Page 1

MULTI-PURPOSE WORKBENCH

WITH LIGHTING

99681

ASSEMBLY INSTRUCTIONS

Tools sold separately.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual revised 08l

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial

number in the back of the manual near the

assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and

dry place for future reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

General Safety Warnings

WARNING Read all safety

warnings and instructions.

Failure to follow the warnings

and instructions may result in

electric shock, re and/or serious

injury. Save all warnings and

instructions for future reference.

Work area safety1.

Keep work area clean and well lit. a.

Cluttered or dark areas invite accidents.

Keep children and bystanders b.

away while operating a power tool.

Distractions can cause you to lose

control.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

SKU 99681 For technical questions, please call 1-800-444-3353. Page 2

Electrical safety2.

Power tool plugs must match the a.

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with grounded power tools.

Unmodied plugs and matching outlets will reduce risk of electric shock.

Do not abuse the cord. Never use b.

the cord for unplugging the power

tool. Keep cord away from heat,

oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

Use personal protective equip-c.

ment. Always wear ANSI-approved

Page 3

safety goggles when assembling

this product.

Prevent unintentional starting. d.

Ensure the switch of the power

strip is in the off-position before

connecting to power source, and

plugging in any power tool.

SAVE THESE

INSTRUCTIONS.

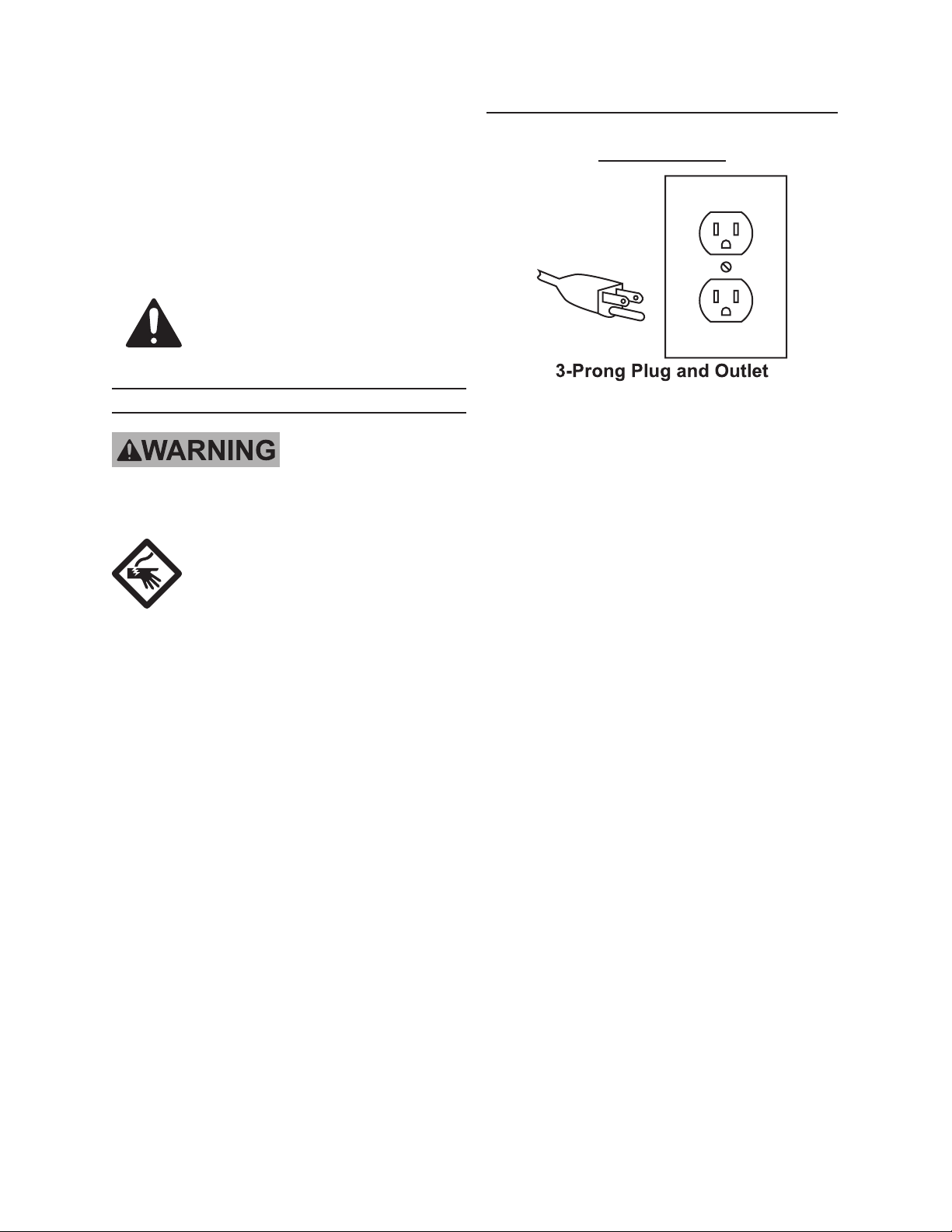

Grounded Tools: Tools with Three

Prong Plugs

GROUNDING

TO PREVENT

ELECTRIC SHOCK

AND DEATH FROM

INCORRECT GROUNDING

WIRE CONNECTION:

Check with a qualied

electrician if you are in doubt

as to whether the outlet is

properly grounded. Do not

modify the power cord plug

provided with the tool. Never

remove the grounding prong

from the plug. Do not use the

tool if the power cord or plug

is damaged. If damaged, have

it repaired by a service facility

before use. If the plug will not

t the outlet, have a proper

outlet installed by a qualied

electrician.

Tools marked with “Grounding Re-1.

quired” have a three wire cord and

three prong grounding plug. The

plug must be connected to a properly

grounded outlet. If the tool should

electrically malfunction or break

down, grounding provides a low

resistance path to carry electricity

away from the user, reducing the risk

of electric shock. (See 3-Prong Plug

and Outlet.)

The grounding prong in the plug is 2.

connected through the green wire inside the cord to the grounding system

in the tool. The green wire in the cord

must be the only wire connected to

the tool’s grounding system and must

never be attached to an electrically

“live” terminal. (See 3-Prong Plug

and Outlet.)

The tool must be plugged into an 3.

appropriate outlet, properly installed

and grounded in accordance with all

codes and ordinances. The plug and

outlet should look like those in the

preceding illustration. (See 3-Prong

Plug and Outlet.)

SKU 99681 For technical questions, please call 1-800-444-3353. Page 3

Page 4

Double Insulated Tools: Tools

with Two Prong Plugs

Tools marked “Double Insulated” do 1.

not require grounding. They have

a special double insulation system

which satises OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Outlets for 2-Prong

Plug.)

Double insulated tools may be used 2.

in either of the 120 volt outlets shown

in the preceding illustration. (See

Outlets for 2-Prong Plug.)

The smaller the gauge number of the 3.

wire, the greater the capacity of the

cord. For example, a 14 gauge cord

can carry a higher current than a 16

gauge cord. (See Table A.)

When using more than one exten-4.

sion cord to make up the total length,

make sure each cord contains at

least the minimum wire size required.

(See Table A.)

If you are using one extension cord 5.

for more than one tool, add the

nameplate amperes and use the sum

to determine the required minimum

cord size. (See Table A.)

If you are using an extension cord 6.

outdoors, make sure it is marked with

the sufx “W-A” (“W” in Canada) to

indicate it is acceptable for outdoor

use.

Make sure the extension cord is prop-7.

erly wired and in good electrical condition. Always replace a damaged

extension cord or have it repaired by

a qualied electrician before using it.

Extension Cords

Grounded1. tools require a three wire

extension cord. Double Insulated

tools can use either a two or three

wire extension cord.

As the distance from the supply outlet 2.

increases, you must use a heavier

gauge extension cord. Using extension cords with inadequately sized

wire causes a serious drop in voltage,

resulting in loss of power and possible tool damage.

(See Table A.)

SKU 99681 For technical questions, please call 1-800-444-3353. Page 4

Protect the extension cords from 8.

sharp objects, excessive heat, and

damp or wet areas.

Page 5

RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS*

(120/240 VOLT)

EXTENSION CORD

NAMEPLATE

LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

TABLE A

25’

50’

75’

100’

* Based on limiting the line

voltage drop to ve volts at

150% of the rated amperes.

Symbology

150’

V~

A

n0 xxxx/min.

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

Volts Alternating Current

Amperes

No Load Revolutions per Minute

(RPM)

SKU 99681 For technical questions, please call 1-800-444-3353. Page 5

Page 6

SPECIFICATIONS

Power Strip Rating 125 V~ / 7 A

Replacement Bulb T5 14W

550 lb. - evenly distributed

as follows:

Maximum Weight

Capacity

Bench Top - 250 lb.

Bottom shelf - 200 lb.

Each Drawer - 25 lb.

Top Shelf - 45 lb.

UNPACKING

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at the number shown on the

cover of this manual as soon as possible.

ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Left Rear Post

Extension (2L)

23 22

Left Rear

Post (1L)

26

Fig. 1

1. Attach the Left Rear Post (1L) to the

Left Post Extension (2L) using Bolts

(26), Washers (22), and Nuts (23).

Attach the Right Rear Post (1R) with

the Right Post Extension (2R) using

Bolts (26), Washers (22), and Nuts

(23).

23

22

2R

1R

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

26

Side with 10

holes facing

down

the end of this manual.

2L

1L

Fig. 2

NOTE:

With the two Rear Posts laying on

the oor, the sides with ten holes (2L

& 1L, 2R & 1R) should be facing the

oor.

SKU 99681 For technical questions, please call 1-800-444-3353. Page 6

Page 7

Side

Beam 8

Top Shelf

Rear

Beam 3

Drawer

Mounts 9

Side

Beam 8

Bottom

Beam 6

Center Beam

with Holes 5

Side

Beam 8

Right Front

Post 10R

Center Beam

with Holes 5

Left Front

Post 10L

24

22

27

26

23

22

Fig. 3

2. From top to bottom, connect the

top shelf Rear Beam (3), the Center

Beam with holes, in the middle (5),

and a Bottom Beam (6) onto the two

rear Legs using Bolts (26), Washers

(22), and Nuts (23).

NOTE: Only put one screw in the top hole

at each end of the Top Shelf Rear

Beam (3) at this stage. The bottom

hole will be used when the Peg Board

(17) is fastened in Step 7.

Using Bolts (26), Washers (22), and 3.

Nuts (23), attach two Side Beams (8)

onto the rear legs at the Center Beam

With Holes (5), to the back, and

another two Side Beams (8) at the

Bottom Beam (6).

Fig. 4

5. Attach the Left Front Post (10L) to

the Left Side Beam (8) and Drawer

Mount with Glide Rail (9), repeat with

the Right Front Post (10R). Attach

Center Beam With Holes (5), to the

front, using Bolts (26, 27), Washers

(22), and Nuts (23, 24). (See Fig. 4.)

At the bottom, attach the Left Front 6.

Post (10L) to the Left Side Beam (8)

and Bottom Beam (6) using Bolts

(26), Washers (22) and Nuts (23).

Repeat the procedure using the Right

Front Post (10R) for the right side.

Center Rear

“L” Bracket 12

27

27

Attach both Drawer Mounts With 4.

Glide Rails (9) below the two Side

Beams (8) using Bolts (27), Washers

(22), and Nuts (24).

24

22

Center Drawer

Glide Rail 13

Center Front

“L” Bracket 11

22

23

Mount with

Center Front

“L” Bracket 11

Fig. 5

7. Stand the frame upright. Fit the Center Front “L” Bracket (11) inside the

SKU 99681 For technical questions, please call 1-800-444-3353. Page 7

Page 8

Front Center Beam With Holes (5)

using Bolts (27), Washers (22), and

Nuts (24).

Attach the Center Drawer Mount With 8.

Glide Rail (13) to the two “L” Brackets

(11, 12) using Bolts (27), Washers

(22), and Nuts (23).

Top Shelf Left

Side Beam 7L

Top Shelf

Front Beam 4

Peg Board 17

27

Top Shelf Right

Side Beam 7R

22

23

Rear Plate of

Drawer 14R

23

Side Plate of

Drawer 15

Front Plate of Drawer 14F

Fig. 6

9. Attach the Front Plate of Drawer

(14F), Side Plates of Drawer (15),

and Rear Plate of Drawer (14R) together with Bolts (25) and Nuts (23).

Repeat for the second drawer. Do not 10.

tighten the screws on the “L” Brackets, Center Drawer Mount With Glide

Rail and two drawers until the two

drawers are t into the bench frame.

25

Fig. 7

11. Attach the Peg Board (17) to the

bottom holes of the Top Shelf Back

Beam (3) using Bolts (27), Washers

(22), and Nuts (23).

Attach two Top Shelf Side Beams (7L, 12.

7R) onto the Left & Right Post Extensions (2L, 2R) with Bolts (26), washers (22), and Nuts (23)

Attach the Top Shelf Front Beam (4) 13.

with Bolts (26), Washers (22), and

Nuts (23).

18

28

Fig 8

14. Place the Top Shelf (18), Bench Top

(19), Drawer Boards (20), and Bottom

Board (21) into position. Attach the

Top Shelf (18) using Wood Screws

(28).

SKU 99681 For technical questions, please call 1-800-444-3353. Page 8

Page 9

29

30

32

33

15. Insert a Slider Bolt (30) through each

of the Lamp Mounting Sliders (29).

32

30

29

16. Slide the Lamp Mounting Sliders (29)

into the slot at the top of the Lamp

(32), as shown above.

18. Attach the Lamp Power Cord (33) to

the receptacle at the end of the Lamp

(32). It will only connect one way.

18

30

17. Insert the ends of the Bolts (30)

through the holes underneath the Top

Shelf (18) and secure in place with

the Slider Nuts (31) from the top.

SKU 99681 For technical questions, please call 1-800-444-3353. Page 9

Page 10

MAINTENANCE AND

SERVICING

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn the Power Switch of the

power-strip to its “OFF”

position so that any power

tool plugged into it cannot be

accidentally turned on. Do

this before performing any

inspection, maintenance, or

cleaning procedures.

bulb up into the slots at the right and

left xture receptacles.

Rotate the bulb lengthwise 90º again d.

to seat the bulb. Replace the clear

cover.

5. WARNING! If the supply cord

of this workbench’s light or power

strip is damaged, it must be re-

placed only by a qualied service

technician.

BEFORE EACH USE,1. inspect the

general condition of the bench.

Check for loose screws, misalignment

or binding of moving parts, cracked or

broken parts, damaged electrical wiring, and any other condition that may

affect its safe operation.

AFTER USE,2. clean external surfaces

of the bench with clean cloth.

Vacuum Bench Top, wipe or brush 3.

clean.

The light xture mounted underneath 4.

the top shelf has a transparent plastic

cover over the bulb.

Gently pull straight down at both a.

ends of the cover and set aside.

Remove the bulb by spinning the b.

bulb 90º, rolling in a forward or backward direction and dropping the bulb

straight down.

With the prongs on either end of the c.

bulb vertically aligned, t the new

SKU 99681 For technical questions, please call 1-800-444-3353. Page 10

Page 11

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

PARTS LIST

Part Description Qty.

1L Left Rear Post 1

1R Right Rear Post 1

2L Left Post Extension 1

2R Right Post Extension 1

3 Top Shelf Rear Beam 1

4 Top Shelf Front Beam 1

5 Center Beam With Holes 2

6 Bottom Beam 2

7L Top Shelf Left Side Beam 1

7R Top Shelf Right Side Beam 1

8 Side Beam 4

9 Drawer Mounts With Glide Rails 2

10L Left Front Post 1

10R Right Front Post 1

11 Center Front "L" Bracket 1

12 Center Rear "L" Bracket 1

13 Center Drawer Mount w/ Rail 1

14F Front Plates Of Drawer 2

14R Rear Plates Of Drawer 2

15 Side Plates Of Drawer 4

PARTS LIST

Part Description Qty.

16 Hooks 20

17 Peg Board 1

18 Top Shelf 1

19 Bench Top 1

20 Drawer Boards 2

21 Bottom Board 1

22 M6 Washers 72

23 M6 Nuts 76

24 M6 Lock Nuts 12

25 M6 x 8 mm Bolt 16

26 M6 x 10 mm Bolt 46

27 M6 x 18 mm Bolt 26

28 Wood Screws 6

29* Lamp Mounting Slider 2

30* Slider Bolt 2

31* Slider Nut 2

32* Lamp 1

33* Lamp Power Cord 1

*Not shown in diagram.

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

SKU 99681 For technical questions, please call 1-800-444-3353. Page 11

Page 12

ASSEMBLY DIAGRAM

SKU 99681 For technical questions, please call 1-800-444-3353. Page 12

Loading...

Loading...