Page 1

98751

5. This guide is not intended to replace the Manual. READ THE MANUAL.

The Nailer may not work if there are only a few nails left in the tool.

remaining nails. The Nailer will be ready for further use.

3 IN 1 AIR FRAMING NAILER START-UP GUIDE

WARNING

To prevent serious injury:

1. Even though the Nailer should be empty during the following procedure, ALWAYS point the Nailer at a

piece of scrap wood when testing.

2. Make sure Trigger and Safety Nosepiece move freely, without sticking. Do not use nailer if Trigger or

Safety sticks.

3. Disconnect the Nailer from the air compressor whenever loading or servicing.

4. WEAR ANSI-APPROVED IMPACT SAFETY GOGGLES WHEN RELOADING OR DOING ANY OTHER

MAINTENANCE ON NAILER. Other people in work area must also wear ANSI-approved safety goggles.

Testing The Safety Mechanism

1. Completely empty the Magazine.

2. The Nailer should not fire if Safety Nosepiece is not depressed against scrap wood.

3. Connect air supply to the Air Coupler. Set the regulator at the recommended 70 to 120 PSI.

4. Test by depressing Safety Nosepiece against a piece of scrap wood without pulling the Trigger.

The Nailer must not fire. If it fires, stop immediately and have the Nailer repaired by a qualified

service technician.

5. Hold tool away or off of scrap wood. The Safety Nosepiece should return to its original position.

Squeeze the Trigger. The Nailer must not fire. If the tool fires, stop immediately and have it repaired

by a qualified service technician.

6. Depress Safety Nosepiece against workpiece and squeeze Trigger. The Nailer must fire only once.

Release the Trigger and squeeze it again. The Nailer must not fire.

With the Trigger held, carefully lift the Nailer and press it against the workpiece again.

The Nailer must not fire. If it fails to perform in the manner explained in bold, have the Nailer

repaired by a qualified service technician.

Loading Nails

1. Slide the Tab back and the Lock will hold it in place.

2. Load a stick of nails (not included) into the top slot,

making sure nail heads are facing up.

Tab

CAUTION

To prevent injury when releasing the Lock, KEEP FINGERS CLEAR OF TAB TRACK.

Tab automatically and forcefully slides forward. PINCH HAZARD.

NOTICE

If there are only a few nails remaining, simply load another strip of nails into the Magazine behind the few

Page 1

Page 2

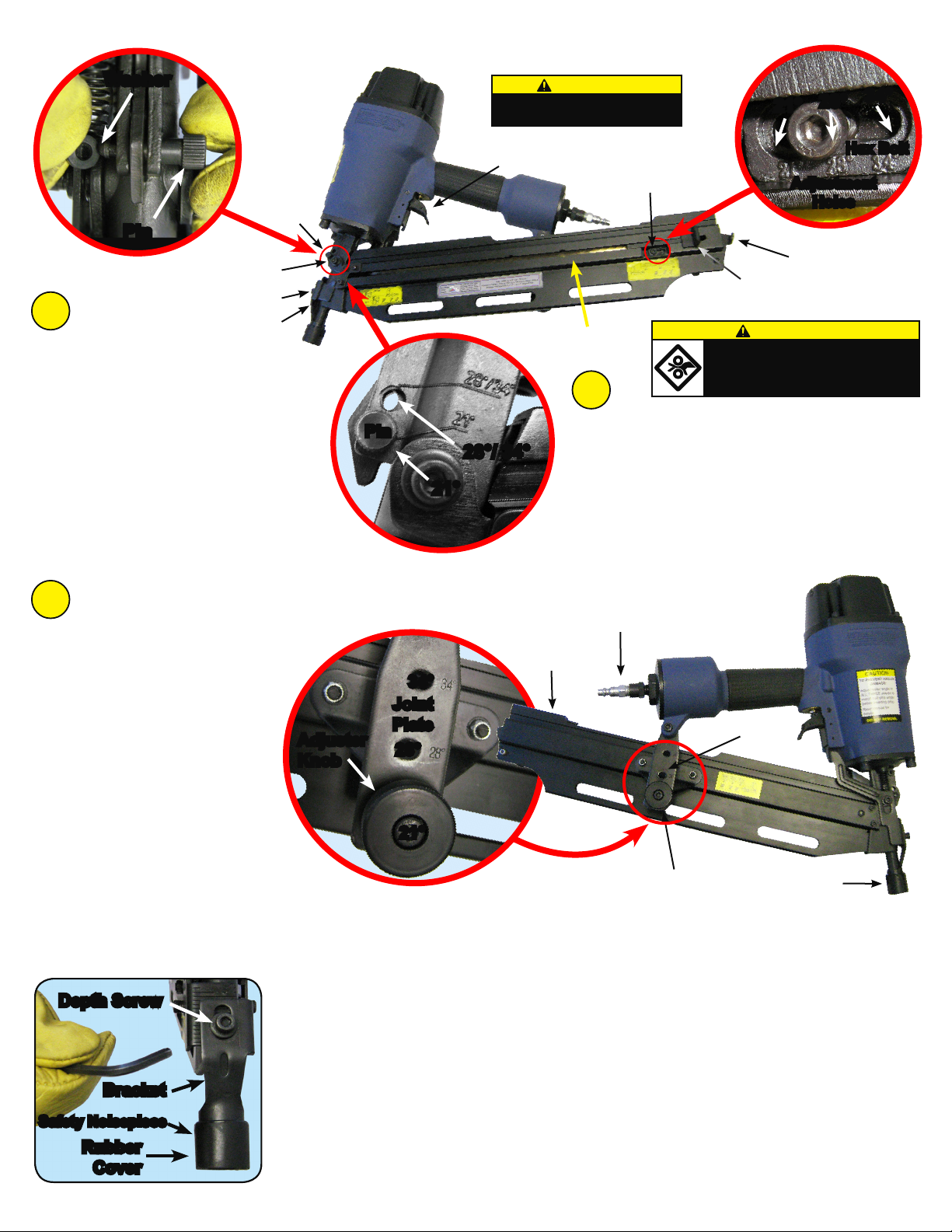

3 STEPS TO SET NAILER ANGLE

Washer

Pin

Pin

Bar Guide

Depth Screw

1

Inspect Pin’s location.

When driving 21° angle nails,

the Pin should be in the lower hole

as shown to the right.

When driving 28° or 34° angle nails,

place the Pin in the upper hole.

If the Pin is in the wrong position, pull

the Pin from its Washer, reposition the

Bar Guide, and reinsert and secure the

Pin and Washer as shown above. Before

using Nailer, be sure Pin is properly secured.

Bracket

Pin

3

Remove the Adjuster Knob.

Move the Magazine until the

desired hole on the Joint Plate

lines up with the nut on the

Magazine. Replace and tighten

the Adjuster Knob.

Adjuster

Knob

34°

Joint

Plate

28°

21°

CAUTION

To prevent injury, disconnect the air

supply before making adjustments.

Trigger

Tab Track

2

Pull back and engage the Tab, exposing

28°/ 34°

Magazine

three adjustment holes. Loosen the hex bolt

and slide it into the appropriate hole (21°, 28°,

34°). Retighten the hex bolt securely, making

sure it fits into the appropriate hole properly.

When done, carefully release Lock while

guiding the Tab towards the front with your

hand.

Air Coupler

Hex Bolt

34°

28°

21°

Hex Bolt

Adjustment

Holes

Lock

Tab

CAUTION

To prevent injury when releasing the Lock,

KEEP FINGERS CLEAR OF TAB TRACK.

Tab automatically slides quickly forward.

PINCH HAZARD.

Joint

Plate

The driving depth of a nail can

be adjusted in two ways.

First, by increasing or decreasing

air pressure (never to exceed the

maximum of 120 PSI).

Second, by loosening the Depth Screw

and adjusting the Bracket as shown below.

Experiment on a scrap piece of material to determine how far to adjust the unit.

Put on ANSI-approved goggles and attach air supply to the Air Coupler.

Depth Screw

Bracket

Safety Noisepiece

Rubber

Cover

Start your air compressor and set between 70-120 PSI.

To fire, place the Safety Nosepiece of the Nailer on the workpiece. The Nailer

should not fire if the Safety Nosepiece is not depressed. Once depressed, quickly

squeeze the Trigger once.

Do not fire repeatedly; nails could bounce off of one another causing injury.

We recommend practicing with a piece of scrap material.

The Rubber Cover provides a non-marring surface.

If desired, the Rubber Cover may be removed to expose the teeth on Safety

Nosepiece. Doing so provides a nonslip surface and can improve accuracy.

When finished, disconnect the Nailer from the air source.

21°

SafetyAdjuster Knob

Page 2

Loading...

Loading...