode and the

target height is 115 cm.

ATTENTION! The boom movements should be smooth and stable. Boom corrections should stop after a few seconds,

μ

under normal conditions (excessive wind may cause small corrections to continue).

• Toggle the "MANUAL" switch to return to MANUAL mode. If the boom corrections are done in an acceptable manner,

your system is ready to use.

Automatic System Setup Complete!

26

Page 27

4 - System setup

Retune

From time to time it may be necessary to recalibrate (Retune) the AutoHeight electronics to your sprayer's hydraulics.

Examples of such times are:

• When a hydraulic solenoid valve is changed

• When the hydraulic pump is changed or adjusted

• A different tractor has been connected to the sprayer.

• The tractor’s hydraulic flow control has been adjusted.

If you are running a pull type sprayer and use different tractors to operate the sprayer, you should run the Retune procedure

each time the tractor is changed. If you have a flow control for the boom hydraulics, set it prior to tuning. If you change the

flow setting by more than 20 percent, you should Retune.

Follow Section “STEP 1: Prepare the Equipment” on page 24 to “STEP 3: Prepare the Equipment” on page 24 (level booms,

working RPM, etc.) before beginning the Retune. Navigate to the "ReTune?" menu prompt in the SETUP menu and

confirm with the "AUTO (YES)" switch. The procedure described in the Automatic System Setup, starting at “STEP 6: Sensor

Detect” on page 25, will begin.

NOTE! The booms are to be levelled at a normal working height when Retune starts - it is not necessary to set them

÷

to 90 cm. The 90 cm height is only required during the Automatic/Manual System Setup.

27

Page 28

4 - System setup

11069

A

B

Manual System Setup

The AutoHeight system will not operate in automatic mode until the system has been completely configured by either the

Automatic System Setup or Manual System Setup. It is recommended that the Automatic System Setup be used, but if

necessary a manual system setup may be used. The manual system setup involves setting up each sensor (programming

serial numbers and sensor locations) as well as tuning the hydraulic parameters manually.

Setting Up Sensors

Before beginning, it is necessary to know the serial number (A/B) and

location for each of the sensors. The sensor serial number is located on

the bottom of the sensor housing, beside the foam disc.

NOTE! The location of serial numbers may differ from sensor to

÷

sensor. Some sensors have the serial number located at position

(A), and others at position (B).

It is recommended that you record the serial numbers according to

sensor locations in the figure because this information may be required

during troubleshooting.

Sensor position Sensor serial number

A

B

C

D

E

The left channel menu prompts are described in Table 3. For the other channels, the basic structure and behaviour of the

prompts are the same. Navigate with Sensor display/Setup switch.

Table 3 - Left Channel SENSOR DISPLAY Menus

Navigating past the end of the menu will return the panel to the Sensor…"More" Menu

LIht 108 Current height reading of the LI sensor is 108 cm.

LI 11070 Serial number 11070 is installed as the left inner (LI) sensor.

LOht 115 Current height reading of the LO sensor is 115 cm.

LO 11069 Serial number 11069 is installed as the left outer (LO) sensor.

Navigating past the end of the menu will return the panel to the Sensor…"More" Menu

Entering Sensor Serial Numbers

To enter a sensor serial number in one of the boom locations:

1. Ensure the AutoHeight panel is in MANUAL mode, at the run screen.

2. Navigate to the "More ?" menu prompt in the SENSOR DISPLAY menu. Toggle "AUTO (YES)" to confirm.

28

Page 29

4 - System setup

11069 115

3. Navigate to the boom section you put the sensor on, for example, "Left ?", if the sensor is mounted on the left

hand boom. Toggle "AUTO (YES)" switch.

4. Navigate to the boom location you mounted the sensor on, for example, "LO" for the left outer sensor. This screen will

show the previously installed sensor serial number (if any) as shown in Table 3.

5. Toggle the "+" switch once to search for all the connected sensors.

6. Use the "+" switch to toggle through a list of available sensor serial

numbers. Sensor height reading is shown beside the serial

number.

7. When the desired serial number is shown, toggle "AUTO (YES)" switch to confirm.

8. Proceed to "LOht" menu prompt to check/calibrate the sensor's height reading (see next section).

9. Toggle and hold "SETUP (NO)" or “SENSOR DISPLAY” switch for two seconds to return to the run screen.

Calibrating the Sensor's Height Reading (Zero Height)

1. Ensure the sprayer boom is unfolded and the sensors are located

over bare soil or gravel. Position the boom at a normal working

height. Do not conduct this procedure over standing crop or tall

grass/weedy areas.

2. Using a tape measure, measure the distance from the bottom of

the spray nozzle closest to the sensor to the ground. Round this

measurement to the nearest cm.

3. Ensure the AutoHeight control panel is in manual mode, at the run

screen.

4. Navigate to the boom section you put the sensor on, for example,

"Left ?", if the sensor is mounted on the left boom. Toggle

"AUTO (YES)" switch.

5. Navigate to the location you measured, for example, "LOht" for

the left outer sensor menu prompt as described in “Table 3 - Left

Channel SENSOR DISPLAY Menus” on page 28.

6. If the currently displayed height reading is not correct, adjust it

using the "+/-" switch. The " + " switch will increase the reading, the

" - " switch will decrease the reading.

7. To return to the run screen, toggle and hold "SETUP (NO)" or “SENSOR DISPLAY” switch for two seconds.

NOTE! To view the absolute height reading from the sensor to the ground, press and hold the “AUTO (YES)” switch

÷

from the “LOht” menu. This height reading can be useful for troubleshooting purposes.

Setting Up Hydraulic Valves

Each valve must be tuned correctly for optimum performance from the AutoHeight system. When setting up the valves, the

sprayer booms must have room to move in their full range of motion. Make sure there are no obstructions, such as power

lines, that the booms may come into contact with.

Before setting up the valves manually, it is recommended you attempt the automatic install. Starting the automatic install

will load the default valve settings, which will make the manual valve setup much simpler. At any time the automatic install

can be cancelled and the default settings are still stored.

Each valve has two settings; dead zone and gain. The dead zone relates to the smallest amount of movement the valve can

produce. The maximum boom speed is dependent on the gain.

A dead zone and gain parameter exists for each valve. Each valve may be tuned:

• Automatically (as part of the automatic install or retune).

• Automatically (one valve at a time).

• Manually.

NOTE! You do not need to run both the AUTO and Manual tests. The tests are entirely independent.

÷

The left channel menu prompts are shown below. For other channels, the basic structure and behavior of the prompts are

the same.

29

Page 30

4 - System setup

Table 4 - Left Channel SETUP Menus

Navigating past the end of the menu will return the panel to the Setup…"More" Menu

Left On Left valve channel is ON. To change the status to OFF, use the "+/-" switch (Section 6.3.5).

DZ 100 Left up DeadZone setting is 100. To adjust the reading use the "+/-" switch.

KP 53 Left up GAIN setting is 53. To adjust the reading use the "+/-" switch.

DZ 100 Left down DeadZone setting is 100. To adjust the reading use the "+/-" switch.

KP 42 Left down GAIN setting is 42. To adjust the reading use the "+/-" switch.

Navigating past the end of the menu will return the panel to the Setup…"More" Menu

These settings will be determined during the Automatic System Setup (“Automatic System Setup” on page 24) and

"ReTune?" (“Retune” on page 27) sequences automatically. However, it is possible to check and adjust these settings

manually as described below.

Automatic DeadZone Calibration

1. Follow the steps, “STEP 1: Prepare the Equipment” on page 24 to “STEP 3: Prepare the Equipment” on page 24 (level

booms, working RPM, etc.), before proceeding.

2. Ensure the AutoHeight panel is in MANUAL mode, at the run screen.

3. Navigate to the "More ?" menu prompt in the SETUP menu. Toggle the "AUTO (YES)" switch to confirm.

4. Navigate to the boom section you wish to set up, for example, "Left ?" to adjust the left up and/or the left down

settings. Toggle the "AUTO (YES)" switch to confirm.

5. Toggle the "SETUP (NO)" switch to access the next menu prompt. Choose the dead zone up or down setting - see

“Table 4 - Left Channel SETUP Menus” on page 30.

6. Toggle and hold the "AUTO (YES)" switch.

7. When the "Done" message is displayed, release the "AUTO (YES)" switch to view the new setting.

Manual DeadZone Calibration

1. Follow the steps, “STEP 1: Prepare the Equipment” on page 24 to “STEP 3: Prepare the Equipment” on page 24 (level

booms, working RPM, etc.), before proceeding.

2. Ensure the AutoHeight panel is in MANUAL mode, at the run screen.

3. Navigate to the "More ?" menu prompt in the SETUP menu. Toggle the "AUTO (YES)" switch to confirm.

4. Navigate to the boom section you wish to set up, for example, "Left ?" to adjust the left up and/or the left down

settings. Toggle the "AUTO (YES)" switch to confirm.

5. Toggle the "SETUP (NO)" switch to access the next menu prompt. Choose the dead zone up or down setting - see

“Table 4 - Left Channel SETUP Menus” on page 30.

6. Toggle and hold the "MANUAL" switch.

7. The valve will turn on at the indicated setting for exactly one second. The screen will show the actual change in height.

8. The change in height reading is live as long as you hold the "MANUAL" switch. Wait until the height reading has settled

to a stable value and record this reading.

9. Average your three readings. The acceptable average change in height should be from 13 to 38 mm (ideal would be

25 mm exactly).

10. If the average is less, increase the DZ setting with the "+/-" switch. If the average is more, decrease the DZ setting with

the "+/-" switch.

11. Repeat the Manual Dead Zone Test until the average falls into the acceptable range.

30

Page 31

4 - System setup

Automatic Gain Calibration

Before tuning the gain setting, the dead zone for that function must be tuned. If the dead zone tuning has not been

completed, follow the instructions for tuning a dead zone.

1. Follow the, “STEP 1: Prepare the Equipment” on page 24 to “STEP 3: Prepare the Equipment” on page 24 (level booms,

working RPM, etc.), before proceeding.

2. Ensure the AutoHeight panel is in MANUAL mode, at the run screen.

3. Navigate to the "More ?" menu prompt in the SETUP menu. Toggle the "AUTO (YES)" switch to confirm.

4. Navigate to the boom section you wish to set up, for example "Left ?" to adjust the left up and/or the left down

settings. Toggle the "AUTO (YES)" switch to confirm.

5. Toggle the "SETUP (NO)" switch to access the next menu prompt. Choose the gain up or down setting - see “Table 4 Left Channel SETUP Menus” on page 30.

6. Toggle and hold the "AUTO (YES)" switch.

7. When the "Done" message is displayed, release the "AUTO (YES)" switch to view the new setting.

Manual Gain Calibration

WARNING! This test will drive the boom at full speed in the selected direction for one second. Make sure the boom

±

has full range of movement, and if driving the boom down, make sure it is not close to the ground.

The pur pose of this test is to de termine the sprayer boom speeds. I t is recommen ded that yo u perfor m each test three times

and average your readings.

1. From the speed measurements taken, use “Table 5 - Right, Left Booms” on page 32 to determine the appropriate gain

values to use for each function. This test will provide approximate results for gain values. Proper gain values rely on

more than just boom speed so it is highly recommended to use the automatic gain setup, if possible.

2. Follow the, “STEP 1: Prepare the Equipment” on page 24 to “STEP 3: Prepare the Equipment” on page 24 (level booms,

working RPM, etc.), before proceeding.

3. Ensure the AutoHeight panel is in MANUAL mode, at the run screen.

4. Navigate to the "More ?" menu prompt in the SETUP menu. Toggle the "AUTO (YES)" switch to confirm.

5. Navigate to the boom section you wish to set up, for example "Left ?" to adjust the left up and/or the left down

settings. Toggle the "AUTO (YES)" switch to confirm.

6. Toggle the "SETUP (NO)" switch to access the next menu prompt. Choose the gain up or down setting - see “Table 4 Left Channel SETUP Menus” on page 30.

7. Toggle and hold the "MANUAL" switch.

8. The valve will turn on at 100 percent speed for exactly one second. The screen will show the actual change in height.

9. The change in height reading is live as long as you hold the "MANUAL" switch. Wait until the height reading has settled

to a stable value and record this reading. This is your boom speed in mm per second (cm/s).

10. Repeat the Manual Gain Test three times, repositioning the boom as necessary.

11. Average your three readings. Typical values are between 40 and 130 cm/sec.

12. Set the Gain value using the "+/-" switch using the tables below as a guideline. Right and left Gain settings are polarized

for direction as shown in “Table 5 - Right, Left Booms” on page 32.

NOTE! Gain values depend on many more factors than just speed and therefore are best set automatically or by an

÷

experienced operator.

NOTE! Test the response at a sensitivity (Sensi) of five, because the Sensi setting will scale the Gain settings

÷

(“Sensitivity (Sensi) Setting” on page 14). If the booms are not reacting quickly enough, a higher Gain setting will make

the boom respond faster. If the booms are too jerky or unstable, you must lower the Gain setting or improve the

boom's mechanical damping.

31

Page 32

4 - System setup

Tab le 5 - R ig ht , Lef t Boom s

Function Boom Speed

(cm/s)

Left / Right 1-13 Too Slow Too Slow

Left / Right 13-38 225-175 100-70

Left / Right 38-63 175-150 70-50

Left / Right 63-102 150-100 50-30

Left / Right 102-178 100-50 30-15

Left / Right 178+ 50-1 15-1

Main (on / off ) 1-13 100-75 100-75

Main (on / off ) 13-25 75-50 75-50

Main (on / off ) 25-38 50-30 50-30

Main (on / off ) 38-51 30-15 30-15

Main (proportional) 1-13 85-75 85-75

Main (proportional) 13-25 75-66 75-66

Main (proportional) 25-38 66-60 66-60

Main (proportional) 38-51 60-53 60-53

Roll 1-25 254-225 254-225

Roll 25-38 225-175 225-175

Roll 38-51 175-150 175-150

Roll 51+ 150-100 150-100

Up Gain Setting

( KP)

Down Gain Setting

( KP)

Table 6 - Main (Centre) Boom

Boom Speed Gain Setting

(cm/s) (KP)

3-13 100-75

13-25 75-50

25-38 50-30

38-51 30-15

Tab le 7 - Rol l S ect io n

Boom Speed Gain Setting

(cm/s) (KP)

<25 225-254

25-38 175-225

38-51 175-200

>51 150-100

Turning Booms OFF or ON

You can turn AutoHeight automatic height control off for each individual boom section. In AUTO mode, boom sections that

are turned off will not automatically adjust and are indicated with a "D" in the run screen, as shown below.

D 88A

Left boom is turned OFF ("D”= disabled) control, the current average boom height = 88, Right boom is in AUTOMATIC mode.

Sections can be turned off or on in the SETUP menu. Refer to the menu structure shown in “Table 4 - Left Channel SETUP

Menus” on page 30. Locate the menu prompts named below.

This may be useful if you are mounting the boom lift sensor directly behind a sprayer tire which can impair the boom lift

control when operating in crop mode. Height readings from crop that is flattened by the sprayer wheel do not provide an

accurate measurement of canopy height, resulting in poor performance. By turning off the main section you can disable the

main section’s automatic control; however, manual height readings from this section will still be available. The sprayer’s wing

booms will still be controlled automatically.

32

Page 33

4 - System setup

1. Ensure the AutoHeight panel is in MANUAL mode, at the run screen.

2. Navigate to the "More ?" menu prompt in the SETUP menu. Toggle the "AUTO (YES)" switch to confirm.

3. Navigate to the boom section you wish to turn off or on, for example "Right ?". Toggle the "AUTO (YES)" switch

to confirm.

4. At the "Right On" menu prompt toggle the "+/-" switch to change the status.

5. Toggle and hold the "SETUP" switch for two seconds to return to the Normal Operational Screen.

33

Page 34

4 - System setup

Install ?

Type +/-Select

HD4 ?

Sensor

Roll OnA

IFh 0

BFh 0

Quick Install

The Quick Install feature of the AutoHeight system is designed to help diagnose problems that cannot be identified during

the Automatic Setup. It will instantly set up the system with typical values for valve calibration and sprayer geometry, based

on the sprayer type selected.

Perform the following procedure for a Quick Install:

A: STANDARD SYSTEM (Including Passive Roll)

1. Your system must have a minimum of two sensors.

2. Verify the sensors are installed with the lowest serial number on the left side increasing to the highest serial number

on the right side (Refer to the AutoHeight Installation Manual).

3. Level the boom at 90 cm height.

4. Navigate in the SETUP menu to the "Install?" screen and

toggle the "AUTO (YES)" switch.

5. At the "Select" "Type +/-" menu prompt, select the

appropriate type for your sprayer (e.g. HD4). Sprayer types are

listed in “Specifications” on page 57.

6. Toggle and hold "AUTO (YES)" for 5 seconds.

7. When the word "Sensor" is displayed, release the switch. Your

system will be configured with the standard settings based on the

type you have selected and the number of sensors present.

8. Exit the cab of the machine and manually push either boom tip near to the ground for a moment and then let go. Push

either boom tip such that the tip moves at least 40 cm (more if you can).

WARNING! Do not walk near the sensors when approaching the boom. Stay at least 1 metre from the sensor in order

±

not to induce measurement error.

9. Once the control panel has detected your sprayer's geometry, perform a ReTune (“Retune” on page 27).

B: ACTIVE ROLL SYSTEM

1. Perform the Quick Install for STANDARD SYSTEM, as described above.

2. Navigate to the "Roll ?" menu prompt in the SETUP menu.

Toggle "AUTO (YES)" and change it to "Roll OnA" using the

"+/-" switch. Toggle "AUTO (YES)" to confirm.

3. Navigate to the "Roll ?" menu prompt in the SENSOR DISPLAY

menu. Toggle "AUTO (YES)" and set the "IFh" (intermediate

frame height) and "BFh" (boom frame height) to zero using the

"+/-" switch. Toggle "AUTO (YES)" to confirm.

4. Perform a ReTune (“Retune” on page 27).

34

Page 35

4 - System setup

Options