Page 1

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

REV 15a

Visit our website at: http://www.harborfreight.com

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2011 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Email our technical support at: productsupport@harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Page 2

Table of Contents

Safety ................................................................. 3

Specifications ..................................................... 4

Assembly ............................................................ 4

SAFETY OPERATION MAINTENANCEASSEMBLY

Operation ............................................................ 8

WARNING SYMBOLS AND DEFINITIONS

Maintenance ...................................................... 12

Parts List and Diagram ...................................... 14

Warranty ............................................................ 16

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Page 2 For technical questions, please call 1-888-866-5797. Item 69377

Page 3

IMPORTANT SAFETY INFORMATION

1. Maintain labels and nameplates on

the tool. These carry important safety

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

2. Keep children away. Children must never be allowed

in the work area. Do not let them handle machines,

tools or let them climb on or play with the product.

3. Store idle equipment. When not in use, tools must

be stored in a dry location to inhibit rust. Always

lock up tools and keep out of reach of children.

4. Use the right tool for the job. Do not attempt to force

a small tool or attachment to do the work of a larger

industrial tool. There are certain applications for

which this tool was designed. It will do the job better

and more safely at the rate for which it was intended.

5. Do not modify this tool and do not use this tool

for a purpose for which it was not intended.

6. Dress properly. Do not wear loose clothing or

jewelry as they can be caught in moving parts.

Protective, electrically nonconductive clothes and

nonskid footwear are recommended when working.

Wear restrictive hair covering to contain long hair.

7. Wear ANSI-approved safety goggles, an

ANSI-approved hardhat and heavy-duty

work gloves during set up and use.

8. Do not overreach. Keep proper footing and balance

at all times. Do not reach over or across a Panel

Hoist while in operation. Do not walk or stand

under Panel Hoist needlessly while in operation.

9. Maintain tools with care. Keep tools clean for

better and safer performance. Follow instructions

for lubricating and changing accessories.

10. Stay alert. Watch what you are doing, use common

sense. Do not operate any tool when you are tired.

11. Check for damaged parts. Before using any

tool, any part that appears damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check

for alignment and binding of moving parts; any

broken parts or mounting fixtures; and any other

condition that may affect proper operation. Any

part that is damaged should be properly repaired

or replaced by a qualified technician. Do not use

the tool if any control does not operate properly.

12. When servicing, use only identical replacement

parts. Use of any other parts will void the

warranty. Only use accessories intended

for use with this tool. Approved accessories

are available from Harbor Freight Tools.

13. Do not operate tool if under the influence of

alcohol or drugs. Read warning labels if taking

prescription medicine to determine if your judgment

or reflexes are impaired while taking drugs. If

there is any doubt, do not operate the tool.

14. For your safety, service and maintenance should

be performed regularly by a qualified technician.

15. Stand clear of the Panel Hoist when

raising or lowering a panel. Never

reach through the winch wheel.

16. Do not exceed the Hoist’s capacity of 150 lb. Check

the manufacturer’s documentation to determine the

actual weight of panels before attempting to lift them.

17. Do not ride on the Panel Hoist, and never have

people or pets in the area while operating Hoist.

18. Only use the Hoist to raise/lower one drywall

panel at a time. After raising the panel,

immediately fix in place using the recommended

type, number and pattern of nails, adhesive or

screws. Do not use this Hoist to store panels.

19. Place Panel Hoist on correct surface. Only use

this Hoist on a stable, level, clean, hard and dry

surface that is capable of sustaining the load.

20. Stabilize the load. Ensure that the load

remains stable at all times. Do not move

the load while it is on the Hoist.

21. Center the load on the Panel Hoist. Off-center loads

can topple, causing property damage or injury.

22. Do not lubricate any part of the Winch components.

The brake is friction based and may fail if lubricated.

23. Before each use, check that the cable

is properly tensioned and wound tightly

and evenly onto the spool.

24. Before lifting load to full height, first lift a

short distance. Check that the brake is

engaged, then continue to lift to full height.

25. The warnings, precautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product,

but must be supplied by the operator.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

SAVE THESE INSTRUCTIONS.

Page 3For technical questions, please call 1-888-866-5797.Item 69377

Page 4

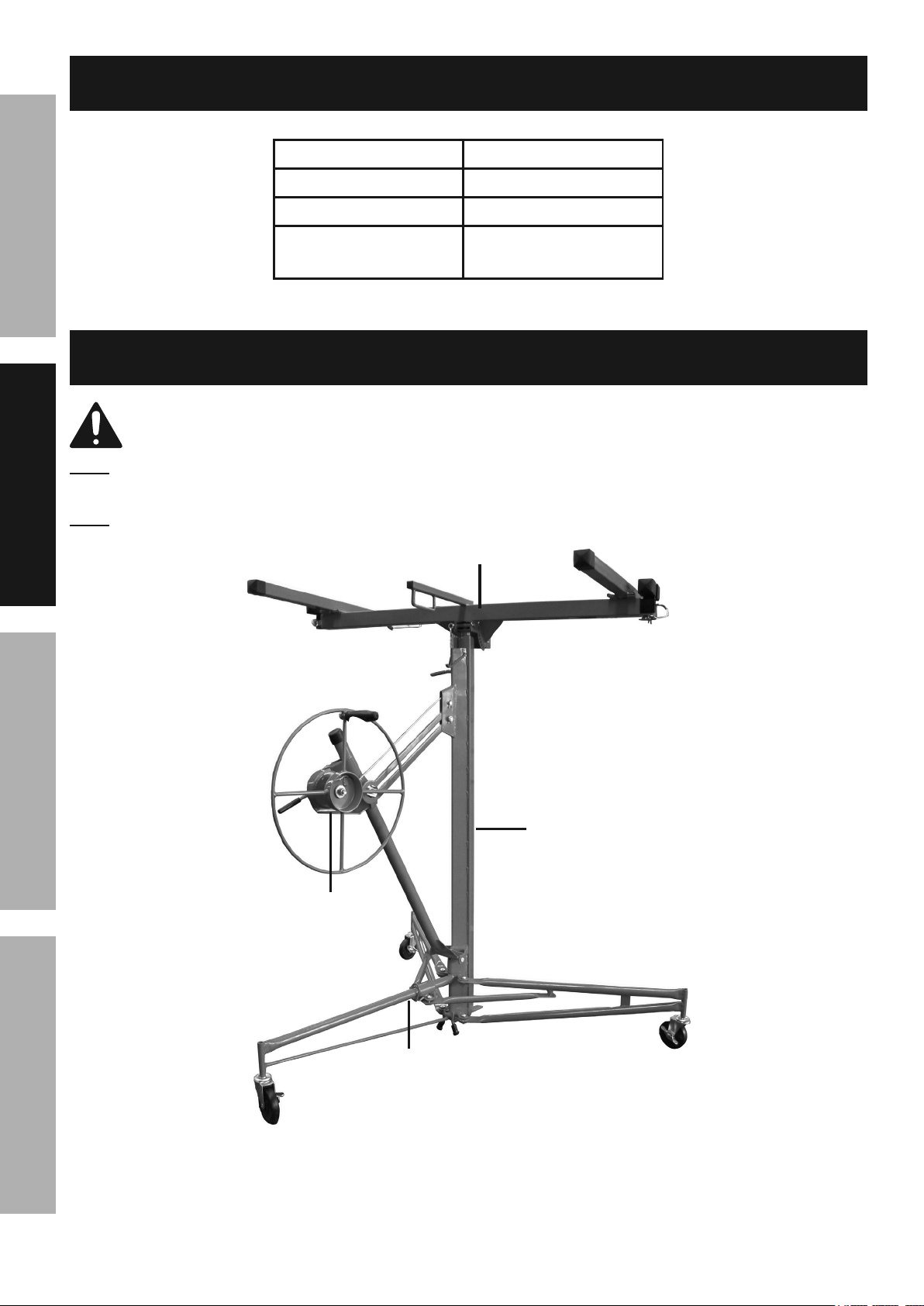

Specifications

SAFETY OPERATION MAINTENANCEASSEMBLY

Weight Capacity 150 LB.

Panel Size Capacity 4 FT. x 16 FT.

Height Range 5 FT. to 11 FT. 5 IN.

Cradle Tilt

Tilt (Loading), 60º

Tilt (Side), 15º

Assembly

Read the entire Important Safety Information section at the beginning of this manual including all

text under subheadings therein before set up or use of this product.

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

Note: Two people are required for assembly.

Cradle

Telescoping

Asm.

Winch

Tripod

Figure A

Page 4 For technical questions, please call 1-888-866-5797. Item 69377

Page 5

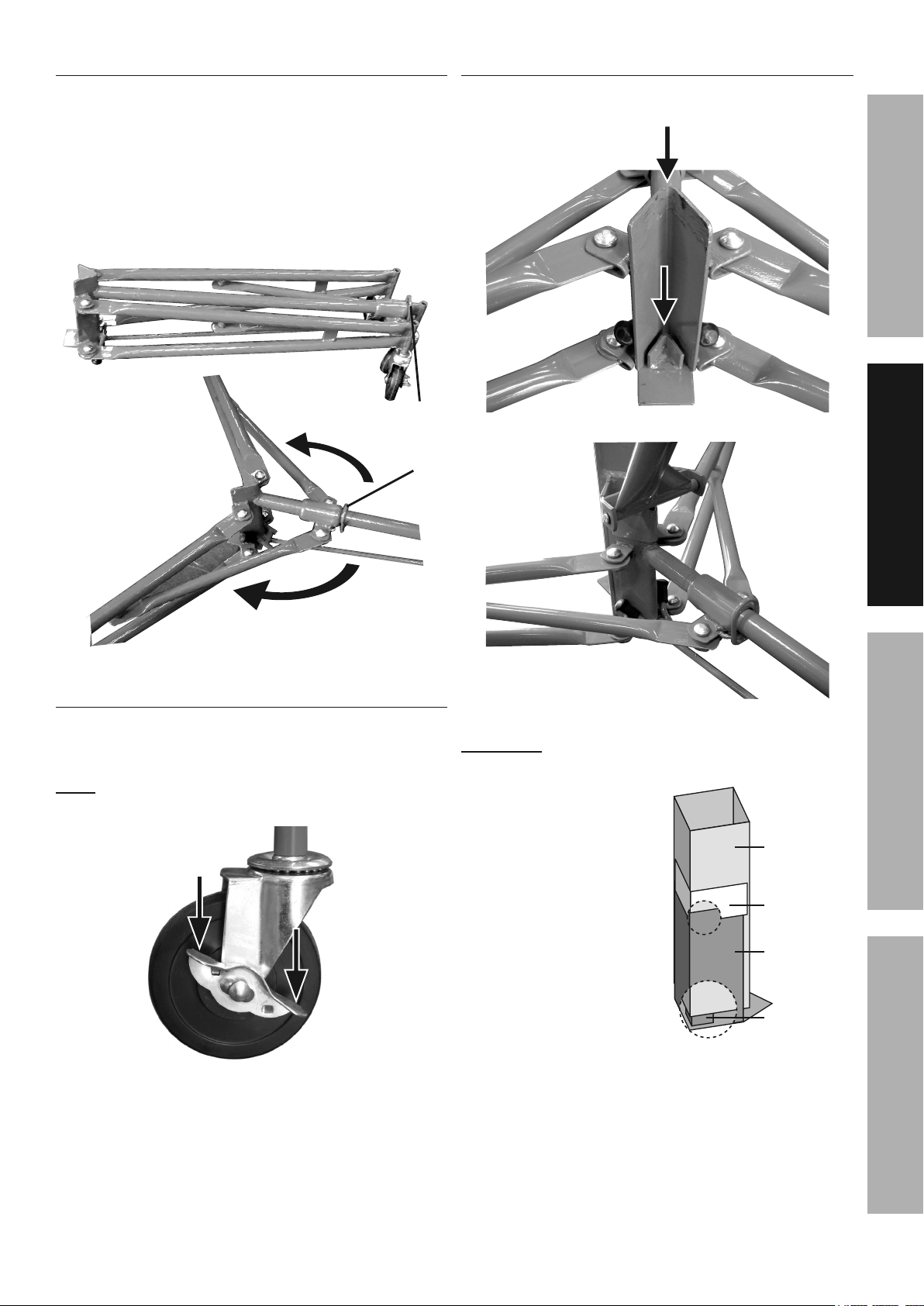

Tripod Setup

Telescoping Assembly

1. Stand the Tripod Base on the floor,

resting on its Caster Wheels.

2. Press down on the Slide Lock Ring on

the center Leg. Hold the Ring down while

swinging the remaining two Legs forward

until the Yoke Ring snaps into the locking

hole near the center of the tripod.

Slide

Lock

Ring

Set the Telescoping Asm. into the Tripod Base.

Back View of Tripod

showing “V” shaped

Flanges:

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Front Assembled View:

Figure B

Locking Caster Wheels

Lock the Caster Wheels by pressing down with

your foot on the front side of the tilting lock.

Note: To unlock the Caster Wheels, press

down on the back side of the tilting lock.

Lock

Unlock

Figure C

Figure D

WARNING! The Telescoping Asm. must fit over both “V”

shaped flanges shown in Figure D (top photo) and at

right. The Telescoping Asm.

must sit exactly vertically. If

the main bar sits at an angle,

then the unit is not tucked

into the inner “V”

Telescoping

Asm.

shaped flange.

Outer Flange

Tripod Base

Inner Flange

Page 5For technical questions, please call 1-888-866-5797.Item 69377

Page 6

Winch Wheel Setup

1. Attach the Handle to the Wheel using the

threaded shaft and nut. Leave some play in

the Nut so that the Handle turns freely.

SAFETY OPERATION MAINTENANCEASSEMBLY

Slide Bar

d. Push the Wheel Asm. back toward the frame

slightly, to engage the Slide Bar Lock, securing

the Winch Wheel Asm. in the working position.

Slide Bar

Lock

(engaged)

Handle

Figure G

Telescoping

Asm.

Support Post

Brake

Figure E

2. To extend the Wheel to its working position:

a. Check that the Caster Wheels are

locked before beginning.

b. Hold the Brake in your left hand and the

Wheel Handle in your right hand. Rotate

the Wheel forward slightly while you lift

on the brake to release the brake.

Wheel

CAUTION! Before proceeding, make sure that

the Slide Bar Lock is rotated as far as it will

go clockwise, so that it is fully engaged.

Attach Cradle to Frame

Insert the Mounting Pin (13), on the

bottom of the Cradle, into the opening

in the top of the Telescoping Asm.

Cradle Beam

Mounting Pin

Telescoping

Asm.

Figure H

Figure F

c. While still holding the brake up, grasp the

Support Post with your right hand and pull the

wheel assembly toward you, pulling evenly.

Page 6 For technical questions, please call 1-888-866-5797. Item 69377

Page 7

Attach Crossarms to Cradle

Testing the Assembly

The Crossarms are interchangeable.

Slide the tapered plate on each Crossarm

into a receiving socket on the Cradle Beam

until the Spring Tab locks into place.

Crossarm

Tapered

Plate

Spring Tab

Cradle

Beam

Figure I

Crossarm

Properly

Installed

1. With assembly completed, check the

Panel Hoist tool to be sure all fasteners

are tight, the Wire Rope is in place and is

undamaged, and the tool is safe to use.

2. Check the Tripod Base to be sure it is firmly

attached to the Telescoping Asm. Be sure the

legs are firmly extended and locked in place.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

3. Check the Telescoping Asm. and Winch to be sure

they are properly installed and functioning properly.

4. Check that the Cradle is properly

attached to the Telescoping Asm.

5. Check that the Crossarms are firmly

attached to the Cradle.

6. Raise and lower the Cradle while empty,

checking for proper function, before

operating the hoist with a load.

CAUTION! Check the assembly for proper

function before using this tool.

Page 7For technical questions, please call 1-888-866-5797.Item 69377

Page 8

Operating Instructions

SAFETY OPERATION MAINTENANCEASSEMBLY

Tool Set Up

Read the ENTIRE IMPORTANT SAFETY INFORMATION section

at the beginning of this manual including all text under

subheadings therein before set up or use of this product.

Designate a work area that is clean and welllit. The work area must not allow access by

children or pets to prevent injury and distraction.

Extending the Cradle

The Cradle can be extended to support

the ends of long panels. For safe use, both

Extensions should be pulled out the same

amount to support the panel equally.

WARNING! Failure to properly adjust the Extensions

could cause the Hoist to tip over, resulting in

serious injury and/or property damage.

1. To adjust the Extension, pull out the Lock Pin and

pull the Extension out from the end of the Cradle

Beam until it lines up with one of the three holes.

Crossarm

Open the Panel Support Hooks

The Panel Support Hooks, located on one

end of the each of the Crossarms, are

used to support the drywall panel.

1. Loosen the Hook Bolts of the Panel Support Hooks,

and rotate them outward to their open position.

Crossarm

Support Hook

Hook Bolt

Figure K

2. Secure in place by tightening the Hook

Bolts. These must be in place during

use to safely support the panel.

Note: Rotate and secure the Support Hooks into

their closed position when transporting or storing

the Hoist, to avoid damaging the Hooks.

End of Extension

Cradle Beam

Lock Pin

Figure J

2. Re-insert the Lock Pin to hold the Extension in place.

3. Repeat with the other Extension.

Note: The Lock Pin will lock the Extension in three

positions. Be sure the Lock Pin is engaged in one

of these positions whenever using the Hoist.

4. Adjust both Extensions equally, and ensure that

both are locked in place using the Lock Pins.

5. To avoid damage, always retract and secure the

Extensions before transporting or storing the Hoist.

Figure L

Page 8 For technical questions, please call 1-888-866-5797. Item 69377

Page 9

Tilt Latch

The Tilt Pin allows the Cradle to tilt to adjust the

panel as needed for installation on sloped ceilings

or walls. When the Cradle is locked with the Tilt

Pin through the aligned holes in the Cradle Beam

and Telescoping Asm., it will support a drywall

panel horizontally for flat ceiling installation.

Locked position:

R-Pin

Cradle

Beam

Tilt Pin

Telescoping

Asm.

CAUTION! Align the Wire Rope

and wind it tightly and evenly on

the spool to prevent tangling.

If they start winding unevenly: stop, reverse

direction to loosen the rope, then carefully

adjust them before continuing.

3. Raise the Telescoping Assembly and lock in

place through the holes in the post either with

the attached Pin and Pin Lever, or, above the

Outer Post with the Square Pin. See Figure O.

Inner Post

Outer Post

Attached Pin

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Figure M

To unlock the Cradle for different angles,

slide the Tilt Pin out of the holes, rotate

the Cradle to its tilted position.

WARNING! To prevent serious injury from falling load:

Only remove the Tilt Pin shown in Figure M. Do not

remove the Hinge Pin on the opposite side of the Cradle.

Winch Asm. & Winch Wheel

1. The Winch Wheel is used to raise and lower

the Cradle, which holds the panel. This

is done by means of a Wire Rope which

wraps around a Spool in the Winch.

Slide Bar

Handle

Telescoping

Asm.

Pin Lever

Square Pin

Figure O

Support Post

Brake

Figure N

2. If necessary, you can grasp the end of the

Support Post for leverage when raising a panel.

CAUTION! Pay attention to the action of the Wire

Rope when operating this tool. Do not allow your

hands, clothing, hair or jewelry to come near the Wire

Rope. If these become caught in the Wire Rope,

you can be injured. Do not allow the Wire Rope to

become tangled or jammed during operation.

Wheel

Page 9For technical questions, please call 1-888-866-5797.Item 69377

Page 10

Operation

Safety Checks Before Operation

1. Carefully inspect the Hoist before operating it.

SAFETY OPERATION MAINTENANCEASSEMBLY

2. Inspect the tool for wear or damage. Pay special

attention to any wear or damage to the Wire Rope.

3. Be sure the Winch components are

clean and dry before operation.

Loading a Drywall Panel

Note: Drywall panels are very heavy; it is recommended

that they be handled by two workers when working with

larger panels. Set the Locking Casters to prevent the

Hoist from moving or rolling while loading a panel on it.

WARNING! Only use hoist with single complete drywall

panels. Lifting damaged, broken, cut, or multiple panels

may cause a panel to fall, causing serious injury.

1. Rotate the Cradle Asm. so the Support

Hooks are on the opposite side of the

Telescoping Asm. from the Winch Wheel.

2. Rotate and secure the Support Hooks to

their open position. (See Figure K.)

6. If the panel will be installed on a flat ceiling, tilt the

Cradle back to its horizontal position and lock in

place with the Tilt Pin. If the panel will be installed on

a side wall or sloped ceiling, leave the Cradle tilted.

7. Check to see that the panel is secure and balanced.

8. Lower the Cradle if needed, and

release the Caster Locks.

9. Carefully roll the Hoist near to the position

where the panel will be installed.

10. When at the appropriate location,

apply the Caster Locks.

Raising the Panel

CAUTION! Lock the Locking Casters to prevent the

Hoist from rolling after it is in position. (See Figure C.)

1. Crank the Winch Wheel clockwise to raise

the panel slightly, then stop, checking that

the Brake is functioning properly.

3. Extend the Crossarms as needed to support the

panel size you are working with. (See Figure J.)

4. Pull the Tilt Pin out and tilt the

Cradle. (See Figure M.)

5. Place the drywall panel on the Cradle, with the outer

side of the panel (the good side) facing the cradle.

Carefully lean the panel on the Crossarms, being

careful not to damage the edges of the panel.

Figure Q

2. Once you have determined that the Brake

is functioning properly, resume raising

the panel to the desired height.

Figure P

Page 10 For technical questions, please call 1-888-866-5797. Item 69377

Page 11

Lowering the Cradle

1. Install the drywall panel correctly

before lowering Cradle.

2. Push and hold the Winch Wheel slightly

forward to support the weight of the Cradle.

3. Release the Pin with the Pin Lever (see Figure S),

then operate the Brake Handle with your left hand

and rotate the Winch Wheel counterclockwise

with your right hand to lower the Cradle.

CAUTION: Do not release control of the

Wheel Handle as the Hoist is lowering or the

Cradle may lower forcefully and cause injury.

4. After each use, lower the Cradle completely and

clean all surfaces of the Hoist with a clean cloth.

Note: If operation becomes rough,

lubricate the post with candle wax.

Storing the Hoist

When not in use for an extended period, the

Hoist can be disassembled as follows:

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Figure R

WARNING! Do not force the panel beyond its

listed height range. If the pole is overextended,

the hoist may become stuck or tip.

CAUTION! The Wire Ropes must be

aligned and wound tightly and evenly on

the spool to prevent tangling. If they start

winding unevenly, lower the load and

carefully adjust them before continuing.

3. Raise the Telescoping Assembly so that the

holes of the inner post align with the Attached Pin

opening, then lock in place with the Pin Lever,

or, slide the Square Pin through the Inner Pin

holes above the Outer Post. See Figure S.

Inner Post

Outer Post

1. Lock the Caster Wheels.

2. Fully lower the Telescoping Asm.

3. Retract the Extensions and close the Support

Hooks on the Cradle. Secure all in place.

4. Remove the Crossarms, then remove the Cradle.

5. Remove the Telescoping Asm.

6. Depress the Slide Lock Ring and fold

the Tripod Base legs together until the

Slide Lock Ring locks in place.

7. Wipe dust and dirt from all parts

with a clean cloth if needed.

8. Store all components in a safe location

indoors out of reach of children.

Attached Pin

Pin Lever

Square Pin

Figure S

Page 11For technical questions, please call 1-888-866-5797.Item 69377

Page 12

Cleaning, Maintenance, and Lubrication

Procedures not specifically explained in this manual

SAFETY OPERATION MAINTENANCEASSEMBLY

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE:

Do not use damaged equipment. If abnormal noise or vibration

occurs, have the problem corrected before further use.

CAUTION! To prevent injury:

Wear ANSI-approved safety goggles and heavy-duty leather work gloves

during inspection and maintenance, especially near the wire rope.

must be performed only by a qualified technician.

1. BEFORE EACH USE, inspect the general condition

of the tool. Check for loose screws, wire rope

fraying and other wire rope wear, misalignment or

binding of moving parts, cracked or broken parts and

any other condition that may affect its safe operation.

2. Inspect the tool before beginning work each day.

Have the Wire Rope replaced immediately

as soon as wear is detected.

Wire Rope Safety Information

1. Since the safe operation of this Hoist depends

on safe maintenance of the steel Wire Rope,

it is important that you carefully monitor and

maintain the included Wire Rope. Have the Wire

Rope replaced by a qualified technician as soon

as it has any fault, defect or noticeable wear.

2. The American Society of Mechanical Engineers

lists standards for the safe use of wire rope in

its standard numbered ASME B30 19-2000.

This standard is available to the public, and we

strongly suggest you become familiar with it.

WARNING! A Wire Rope breaking while under

load can cause serious personal injury and

property damage. Broken Wire Rope strands

are sharp and can cause puncture injuries.

WARNING! Do not lubricate any part of the

Winch components. The Brake is friction

based and may fail if lubricated.

3. Occasionally oil the Caster Wheel bearings.

4. If the telescoping sections do not slide

freely, apply paraffin wax or candle

wax to the sides as a lubricant.

3. The following does not replace the information

found in ASME B30 19-2000, but paraphrases some

of the important information contained therein.

a. Inspection should be made at least once every

work day. Inspector should look for damage to

the wire rope, such as crushing, kinking, broken

strands, corrosion etc. Particular attention should

be paid to undue wear and stress points, such

as near pulleys, crimped ends, hooks, etc.

b. Wire ropes should be taken out of service if

discovered to be damaged, and must be replaced

before resuming use of the affected tool.

4. The wire rope must be replaced with one

of identical diameter and construction. The

wire rope provided with this Hoist is suited

to the purpose, and any replacement must

be at least to the original standard.

Page 12 For technical questions, please call 1-888-866-5797. Item 69377

Page 13

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Page 13For technical questions, please call 1-888-866-5797.Item 69377

Page 14

Parts List and Diagram

Parts List

SAFETY OPERATION MAINTENANCEASSEMBLY

Part Description Qty

A Tripod 1

B Telescoping Asm. 1

C Winch 1

D Cradle 1

1 Leg, Inner 1

2 Pull Spring A 1

3 Rivet 6

4 Flat Washer Ø12 8

5 Cotter Pin Ø2.5×25 12

6 Foot Cap 2

7 Support Rod 2

8 Leg, Outer 2

9 Lock Caster 3

10 Housing, Frame 1

11 Telescoping Section, Inner 1

Part Description Qty

29 Slide Bar 1

30 Slide Bar Lock 1

31 Nylon Insert Nut M12 2

32 Support Post 1

33 Pull Spring B 2

34 Brake Handle 1

35 Brake Handle Cover 1

36 Winch Wheel 1

37 Long Bushing 1

38 Long Pin 1

39 Back Ring Ø10 1

40 Bushing 2

41 Cradle Beam 1

42 Crossarm 2

43 Pin 2

12 Telescoping Section, Outer 1

13 Mounting Pin 1

14 Hinge Pin 1

15 Tilt Pin 1

16 Mini Chain 1

17 Ring 4

18 Press Plate 2

19 Bolt M8×15 2

20 Hook Bolt M8x25 2

21 Panel Support Hook 2

22 Safety Hook 1

23 Pulley 3

24 Bearing 3

25 Pulley Pin 3

26 Bolt M10×25 1

27 Nylon Insert Nut M10 1

44 Spring 2

45 Flat Washer Ø5 2

46 Extension 2

47 End Cap 8

48 Big Flat Washer Ø12 1

49 Winch Handle 1

50 Bolt M12x120 1

51 R Pin Ø2 2

52 Cap 2

53 Lock Spring 2

54 Square Pin 1

55 Partial Post 1

56 Round Tube Cap 1

57 Bolt M10x16 2

58 Nut M12 1

59 Bolt M6 x16 1

28 Wire Rope 1

Page 14 For technical questions, please call 1-888-866-5797. Item 69377

Page 15

Assembly Diagram

D

SAFETYOPERATIONMAINTENANCE ASSEMBLY

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Page 15For technical questions, please call 1-888-866-5797.Item 69377

Page 16

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality

and durability standards, and warrants to the original purchaser that this product is free from

defects in materials and workmanship for the period of 90 days from the date of purchase. This

warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence or

accidents, repairs or alterations outside our facilities, criminal activity, improper installation,

normal wear and tear, or to lack of maintenance. We shall in no event be liable for death,

injuries to persons or property, or for incidental, contingent, special or consequential damages

arising from the use of our product. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation of exclusion may not apply to

you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection verifies the defect, we will either repair or

replace the product at our election or we may elect to refund the purchase price if we cannot

readily and quickly provide you with a replacement. We will return repaired products at our

expense, but if we determine there is no defect, or that the defect resulted from causes not

within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • 1-888-866-5797

Loading...

Loading...