Page 1

13” PLANER

WITH DUST COLLECTOR

98524

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial

number in the back of the manual near the

assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and

dry place for future reference.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

General Power Tool Safety

Warnings

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

WARNING Read all safety

warnings and instructions.

Failure to follow the warnings and

instructions may result in electric

shock, re and/or serious injury.

Save all warnings and

instructions for future reference.

The term ″power tool″ in the

warnings refers to your mains-

operated (corded) power tool.

Work area safety1.

Keep work area clean and well lit. a.

Cluttered or dark areas invite acci-

dents.

Do not operate power tools in b.

explosive atmospheres, such as in

the presence of ammable liquids,

gases or dust. Power tools create

sparks which may ignite the dust or

fumes.

Keep children and bystanders c.

away while operating a power tool.

Distractions can cause you to lose

control.

Electrical safety2.

Power tool plugs must match the a.

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with grounded power tools.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 2

Page 3

Unmodied plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with grounded b.

surfaces such as pipes, radiators,

ranges and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

Do not expose power tools to rain c.

or wet conditions. Water entering

a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use d.

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts. Damaged

or entangled cords increase the risk

of electric shock.

When operating a power tool out-e.

doors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the

risk of electric shock.

If operating a power tool in a damp f.

location is unavoidable, use a

Ground Fault Circuit Interrupter

(GFCI) protected supply. Use of

a GFCI reduces the risk of electric

shock.

Personal safety3.

Stay alert, watch what you are do-a.

ing and use common sense when

operating a power tool. Do not use

a power tool while you are tired

or under the inuence of drugs,

alcohol or medication. A moment

of inattention while operating power

tools may result in serious personal

injury.

Use personal protective equip-b.

ment. Always wear ANSI-approved

eye protection. Safety equipment

such as dust mask, non-skid safety

shoes, hard hat, or hearing protection

used for appropriate conditions will

reduce personal injuries.

Prevent unintentional starting. c.

Ensure the switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carry-

ing power tools with your nger on

the switch or energizing power tools

that have the switch on invites acci-

dents.

Remove any adjusting key or d.

wrench before turning the power

tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

Do not overreach. Keep proper e.

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

Dress properly. Do not wear loose f.

clothing or jewelry. Keep your

hair, clothing and gloves away

from moving parts. Loose clothes,

jewelry or long hair can be caught in

moving parts.

If devices are provided for the con-g.

nection of dust extraction and collection facilities, ensure these are

connected and properly used. Use

of these devices can reduce dust-

related hazards.

Only use safety equipment that h.

has been approved by an appropriate standards agency. Unapproved

safety equipment may not provide

adequate protection. Eye protection

must be ANSI-approved and breathing protection must be NIOSH-approved for the specic hazards in the

work area.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 3

Page 4

Power tool use and care4.

Do not force the power tool. Use a.

the correct power tool for your application. The correct power tool will

do the job better and safer at the rate

for which it was designed.

Do not use the power tool if the b.

switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

Disconnect the plug from the c.

power source and/or the battery

pack from the power tool before

making any adjustments, changing accessories, or storing power

tools. Such preventive safety mea-

sures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the d.

reach of children and do not allow

persons unfamiliar with the power

tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained

users.

Maintain power tools. Check for e.

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are

caused by poorly maintained power

tools.

Keep cutting tools sharp and f.

clean. Properly maintained cutting

tools with sharp cutting edges are

less likely to bind and are easier to

control.

Use the power tool, accessories g.

and tool bits etc. in accordance

with these instructions, taking into

account the working conditions

and the work to be performed. Use

of the power tool for operations different from those intended could result

in a hazardous situation.

Service5.

Have your power tool serviced by a.

a qualied repair person using

only identical replacement parts.

This will ensure that the safety of the

power tool is maintained.

Specic Safety Warnings

Always wear ANSI-approved safety 1.

impact eye goggles and heavy-duty work gloves when using Planer.

Using personal safety devices reduce

the risk for injury. Safety impact eye

goggles and heavy work gloves are

available from Harbor Freight Tools.

Dust mask, non skid safety shoes,

hard hat, or hearing protection must

be used for appropriate conditions.

Use a platform, or other practical 2.

way, to support a long workpiece

as it enters the Planer. Holding the

work by hand or against your body

is unstable and may lead to loss of

control.

Avoid unintentional starting. 3. Make

sure you are prepared to begin work

before turning on the Planer.

Do not force the Planer. 4. This tool

will do the work better and safer at

the speed and capacity for which it

was designed.

Always unplug the Planer from its 5.

electrical outlet before changing

blades or performing any inspection, maintenance, or cleaning

procedures.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 4

Page 5

Never leave the Planer unattended 6.

while running. Turn power off if you

have to leave the Planer.

Turn off Planer when jammed.7.

Before each use, check all nuts, 8.

bolts, and screws for tightness.

Keep extension cord off the 9.

ground and away from water.

Install this product on a proper 10.

surface. Locate on a at, level, and

solid surface that is capable of supporting the weight of the Planer and

the stock being planed.

Maintain labels and nameplates 11.

on the tool. These carry important

safety information. If unreadable or

missing, contact Harbor Freight Tools

for a replacement.

This product is not a toy.12. Keep it

out of reach of children.

People with pacemakers should 13.

consult their physician(s) before

use. Electromagnetic elds in close

proximity to heart pacemaker could

cause pacemaker interference or

pacemaker failure. In addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with power switch locked

on.

• Properly maintain and inspect to

avoid electrical shock.

• Any power cord must be properly

grounded. Ground Fault Circuit Interrupter (GFCI) should also be implemented – it prevents sustained electrical shock.

contains chemicals known [to the

State of California] to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement or other masonry products

• Arsenic and chromium from chemi-

cally treated lumber

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your

exposure to these chemicals: work in

a well ventilated area, and work with

approved safety equipment, such as

those dust masks that are specially

designed to lter out microscopic

particles. (California Health & Safety

Code § 25249.5, et seq.)

The warnings, precautions, and 15.

instructions discussed in this instruction manual cannot cover all

possible conditions and situations

that may occur. It must be under-

stood by the operator that common

sense and caution are factors which

cannot be built into this product, but

must be supplied by the operator.

SAVE THESE

INSTRUCTIONS.

Some dust created by power sand-14.

ing, sawing, grinding, drilling,

and other construction activities,

SKU 98524 For technical questions, please call 1-800-444-3353. Page 5

Page 6

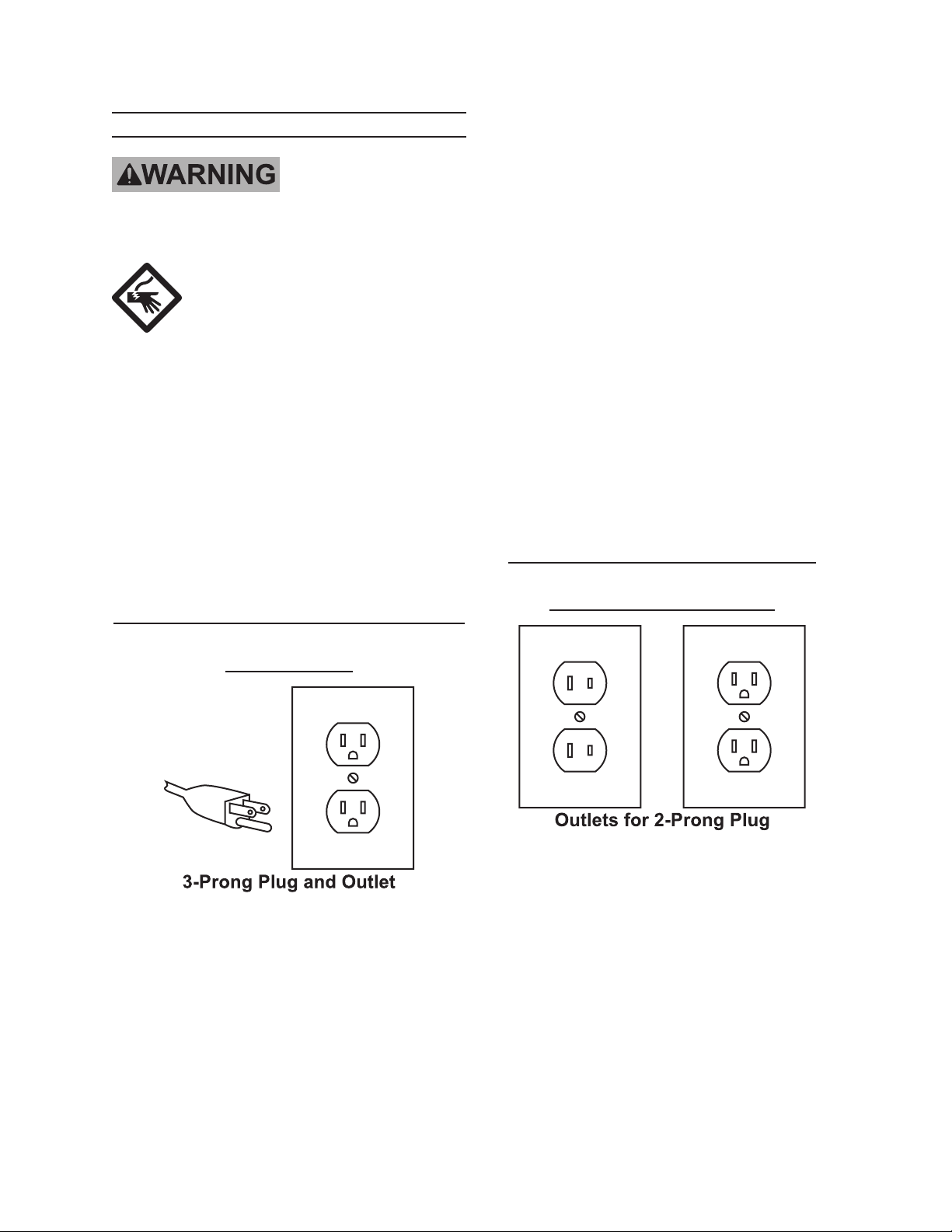

GROUNDING

TO PREVENT

ELECTRIC SHOCK

AND DEATH FROM

INCORRECT GROUNDING

WIRE CONNECTION:

Check with a qualied

electrician if you are in doubt

as to whether the outlet is

properly grounded. Do not

modify the power cord plug

provided with the tool. Never

remove the grounding prong

from the plug. Do not use the

tool if the power cord or plug

is damaged. If damaged, have

it repaired by a service facility

before use. If the plug will not

t the outlet, have a proper

outlet installed by a qualied

electrician.

of electric shock. (See 3-Prong Plug

and Outlet.)

The grounding prong in the plug is 2.

connected through the green wire inside the cord to the grounding system

in the tool. The green wire in the cord

must be the only wire connected to

the tool’s grounding system and must

never be attached to an electrically

“live” terminal. (See 3-Prong Plug

and Outlet.)

The tool must be plugged into an 3.

appropriate outlet, properly installed

and grounded in accordance with all

codes and ordinances. The plug and

outlet should look like those in the

preceding illustration. (See 3-Prong

Plug and Outlet.)

Double Insulated Tools: Tools

with Two Prong Plugs

Grounded Tools: Tools with Three

Prong Plugs

Tools marked with “Grounding Re-1.

quired” have a three wire cord and

three prong grounding plug. The

plug must be connected to a properly

grounded outlet. If the tool should

electrically malfunction or break

down, grounding provides a low

resistance path to carry electricity

away from the user, reducing the risk

Tools marked “Double Insulated” do 1.

not require grounding. They have

a special double insulation system

which satises OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Outlets for 2-Prong

Plug.)

SKU 98524 For technical questions, please call 1-800-444-3353. Page 6

Page 7

Double insulated tools may be used 2.

in either of the 120 volt outlets shown

in the preceding illustration. (See

Outlets for 2-Prong Plug.)

Extension Cords

Grounded1. tools require a three wire

extension cord. Double Insulated

tools can use either a two or three

wire extension cord.

As the distance from the supply outlet 2.

increases, you must use a heavier

gauge extension cord. Using extension cords with inadequately sized

wire causes a serious drop in voltage,

resulting in loss of power and possible tool damage.

(See Table A.)

The smaller the gauge number of the 3.

wire, the greater the capacity of the

cord. For example, a 14 gauge cord

can carry a higher current than a 16

gauge cord. (See Table A.)

dition. Always replace a damaged

extension cord or have it repaired by

a qualied electrician before using it.

Protect the extension cords from 8.

sharp objects, excessive heat, and

damp or wet areas.

RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS*

(120/240 VOLT)

EXTENSION CORD

NAMEPLATE

LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

TABLE A

25’

50’

75’

100’

* Based on limiting the line

voltage drop to ve volts at

150% of the rated amperes.

150’

When using more than one exten-4.

sion cord to make up the total length,

make sure each cord contains at

least the minimum wire size required.

(See Table A.)

If you are using one extension cord 5.

for more than one tool, add the

nameplate amperes and use the sum

to determine the required minimum

cord size. (See Table A.)

If you are using an extension cord 6.

outdoors, make sure it is marked with

the sufx “W-A” (“W” in Canada) to

indicate it is acceptable for outdoor

use.

Make sure the extension cord is prop-7.

erly wired and in good electrical con-

V~

A

n0 xxxx/min.

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

Volts Alternating Current

Amperes

No Load Revolutions per Minute

(RPM)

SKU 98524 For technical questions, please call 1-800-444-3353. Page 7

Page 8

SPECIFICATIONS

Electrical Requirements 120 V~ / 60 Hz / 15 A

Motor (Cutter head)

Speed

Maximum Cutting Depth 3/32”

Stock Capacity 13” W x 6” H

Cutting Blades Two 13-1/8” L

Feed Speed 23 Feet per Minute

Dust Port Opening 2-3/16” I.D.

Included Accessories

8,000 RPM, 16,000

cuts per minute

1 Hex Wrench (4mm)

2 Magnets

1 Dust Bag

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Assembly

Select an area with enough room to 1.

t the chosen dust collection system.

Select a workbench to mount the

Planer. Place the Planer on a workbench able to support the weight of

the Planer and the wood stock being

planed. The orientation of the Planer

should enable the easy entry and exit

of long pieces of wood stock.

Using a pencil, mark through the 2.

mounting holes of the Planer, onto

the workbench. Slide the Planer

aside and drill four 3/8 inch mounting

holes into the workbench.

INSTRUCTIONS FOR

PUTTING INTO USE

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn the Power Switch of the

tool to its “OFF” position and

unplug the tool from its

electrical outlet before

assembling or making any

adjustments to the tool.

Before drilling, verify that there are no utility

wires or other obstructions under

the workbench.

Slide the Planer back over the mount-3.

ing holes in the workbench, and secure the Planer to the workbench with

bolts, washers, spring washers and

nuts (not included). Securely tighten.

Handle (4)

Head

Screw (1)

SKU 98524 For technical questions, please call 1-800-444-3353. Page 8

Page 9

Mount the Elevating Handle (4) on 4.

top of the unit on the right or left side

with Flat Washer (2) and Head Screw

(1), as shown above. Place the Cap

(9) on the other side.

creating a tripping hazard or exposing

the power cord to possible damage.

The power cord must reach the work

area with enough extra length to allow free movement while working.

The Filter Bag (27.6) of the dust col-5.

lection system has an open bottom.

The open bottom should be connected to a thirty gallon plastic bag or

garbage can (neither included) using

the Connector (27.8) and fasten with

the Pin (27.7).

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Tool Set Up

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn the Power Switch of the

tool to its “OFF” position and

unplug the tool from its

electrical outlet before

performing any inspection,

maintenance, or cleaning

procedures.

There must not be hazardous ob-3.

jects, such as utility lines or foreign

objects, nearby that will present a

hazard while working.

General Operating Instructions

Lower the Table Support (221) and 1.

the Extension Table (222).

The Adjustment Knob on top of the 2.

Planer is used to adjust the depth of

cut. Recommended depth of cut is

as follows:

Wood up to 6” wide: 3/32”

Wood over 6” wide: 1/16”

The depth of the cut is read on the •

meter above the cutting area on the

front of the Planer.

The pre-set Thickness Knob can be 3.

adjusted to set to the maximum thickness desired; 1/8”, 1/4”, 1/2”, 3/4”, 1”

or 1-1/4”. See below.

Work Piece and Work Area Set Up

Designate a work area that is clean 1.

and well-lit. The work area must not

allow access by children or pets to

prevent injury and distraction.

Route the power cord along a safe 2.

route to reach the work area without

SKU 98524 For technical questions, please call 1-800-444-3353. Page 9

The Planer can be locked to ensure 4.

an even cut by pulling the handle

Page 10

of the Lock Lever (49) down. See

below.

become a projectile. Do not plane

boards that have foreign objects

(nails, staples, etc.) in them.

Do not plane material:7.

Handle of Lock

Lever (49)

5. The Handle (75) can be used to vary

the depth or shallowness of cut beyond the pre-set Thickness Knob.

Handle

(75)

On/off Lock

Switch

shorter than 15”, •

narrower than 3/4”, •

wider than 13”, •

or thinner than 1/8”•

Push the On/Off Lock switch down to 8.

turn the Planer on. Allow the planer

to come up to full speed before beginning a job.

The planer has a maximum depth 9.

cut of 3/32” per pass. The Planer will

operate best when the depth of cut is

less than 1/16”. It is recommended to

make a series of shallow cuts rather

than a single deep cut.

Note: Always keep the boards being

planed level. Support long boards at

both ends.

Circuit

Reset

6. Plug the Planer into a grounded,

120V electrical outlet.

Note: Do not stand behind the end of the

board during planing. Plane dry,

unwarped, clean boards only. Avoid

planing boards that have knots;

loose knots can jam the machine or

Plane along the grain of the wood.10.

Plane alternating sides of the 11.

board until the desired thickness is

achieved.

When planing multiple boards to the 12.

same thickness place the ends so

they are touching (butting) for best

results.

An assistant can return the boards to 13.

the operator using the Rollers (13) on

top of the Planer.

If the Planer turns off unexpectedly 14.

during operation; turn the Planer off

and unplug it from the electrical out

let. Refer to the “Troubleshooting

Section” of this manual for possible

reasons. If the Circuit Breaker has

SKU 98524 For technical questions, please call 1-800-444-3353. Page 10

Page 11

tripped, remove any materials from

the Planer and push the Circuit Reset

button.

To prevent accidents, turn off the tool 15.

and disconnect its power supply after

use. Clean, then store the tool indoors out of children’s reach.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 11

Page 12

MAINTENANCE AND

SERVICING

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Turn the Power Switch of the

tool to its “OFF” position and

unplug the tool from its

electrical outlet before

performing any inspection,

maintenance, or cleaning

procedures.

TO PREVENT SERIOUS

INJURY FROM TOOL

FAILURE:

Do not use damaged

equipment. If abnormal noise

or vibration occurs, have the

problem corrected before

further use.

Cleaning, Maintenance, and

Lubrication

BEFORE EACH USE,1. inspect the

general condition of the tool. Check

for loose screws, misalignment or

binding of moving parts, cracked or

broken parts, damaged electrical wiring, and any other condition that may

affect its safe operation.

AFTER USE,2. clean external surfaces

of the tool with clean cloth.

PERIODICALLY, 3. blow the interior of

the Planer out with compressed air

and lubricate moving parts with white

lithium grease.

CARBON BRUSH MAINTENANCE.4.

The carbon brushes may require

maintenance when the motor performance of the tool decreases or stops

working completely. To maintain the

brushes:

Remove the brush caps on the front a.

and back of the motor housing.

Remove the carbon brushes from b.

the housing. Keep track of which

orientation the old carbon brushes were in to prevent needless

wear if they will be reinstalled.

If either carbon brush is worn down c.

by more than 1/2, replace both carbon brushes.

To clean old carbon brushes before d.

reusing them, rub the contact areas

with a pencil eraser.

Reinsert the old carbon brushes in e.

the same orientation to reduce wear.

When installing the carbon brushes, f.

make sure the carbon portions of the

carbon brushes contact the motor

armature, and that the springs face

away from the motor. Also, make

sure the springs operate freely.

Replace the brush caps. Do not g.

overtighten.

Note: New carbon brushes tend to spark

when rst used until they wear and

conform to the motor’s armature.

BLADE MAINTENANCE. 5.

When cutting ability deteriorates or

the planed surface starts to get uneven or rough, the blades will have to

be replaced.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 12

Page 13

Use the included Hex Wrench to 6.

remove both Hex Bolts on the back of

the blade case.

Blade Cover

Hex Bolts

(19, 21)

7. Remove the Blade Cover.

Wearing work gloves, rotate the cut-8.

ter head until the latch engages.

Remove the six bolts (172) from the 9.

Cutter Head (168) and use the magnets to remove it.

Replace the cover. Secure all hard-15.

ware.

ADJUST ROLLER CASE LEVEL. 16.

If the Roller Case (151) is not parallel to the base (212), the planer will

produce cuts of uneven depth.

Use a test piece to measure the 17.

height of the taper.

Turn the Planer off and disconnect it 18.

from the power supply.

Fold both Extension Tables up and 19.

lay the planer on its back.

Loosen the two Head Screws (226, 20.

232). Loosen the Chain (231) by sliding the Idler Bracket (224).

Rotate the Elevation Screws (211) to 21.

correct the orientation of the Roller

Case to Base. Each turn of the

screw will move the Roller Case by

1/16”.

REPLACING THE V-BELT. 22.

Remove the Elevating Handle (4).

Use the magnets to remove the 10.

Blade (171) from the pins that hold it

in place.

Using the magnets, put a new blade 11.

Remove the four Head Screws (15) 23.

from the Upper Cover (10). Remove

the Upper Cover.

Remove the right side cover.24.

onto the pins.

Remove the V-Belts (61, 186) from 25.

Replace the Cutter Head and secure 12.

it.

the Pulleys (188 & 189, 60 & 184)

and replace with new belts. Always

change both belts at the same time.

Push down on the latch to release the 13.

cutter head.

Rotate the cutter head until it latches 14.

in place and replace the other blade

as instructed above.

Reassemble the Planer.26.

27. WARNING! If the supply cord of

this power tool is damaged, it must

be replaced only by a qualied

service technician.

Note: Always replace both blades at the

same time.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 13

Page 14

Troubleshooting

Problem Possible Causes Likely Solutions

Tool will not start No power at outlet.1.

Cord not connected.2.

Gouging at ends of

board (snipe)

Grain is ragged Wood has a high moisture 1.

Torn grain Cut is too heavy.1.

Rough, raised

grain

Uneven side-toside depth of cut

Roller case

adjustment difcult

Board feeds in,

but will not move

through.

Board thickness

does not match

depth of cut scale.

Chain jumping Sprockets worn.1.

Belt Slipping Belt is loose.1. Replace belt.1.

Roller case will not

lower

Excessive dust in

air

Fan very loud Debris caught in fan.1.

Dull Blades.1.

Too little support of long 2.

boards.

Uneven force on cutter head. 3.

Roller case not level with base.4.

Lumber not butted properly.5.

content.

Blades cutting against grain.2.

Dull blades.3.

Dull blades.1.

Cut is too heavy.2.

Moisture content is too high.3.

Roller case not level with 1.

planer base.

Sprockets or chain dirty.1.

Elevation screws or columns 2.

dirty.

Elevation screws worn.3.

Friction between roller case 4.

and covers.

Roller case not parallel.5.

Roller case lock engaged.6.

Out feed rollers are clogged.1.

Too much pressure on cutter 2.

head from long board.

Indicator not set correctly.1. Have indicator repaired by a qualied 1.

Chain worn.2.

Thickness gauge setting 1.

restricts roller case.

Leaking bag or hose 1.

connection.

Fan is loose.2.

Check power at outlet.1.

Check that cord is plugged in.2.

Replace blades.1.

Provide better support for long blades. 2.

Adjust board when it is in contact with only 3.

one feed roller.

Adjust roller case.4.

Butt each end of stock together evenly.5.

Dry the wood.1.

Reduce depth of cut.1.

Cut boards along grain.2.

Replace blades.3.

Replace blades.1.

Reduce depth of cut.2.

Dry the wood.3.

Adjust so that roller case is level.1.

Clean and lubricate sprockets and chain.1.

Clean and lubricate elevation screws and 2.

columns.

Replace elevation screws.3.

Clean and lubricate roller case and cover. 4.

Adjust roller case.5.

Release roller case lock.6.

Clean Planer.1.

Use supports to hold workpiece up.2.

technician.

Have sprockets replaced.1.

Have chain replaced.2.

Reset thickness gauge.1.

Check connections or replace collection bag.1.

Remove debris.1.

Tighten hardware on fan.2.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect power supply before service.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 14

Page 15

Troubleshooting

Problem Possible Causes Likely Solutions

Motor overheats Motor overloaded.1.

Circuit breaker or

fuse keeps tripping

Motor not cooling right.2.

Motor overloaded.1.

Wrong circuit breaker or fuse.2.

Dull blades.3.

Reduce depth of cut1.

Clean sawdust from Planer.2.

Reduce depth of cut.1.

Use correct circuit breaker or fuse.2.

Replace blades.3.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect power supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 15

Page 16

PARTS LIST

PARTS LIST

PARTS LIST

Part Description Qty

1 Head Screw

(20mm)

2 Flat Washer

(6mm)

4 Elevating Handle 1

5 Label 1

6 Handle Cap 1

7 Handle Bolt 1

8 Handle Base 1

9 Cap 1

10 Upper Cover 1

11 Clevis Pin 4

12 Bushing 4

13 Roller 2

15 Head Screw

(16mm)

16 Grip 2

17 Screw (6mm) 4

18 Air Guide 1

19 Head Screw

(10mm)

20 Dust Guard 1

21 Screw (5mm) 3

22 Head Screw

(10mm)

23 Dust Chute Panel 1

24 Head Screw

(10mm)

25 Fan Cover 1

26 Head Screw

(25mm)

27 Dust Chute 1

27.1 Hex Nut (10mm) 1

27.2 Collar 1

27.3 Pin 1

27.4 Clamp 1

27.5 Eye Bolt (50mm) 1

27.6 Filter Bag 1

27.7 Pin 3

27.8 Connector 3

44 Hex Nut (1.25mm) 1

45 Spring Washer

(8mm)

46 Cam (Left) 1

47 Retainer Ring 2

48 Spring Pin

(12mm)

49 Lock Lever 1

50 Spring 1

51 Lock Lever Cap 1

1

1

4

2

3

2

1

1

2

Part Description Qty

52 Head Screw

(12mm)

53 Flat Washer

(6mm)

54 Fan 1

55 Fan Shaft 1

56 Bearing 2

57 Spacer 1

58 Deector Cover 1

59 Set Screw (6mm) 1

60 Fan Pulley 1

61 Belt 1

62 Rod 4

63 Spring 4

64 Pad 4

65 Cam (Right) 1

66 Spring Washer 1

67 Hex Nut (1.25mm) 1

68 Bushing 1

69 Guide Rod 1

70 Retainer Ring 1

71 Head Screw

(10mm)

72 Bushing 1

73 Bracket 1

74 Handle Grip 1

75 Handle 1

76 Retainer Ring 3

77 Set Screw (6mm) 1

78 Guide Bracket 1

79 Set Screw (6mm) 1

80 Sliding Bar 1

81 Head Screw

(12mm)

82 Bearing 1

83 Bearing Retainer 1

84 Spindle Washer 1

85 Sprocket 1

86 Washer (4mm) 1

87 Socket Head

Screw (10mm)

88 Spring 2

88A Spindle Washer 2

89 Head Screw

(30mm)

90 Guide Rod 1

91 Gear 2

92 Transmission Seat 1

93 Bearing 1

94 Gear 1

95 Spring Holder 4

1

1

2

2

1

2

Part Description Qty

96 Spring 3

96A Spring 1

97 Steel Ball 4

98 Bushing 4

99 Transmission

Collar

100 Head Screw

(16mm)

101 Holder 1

102 Retainer Ring 1

103 Chain 1

104 Sprocket 1

105 Head Screw

(20mm)

106 Flat Washer 1

107 Spring 1

108 Tension Wheel

Assembly

109 Spacer 1

110 Head Screw

(30mm)

111 Head Screw

(35mm)

112 Outside Cover 1

113 Bearing 1

114 Shaft 1

114a Key (20mm) 1

115 Gear

(Intermediate)

116 Gear (Large) 1

117 Spacer 2

118 Inside Cover 1

119 Pinion Gear 1

120 6202 Bearing 1

122 Gear (Small) 1

123 Bushing 5

124 Spacer Undercut 4

125 Nut 1

126 Set Screw (6mm) 1

127 Elevating Nut (L) 1

128 Head Screw

(10mm)

129 Set Plate 1

130 Head Screw

(14mm)

131 Head Screw

(10mm)

132 Cable Clamp 1

133 Head Screw

(10mm)

134 Belt Guard 1

1

2

1

1

2

4

1

2

2

1

2

SKU 98524 For technical questions, please call 1-800-444-3353. Page 16

Page 17

PARTS LIST

PARTS LIST

PARTS LIST

Part Description Qty

135 Screw 1

136 Elevating Nut (R) 1

137 Hex Screw

(16mm)

138 Hex Nut (8mm) 4

139 Tap Screw (8mm) 2

140 Tooth Washer 2

141 Cover 1

142 Head Screw

(10mm)

143 Pointer Cover 1

144 Head Screw

(14mm)

145 Spring 1

146 Pointer 1

147 Bushing 2

148 Head Screw

(8mm)

149 Pointer Housing 1

150 Nut 1

151 Roller Case 1

151.1 Motor 1

151.2 Gasket 1

151.3 Cap 1

151.4 Head Screw

(6mm)

151.5 Flat Washer 2

151.6 Pointer 1

152 Steel Ball 1

153 Retaining Plate 1

154 Tap Screw (6mm) 2

155 Magnet 4

156 Magnet Seat 4

157 Head Screw

(10mm)

158 Hex Nut (5mm) 1

159 Step Rod 1

160 Hex Nut (8mm) 1

161 Head Screw

(16mm)

162 Flat Washer 1

163 Head Screw

(25mm)

164 Press Line Plate 1

165 Head Screw

(10mm)

166 Flat Washer 1

167 Head Screw

(10mm)

168 Cutter Head 1

169 Key (12mm) 1

170 Blade 2

4

2

1

2

2

4

1

1

1

1

Part Description Qty

171 Blade Lock Bar 2

172 Head Screw

(16mm)

173 Cutter Head Pin 4

174 Spring 4

175 Bearing Retainer 1

176 Bearing 1

177 Bearing Cover 1

178 Head Screw

(12mm)

179 Spring 1

180 Cutter Head Lock 1

181 Lock Spacer 1

182 Head Screw

(10mm)

184 Cutter Head

Pulley

185 Hex Nut 1

186 Belt 1

187 Set Screw (6mm) 1

188 Cutter Head

Extend Pulley

189 Motor Pulley 1

190 Spring (Outfeed) 2

191 Roller 2

192 Spring (Infeed) 2

193 Retainer Ring 2

194 Sprocket 2

195 Bearing Block 4

196 Retainer 4

197 Head Screw

(10mm)

198 Side Cover (L) 1

200 Thread Forming

Screw (30mm)

201 Line Knob 2

203 Hex Wrench 1

204 Magnet 2

205 Plate 1

206 Guide 2

207 Head Screw

(10mm)

208 Retainer Ring 2

209 Column 2

210 Column 2

211 Elevating Screw 2

212 Base 1

213 Hex Nut (1.75mm) 4

214 Head Screw

(20mm)

215 Hex Nut 4

12

3

1

1

1

8

4

8

4

Part Description Qty

220 Head Screw

(6mm)

220.1 Flat Washer 8

221 Table Support 2

222 Extension Table 2

223 Roller Plate

(Right)

224 Idler Bracket 1

225 Flat Washer 2

226 Head Screw

(12mm)

227 Sprocket 1

228 Spacer 1

229 Flat Washer 1

230 Head Screw

(20mm)

231 Chain 1

232 Head Screw

(10mm)

233 Bearing 2

234 Bearing Retainer 2

235 Spindle Washer 2

236 Sprocket 2

237 Washer 2

238 Head Screw

(12mm)

239 Hex Nut 4

240 Adjust Screw 4

241 Retainer Ring 1

242 Step Bracket 1

243 Step 1

244 Shaft 1

245 Head Screw

(16mm)

246 Steel Ball 1

247 Spring 1

248 Set Screw (6mm) 1

249 Spring Pin 1

250 Side Cover (R) 1

251 Height Adjustment

Knob

252 Spring Washer 4

8

2

2

1

4

2

2

1

SKU 98524 For technical questions, please call 1-800-444-3353. Page 17

Page 18

ASSEMBLY DIAGRAM

Diagram continued next page

SKU 98524 For technical questions, please call 1-800-444-3353. Page 18

Page 19

ASSEMBLY DIAGRAM, CONTINUED

Base of Planer

SKU 98524 For technical questions, please call 1-800-444-3353. Page 19

Page 20

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from

the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from the use of our product. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection veries the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect

resulted from causes not within the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

SKU 98524 For technical questions, please call 1-800-444-3353. Page 20

Loading...

Loading...