Page 1

ATV SPRAYER

DIAPHRAGM

Operator's Manual

67302803 7/05

Page 2

Page 3

HARDI

ATV SPRAYER

DIAPHRAGM

Operator's Manual

67302803 (7/05)

HARDI® reserves the right to make changes in design,

material, or specifi cation without notice thereof.

®

HARDI

and other product names are registered trademarks

of HARDI® Inc. in the U.S. and in other countries.

Page 4

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.0 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Follow Safety Instructions . . . . . . . . . . . . . . . . . . . 8

2.2 Operating the Sprayer Safely . . . . . . . . . . . . . . . . . 8

2.3 Handling Chemical Products Safely . . . . . . . . . . . . 10

2.4 Local Poison Information Center . . . . . . . . . . . . . . 11

3.0 HOOKING UP THE SPRAYER . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Tow Vehicle Requirements . . . . . . . . . . . . . . . . . . . 12

3.2 Tongue Weight Adjustment . . . . . . . . . . . . . . . . . . 12

3.3 Hitch Height Adjustment . . . . . . . . . . . . . . . . . . . . . 13

3.4 Wheel Spacing Adjustment . . . . . . . . . . . . . . . . . . 14

3.5 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7 Gas Engine Requirements . . . . . . . . . . . . . . . . . . . 16

4.0 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Filling The Main Tank . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Filling The Handwash (Clean Water) Tank . . . . . . . 17

4.3 Standard Plumbing Diagram . . . . . . . . . . . . . . . . . 18

4.4 Plumbing Diagram with optional Rate Controller . . 19

4.5 Adjustment Of The Sprayer Controls . . . . . . . . . . . 20

4.6 Agitation Adjustment . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 Operation Of The Tank Drain Valve . . . . . . . . . . . . 22

4.8 Adjustment Of Air Pressure in Pressure Damper . . 23

4.9 Unfolding/Folding Boom . . . . . . . . . . . . . . . . . . . . . 23

4.10 Boom Height Adjustment . . . . . . . . . . . . . . . . . . . . 24

5.0 NOZZLE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 5

6.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Cleaning The Sprayer . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3 Nozzle Tubes And Fittings . . . . . . . . . . . . . . . . . . . 35

6.4 Wheel Nuts and Bearings Adjustment . . . . . . . . . . 35

6.5 Recommended Tire Pressure . . . . . . . . . . . . . . . . 36

6.6

Changing The Valves And Diaphragms (1203 Pump)

36

6.7 Breakaway Clutch Adjustment . . . . . . . . . . . . . . . . 37

6.8 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.0 OFF-SEASON STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1 Preparation After Off-Season Storage . . . . . . . . . . 42

8.0 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.1 Clean Water Dispenser . . . . . . . . . . . . . . . . . . . . . 43

8.2 Spraygun And Hose wrap (optional) . . . . . . . . . . . 43

8.3 Maverick Rate Controller (optional) . . . . . . . . . . . . 44

8.4 SMV Sign Kit (optional) . . . . . . . . . . . . . . . . . . . . . 44

9.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 General Spray Systems . . . . . . . . . . . . . . . . . . . . . 45

10.0 WARRANTY POLICY AND CONDITIONS . . . . . . . . . . . . 46

11.0 NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 6

Dear Owner,

Thank you for purchasing a HARDI® product and welcome to the everincreasing family of HARDI® sprayer owners.

Our sprayers and accessories are rapidly becoming a familiar sight

on North American farms. We believe that this results from growers

becoming increasingly conscious of crop protection input costs and the

vital need for cost effective application equipment.

Please take the time to thoroughly read the Operator’s Manual before

using your equipment. You will fi nd many helpful hints as well as

important safety and operation information.

Some of the features on your ATV sprayer were suggested by growers.

There is no substitute for “on farm” experience and we invite your

comments and suggestions. If any portion of this instruction book

remains unclear after reading it, contact your HARDI® dealer or service

personnel for further explanation before using the equipment.

For Product, Service or Warranty Information:

- Please contact your local HARDI® dealer.

To contact HARDI® directly:

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to CUSTSERV@hardi-us.com

HARDI® INC. Visit us online at: www.hardi-us.com

HARDI® MIDWEST

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1710

HARDI® GREAT LAKES

290 Sovereign Rd.

London, Ontario N6M 1B3

Phone: (519) 659-2771

Fax: (519) 659-2821

HARDI® WEST COAST

8550 W. Roosevelt Avenue

Visalia, California 93291

Phone: (559) 651-4016

Fax: (559) 651-4160

Sincerely,

Tom L. Kinzenbaw

President

4 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 7

1.0 INTRODUCTION

We congratulate you for choosing a HARDI® plant protection product.

The reliability and effi ciency of this product depends on your care.

The fi rst step is to carefully read and pay attention to this operator's

manual. It contains essential information for the effi cient use and long

life of this quality product.

®

This manual covers the HARDI

directly coupled to a HARDI® 1203 diaphragm pump. The HARDI® ATV

sprayer is available in a 150 gallon (550 L) capacity.

The heart of your sprayer is the diaphragm pump. The design is simple,

resulting in low maintenance requirements and guaranteed pump life.

The bearings and crankshaft are grease lubricated and are therefore

protected from spray solution if any diaphragm fails in service. A drain

hole is located in the base of the crank case to facilitate the draining of

any foreign matter. The pump is self-priming and can be run dry without

damage.

The HARDI® ATV sprayer is equipped with a manual control which

features: electrically operated master on/off control, electrically

operated boom distribution valves, manual pressure adjustment valve,

pump bypass agitation, and a 4" boom pressure gauge.

The tank, made of impact proof and chemical resistant poly eth yl ene,

has a purposeful design with rounded contours which allows for

ef fi cient cleaning and draining. The tank is designed with a large deep

sump, so that it can be completely emptied even when the sprayer is

used on slopes. A tank level indicator is molded into the front and side

of the tank. A remote operated tank drain valve is fi tted for safe and

easy draining. Bottom tank suction includes a shut-off valve for easy

cleaning of suction fi lter.

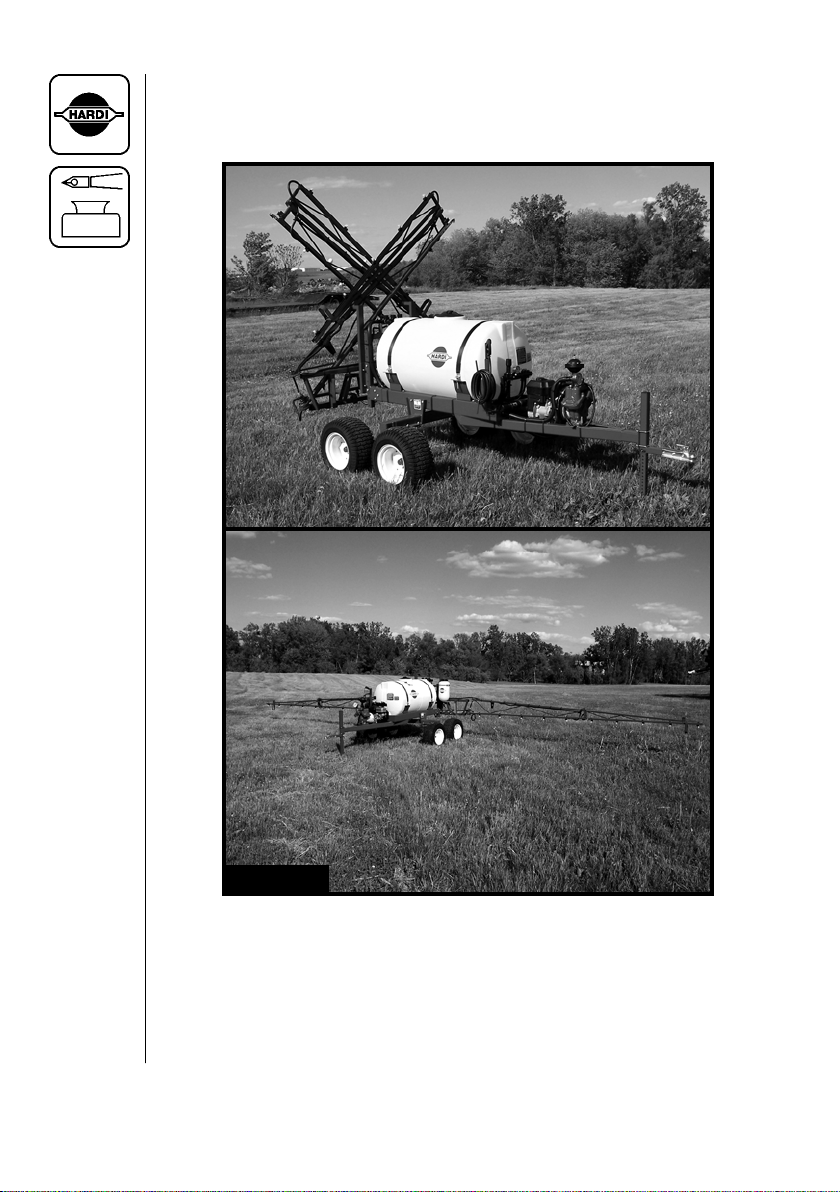

ATV sprayer equipped with gas engine

Available options include: 4 gallon (15 L) clean water dispenser, hose

wrap with 25' of 3/8" hose and a model 60L HARDI® spray gun, fi lter

basket and SMV sign.

The HARDI® ATV sprayer is available with either the 20', 26', 33' or 40'

MB boom. The 40' MB boom features a self-levelling trapeze center. All

booms feature ISO fl at fan nozzles with 20" spacing.

5HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 8

The frame and boom of your HARDI® ATV sprayer are fi nished with a

powder coat paint which provides maximum protection from chemicals

and rust.

Fig. 1

150 GALLON ATV SPRAYER WITH 40' MB BOOM

6 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 9

2.0 SAFETY INFORMATION

WARNING!

ALWAYS READ OPERATOR'S MANUAL BEFORE

USING THIS EQUIPMENT

DO NOT REMOVE ANY SAFETY DEVICES OR

SHIELDS. NEVER SERVICE, CLEAN OR REPAIR A

MACHINE WHILE IT IS OPERATING

WARNING!

ALWAYS WATCH FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS

IT MEANS ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

7HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 10

RECOGNIZE SAFETY INFORMATION

This is the Safety-alert symbol. When you see

this symbol on your machine or in this manual,

be alert to the potential for per son al injury.

Follow recommended precautions and safe

op er at ing practices.

2.1 Follow Safety Instructions

1. Carefully read all the safety messages in this manual and the

safety labels fi tted to the machine. Keep safety labels in good

condition. Replace missing or damaged safety labels. Make sure

that new equipment components include any current safety labels.

Replacement safety labels are available from your authorized

HARDI® dealer.

2. Learn how to operate the sprayer and how to use the controls

prop er ly. Do not let anyone operate the machine without proper

instructions.

3. Keep your sprayer in proper working condition. Unauthorized

modifi cations or use may impair the function and/or safety and affect

the machine's life.

4. If you do not understand any part of this manual and need

assistance, please contact your authorized HARDI® dealer.

2.2 Operating The Sprayer Safely

1. Read the complete manual carefully and become familiar with

the operation of the equipment before initial operation in each

spraying season. Failure to do so may result in possible over or

under-application of spray solution which may drastically affect crop

production and may lead to personal injury.

2. Always keep children away from your HARDI® ATV sprayer.

3. Before starting the gas engine on the HARDI® ATV sprayer, make

sure that all operating controls are in the off or neutral position

(including spray controls).

4. One of the most frequent causes of personal injury or death results

from persons falling off or being run over. Do not permit others

to ride on or in. Only one person, the operator, should be on the

machine when in operation.

8 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 11

5. Slow moving vehicles and spray equipment can create a hazard

when on public roads. Avoid personal injury or death resulting from

any accidents by using fl ashing lights. Some local regulations may

require installation of fl ashing warning lights.

6. Check local regulations before transporting the HARDI

®

ATV sprayer

on public roads. It may be necessary to use a trailer.

7. Before leaving the ATV/tractor seat, stop the engine, put all controls

in neutral, and put the transmission control lever in the park position

or neutral with the brakes locked. Read the ATV/tractor operator's

manual for added safety precautions.

8. Understand service procedures before undertaking any

maintenance. Never lubricate, service, or adjust the machine while

it's moving. Securely support any components before working on

them.

9. Keep all parts in good condition and properly installed. Repair

damaged parts immediately. Replace worn or broken parts.

9HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 12

2.3 Handling Chemical Products Safely

1. Direct exposure to hazardous chemicals can cause serious injury.

These chemicals can include lubricants, coolants, paints, adhesives

and agricultural chemicals. Material Safety Data Sheets (M.S.D.S.)

are available for all hazardous chemicals which inform the user of

specifi c details including, physical and health hazards, safety procedures, and emergency response techniques.

2. Protective clothing such as rubber gloves, goggles, coveralls and

respirator must be worn while handling chemicals. All protective

clothing should be kept in excellent condition and cleaned regularly

or discarded.

3. If chemicals come in contact with any exposed skin areas, wash immediately with clean water and detergent. Never place nozzle tips or

any other components that have been exposed to chemicals to lips

to blow out obstructions. Use a soft brush to clean spray nozzles.

4. Dedicate an area to fi ll, fl ush, calibrate and decontaminate sprayer

where chemicals will not drift or run off to contaminate people, animals, vegetation, water supply, etc. Locate this area where there is

no chance of children coming in contact with this residue.

5. Decontaminate equipment used in mixing, transferring and applying

chemicals after use. Follow the instructions on the chemical label for

the correct procedure required. Wash spray residue from outside of

the sprayer to prevent corrosion.

6. Extreme care should be taken in measuring spray products. Powders

should be used in suitable sized packages or weighed accurately.

Liquids should be poured into a suitable graduated container. Keep

chemical containers low when pouring. Wear a fi ltered respirator

and let the wind blow away from you to avoid dust and/or splashes

contacting the skin or hair.

7. Store chemicals in a separate, plainly marked locked building. Keep

the chemical in its original container with the label intact.

8. Dispose all empty containers after rinsing in accordance with local

regulations & by-laws. Dispose of all unused chemicals and left over

fertilizer in an approved manner

9. Keep a fi rst aid kit and fi re extinguisher available at all times when

handling chemicals.

10 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 13

2.4 Local Poison Information Center

If you live anywhere in the United States, the following toll free number

will connect you to your Local Poison Information Center.

PHONE NO. 1 - 8 0 0 - 2 2 2 - 1 2 2 2

If you live outside the United States, fi nd the number for the poison control

center in your phone book and write it in the space below:

PHONE NO. _________ - _________ - _____________

Keep a list, in the space provided below, of all the chemicals that you

have in use.

1. __________________________________________________

2. __________________________________________________

3. __________________________________________________

4. __________________________________________________

5. __________________________________________________

6. __________________________________________________

7. __________________________________________________

8. __________________________________________________

9. __________________________________________________

10. __________________________________________________

11HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 14

3.0 HOOKING UP THE SPRAYER

3.1 Tow Vehicle Requirements

ATV or Lawn & Garden tractor equipped with a 2" ball hitch and

suffi cient horsepower and braking ability to safely control a sprayer with

the following specifi cations:

Empty* Loaded**

Total weight

Tongue weight

*Weight with empty tank, 40' MB boom and axle in middle holes.

**Weight with tank full of water, 40' MB boom and axle in middle holes.

Note: Actual weight varies depending on boom size, axle position and

options. Check your sprayer for accurate results.

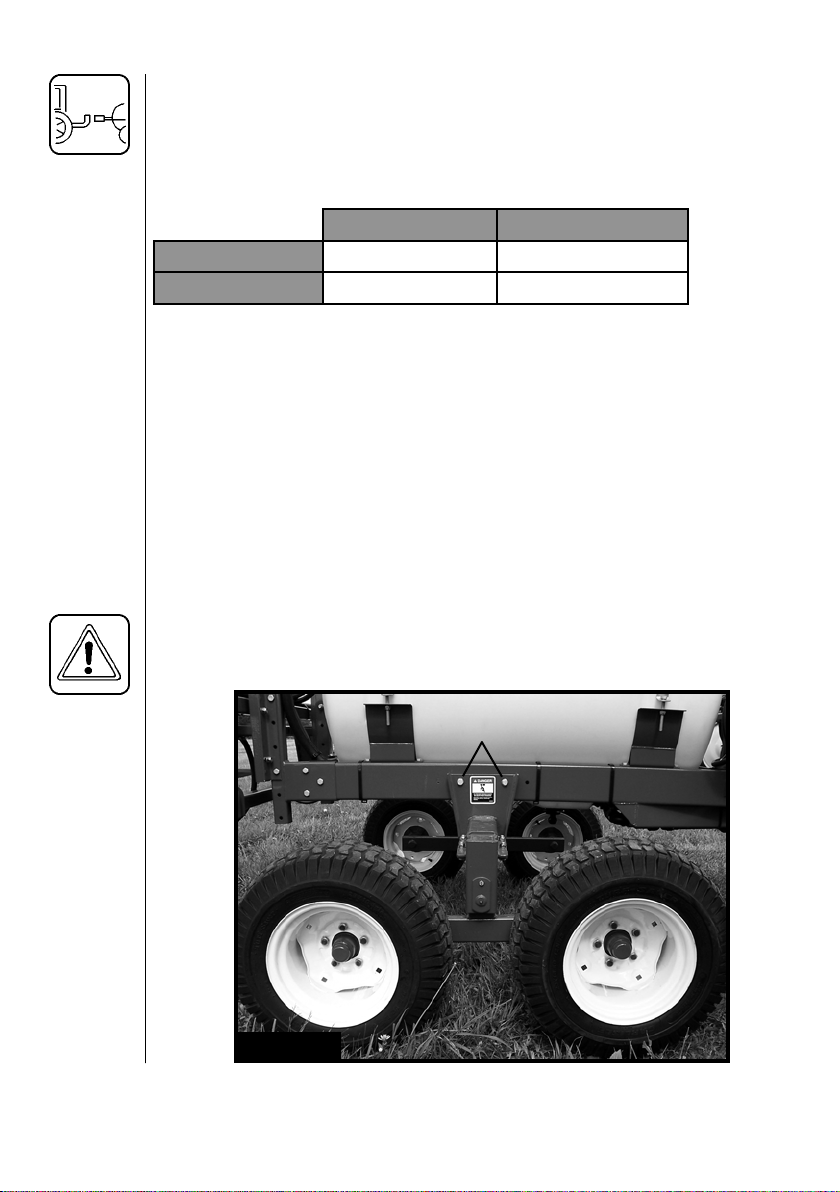

3.2 Tongue Weight Adjustment

The axle is installed at the factory and should not normally need

adjustment. If a different boom is installed, the axle may need to be

moved to increase or decrease the tongue weight.

Moving the axle forward will decrease the tongue weight.

Moving the axle rearward will increase the tongue weight.

WARNING: IF THE SPRAYER IS EQUIPPED WITH A 40' MB BOOM,

IT IS NOT RECOMMENDED TO USE THE FRONT AXLE

POSITION DUE TO THE LIGHT TONGUE WEIGHT.

932 lbs (423 kg) 2210 lbs (1002 kg)

24 lbs (11 kg) 104 lbs (47 kg)

A

Fig. 2

12 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 15

1. The sprayer should not be attached to any ATV/tractor while

adjusting the axle position. Make sure the storage jack is supporting

the tongue of the sprayer.

2. Using suitable lifting equipment, lift the rear of the sprayer frame until

the wheels just leave the ground.

3. Remove bolts A (Fig. 2) from both sides of the sprayer frame.

4. Move the axle to the desired set of holes. Re-install and tighten bolts

A (Fig. 2).

5. Lower sprayer frame.

WARNING: ALWAYS CHECK THE TONGUE WEIGHT AFTER

CHANGING THE AXLE POSITION. MAKE SURE THE

TONGUE WEIGHT IS NOT TOO HEAVY OR TOO LIGHT

FOR SAFE OPERATION WITH YOUR ATV/TRACTOR.

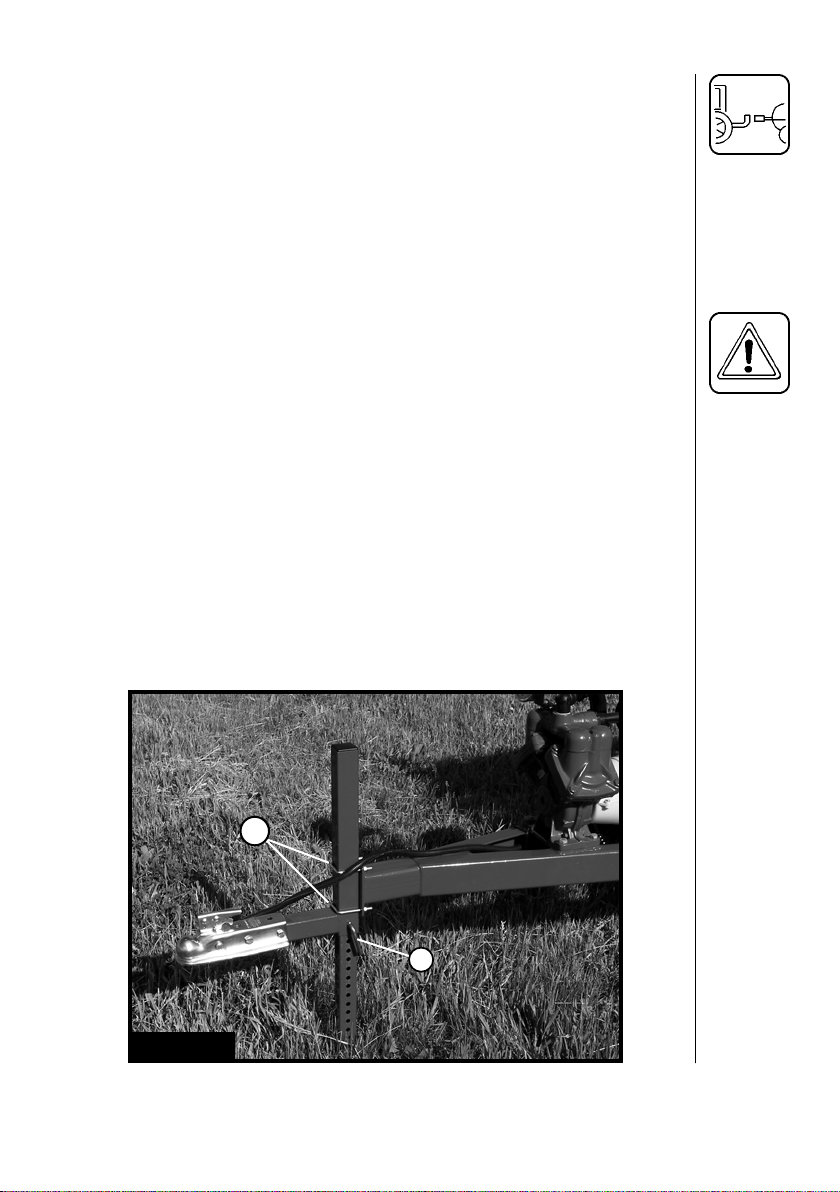

3.3 Hitch Height Adjustment

1. Attach sprayer tongue to ball hitch on ATV/tractor.

2. Lock the ball hitch lever and secure with safety pin.

3. Remove storage jack pin B (Fig. 3). Raise storage jack to highest

position and replace pin.

4. If the sprayer tank is not level, support the front of the sprayer frame

with an adjustable jack and loosen the two U-bolts C (Fig. 3).

5. Raise or lower the sprayer frame with the adjustable jack until the

tank is level.

6. Tighten U-bolts C (Fig. 3) and remove adjustable jack.

Fig. 3

C

B

13HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 16

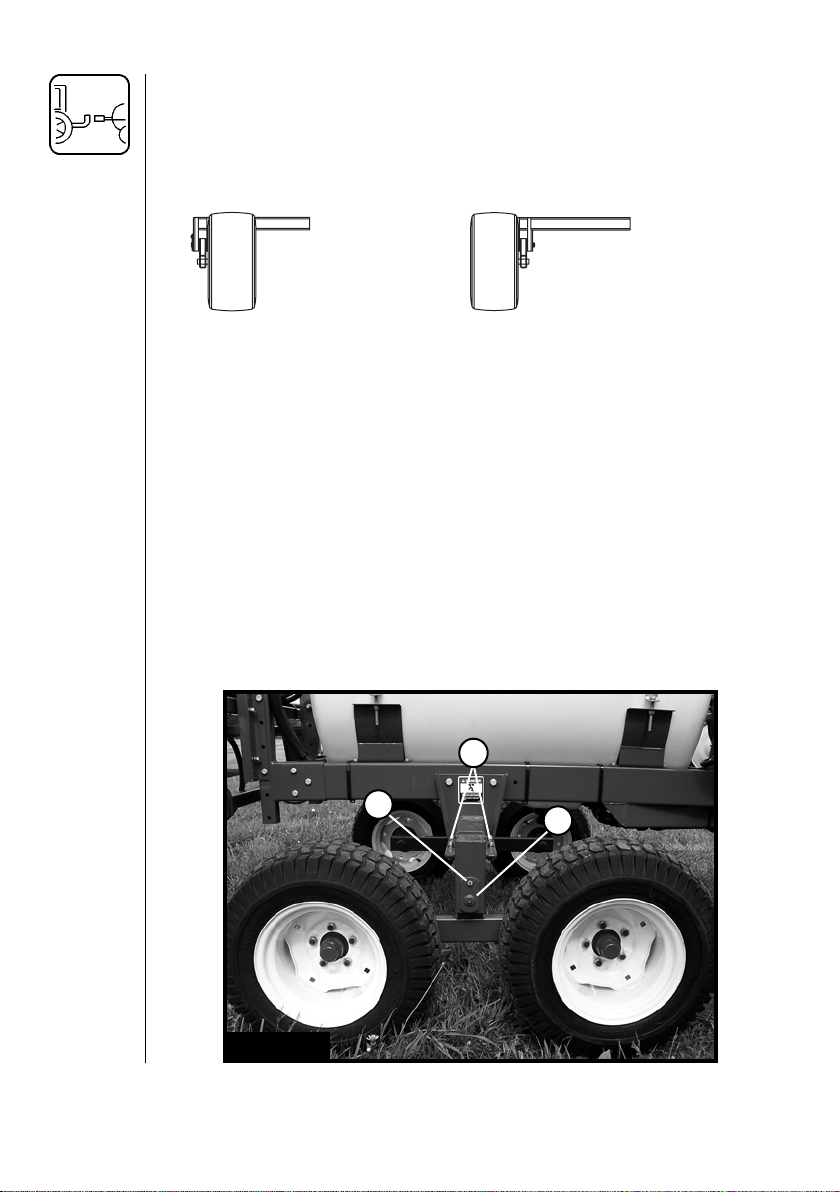

3.4 Wheel Spacing Adjustment

Wheel spacing can be infi nitely adjusted from 40" to 80".

Note: The tandem beam may need to be removed from the axle insert

and reinstalled with the wheels facing the opposite direction to

obtain the desired width:

40" - 68"

Wheels to inside

of tandem beam

68" - 80"

Wheels to outside

of tandem beam

1. Attach sprayer to the ATV/tractor and engage parking brake.

2. Using suitable lifting equipment, jack up the side of the sprayer

frame behind the axle you wish to adjust.

3. If the tandem beam does not need to be reversed (see note above),

skip to step 4. To reverse tandem beam, remove retaining bolt A

(Fig. 4) and remove pin B (Fig. 4). Remove the tandem beam and

reinstall with the wheels on the opposite side. Reinstall pin B (Fig. 4)

and retaining bolt A (Fig. 4).

4. Loosen the four bolts C (Fig. 4) and slide the axle insert in or out

until the required wheel spacing is obtained (center of tire to center

of frame must be equal for both sides). Tighten bolts C (Fig. 4).

5. Repeat steps 2 through 4 for opposite side. Measure to confi rm

correct wheel spacing (center of right tire to center of left tire). Adjust

if necessary.

C

A

B

Fig. 4

14 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 17

3.5 Power Supply

A 12 Volt DC power supply is required to operate the electrical boom

distribution valve solenoids (Fig. 5). Connect the power supply wiring

harness as follows:

Red wire to positive (+) and Black wire to negative (-).

IMPORTANT: Do not connect to the starter motor or generator/

alternator. Warranty is void if this is done.

The power supply wiring harness is equipped with a 7.5 Amp inline

fuse to protect the control box.

DISTRIBUTION VALVE SOLENOIDS

Fig. 5

15HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 18

3.6 Control box

The HARDI® ATV sprayer uses an electrical control box for master on/

off control and individual boom section on/off control. An optional rate

controller box is also available.

1. Mount the control box in a convenient location near the operator.

2. Route the power supply (installed in section 3.5) to the small plug on

the control box.

3. Route the main wiring harness from the sprayer to the large plug on

the control box.

Fig. 6

3.7 Gas Engine Requirements

IMPORTANT: The gas engine equipped on the HARDI® ATV sprayer is

shipped from the factory without oil in the engine crankcase or reduction box.

1. Before operating the gas engine, you must:

A. Check the engine crankcase oil level.

B. Check the reduction gearbox oil level.

C. Fill the gas tank.

D. Make sure the engine air fi lter is not plugged.

2. Refer to gas engine operating manual for oil change and

maintenance information.

16 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 19

4.0 OPERATING INSTRUCTIONS

4.1 Filling The Main Tank

Water is fi lled into the tank by re mov ing the tank lid located in the

center of the sprayer tank. It is rec om mend ed to use water as clean as

possible for spraying pur pos es. Fill water through the strainer basket

(optional) to pre vent foreign par ti cles from entering the tank.

WARNING: DO NOT LET THE FILLING HOSE ENTER THE

TANK. KEEP IT OUT SIDE THE TANK, POINTING

TOWARDS THE FILLING HOLE. IF THE END OF

THE HOSE IS BENEATH THE SURFACE OF

THE TANK CONTENTS AND THE WATER

SUPPLY STOPS, CHEMICALS MAY BE

SIPHONED BACK AND

CONTAMINATE THE

WATER SUPPLY

SOURCE AND LINES.

4.2 Filling The Handwash (Clean Water) Tank

Unscrew the clean water tank lid and fi ll with clean water only.

IMPORTANT: The water from this tank is only for hand washing,

cleaning blocked nozzles, etc.

WARNING: ALTHOUGH THE HANDWASH

TANK IS ONLY FILLED WITH

CLEAN WATER, THE WATER MUST

NEVER BE USED FOR DRINKING,

DUE TO THE SMALL RISK OF

CONTAMINATION WHILE FILLING,

ETC.

17HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 20

4.3 Standard Plumbing Diagram

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

Standard Plumbing Diagram

10

9

1. Bottom Suction Valve

2. Suction Filter

3. Diaphragm Pump

4. Pressure Control Valve

5. Manifold Pressure Gauge

6. Agitation Valve

7. Spraygun Valve (optional)

12

13

4

5

6

7

11

1

2

8

3

14

Fig. 7

8. Spraygun (optional)

9. Agitation

10. Tank

11. Bypass Return

12. Boom Distribution Valves

13. Boom

14. Boom Pressure Gauge

18 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 21

4.4 Plumbing Diagram with optional Rate Controller

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

Rate Controller Plumbing Diagram

9

11

10

13

1. Bottom Suction Valve

2. Suction Filter

3. Diaphragm Pump

4. Pressure Relief Valve*

5. Manifold Pressure Gauge

6. Agitation Valve

7. Spraygun Valve (optional)

8. Pressure Regulator

12

14

15

4

5

6

1

2

8

7

3

16

Fig. 8

9. Spraygun (optional)

10. Agitation

11. Tank

12. Bypass Returns

13. Flowmeter

14. Boom Distribution Valves

15. Boom

16. Boom Pressure Gauge

Turn Pressure Relief Valve clockwise all the way in when used with

*

the optional Rate Controller.

19HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 22

4.5 Adjustment Of The Sprayer Controls

2

1

3

4

SPRAYER CONTROLS:

1. Pressure control valve

2. Manifold Pressure gauge

3. Agitation valve

4. Spraygun valve (optional)

5. Boom Pressure gauge

5

CONTROL BOX:

6. Master On/Off Switch

7. Distribution Switches

6

SPRAYGUN

VALVE

OFF

7

Fig. 9

ON

Boom Operation

1. Locate your sprayer in a suitable location to spray water from the

boom.

2. Fill the tank with clean water.

3.

Turn the Pressure Control Valve 1 (Fig. 9) counter clockwise all the

way out.

4. Set Master On/Off boom switch 6 and individual boom switches 7

(Fig. 9) "ON". Set spraygun valve 4 (Fig. 9) "OFF".

5. Start the engine.

6. Increase pressure by turning Pressure Control Valve 1 (Fig. 9)

clockwise. Watch the boom pressure gauge 5 (Fig. 9) until the

desired pressure is reached (turn Pressure Control Valve 1 (Fig. 9)

counter clockwise to decrease pressure).

Note: Always use Boom Pressure Gauge (not Manifold Pressure

Gauge) for nozzle calibration. Refer to Section 5.0 for nozzle

selection and calibration.

20 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 23

Operating the Spraygun (optional)

1. Locate your sprayer in a suitable location to spray water from the

spraygun.

2. Fill the tank with clean water.

3.

Turn the Pressure Control Valve 1 (Fig. 9) counter clockwise all the

way out.

4. Set spraygun valve 4 (Fig. 9) "ON" and set Master On/Off boom

switch 6 (Fig. 9) "OFF".

5. Start the engine.

6. Increase pressure by turning Pressure Control Valve 1 (Fig. 9)

clockwise. Watch the manifold pressure gauge 2 (Fig. 9) until the

desired pressure is reached (turn Pressure Control Valve 1 (Fig. 9)

counter clockwise to decrease pressure).

7. Then depress the red handle A (Fig. 10) to spray fl uid from the

spraygun. Check the pressure on the manifold pressure gauge 2

(Fig. 9) and follow step 6 to adjust.

8. To adjust the spray pattern, turn the black handle B (Fig. 10) OUT for

a narrow spray pattern for long distances and IN for a wide pattern

for more coverage at close distances.

Fig. 10

21HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 24

4.6 Agitation Adjustment

Ag i ta tion is nec es sary to keep the so lu tion in your tank prop er ly mixed.

Con sult your chem i cal sup pli er for the rec om mend ed amount of

ag i ta tion.

In gen er al, max i mum agitation is required but some products tend to

foam easily. To reduce foaming in some instances anti-foaming agents

may be added to the tank (Refer to chemical label). When running low

liquid levels in the tank, agitation may be reduced to fa cil i tate pump

priming and avoid pressure fl uc tu a tions. Make sure that you have

ad just ed the agitation properly before sprayer calibration.

Turning the agitation valve 3 (Fig. 9) clockwise will reduce the agitation

fl ow. Turning the valve counter-clockwise will in crease the agitation

fl o w .

4.7 Operation Of The Tank Drain Valve

WARNING: BEFORE USING THE TANK DRAIN, VERIFY THAT

DISPOSAL OF WASTE IS DONE ACCORDING TO

CHEMICAL LABEL INSTRUCTIONS AND LOCAL

REGULATIONS.

The HARDI® ATV Sprayer is equipped with a remote operated tank

drain. Pull the string at the left hand side of the tank to open the drain

valve. The valve is spring loaded to close, but can be kept open by

pulling the string out and upwards into the V-shaped slot (Fig. 11).

To release and close the drain valve again, pull the string downwards

and the valve will close automatically.

Fig. 11

22 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 25

4.8 Adjustment Of Air Pressure In Pressure Damper

The air pressure in the damper on the 1203

pump is factory preset at 30 psi (2 bar). This

is suitable for nozzle spray pressures between

45 psi (3 bar) and 225 psi (15 bar). If different

nozzle pressures are required, set pressure

damper at pressures indicated.

PSI (BAR) PSI (BAR)

20-45 (1-3) 0-15 (0-1)

45-255 (3-15) 15-45 (1-3)

4.9 Unfolding/Folding Boom

Unfolding Boom into operating position

1. Remove transport lock pins A (Fig. 12) and swing boom into

operating position. Store transport lock pins in original locations so

they don't get lost.

2. Lift outer boom sections up and over to horizontal position (not

necessary for 20' MB boom). Carefully check that feed hoses do not

interfere with spray pattern.

3. Remove trapeze lock pin B (Fig. 12) to allow for self-levelling boom

feature (40' MB boom only).

Note: The trapeze lock pin may also be used to lock the boom in a

tilted position (40' MB boom only).

Fig. 12

A

B

23HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 26

Folding Boom into transport position

1. Replace trapeze lock pin B (Fig. 12) in center position (40' MB boom

only).

2. Fold outer boom section over to rest on inner boom section (not

necessary for 20' MB boom).

3. Remove transport lock pins A (Fig. 12) and fold boom into transport

position. Secure with transport lock pins A (Fig. 12).

WARNING: MAKE ABSOLUTELY CERTAIN BOOM TRANSPORT

LOCK PINS ARE INSTALLED AND SECURED WITH

CLIP PINS BEFORE TRANSPORTING THE SPRAYER.

4.10 Boom Height Adjustment

Correct boom height is important to ensure even spray distribution. For

the best distribution with HARDI® ISO F-110 standard fl at fan nozzles,

HARDI® recommends a boom height of 20" above the target surface.

Consult your HARDI® NOZZLES product guide for recommended

boom height for other nozzles.

The boom height for the MB booms on the ATV sprayer is adjusted

manually as follows:

1. Support boom with appropriate lifting device.

2. Loosen bolts A and remove bolts B (Fig. 13) on both sides of sprayer

frame.

3. Raise or lower boom to desired hole setting.

4. Reinstall bolts B and tighten bolts A (Fig. 13).

A

Fig. 13

24 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

B

Page 27

5.0 NOZZLE SELECTION

Correct selection of nozzle and calibration of the sprayer are critical to

achieve accurate and cost effective use of farm crop protection prod ucts.

Your HARDI

®

sprayer has been supplied with 110° fl at spray Red ISO

Color Tips™ that will apply approximately 20 U.S. GPA at 30 PSI and

5 MPH.

The 110° fl at spray nozzle was chosen rather than the 80 degree

nozzle for two reasons: 1- It may be used at a lower minimum height

which reduces the risk of wind drift; 2- it's greater overlap permits better uniformity of spray distribution, particularly if boom height varies on

rough ground. Normal boom height setting with 110° nozzles is 18" to

20" above the crop or weeds, whichever is taller.

Should you wish a different application rate or different type of nozzle,

HARDI® manufactures a nozzle for virtually every need.

IMPORTANT: Always consult your chemical supplier for rec om mend ed chemical rate and water application rate. Always wear

protective gloves when handling nozzles.

The following tables show what types of spray nozzles are suitable for

different applications. It is important to use the correct nozzle.

HARDI® ISO COLOR TIPS™

110 degree fl at fan, one piece

cap and nozzle; color coded for

fl ow rate se lec tion.

For herbicides, insecticides, and

F110

fertilizer applications. 50, 80, and

100 mesh screens are normally

used.

HARDI® ISO LowDrift COLOR

TIPS™ 110 degree fl at fan, one

piece cap and nozzle, 1553 solid

stream nozzle; color coded for

fl ow rate selection.

In-Line Filters will normally be

used.

LD110

25HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 28

HARDI® INJET™ NOZZLES; air

inclusion nozzles with removable

restrictor. Color coded for fl ow

rate selection. In-Line Filters will

normally be used.

FLAT SPRAY NOZZLES in

65 degree, 80 degree, and

110 degree spray angles. For

her bi cides, insecticides, and

fertilizer applications. 50, 80,

and 100 mesh screens are

normally used.

FLOOD NOZZLES set at 40°

spacing. Designed for high

vol ume application.

HOLLOW CONE NOZZLES

for high pressure and high

vol ume insecticide application

in row crops. 1553 nozzles are

ALWAYS used with swirl plates

shown below EXCEPT when

used as solid stream nozzles.

50, 80, or 100 mesh screens

are normally used with these

nozzles

SWIRL PLATE used in con junc tion with cone nozzle to create

desired spray pattern. These

swirls work with 1553 series

cone nozzles. Grey, blue, or black

swirls are used to create hollow

cone effect. White swirls are used

to create full cone effect.

4665-65 degree

2080-80 degree

4110-110 degree

Part # 330013-

O-ring

4598

1553

Must add swirl

to produce

hollow cone

pattern

Grey

Blue

Black

White

26 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 29

HOLLOW CONE CERAMIC

NOZZLES for high pressure

and high volume fungicide and

insecticide application.

LARGE DROPLET HOLLOW

CONE NOZZLE for use where

drift must be kept to a minimum.

These nozzles must always be

fi tted with 1553 nozzles and grey

swirl plates. 50, 80 or 100 mesh

screens are normally used with

these nozzles.

LARGE DROPLET FLAT

SPRAY TIP IN 150 DEGREE

SPRAY ANGLE. Always used in

conjunction with 1553-14-16-18

or 20 cone nozzle. 50, 80 or 100

mesh screens are normally used

with these nozzles.

SOLID STREAM NOZZLE

for high volume liquid fertilizer

ap pli ca tion. In this application,

the 1553 nozzle is always used

with 330013 o-ring and 50, 80 or

100 mesh screens.

HARDI® QUINTASTREAM

5 HOLE LIQUID FERTILIZER

NOZZLE Five streams of liquid

are distributed at different angles

and fl ows. Highest fl ow is from the

middle stream and lowest in the

outer; overlapping streams. This

allows for boom movements that

do not influence distribution.

Boom heights of 20" can be used

as safely as 30".

1299

371077

371551

1553 less swirl

372011

thru

372019

27HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 30

5.1 Calibration

WARNING: ALWAYS CALIBRATE YOUR SPRAYER WITH CLEAN

WATER ONLY! IN ADDITION, WEAR PROTECTIVE

CLOTHING WHEN CALIBRATING YOUR SPRAYER!

Why must you calibrate a sprayer?

A nozzle selection chart will tell you what application rate you should

expect. Variations due to nozzle wear, errors in pressure adjustment, and

tractor speedometer can result in a possible error in application rate.

How do you calibrate a sprayer?

Calibration kits are available from HARDI

®

, #818493 for US gallons &

#818492 for metric calibration.

Following are some tips to remember when using the calibration kit

method:

• When determining the length of time required to drive the recommended

distance, drive in actual fi eld conditions with a half-full tank.

• Repeat the test several times, each time avoiding the tracks from the

previous test. Take the average of the times recorded.

• Calibration of the sprayer should be completed at the beginning of the

season and repeated after every 2 to 3 full days of spraying, and every

time you change volume rate or use new nozzles.

• Before you calibrate, check the fl ow of each nozzle. If it puts out more

than 10% of its original volume, replace it.

Select your calibration method: Ounce method or Formula method.

Then follow the steps described in the corresponding section(s):

28 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 31

Ounce Method

1. Determine how long it takes to cover the test strip. Use the following

chart to determine the length of your test strip. Row width for broadcast

application is equal to your nozzle spacing. For your drop nozzle or

band application, use row spacing.

Row width or nozzle spacing (in.) Distance (ft.)

40 102

38 107

36 113

34 120

32 127

30 136

28 146

26 157

24 170

22 185

20 204

18 227

16 255

14 291

2. Measure the amount of time it takes you to travel the test strip when

throttle is set at spraying speed.

3. In a container (with oz. measurements), catch the spray from one nozzle

for that amount of time. For drop or band nozzles, catch the spray from

all nozzles for the row.

4. Read the ounces in the container. That is the actual U.S. GPA applied.

(ounces = GPA)

29HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 32

Formula Method

1. Check your spraying speed. Measure a test strip of at least 200 feet

(300 feet is ideal). Travel the distance at the speed you plan on spraying

and record the time it takes to travel the distance. Read from the chart

or use the formula to fi nd your exact travel speed.

Travel Time (in seconds)

Speed in MPH 200 ft. 300 ft.

3.0 45 68

3.5 39 58

4.0 34 51

Formula: 4.5 30 45

distance (ft.) x 0.68

seconds 6.0 23 34

7.0 19 29

7.5 18 27

8.0 17 26

9.0 15 23

= MPH

5.0 27 41

2. Calculate the required nozzle output. Use either the nozzle wheel (if

nozzle spacing is 20 inches), or this formula:

Formula: Formula:

GPA x MPH x W (in.)

GPM =

5940 5940

GPM =

10 x 7 x 20

= .24 GPM

Note: W= • Nozzle spacing (in inches) for broadcast application.

• Row spacing (in inches) divided by number of nozzles

per row for drop nozzle application.

• Sprayed band width or swath width (in inches) for band

application divided by number of nozzles per band.

• Note that on the nozzle wheel, W = 20 inches.

3. Set correct pressure. Read the required pressure from the nozzle table

in the nozzle catalogue or nozzle wheel. With clean water in the tank

and line, turn on the sprayer and set the target pressure. Collect the

spray from one nozzle for one minute in a container. Adjust pressure

until you collect the precise GPM called for.

30 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 33

Calibration For Carriers Other Than Water

Use the following water rate conversion chart to determine the right

conversion factor. When you've determined the new converted GPM or

GPA, you can follow the steps on either the pressure or ounce method

of calibration.

Weight of solution Specifi c Gravity Conversion Factors

7.00 lbs/gal .84 .92

8.00 lbs/gal .96 .98

8.34 lbs/gal-water 1.00 1.00

9.00 lbs/gal 1.08 1.04

10.00 lbs/gal 1.20 1.10

10.65 lbs/gal-28% N 1.28 1.13

11.00 lbs/gal 1.32 1.15

12.00 lbs/gal 1.44 1.20

14.00 lbs/gal 1.68 1.30

Example: 20 GPA of 28% N

Then GPA (solution) x conversion factor = GPA (water)

20 GPA (28% N) x 1.13 = 22.6 GPA (water)

Calibrate for 22.6 GPA of water

For conversion to Imperial gallons per acre, multiply U.S. GPA by .833

For conversion to liters per hectare, multiply U.S. GPA by 9.34

For conversion to liters per acre, multiply U.S. GPA by 3.78

Formula for tractor speed: Distance (in feet) x .682

= MPH

Second

31HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 34

6.0 MAINTENANCE

IMPORTANT: Always clean the boom at the end of your workday

or

before servicing is done to avoid unnecessary contact with

chem i cals.

In order to derive full benefi t from the sprayer for many years, the following

service and maintenance program should be followed.

6.1 Cleaning The Sprayer

Guidelines

Read the whole chemical label. Take note of any particular instructions

regarding recommended protective clothing, deactivating agents, etc. Read

the detergent and deactivating agent labels. If cleaning procedures are

given, follow them closely.

Be familiar with local legislation regarding disposal of pesticides washings,

mandatory decontamination methods, etc. Contact the appropriate

department, e.g. Dept. of Agriculture.

Pesticide washings can usually be sprayed out on a soakaway. This is an

area of ground that is not used for cropping. You must avoid seepage or

runoff of residue into streams, water courses, ditches, wells, springs, etc.

The washings from the cleaning area must not enter sewers. Drainage

must lead to an approved soakaway.

Cleaning starts with the calibration, as a well calibrated sprayer will ensure

the minimal amount of remaining spray liquid.

It is good practice to clean the sprayer immediately after use, thereby

rendering the sprayer safe and ready for the next pesticide application.

This also prolongs the life of the components.

It is sometimes necessary to leave spray liquid in the tank for short periods,

e.g. overnight, or until the weather becomes suitable for spraying again.

Unauthorized persons and animals must not have access to the sprayer

under these circumstances.

If the product applied is corrosive, it is recommended to coat all metal

parts of the sprayer before and after use with a suitable rust inhibitor.

Remember: Clean sprayers are safe sprayers.

Clean sprayers are ready for action.

Clean sprayers can not be damaged by pesticides and their

solvents.

32 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 35

Cleaning the tank

1. Dilute remaining spray liquid in the tank with at least 10 parts of

water and spray the liquid out in the fi eld you have just sprayed.

Note: It is advisable to increase the forward speed (double if

possible) and reduce the pressure. For ISO F110 nozzles,

pressure may be reduced to 22psi (1.5 bar).

2. Select and use the appropriate protective clothing. Select detergent

suitable for cleaning and suitable deactivating agents if necessary.

3. Rinse and clean sprayer and tractor externally. Use detergent if

necessary.

4. Remove and clean tank fi lters and suction fi lters. Be careful not to

damage the mesh. Replace suction fi lter lid. Replace fi lters when the

sprayer is completely clean.

5. With the pump running, rinse the inside of the tank. Remember the

tank roof. Rinse and operate all components and any equipment that

has been in contact with the chemical.

6. After spraying the liquid out again in the fi eld, stop the pump and fi ll

at least 1/5 of the tank with clean water. Note that some chemicals

require the tank to be completely fi lled. Add appropriate detergent

and/or deactivating agent, eg. Washing soda or Triple ammonia.

Note: If a cleaning procedure is given on the chemical label, follow it

closely.

7. Start the pump and operate all controls enabling the liquid to come

in contact with all the components. Leave the distribution valves until

last. Some detergents and deactivating agents work best if left in the

tank for a short period. Check the label.

8. The Self-Cleaning Filter can be fl ushed by removing the bypass

hose from the bottom of the fi lter. Stop the pump and remove the

hose. Start the pump for a few seconds to fl ush the fi lter. Be careful

not to lose the restrictor nozzle.

9. Drain the tank and let pump run dry. Rinse inside of tank, again

letting the pump run dry.

10.Stop the pump. If the chemicals used have a tendency to block

nozzles and fi lters, remove and clean them now. Check also for

sediment on the pressure side of the safety valve for the SelfCleaning Filter.

11.Replace all the fi lters and nozzles and store the sprayer. If, from

previous experiences, it is noted that the solvents in the chemicals

are particularly aggressive, store the sprayer with the tank lid open.

Note: If the sprayer is cleaned with a high pressure cleaner we

recommend lubrication of the entire machine.

33HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 36

6.2 Filters

IMPORTANT: Wear protective clothing when servicing & handling

components that have been in contact with spray liquid.

Clean fi lters ensure :

• Sprayer components such as valves, diaphr agms and operat ing unit

are not hindered or damaged during operation.

• Nozzle blockages do not occur while spray ing.

• Long life of pump. A blocked suction fi lter will result in pump

cavit ation.

Suction fi lter

The main fi lter protecting spray er com po nents is

the suc tion fi l ter at the bottom of the tank. Check

it reg u lar ly.

To service the suction fi lter:

1. Pull the steel clip (A) (Fig. 14) out.

2. Remove the suction hose fi tting (B) (Fig. 14)

from hous ing.

3. Remove fi lter guide and fi lter (C) (Fig. 14).

To reassemble:

4. Press the guide onto fi lter end.

5. Place the fi lter into housing with guide fac ing to the front.

6. Ensure the O-ring (D) (Fig. 14) on the hose fi t ting is in good

condition and lu bri cat ed.

7. Refi t the suction hose (B) (Fig. 14) and steel clip (A) (Fig. 14).

ISO Nozzle

Size

Pink (075)

Orange (01)

Green (015)

Yellow (02)

Suction Filter Nozzle Screen

(optional)

50 100 100

D

C

B

Inline Filters

Fig. 14

A

Lilac (025)

Blue (03)

Red (04)

& Larger

*Standard mesh

34 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

50 80 80

30* 50* 50*

Page 37

6.3 Nozzle Tubes And Fittings

Poor seals are usually caused by:

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign materials

Therefore, in case of leaks; DO NOT overtighten (Fig. 15). Disassemble,

check condition and position of O-ring or gasket, clean, lubricate and

reassemble. For radial type seals (O-ring)(Fig.15) hand tighten only, do

not use pliers.

The O-rings need to be lubricated ALL THE WAY AROUND before fi tting

on to the nozzle tube.

Fig. 15

HARDI

®

recommends using a vegetable based oil to prolong the life of

the O-ring.

6.4 Wheel Nuts And Bearings Adjustment

WARNING: BLOCK WHEELS ON TRAILER TO PREVENT ROLLING.

Check wheel bolt tension after the fi rst 8 working hours, hereafter every

50 hours. Torque wheel nuts to 85 ft. lbs. maximum.

Check bearing for slack after the fi rst 8 hours of operation and again after

50 hours of operation. Thereafter every 100 hours. (Fig. 16)

If necessary, adjust as follows:

1. Jack sprayer up. It is best

to remove the wheel. (Make

sure to adequately support

the sprayer and completely drain

Fig. 16

tank.)

2. Remove hub cap and cotter pin.

3. Axle nut is tightened until slight rotation

resistance of hub is noted.

4. Now loosen axle nut until fi rst split pin hole is visible.

5. Insert cotter pin, fold and replace hub cap.

Af ter 1000 hours or once a year, the axle bear ings should be repacked

with new grease.

35HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 38

6.5 Recommended Tire Pressure

The tires should not run under-infl ated. This only promotes instability

and rapid wear.

Tire size Maximum pressure

23 x 10.5 - 12 20 psi (1.5 bar)

Do not exceed 15 mph.

6.6 Changing The Valves And Diaphragms (1203 Pump)

Note: It is recommended that if one or more diaphragms and or valves

need replacing, they should all be replaced (HARDI® Complete rebuild

kit for 1203 diaphragm pump - #750696).

1. Remove the valve cover 1 (Fig. 17). Before

changing the valves 2 (Fig. 17), note the

orientation of the valves so that they

are replaced correctly.

2. It is recommended to use new

O-rings 3 (Fig. 17) (part #330072)

when changing or checking valves.

3. Remove diaphragm covers 4 (Fig. 17) to

gain access to the diaphragms.

4. Remove the diaphragm bolts 5 (Fig. 17).

The diaphragms 6 (Fig. 17) may now be

changed.

5. If fl uids have reached the crankcase,

regrease the pump thoroughly. Also make

sure the drain hole at the bottom of the

pump is not blocked.

6. Reassemble with torque settings shown below.

Valve Cover

Ft/lb(Nm)

45 (60) 45 (60) 50 (70)

Diaphragm

Bolt Ft/lb(Nm)

Diaphragm

Cover Ft/lb(Nm)

4

5

Fig. 17

1

6

2

3

36 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 39

6.7 Breakaway Clutch Adjustment

WARNING: NEVER PLACE FINGERS INTO OPEN BREAKAWAY

CLUTCH OR YOU MAY BE INJURED SHOULD CLUTCH

SNAP CLOSED! DO NOT TIGHTEN THE BREAKAWAY

CLUTCH MORE THAN WHAT IS NECESSARY! OVER

TIGHTENING CAN CAUSE DAMAGE TO THE BOOM!

IMPORTANT: Properly lubricate clutch assembly before adjusting the

tension. Breakaway clutch cap screws (A) (Fig. 18) must be torqued

to 40 Ft/lb (55 N-m) every week (40 hours) to prevent boom damage.

Lubricate every day (8 hours) to ensure maximum performance and

life.

The tension on the clutch for the breakaway wing section can be

adjusted by loosening or tightening nut C (Fig. 18).

1. Check that the lower nut D (Fig. 18) is fully tightened.

2. The breakaway wing section should pivot around the axle shaft E

(Fig. 18). Make sure wing section is free to move.

3. Loosen jam nut B (Fig. 18).

4. If the breakaway clutch releases too easily, tighten nut C (Fig. 18).

If the breakaway clutch releases too stiffl y, loosen nut C (Fig. 18).

Clutch is properly tensioned when breakaway wing section returns

to alignment with center section after breaking away.

5. Tighten jam nut B (Fig. 18) after adjustment.

Fig. 18

B

E

A

C

D

37HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 40

6.8 Lubrication

Recommended lubrication is shown in following tables.

Use ball bearing grease (lithium grease No. 2)

Note: If the sprayer is cleaned with a high pressure cleaner or fertilizer

has been used, we recommend lubrication of all sections.

Position on

sprayer

Oil

Grease

Operation

hours

2

1

3

150 GALLON ATV SPRAYER

Page to find more

information

Winter protection

or off-season

storage

5

4

6

1. Pump

2. Agitation Control

3. Axle

4. Wheel Bearings

5. MB Boom

6. Trapeze (40' MB only)

38 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 41

1X40

2X 50

36

3X8

14

39HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 42

4 1000X35

58X 37

68X

40 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 43

7.0 Off-Season Storage

When the spraying season is over, you should de vote some extra time

to the Spray er. If chem i cal res i dues are left over in the spray er for long

periods, it can reduce the life of the individual com po nents. To pre serve

the sprayer and pro tect the com po nents, carry out the following offsea son stor age pro gram:

1. Clean the sprayer completely - inside and outside - as described

under "Cleaning The Spray er" (section 5.1). Make sure that all

valves, hos es and auxiliary equipment have been cleaned with

de ter gent and fl ushed with clean wa ter afterwards, so no chem i cal

residues are left in the sprayer.

2. Replace any damaged seals and repair any Ieaks.

3. Empty the sprayer completely and let the pump work for a few

minutes. Operate all valves and handles to drain as much water

out of the spraying circuit as pos si ble. Let the pump run until air is

coming out of all the nozzles.

4. Pour in a mixture of ethylene glycol base antifreeze and water at the

ratio for the desired temperature protection (there will be a small

amount of water left in the hoses, pump and bottom of tank). The

volume of the mixture needs to be enough to keep the tank sump full

while the pump is running fl uid through the entire circuit.

5. En gage the pump and op er ate all valves and func tions of the

plumbing system. Spray the spraygun (optional) into the tank until

antifreeze sprays out to make sure the line is full of antifreeze.

Open the distribution valves so the an ti freeze is sprayed through

the nozzles as well. The an ti freeze will also pre vent O-rings, seals,

di a phragms etc. from dry ing out.

6. When the sprayer is dry, re move rust from any scratch es or

damages in the paint and touch up the paint.

7. Lubricate all lubricating points according to the lu bri cat ing scheme

regardless of intervals stated.

8. Re move the glycerine-fi lled pres sure gaug e and store in a vertical

position in frost free con di tions.

9. Apply a thin layer of an ti cor ro sive oil (e.g. SHELL ENSIS FLU ID,

CASTROL RUSTILLO or sim i lar) on all metal parts. Avoid oil on

rubber parts, hoses and tires.

41HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 44

Off-Season Storage (continued)

10. All electric plugs and sockets are to be stored in a dry plastic bag to

protect them against moisture, dirt, and corrosion.

11. Remove all the control boxes (including any rate controller control

box) from the ATV/tractor and store them in a dry and clean place.

12. Jack up the axle and place wooden blocks under the wheels to

prevent moisture damage and deformation of the tires. Tire black

can be applied to the tire side walls to preserve the rubber.

13. To pro tect against dust, the spray er can be cov ered by a tar pau lin.

Ensure ventilation to prevent condensation.

7.1 Preparation After Off-Season Storage

After a stor age period, the sprayer should be pre pared for the next

season the fol low ing way:

1. Remove the cover. (If fi tted)

2. Remove the blocks from under the wheels and adjust the tire

pressure.

3. Replace the pressure gauge. Seal with Tefl on tape.

4. Con nect the sprayer to the ATV/trac tor, including electrics.

5. Emp ty the tank of remaining an ti freeze.

6. Rinse the entire liquid circuit on the spray er with clean water.

7. Fill with clean water and check all functions.

42 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 45

8.0 ACCESSORIES

8.1 Clean Water Dispenser

Fig. 30

Fig. 19

Clean Water Dispenser

A handy source of fresh water on the sprayer to clean up plugged

nozzles and for rinsing gloves and hands after performing service or

maintenance.

8.2 Spraygun And Hose Wrap (optional)

Fig. 20

A spraygun with adjustable spray pattern and 25 ft. of 3/8" hose for

spraying fence row or spot spraying a small area can be installed onto

your sprayer. A handy hose wrap and spraygun holder can be conveniently located on the sprayer to transport the spraygun.

43HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 46

8.3 Maverick Rate Controller (optional)

Fig. 21

The Maverick Rate Controller offers precise rate control regardless of

fi eld conditions. It is equipped with a Master control switch and built-in

boom switches. It features on-the-go rate adjustment, push button auto/

manual control for spot treatment, as well as a minimum fl ow feature to

ensure proper application pattern as ground speed slows to extremes.

8.4 SMV Sign Kit (optional)

Fig. 22

A kit is available to mount an SMV Sign to the ATV Sprayer.

44 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 47

9.0 TROUBLESHOOTING

9.1 General Spray Systems

Problem Cause

1. No liquid getting to the pump. A. Suction fi lter plugged.

B. Suction valve off.

2. Lack of pressure A. Suction fi lter plugged.

B. Suction side air leak.

C. Check pump valves for

obstructions and wear.

Replace valves if necessary.

(Section 6.6)

D. Check pressure gauge.

3. Pressure jumping A. Small tear or pin hole in

suction hose.

B. Suction fi lter partially plugged.

C. Check pressure gauge.

4. Control box not operating A. Check connections at battery.

one or more boom sections B. Check for blown inline fuse on

power supply wiring harness.

(7.5 Amp - Section 3.5)

C. Check electrical wiring for

bad connection.

D. Check for 12 Volts at boom

distribution valve solenoids.

5. Liquid leaking from pump A. Replace diaphragms.

(Section 6.6)

6. Poor agitation A. Agitation valve not open.

B. Agitation nozzle plugged.

C. Agitation nozzle missing.

7. Can't get tank empty. A. Small tear or pin hole in

suction hose.

B. Tank is not level (change angle

of tongue).

45HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 48

10.0 WARRANTY POLICY AND CONDITIONS

HARDI® INC. , 1500 West 76th Street, Davenport, Iowa USA: 5646 W. Barstow, Fresno, CA, USA; and 290

Sovereign Road, London, Ontario, Canada hereinafter called "HARDI®", offers the following limited warranty

in accordance with the provisions below to each original retail purchaser of HARDI

own manufacturer, from an authorized HARDI® dealer, that such equipment is at the time of delivery to such

purchaser, free from defects in material and workmanship and that such equipment will be warranted for a

period of one year from the date of delivery to the end user providing the machine is used and serviced in accordance with the recommendations in the Operator's Manual and is operated under normal farm conditions.

1. This limited warranty is subject to the following exceptions:

a) Parts of the machine not manufactured by HARDI®, (i.e. engines, tires, tubes, electronic controls, and

other components or trade accessories, etc.) are not covered by this warranty but are subject to the

warranty of the original manufacturer. Any claim falling into this category will be taken up with the manufacturer concerned.

b) This warranty will be withdrawn if any equipment has been used for purposes other than for which it

was intended or if it has been misused, neglected, or damaged by accident, let out on hire or furnished

by a rental agency. Nor can claims be accepted if parts other than those manufactured by HARDI® have

been incorporated in any of our equipment. Further, HARDI® shall not be responsible for damage in

transit or handling by any common carrier and under no circumstances within or without the warranty

period will HARDI® be liable for damages of loss of use, or damages resulting from delay or any consequential damage.

2. We cannot be held responsible for loss of livestock, loss of crops, loss because of delays in harvesting

or any expense or loss incurred for labor, supplies, substitute machinery, rental for any other reason, or

for injuries either to the owner or to a third party, nor can we be called upon to be responsible for labor

charges, other than originally agreed, incurred in the removal or replacement of components.

3. The customer will be responsible for and bear the costs of:

a) Normal maintenance such as greasing, maintenance of oil levels, minor adjustments, etc.

b) Transportation of any HARDI® product to and from where the warranty work is performed.

c) Dealer travel time to and from the machine or to deliver and return the machine from the service work-

shop for repair.

d) Dealer traveling costs.

4. Parts defi ned as normal wearing items, (i.e. tires and V-belts) are not in any way covered under this war-

ranty.

5. This warranty will not apply to any product which is altered or modifi ed without the express written permis-

sion of HARDI® and/or repaired by anyone other than an Authorized Service Dealer.

6. Warranty is dependent upon the strict observance by the purchaser of the following provisions:

a) That this warranty may not be assigned or transferred to anyone.

b) That the Warranty Registration Certifi cate has been correctly completed by dealer and purchaser with

their names and addresses, dated, signed and returned to the appropriate address as given on the

Warranty Registration Certifi cate.

c) That all safety instructions in the operator's manual shall be followed and all safety guards regularly

inspected and replaced where necessary.

7. No warranty is given on second-hand products and none is to be implied.

®

new equipment of its

46 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 49

WARRANTY POLICY AND CONDITIONS

8. Subject to the following terms, conditions and contributions, HARDI® extends the warranty on polyethylene

tanks (excluding fi ttings, lids and gaskets) to FIVE YEARS. To qualify for this extended warranty, the tank

must be drained and fl ushed with fresh water after each day of use. HARDI®'s liability is limited to replacement of the tank, FOB our plant at no cost to the purchaser during the fi rst twelve months; at 20% of the

then current price during the second year ; at 40% during the third year ; at 60% during the fourth year ;

and at 80% during the fi fth year. This fi ve year extended warranty is subject, in each instance, to the tank

being inspected and approved for replacement or repair by HARDI® personnel before HARDI® will accept

any liability hereunder.

9. Subject to the following terms, conditions and contributions, HARDI® extends the warranty on HARDI

diaphragm pumps (excluding wearing parts such as diaphragms, valves, etc.) to FIVE YEARS. To qualify

for this extended warranty, the pump must be drained and fl ushed with fresh water after each day of use.

HARDI®'s liability is limited to replacement of defective parts, FOB our plant at no cost to the purchaser

during the fi rst twelve months after date of purchase, at 20% of the then current retail price during the

second year ; at 40% during the third year ; at 60% during the fourth year ; and at 80% during the fi fth

year. This fi ve year extended warranty is subject, in each instance, to the pump being inspected and approved for replacement or repair by HARDI® personnel before HARDI® will accept any liability hereunder.

10. HARDI® reserves the right to incorporate any change in design in its products without obligation to make

such changes on units previously manufactured.

11. The judgement of HARDI® in all cases of claims under this warranty shall be fi nal and conclusive and the

purchaser agrees to accept its decisions on all questions as to defect and to the exchange of any part or

parts.

12. No employee or representative is authorized to change this warranty in any way or grant any other warranty unless such change is made in writing and signed by an offi cer of HARDI® at it's head offi ce.

13. Any warranty work performed which will exceed $400.00 MUST be approved IN ADVANCE by the Service

Manager.

14. Claims under this policy must be fi lled with HARDI® within thirty (30) days of work performed or warranty

shall be void.

15. Parts requested must be returned prepaid within thirty (30) days for warranty settlement.

16. Warranty claims must be COMPLETELY fi lled out properly or will be returned.

DISCLAIMER OF FURTHER WARRANTY

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, EXCEPT AS SET FORTH ABOVE. THERE

ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE PRODUCT CONTAINED

HEREIN. IN NO EVENT SHALL THE COMPANY BE LIABLE FOR INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES (SUCH AS LOSS OF ANTICIPATED PROFITS) IN CONNECTION WITH THE RETAIL

PURCHASER'S USE OF THE PRODUCT.

®

47HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 50

11.0 NOTES

48 HARDI® ATV SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 51

Page 52

For Product, Service or Warranty Information:

- Please contact your local HARDI® dealer.

To contact HARDI® directly:

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to: CUSTSERV@hardi-us.com

HARDI® INC.

HARDI® MIDWEST

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1710

Visit us online at: www.hardi-us.com

®

HARDI

290 Sovereign Rd.

London, Ontario N6M 1B3

Phone: (519) 659-2771

Fax: (519) 659-2821

GREAT LAKES

®

HARDI

5646 W. Barstow, Suite 101

Fresno, California 93722

Phone: (559) 271-3106

Fax: (559) 271-3107

WEST COAST

Loading...

Loading...