Page 1

1/4 HP SUBMERSIBLE

WATER PUMP

98342

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

Before start-up, note the following:

The pump can be connected to any

shock-proof plug which has been installed

according to regulations. The plug must

have a supply voltage of 115 V~ at 60 Hz.

CAUTION

This pump has been evaluated for

use with water only.

Access by children should also be 8.

prevented with appropriate measures.

WARNING: Handling the Power Cord 9.

on this product will expose you to

lead, a chemical known to the State

of California to cause cancer, and

birth defects or other reproductive

harm. Wash hands after handling.

(California Health & Safety Code §

25249.5, et seq.)

WARNING

IMPORTANT! For your own safety –

before starting to run the pump, please

have the following items checked by an

expert:

Risk of electric shock – This pump is 1.

supplied with a grounding conductor

and grounding-type attachment plug.

To reduce the risk of electric shock,

connect only to a properly grounded,

grounding-type receptacle.

Risk of electric shock – This pump 2.

has not been investigated for use in

swimming pool areas.

The electrical connections must be 3.

protected from moisture.

If there is danger of ooding, the 4.

electrical connections must be taken

to higher ground.

Circulation of caustic uids, as well 5.

as the circulation of abrasive materi-

als, must be avoided at all costs.

The pump must be protected from 6.

frost.

The warnings, precautions, and in-10.

structions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

Fluid Type

The Pump is designed for use with

water with a maximum temperature of 95°

F (35°C). Do not use the pump for other

uids, especially not fuels, cleaning uids,

or other chemical products.

SPECIFICATIONS

Pump Applications

Electrical

Requirements

Power Cord 18AWG X 3C - SJTW

Maximum Capacity 1400 GPH (Approx. 23 GPM)

Maximum Delivery Height 26.3 Ft.

Discharge Size

Removes Clear Water Down to

1/8” of Surface

115 V~ / 60 Hz / 1/4 HP

2.6 A (Start) / 2.5 A (Run)

1” Pipe with 3/4”-11.5 TPI Garden

Hose Adapter

The pump must be protected from 7.

running dry.

SKU 98342 For technical questions, please call 1-800-444-3353. Page 2

Page 3

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

INSTALLATION

Make sure that the socket is suf-2.

ciently secured and is in excellent

condition.

When the plug is inserted into the 3.

socket the pump will be on standby.

WARNING! If the power cord or plug is

damaged, do not use the pump. The

power cord or plug may only be re-

paired by a certied electrician.

The submersible motor pump must

be installed in a stationary position with

either:

A xed pipeline ora.

A exible hose pipe.b.

Please note!

Do not install the pump by suspend-1.

ing it unsupported from its delivery

pipe or power cord. The pump must

be suspended from the handle or be

placed on the bottom of the shaft. To

ensure that the pump works properly,

keep the bottom of the shaft free from

sludge and dirt of all kinds.

If the water level sinks too low, any 2.

sludge in the shaft will dry out and

stop the pump from starting. To help

ensure the pump will start as re-

quired, check the pump regularly with

start-up tests.

The pump must be installed with an 3.

automatic oat switch (not included)

to prevent running dry.

Areas of use

This pump is designed for use as a 1.

basement pump. When installed in a

shaft, this pump provides some pro-

tection from basement ooding.

This pump can also be used to trans-2.

fer water (e.g. household, farming,

plumbing).

OPERATION

After reading these instructions, consider the following points before starting

the pump:

Verify that the pump rests on the oor 1.

of the shaft, if it is not suspended by

the handle.

Verify that the delivery pipe is prop-2.

erly connected.

Verify that the electrical connection is 3.

115 V~, 60 Hz.

Verify that the electrical socket is in 4.

good condition.

Power Supply

The pump is equipped with a shock-1.

proof plug according to regulations.

The pump is designed to be connected to 115 V~, 60 Hz safety socket.

SKU 98342 For technical questions, please call 1-800-444-3353. Page 3

Verify that water and moisture cannot 5.

get near the power supply socket.

Verify that the pump is installed so as 6.

to prevent running dry.

Page 4

MAINTENANCE

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Unplug the Pump from its

electrical outlet before

performing any inspection,

maintenance, or cleaning

procedures.

IMPELLER

(14)

FIGURE B

If the pump is moved during op-

eration, ush it out with clean water after

every use.

Quarterly Maintenance

The below maintenance must be performed at least once every 3 months under

optimal conditions. For frequent use, or

dirty areas, more frequent maintenance is

required.

Clean sludge and debris from the bot-1.

tom of the shaft.

Rinse the housing off with clean wa-2.

ter.

Clean bers from inside the pump 3.

housing with a pressure washer (not

included).

FILTER

(11)

a. Remove the Filter (11) from the

pump case.

Clean the impeller with clean water.b.

To prevent damage, do not rest the c.

pump on the impeller or pry against

the impeller.

Reassemble in reverse order.d.

If the pump housing cannot be 4.

cleaned from the outside, it must be

thoroughly cleaned. Make sure the

power cord is unplugged before

maintenance. Dismantle the bottom

part of the pump as follows:

SKU 98342 For technical questions, please call 1-800-444-3353. Page 4

Page 5

Troubleshooting

Problem Possible Causes Possible Solutions

Pump runs, but

will not deliver any

water.

Pump won’t start

or run.

Excessive noise or

vibration.

Pump starts

and stops too

frequently.

Filter and/or impeller clogged.1.

When starting, the pump water 2.

height (1/8”) falls below the

minimum water level.

Low line voltage.3.

Optional check valve stuck or 4.

installed backwards.

Check power connections and 1.

circuits/fuses.

Water level too low.2.

Filter and/or impeller clogged.3.

Defective motor.4.

Worn bearings.1.

Debris in impeller.2.

Discharge garden hose 3.

restricted.

Water temperature too high.1.

Back ow of water from 2.

discharge garden hose.

Remove lter. Clean out dirt and debris from 1.

lter and impeller. Then replace Filter.

There must be at least 1/8” deep water for the 2.

Pump to operate properly.

Consult with an electrician.3.

Remove and examine check valve.4.

Consult with an electrician.1.

Allow water level to rise above 1/8”, or move 2.

Pump to a lower location.

Remove lter. Clean out dirt and debris from 3.

lter and impeller. Then replace lter.

Have a qualied service technician repair or 4.

replace.

Have a qualied service technician repair or 1.

replace.

Remove lter. Clean impeller. Then replace 2.

lter.

Clean Pump and discharge garden hose.3.

Do not exceed temperatures above 95° 1.

Fahrenheit.

Install or inspect optional check valve.2.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect power supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 98342 For technical questions, please call 1-800-444-3353. Page 5

Page 6

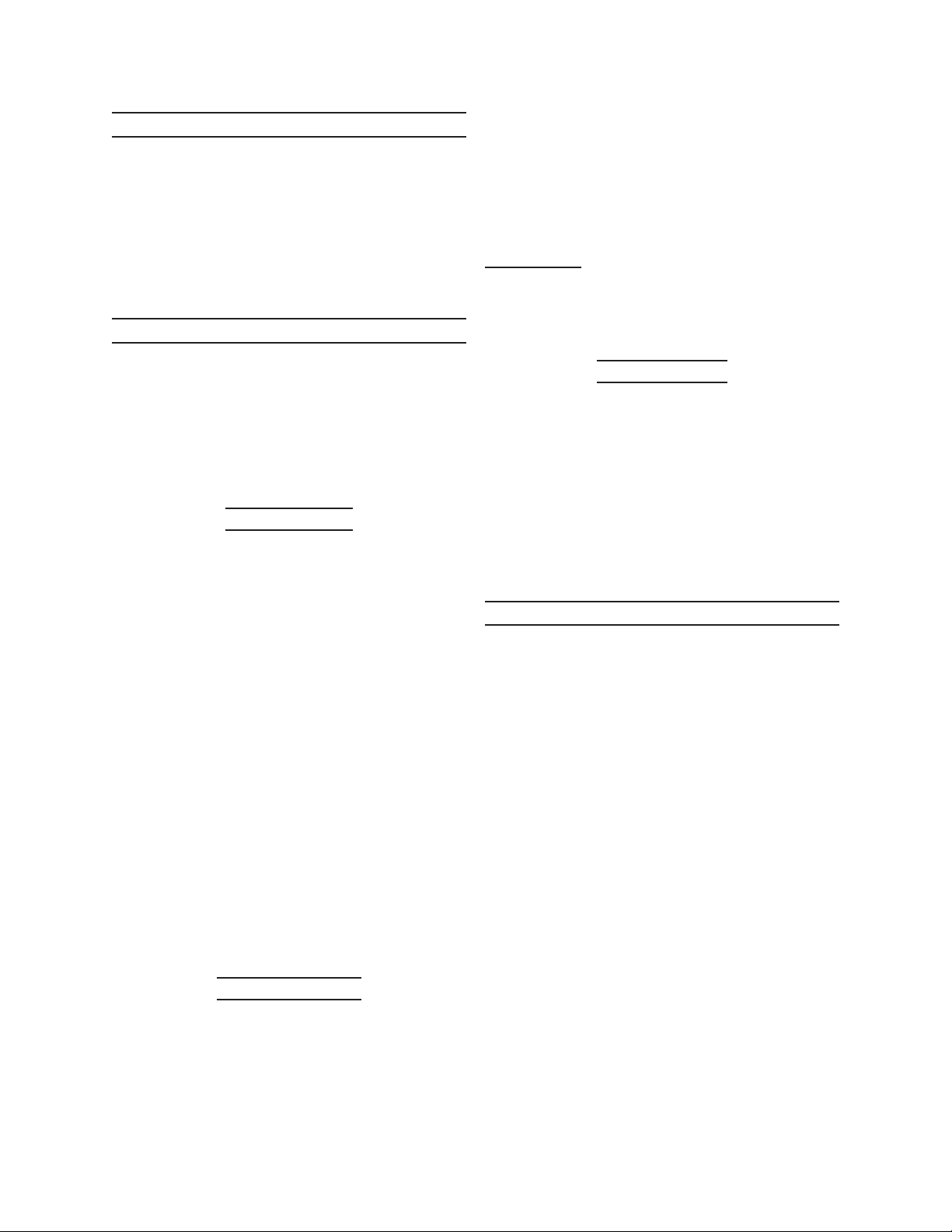

PARTS LIST

Part Description Qty.

1 Power Cord & Plug 1

2 Water Outlet 1

3 Pump Shell 1

4 O-Ring 1

5 Cable Guard 1

6 Cable Compaction Buckle 1

7 Capacitor 1

8 Cable Compaction Board 1

9 Screw 3

10 Screw 4

11 Filter 1

12 Base 1

13 Nut 1

14 Impeller 1

15 Washer 1

Part Description Qty.

16 Screw 5

17 Screw 1

18 Hold Down Ring 1

19 O-Ring 1

20 Oil Seal 3

21 Motor Foreside 1

22 O-Ring 1

23 Motor Lining 1

24 Stator 1

25 Bearing 2

26 Rotor 1

27 Washer 1

28 Back Cover 1

29 Wire Jacket 1

SKU 98342 For technical questions, please call 1-800-444-3353. Page 6

Page 7

ASSEMBLY DIAGRAM

SKU 98342 For technical questions, please call 1-800-444-3353. Page 7

Page 8

LIMITED 1 YEAR / 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that for a period

of ninety days from date of purchase that the engine/motor, the belts (if so equipped),

and the blades (if so equipped) are free of defects in materials and workmanship. Harbor Freight Tools also warrants to the original purchaser, for a period of one year from

date of purchase, that all other parts and components of the product are free from

defects in materials and workmanship (90 days if used by a professional contractor or

if used as rental equipment). This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our

facilities, normal wear and tear, or to lack of maintenance. We shall in no event be liable

for death, injuries to persons or property, or for incidental, contingent, special or consequential damages arising from the use of our product. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation

of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection veries the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect

resulted from causes not within the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

SKU 98342 For technical questions, please call 1-800-444-3353. Page 8

Loading...

Loading...