Page 1

WALK-BEHIND SPREADER

Model

99623

50 LB. CAPACITY

ASSEMBLY, OPERATING, AND MAINTENANCE

INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number

in the back of the manual (or month and

year of purchase if product has no number). Keep this manual and the receipt in

a safe and dry place for future reference.

IMPORTANT SAFETY

INSTRUCTIONS

In this manual, on the labeling,

and all other information

provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

When using

gardening

equipment, basic safety

precautions should always be

followed to reduce the risk of

personal injury, including the

following:

READ ALL INSTRUCTIONS

Personal Safety

Dress properly - Do not wear loose 1.

clothing or jewelry. They can be

caught in moving parts. Use of rubber gloves and substantial footwear is

recommended when working outdoors. Wear protective hair covering

to contain long hair.

2. Wear ANSI-approved safety

goggles, NIOSH-approved

dust mask/respirator, and

heavy-duty work gloves.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

Do not overreach - Keep proper foot-3.

ing and balance at all times.

Stay alert - Watch what you are do-4.

ing. Use common sense. Do not operate this product when you are tired.

Gardening Appliance Use and Care

Avoid a dangerous environment - Do 1.

not use this product in damp or wet

locations.

Page 2SKU 99623 For technical questions, please call 1-800-444-3353.

Page 3

Do not use in rain.2.

Keep children away - All visitors 3.

should be kept at a distance from

work area.

When servicing use only identical 4.

replacement parts.

Use the right equipment - Do not use 5.

appliance for any job except that for

which it is intended.

Do not force this equipment - It will do 6.

the job better and with less likelihood

of injury at the rate for which it was

designed.

Store idle equipment indoors - When 7.

not in use, gardening equipment

should be stored indoors in a clean,

dry location out of reach of children.

Maintain this product with care - Keep 8.

this product clean for best performance and to reduce the risk of

injury. Follow instructions for maintenance. If damaged, have this product

repaired by an authorized service

facility. Keep handle dry, clean, and

free from oil and grease.

Keep guards in place and in working 10.

order.

General Safety

Do not exceed the maximum weight 1.

capacity (50 pounds) of the Spreader.

Use this product only with powdered 2.

and granular fertilizers, seed, sand,

and ice-melt products.

Never leave contents in the Spreader. 3.

Pour leftover material back into its

package and seal the package tightly.

Never allow children or pets near any

materials you apply.

Always follow the fertilizer manufac-4.

turer’s instructions for proper use of

the fertilizer.

Do not use appliance for other than 5.

intended use.

Maintain labels and nameplates on 6.

the Spreader. These carry important

safety information. If unreadable or

missing, contact Harbor Freight Tools

for a replacement.

Check for damaged parts - Before 9.

further use of this product, a guard

or other part that is damaged should

be carefully checked to determine

that it will operate properly and perform its intended function. Check for

alignment of moving parts, binding of

moving parts, breakage of parts, and

any other condition that may affect its

operation. A guard or other part that

is damaged should be properly repaired or replaced by a qualied technician unless indicated elsewhere in

this manual.

The warnings, precautions, and in-7.

structions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

SAVE THESE

INSTRUCTIONS.

Page 3SKU 99623 For technical questions, please call 1-800-444-3353.

Page 4

SPECIFICATIONS

Designed for spreading

Product Applications

Hopper Capacity 50 Pounds (Dry)

Tires 4.10/3.50-6 / 24 PSI / Qty. 2

Construction Materials

powdered and granular fertilizer,

seed, sand, and ice-melt

products.

Molded Polypropylene Hopper &

Spreader Impeller.

Steel Tubular Frame & Handle.

Pneumatic Tires.

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

ASSEMBLY INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INSTRUCTIONS

section at the beginning of this

manual including all text under

subheadings therein before

assembly or use of this

product.

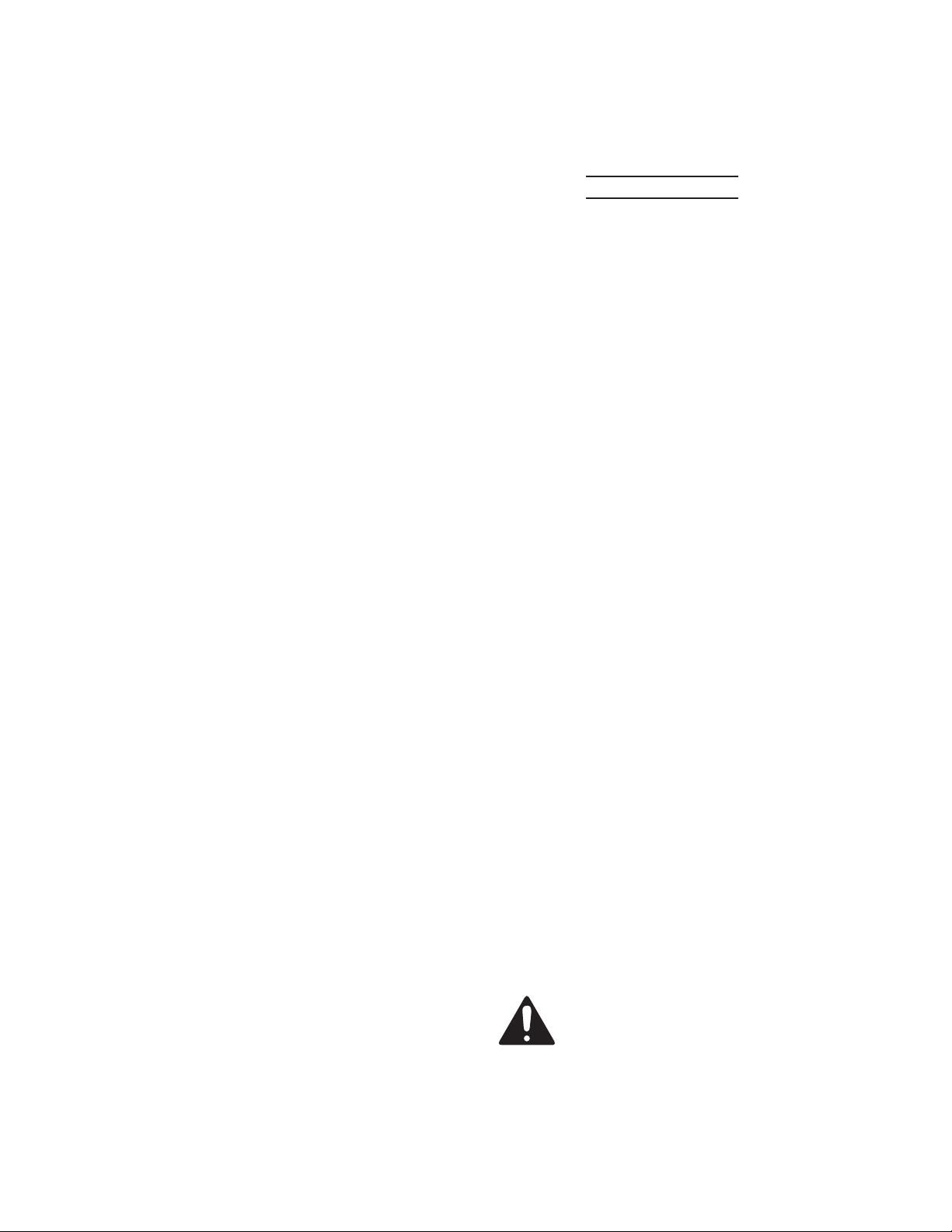

SCREWS

(43)

FRAME

(30)

HOPPER

(16)

FIGURE A

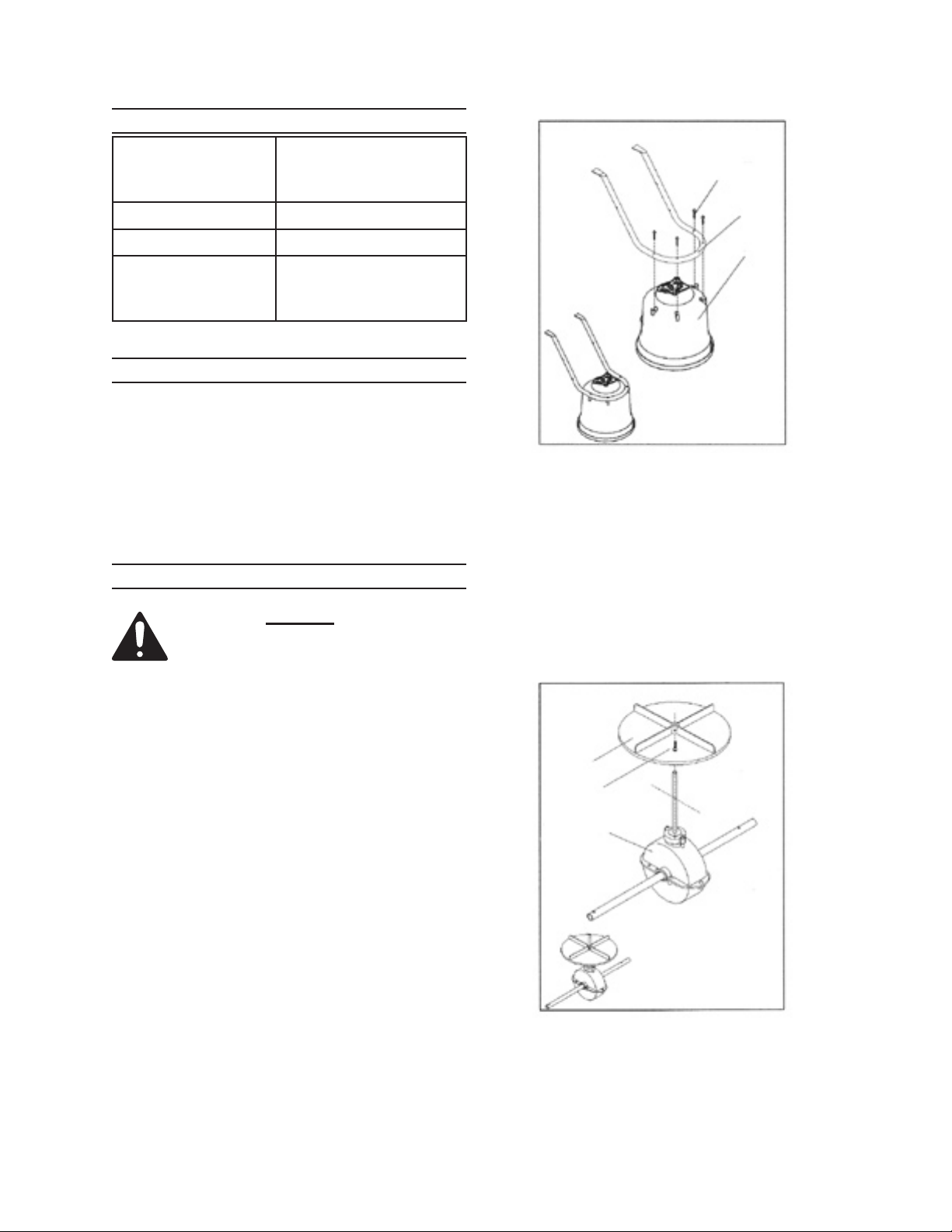

Attach the Impeller (42) to the Gear 2.

Box & Axle Assembly (39). To do

so, insert the Screw (41) through the

Impeller, then through the Gear Box

Axle. Use the hole nearest the Gear

Box. Then tighten the Screw.

(See Figure B.)

IMPELLER

(42)

Note: For additional information regarding

the parts listed in the following pages, refer

to the Assembly Diagram near the end of

this manual.

Turn the Hopper (16) upside down 1.

and install the Frame (30), using four

Screws (43). (See Figure A.)

SCREW

(41)

GEAR BOX

&

AXLE ASSY.

(39)

FIGURE B

Install the Wheel Assembly Frames 3.

(20) on each side of the Gear Box

Page 4SKU 99623 For technical questions, please call 1-800-444-3353.

Page 5

Axle (39). Insert a Hex Bolt (32)

through both Wheel Assembly

Frames and the Hopper Frame (30).

Then secure the Wheel Assembly

Frames to the Hopper Frame, using

two Lock Nuts (24). NOTE: Do not

tighten hardware at this time.

(See Figure C.)

GEAR BOX & AXLE

(39)

WHEEL ASSY. FRAME

(20)

HEX BOLT

(32)

CROSS BRACE

(45)

FRAME BRACE

(31)

BOLT

(33)

BOLT

(11)

HOPPER

LOCK NUT

(24)

(16)

FIGURE D

LOCK NUT

(24)

HOPPER

(16)

FIGURE C

Attach one end of the Frame Braces 4.

(31) to the Hopper Frame (30), us-

ing two Bolts (33) and two Lock Nuts

(24). Then attach the other ends of

the Frame Braces, with the Cross

Brace (45) positioned between the

Frame Braces, to the Wheel Assem-

bly Frame (20), using two Bolts (11).

NOTE: Do not tighten hardware at

this time. (See Figure D.)

Slide an Axle Bushing (37) over the 5.

Axle (39) and into an Axle Bearing

(38) on both ends of the Axle. Install

a Wheel (36) on each end of the Axle

and secure the Wheels using two Hex

Bolts (47) and two Hex Lock Nuts (44).

Then install a Flat Washer (34) and

End Cap (35) for each Wheel.

(See Figure E.)

WHEEL

(36)

HEX BOLT

(47)

TH RE ADE D

HOLE

AXLE BUSHING

(37)

END CAP

(35)

FLAT

WASHER

(34)

Note: Find the threaded hole in one

side of Axle. Install a Wheel (36) on

this end of the Axle and secure the

Wheel using one Hex Bolt (47) and

one Lock Nut (44). Then install a Flat

Washer (34) and End Cap (35) for this

Wheel. Install the other Wheel on the

Axle and secure it in place with a Flat

Washer (34) and End Cap (35).

HEX

LOCK NUT

(44)

HOPPER

(16)

FIGURE E

REV 09b

Page 5SKU 99623 For technical questions, please call 1-800-444-3353.

Page 6

Insert the Handle Shaft (26) between 6.

the two Wheel Assembly Frames

(20). Attach the Pivot and Bracket

Assembly (19) to the Wheel Assem-

bly Frames and Handle Shaft, using

two Bolts (11) and two Nuts (21).

(See Figure F.)

HANDLE SPACER

UPPER

HANDLE

(23)

BOLT

(11)

(1)

FLAT WASHER (48)

NUTS (21)

GAUGE

& LEVER

ASSY.

(4)

HANDLE SHAFT

(26)

NUT

(21)

PIVOT

&

BRACKET

ASSY.

BOLT

(11)

WHEEL ASSY.

FRAME

(20)

(19)

HOPPER

(16)

FIGURE F

7. The Upper Handle (23) features

three positions for operating comfort.

To use the middle or upper positions,

place the Handle Spacer (1) between

the mounting holes nearest to the

Handle Covers (15). Insert a Bolt

(11) through the Upper Handle (23),

through the Handle Spacer, through

the other Upper Handle and secure

with a Flat Washer (48) and Nut (21).

Install the Gauge & Lever Assembly

(4) on the left hand side, using two

Bolts (11) and two Nuts (21).

(See Figure G.)

FIGURE G

Unscrew and remove 8. one Lock Nut

(24) from the Control Rod (25). Insert

the threaded portion of the Control Rod

into the hole in the Pivot and Bracket

Assembly (19). Then re-thread the

Lock Nut back onto the Control Rod.

(See Figure H.)

FIGURE H

CONTROL ROD

(25)

PIVOT & ASSY.

BRACKET

(19)

LOCK

NUT

(24)

Insert the Adjust Connect Rod (46) into 9.

the Shut Off Plate (27). Then secure

the Adjust Connect Rod to the Shut Off

Plate, using one Flat Washer (48) and

Page 6SKU 99623 For technical questions, please call 1-800-444-3353.

Page 7

one Lock Nut (24).

(See Figure I.)

HOPPER

(16)

FIGURE I

FLAT

WASHER

(48)

LOCK

NUT

(24)

SHUT OFF PLATE

(27)

Pull up on the Adjust Handle (6) to its 12.

upper position, making sure the holes

in the Hopper (16) and the holes in the

Shut Off Plate (27) are 100% open.

(See Figure J.)

Adjust the position of the Wing Nut 13.

(10). By doing so, you are able to control the size of the holes you need.

(See Figure J.)

Insert the “R” Pin (17) into the Pinion 14.

Shaft on the Gear Box and Axle Assembly (39). Make sure the Impeller

(42) is turning in the correct direction as

indicated by the arrow in the illustration.

(See Figure J.)

10. Push down on the Adjust Handle (6)

to its lowest position.

(See Figure J.)

“R” PIN

(17)

ADJUST

HANDLE

PINION

SHAFT

FIGURE J

PUSH FORWARD.

IMPELLER MUST TURN

IN THIS DIRECTION.

(6)

WING

LOCK NUTS

(24)

“R” PIN (17)

NUT

(10)

11. Adjust the position of the two Lock

Nuts (24) on the Control Rod (25),

making sure the holes at the bottom

of the Hopper (16) line up with the

holes in the Shut Off Plate (27) prop-

erly. (See Figures I and J.)

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section

at the beginning of this manual

including all text under

subheadings therein before

assembly or use of this product.

Before operating the Spreader make 1.

sure to wear ANSI-approved safety

impact glasses, NIOSH-approved dust

mask/respirator, and heavy duty work

gloves.

Remove the Screen (14) on the Hopper 2.

(16) and ll the Hopper with the material you wish to apply. Do not exceed 50

pounds of material. Then replace the

Screen. (See Figure K, next page.)

Refer to the manufacturer’s recom-3.

mended ow rate (0 to 5, typically

shown on the bag/container of the

material being applied).

Adjust the ow rate on the Gauge and 4.

Lever Assembly (4) to that of the mate-

Page 7SKU 99623 For technical questions, please call 1-800-444-3353.

Page 8

rial manufacturer’s recommendation.

To do so, move the Wing Nut (10) to

the proper setting. (See Figure K.)

Suggested walking pattern at 10. full rate

settings: (See Figure L.)

Grip the Upper Handles (23) with 5.

both hands, pull the Adjust Handle

(6) back and immediately begin

pushing the Spreader at a slow and

even rate over the area you wish to

apply. (See Figure K.)

IMPORTANT: 6. Always PUSH the

Spreader when applying material.

When pulled backward while the

Hopper (16) is open, the Spreader

may apply an excessive amount of

material. (See Figure K.)

When nished applying the material, 7.

push the Adjust Handle (6) forward

to stop the release of material being

applied. (See Figure K.)

SCREEN

(14)

HOPPER

(16)

UPPER HANDLES

(23)

FIGURE L

START

FINISH

11. Suggested walking pattern at half rate

settings: (See Figure M.)

FIGURE M

START

(1ST PASS)

ADJUST HANDLE

(6)

WING NUT

(10)

FIGURE K

8. Never leave material in the Spreader.

Pour leftover material back into its

bag/container and seal the bag/container tightly.

To prevent accidents, wash thor-9.

oughly to remove all material in the

Spreader. Allow the unit to dry. Then

store the unit indoors out of children’s

reach.

FINISH

(1ST PASS)

(2ND PASS)

START

FINISH

(2ND PASS)

Page 8SKU 99623 For technical questions, please call 1-800-444-3353.

Page 9

MAINTENANCE AND

SERVICING

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

SERIOUS INJURY

FROM TOOL FAILURE:

Do not use damaged

equipment. If abnormal noise

or vibration occurs, have the

problem corrected before

further use.

AFTER USE,2. Never leave material in

the Spreader. Pour leftover material

back into its bag/container and seal the

bag/container tightly.

CLEANING AND STORAGE: wash 3.

thoroughly to remove all material in the

Spreader. Allow the unit to dry. Then

store the unit indoors out of children’s

reach.

NOTE: This Spreader does not require 4.

lubrication.

PLEASE READ THE

FOLLOWING CAREFULLY

Inspection, Maintenance, and

Cleaning

BEFORE EACH USE, inspect the 1.

general condition of the Spreader.

Check for loose screws, misalignment or binding of moving parts,

cracked or broken parts, and any

other condition that may affect its

safe operation.

TROUBLESHOOTING

Problem Possible Cause(s) Possible Solution(s)

Unit will not release material. Improper use of Adjust Handle.1.

Improper ow rate setting.2.

Wet, or wrong type of materal.3.

THE MANUFACTURER AND/OR DISTRIBUTOR HAS

PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER

THE MANUFACTURER OR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE

BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY

REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT.

IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED

AND LICENSED TECHNICIANS, AND NOT BY THE BUYER.

THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT

OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR

REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Pull Adjust Handle backward to 1.

release material. Push forward

to stop ow of material.

Make sure Adjust Handle setting 2.

is adjusted to that of material

manufacturer’s recommended

setting.

Unit is designed only for dry, 3.

powered, and granular material.

Unit releases too much or too little

material.

Follow all safety precautions whenever diagnosing or servicing the Spreader.

Improper ow rate setting.1. Make sure Adjust Handle setting 1.

is adjusted to that of material

manufacturer’s recommended

setting.

Page 9SKU 99623 For technical questions, please call 1-800-444-3353.

Page 10

PARTS LIST

Part #

Description Qty.

Gear Box & Axle Assembly

2

REV 09b

Page 10SKU 99623 For technical questions, please call 1-800-444-3353.

Page 11

ASEMBLY DIAGRAM

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

Page 11SKU 99623 For technical questions, please call 1-800-444-3353.

Loading...

Loading...