Page 1

®

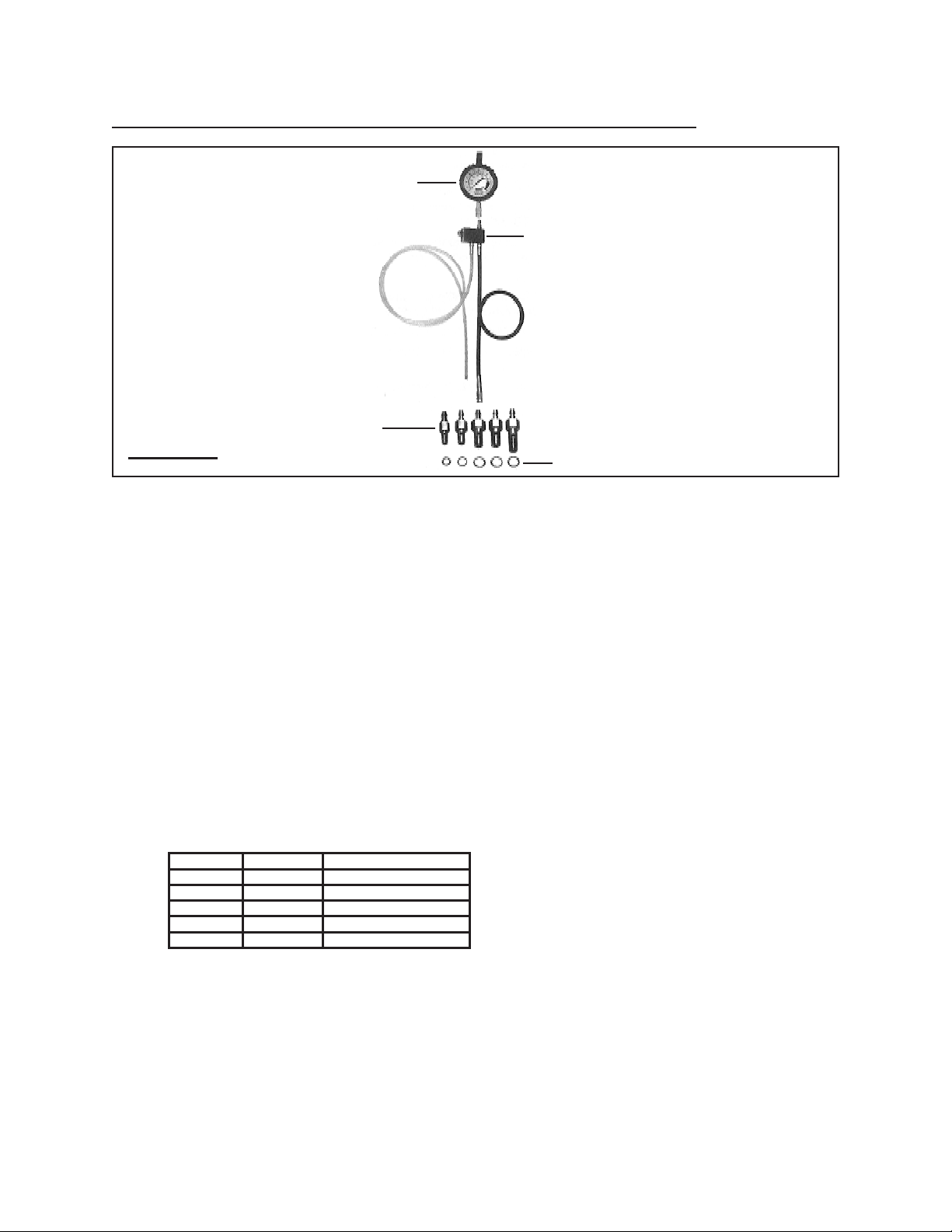

FUEL INJECTION

Model

97706

PRESSURE TEST KIT

OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2006 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Cover revised 08a

Page 2

PRODUCT SPECIFICATIONS

Product Features (A) Allows for accurate and quick diagnoses of fuel intake issues.

(B) Compatible with most domestic and import cars.

(C) Includes all necessary adapter clamps and hoses.

(D) Quick, convenient hook ups.

Material Brass / Steel / Aluminum / Polyurethane / Rubber / Vinyl / Thermoplastic

Contents Fuel Gauge w/Quick Release Valve / Seven Various Hose Assemblies

Four Metric Paired Hose Adapters / Two Steel Hose Clamps

Four Copper Washers / Fifteen Metric Sized Fittings / 8 SAE Sized Fittings

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions detailed in this manual may

result in serious personal injury.

SAVE THESE INSTRUCTIONS

Keep your work area clean and well lit. 1. Cluttered and dark work areas invite

accidents.

Stay alert. 2. Watch what you are doing, and use common sense when operating

tools and equipment. Do not assemble or use this product while tired or under

the inuence of drugs, alcohol, or medication. A moment of inattention while operating tools and equipment may result in serious personal injury.

3. Wear eye protection. Wear ANSI-approved safety impact glasses and

full face shield when using this product.

Do not force the Pressure Test Kit. 4. Use the correct product for your applica-

tion. The correct product will do the job better and safer at the rate for which it is

designed.

Maintain the Pressure Test Kit with care. 5. Keep this product clean. Properly

maintained products are less likely to malfunction. Do not use damaged products. Tag damaged products “Do not use” until repaired.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 2

Page 3

Check for any condition that may negatively affect the Pressure Test Kit’s 6.

operation. If readings are inconsistent, or if it appears that the fuel gauge is not

functioning properly, the Test Kit should be serviced by a qualied service technician. Many accidents are caused by poorly maintained products.

Use only accessories that are recommended by the manufacturer for your 7.

model. Accessories that may be suitable for one product may become hazard-

ous when used on another product.

Industrial applications must follow OSHA requirements.8.

Maintain labels and nameplates on the Pressure Test Kit. 9. These carry im-

portant information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

Use the right product for the job. 10. There are certain applications for which

this product was designed. Do not use small products to do the work of larger

industrial products. Do not use this product for a purpose for which it was not

intended.

Product service must be performed only by qualied service technician. 11.

Service or maintenance performed by unqualied personnel could result in a risk

of injury.

When servicing the Pressure Test Kit, use only identical replacement parts. 12.

Follow instructions in the “Inspection, Maintenance, And Cleaning” section of this

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of personal injury.

Always make sure the area of use for this product is clear of any children. 13.

Do not allow children to play with this product.

Do not allow the vehicle’s engine to run while using the Pressure Test Kit. 14.

When running, the engine of a vehicle produces carbon monoxide, a colorless,

odorless, toxic gas that, when inhaled, can cause serious personal injury or

death.

Prior to using this product, make sure to read and understand all instruc-15.

tions and safety precautions as outlined in the vehicle manufacturer’s

manual.

Always keep hands and ngers away from the moving parts and hot parts 16.

of an engine.

Do not use this Pressure Test Kit on diesel fuel systems.17.

Do not smoke while performing any fuel injection tests or repairs.18.

Always have a dry chemical (Class B) re extinguisher within reach.19.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 3

Page 4

Make sure to provide a suitable container to catch released fuel when the 20.

system is de-pressurized.

Take extra care to prevent fuel from contacting hot engine parts. 21. It is rec-

ommended that tests be performed when the engine is cold.

If a drop light is used, do not allow fuel to contact the hot surface of the 22.

bulb.

Never remove any ttings with the engine running.23.

Never loosen any ttings or attempt to remove hoses of vehicle or Pressure 24.

Test Kit until you have relieved the fuel system pressure. Refer to the ve-

hicle manufacturer’s service manual for specic fuel pressure relief procedures.

Always check all connections for leaks during the testing procedure. 25. At

any sign of leaks, turn off the engine or disable the fuel pump. Clean up any

spilled fuel and repair all leaks before resuming test.

When preparing for pressure testing, make sure the vehicle’s transmission

is placed in “PARK” or “NEUTRAL” and the emergency brake is applied.

When the test is complete, de-pressurize the system and remove the Pres-26.

sure Test Kit. Re-assemble the vehicle’s fuel line(s) to its original condition.

Start the engine and check for leaks. If any leaks are present, stop the engine,

relieve fuel pressure and repair all leaks.

WARNING: The brass components of this product contain lead, a chemical 27.

known to the State of California to cause birth defects (or other reproductive

harm). (California Health & Safety code § 25249.5, et seq.)

People with pacemakers should consult their physician(s) before use. Electro-28.

magnetic elds in close proximity to heart pacemaker could cause pacemaker

interference or pacemaker failure.

Caution is necessary when near coil, spark plug cables, or distributor of running

engine. Engine should be off during distributor adjustment.

The warnings and cautions discussed in this manual cannot cover all possible 29.

conditions and situations that may occur. It must be understood by the operator

that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 4

Page 5

UNPACKING

When unpacking, check to make sure all the parts shown in the Parts List on page 23

are included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the front cover of this manual as soon as possible.

APPLICATIONS

# Picture DESCRIPTION APPLICATION

1

2

3

4

5

6

7

8

9

10

THRU

14

15

THRU

24

Basic Gauge with Boot

and Hook - 100 PSI

General Motors 2.5L & 5.7L

(Non Multi-Port)

General Motors 2.2L

(Non Multi-Port)

Hose Clamps and

Connection Hoses

General Motors Throttle

Body Injection (TBI)

Parts Seals, Tank Valve, and Gasket

Double End Barbed Hose

Adapter

Single End Barbed Hose

Adapter

Honda, Acura & Sterling

Multi-Port (PGM-FI)

Asian and European vehicles

with Multi-Port & Bosch AFC

E & K Jetronic Systems

CISE

Connects to #8 for basic testing

For vehicles with quick connect fuel lters such as

2.5L Oldsmobile Ciera 1989 & up, and 5.7L

Chevrolet Caprice 1991 & up

1992 & up: Chevrolet Cavalier, Pontiac Sunbird, Buick

Skylark, and Quad 4 equipped Pontiac Grand Am

For use in making certain hook up connections

Inline Adapter - Replaces fuel lter with threads on

both ends

When vehicles require testing by splicing into 1/4”,

5/16”, or 3/8” fuel line hose

All vehicles requiring end of line testing with 1/4”,

5/16”, or 3/8” fuel line hose

For vehicles with 6mm-1.00 ttings

For vehicles with 8mm-1.00, 10mm-1.00, 12mm-1.25,

12mm-1.50, & 14mm-1.50 Banjo Bolts

Test CIS (Continuous Injection Systems) found on European cars and Volkswagon models assembled in the

U.S. For vehicles with metric threads

Test CISE (Constant Injection System Electronic) found

on European cars with metric threads

25

26

27

28

29

30

31

Pressure Testing and

Bleed-off Assembly

Ford Multi-Port (EFI) For smaller Schrader valves

General Motors, Chrysler

& Imports with 7/16”-20

threaded test port

Ford CFI For 5/16” hair pin connections

General Motors and

Chrysler Inline Adapter

Ford EFI For Spring Lock ttings

CIS Testing Assembly

with Ball Valve

For use in performing tests with Basic Gauge (1)

and Adapters

For larger Schrader valves on Multi-Port vehicles

Inline Adapter for vehicles with 3/8” hair pins

For use in testing with Basic Gauge (1), Pressure

Testing, and Bleed-off Assembly (25) and Adapters

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 5

Page 6

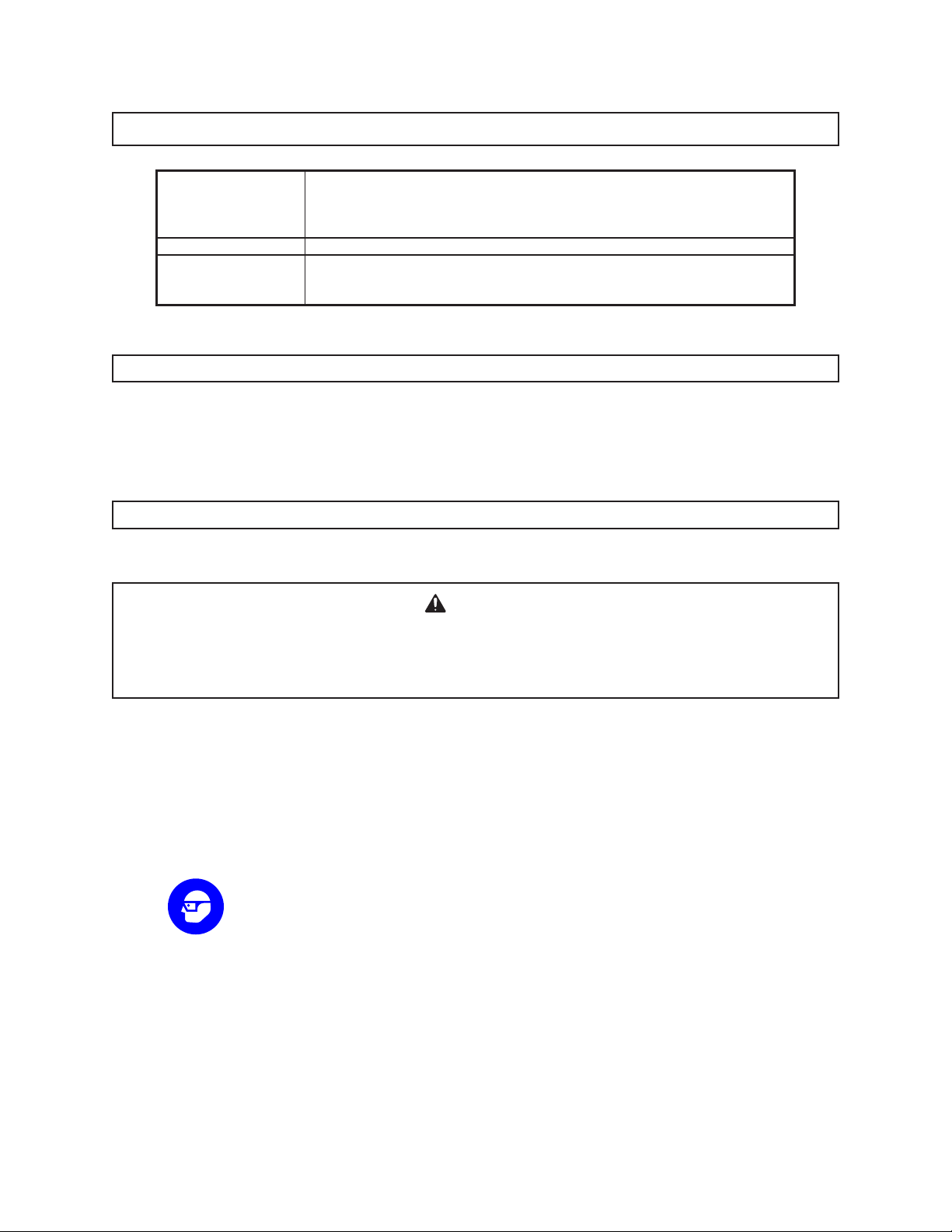

TYPICAL HOOK-UPS

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER

(27)

FIGURE A

Note: Prior to using this product, make sure to read and understand all instructions and

safety precautions as outlined in the vehicle manufacturer’s manual.

GM Multi-Port And Chrysler Multi-Port - FIGURE A:

1. Turn off ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).3.

Remove the protective cap from test tting on vehicle.4.

Attach the swivel female tting on the Adapter (27) to the test tting on the ve-5.

hicle. Hand tighten.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 6.

(25) to the male quick connector on the Adapter (27).

Start the engine and allow it to idle. Check for leaks.7.

Read the Gauge (1) and compare result with the pressure in service manual.8.

Stop engine and turn ignition OFF.9.

With free end of Bleed-off Hose in suitable container, press the Button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to the 11. General Safety Rules section before removing Tester from vehicle.

Replace the protective cap onto the test tting on vehicle. Check for leaks.12.

REV 07f, 07i

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 6

Page 7

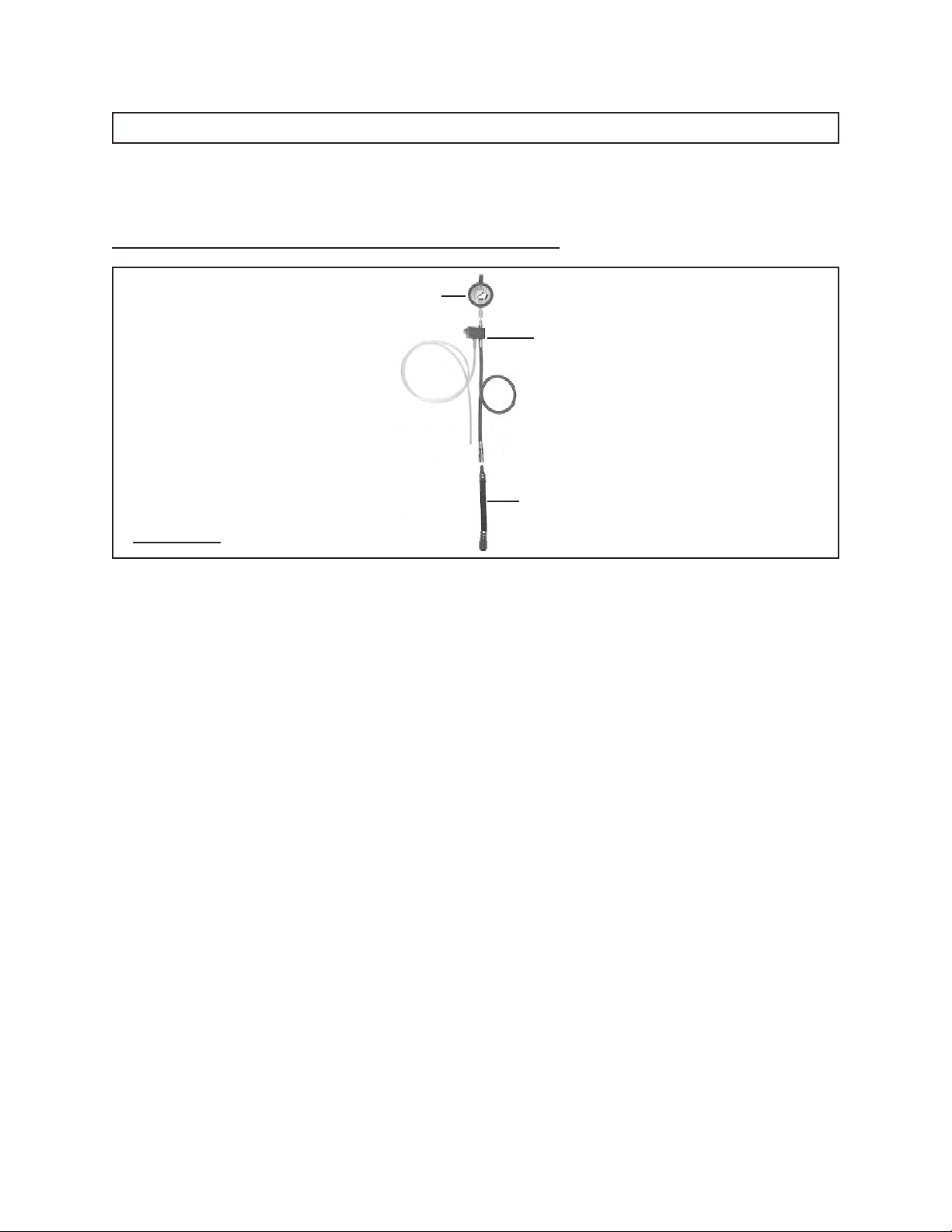

Ford Multi-Port (EFI) - FIGURE B:

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

GAUGE

(1)

FORD ADAPTER

(26)

FIGURE B

1. Turn off ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

If the vehicle has multi-port fuel injection, the test valve is located on the fuel rail. 3.

Remove the protective cap from the test valve.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).4.

Attach the female end of Ford Adapter (26) to test the valve. Hand tighten.5.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 6.

(25) to the male quick coupler on the Ford Adapter (26).

Start the engine and allow it to idle. Check for leaks.7.

Read the Gauge (1) and compare result with pressure in service manual.8.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in suitable container, press the button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to the 11. General Safety Rules section before removing the tester from the

vehicle.

Replace the protective cap onto test tting on vehicle. Check for leaks.12.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 7

Page 8

Asian And European Multi-Port Vehicles (Bosch AFC) - FIGURE C:

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

GAUGE

(1)

ADAPTERS

(10, 11, 12, 13, 14)

GASKETS (6)

FIGURE C

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

The pressure test connection for these vehicles is located at the point where the 3.

fuel inlet meets the fuel rail or cold start injector. The fuel inlet is secured to the

fuel rail of cold start injector by a banjo tting.

Remove the banjo tting that secures the fuel inlet to the fuel rail or cold start 4.

injector. Place a shop cloth around the bolt to catch any spilled fuel.

Install one of the ve pressure test Adapters (10, 11, 12, 13, 14) with the corre-5.

sponding sealing washer and one of the gaskets from the banjo tting so that the

fuel inlet is once again connected to the fuel rail or cold start injector. The test

Adapter will hold the banjo assembly in position.

Torque the Adapters (10, 11, 12, 13, 14) to the following specications:6.

Adapter # Size Torque Specications

10 8mm-1.00 48 In./Lb. (5.5 N-m)

11 10mm-1.00 72 In./Lb. (8.0 N-m)

12 12mm-1.25 96 In./Lb. (11.0 N-m)

13 12mm-1.50 96 In./Lb. (11.0 N-m)

14 14mm-1.50 125 In./Lb. (14.0 N-m)

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).7.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 8.

to the male quick coupler on the test Adapter.

Start the engine and allow it to idle. Check for leaks.9.

Read the Gauge (1) and compare the result with pressure in the service manual.10.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 8

Page 9

Stop the engine and turn the ignition OFF.11.

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

GM TBI ADAPTER (5)

FIGURE D

With free end of bleed-off hose in a suitable container, press the button on side of 12.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to 13. General Safety Rules section before removing tester from vehicle.

Remove the Tester and the pressure test Adapter.14.

Re-assemble the banjo tting to the fuel inlet and fuel rail (or cold start injec-15.

tor). New Gaskets (6) should be used when re-assembling fuel lines. Check for

leaks.

GM Throttle Body Injection (TBI) With Fuel Filter Threaded On Both Sides FIGURE D:

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Locate the fuel lter on the vehicle.3.

Remove the fuel lter by unscrewing the fuel lines from both ends of the fuel lter. 4.

Use a container to catch any fuel that may spill out. Wipe off any excess fuel that

may spill on the vehicle.

Install the GM TBI Adapter (5) in place of the fuel lter by threading each fuel line 5.

into either end of the Adapter. Do not overtighten.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 9

Page 10

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).6.

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER

(2)

FIGURE E

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 7.

to the male quick coupler on the GM TBI Adapter (5).

Start the engine and check for leaks. Read the fuel pressure. Compare the 8.

value on the Gauge (1) to the value in the service manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press the button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to the 11. General Safety Rules section before removing tester from vehicle.

Remove the fuel pressure Adapter following the above instructions for removing 12.

the fuel lter.

Re-install the fuel lter. Start the vehicle and check for leaks.13.

GM Throttle Body Injection (TBI) With Quick Connect Fuel Filter (2.5L 1989 And

Up, 5.7L 1991 And Up - FIGURE E:

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Locate the fuel lter on the vehicle.3.

Remove the fuel lter by compressing the tabs while pulling outward on each fuel 4.

line. Use a container to catch any fuel that may spill out. Wipe off any excess

fuel that may spill on the vehicle.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 10

Page 11

Install the fuel pressure Adapter (2) in place of the fuel lter by pushing each of 5.

ADAPTER (3)

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

FIGURE F

the Adapter’s male tubes into the fuel lines. Make sure the nylon clips on the

tubes are seated inside the fuel line connectors.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).6.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 7.

to the male quick coupler on the Adapter (2).

Start the engine and check for leaks. Read the fuel pressure. Compare the 8.

value on the Gauge (1) to the value in the service manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to 11. General Safety Rules section before removing tester from vehicle.

Remove the fuel pressure Adapter following the above instructions for removing 12.

the fuel lter.

Re-install the fuel lter. Start the engine and check for leaks.13.

GM 2.2L Engines, 1992 And Up - FIGURE F:

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Locate the fuel lter on the vehicle.3.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 11

Page 12

Remove the fuel lter by unscrewing the steel fuel line from one end of the fuel 4.

lter. Remove the nylon fuel line on the other end by compressing the tabs while

pulling outward on the fuel line. Use a container to catch any fuel that may spill

out. Wipe off any excess fuel that may spill out.

Install the fuel pressure Adapter (3) in place of the fuel lter by threading the steel 5.

fuel line into the threaded end of the Adapter. Do not overtighten. Connect the

other end of the Adapter by pushing the male tube into the nylon fuel line. Make

sure the nylon clip on the tube is seated inside the fuel line connector.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).6.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 7.

(25) to the male quick coupler on the Adapter (3).

Start the engine and check for leaks. Read the fuel pressure. Compare the 8.

value on the Gauge (1) to the value in the service manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to 11. General Safety Rules section before removing tester from vehicle.

Remove the fuel pressure Adapter (3) following the above instructions for remov-12.

ing the fuel lter. Re-install the fuel lter. Start the engine and check for leaks.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 12

Page 13

Ford Central Fuel Injection (CFI) 1.9L and 2.3L With 5/16” Hair Pin Coupling And

ADAPTER

(28 OR 29)

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

FIGURE G

GM And Chrysler 3/8” Hair Pin Coupling - FIGURE G:

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

The connection with the vehicle’s fuel injection system is at the throttle body. Re-3.

move the fuel line at the inlet by prying up on the hair pin from the coupling with

a small screwdriver. Use care as the hair pin is made of plastic. Once disconnected, re-install the hair pin into the hair pin coupling.

Attach the Hair Pin Adapter (28 for Ford and 29 for GM and Chrysler) to the dis-4.

connected fuel line. Make sure both ends of mating parts are seated and locked

together.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25). At-5.

tach the female quick coupler on the Pressure Testing and Bleed-off Assembly

(25) to the male quick coupler on the Adapter (28 or 29).

Start the engine and allow it to idle. Check all connections for leaks.6.

Read the Gauge (1) and compare the result with the pressure values in the ser-7.

vice manual.

Stop the engine and turn the ignition OFF.8.

With free end of bleed-off hose in a suitable container, press button on side of 9.

bleed-off assembly slowly to de-pressurize the fuel system. Refer to General

Safety Rules section before removing tester from vehicle.

Remove the fuel pressure Adapter following the above instructions. Re-install 10.

the vehicle’s fuel line. Start the engine and check for leaks.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 13

Page 14

Ford Central Fuel Injection (CFI) With Spring Lock Fittings - 2.5L - FIGURE H:

ADAPTER (30)

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

FIGURE H

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

The connection with the vehicle’s fuel injection system is on the fuel rail.3.

A disconnect tool (not included) is required to separate the spring lock tting on 4.

the vehicle’s fuel line.

After the spring lock tting has been disconnected, assemble the Ford Spring 5.

Lock Adapter (30) into the line, making sure both ends of the mating couplings

are locked together.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25). At-6.

tach the female quick coupler on the Pressure Testing and Bleed-off Assembly

(25) to the male quick coupler on the Adapter (30).

Start the engine and allow it to idle. Check all connections for leaks.7.

Read the Gauge (1) and compare the result with the pressure values in the ser-8.

vice manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system. Refer to General

Safety Rules section before removing tester from vehicle.

Using a disconnect tool, remove the test Adapter (30) and install the vehicle’s fuel 11.

line. Start the vehicle and check for leaks.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 14

Page 15

Honda, Acura, & Sterling Multi-Port (PGM-FI) - FIGURE I:

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER (9)

FIGURE I

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

The test port is at the vehicle’s fuel lter, under the hood, just forward of the re-3.

wall.

The Fuel outlet is secured to the fuel lter by a “double D” bolt. Within this bolt is 4.

a smaller hex bolt that provides access to the test connection.

Place a shop cloth around the fuel outlet and slowly remove the smaller hex bolt.5.

Screw the small male end of the Honda Adapter (9) into the hole where the re-6.

moved hex bolt was. Hand tighten.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25). At-7.

tach the female quick coupler on the Pressure Testing and Bleed-off Assembly

(25) to the male quick coupler on the Adapter (9).

Start the engine and allow it to idle. Check all connections for leaks.8.

Read the Gauge (1) and compare the result with the pressure values in the ser-9.

vice manual.

Stop the engine and turn the ignition OFF.10.

With free end of bleed-off hose in a suitable container, press button on side of 11.

bleed-off assembly slowly to de-pressurize the fuel system. Refer to General

Safety Rules section before removing tester from vehicle.

Re-install the hex bolt on the fuel lter. Check for leaks.12.

07f

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 15

Page 16

Ford Throttle Body Injection With Small Schrader Valve - FIGURE J:

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER

(26)

FIGURE J

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Remove the air cleaner assembly. The test valve is located at the top of the 3.

throttle body unit.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).4.

Attach the female end of the Ford Adapter (26) to the test valve.5.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 6.

(25) to the male quick coupler on the Adapter (26).

Start the engine and allow it to idle. Check all connections for leaks.7.

Read the Gauge (1) and compare the result with the pressure values in the ser-8.

vice manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system.

Refer to the 11. General Safety Rules section before removing tester from vehicle.

Start the vehicle and check for leaks.12.

07f

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 16

Page 17

All Vehicles With 1/4”, 5/16”, or 3/8” Fuel Line Hose - FIGURE K:

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER

(7)

HOSE & HOSE CLAMPS

(4)

TO INLET FUEL LINE HOSE

TO THROTTLE BODY INLET

OR

DISCHARGE SIDE OF FUEL PUMP

FIGURE K

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Loosen the hose clamp and disconnect the fuel line hose from the inlet side of 3.

the vehicle’s throttle body or discharge side of the fuel pump.

Assemble the Double End Barbed Adapter (7) and Hose (4) with Hose Clamps 4.

(4).

Connect the Double End Barbed Adapter (7) as assembled above between the 5.

disconnected fuel line and the throttle body inlet or fuel pump. Tighten all Hose

Clamps (4) securely.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).6.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 7.

(25) to the male quick coupler on the Adapter (7).

Start the engine and allow it to idle. Check all connections for leaks. Read the 8.

Gauge (1) and compare the result with the pressure values in the service manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system. Refer to the General

Safety Rules section before removing tester from vehicle.

Replace the vehicle’s fuel line and tighten all clamps securely. Check all connec-11.

tions for leaks.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 17

Page 18

All Vehicles Requiring End Of Line Testing With 1/4”, 5/16”, Or 3/8” Fuel Line

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER

(8)

FIGURE L

Hose - FIGURE L:

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Loosen the hose clamp and disconnect the fuel line.3.

Install the Single End Barbed Hose Adapter (8) into the fuel supply hose. 4.

Tighten hose clamp securely.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).5.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 6.

(25) to the male quick coupler on the Adapter (8).

Start the engine and allow it to idle. Check all connections for leaks. Read the 7.

Gauge (1) and compare the result with the pressure values in the service manual.

Stop the engine and turn the ignition OFF.8.

With free end of bleed-off hose in a suitable container, press button on side of 9.

bleed-off assembly slowly to de-pressurize the fuel system. Refer to the General

Safety Rules section before removing tester from vehicle.

Reconnect vehicle’s fuel line and tighten all clamps securely. Check all connec-10.

tions for leaks.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 18

Page 19

Chrysler Throttle Body Injection - FIGURE M:

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTER

(7)

HOSE & HOSE CLAMPS

(4)

TO INLET FUEL LINE HOSE

TO THROTTLE BODY INLET NIPPLE

FIGURE M

1. Turn off the ignition.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-2.

sure relief procedures.

Loosen the hose clamp and disconnect the fuel line hose from the inlet side of 3.

the vehicle’s throttle body.

Conrm if the size of the inlet fuel line hose is 1/4” or 5/16”.4.

Assemble the correct Hose (4) and Hose Clamps (4) onto the Double End 5.

Barbed Adapter (7).

Connect the Adapter assembly between the disconnected fuel line and the throt-6.

tle body inlet nipple on the vehicle. Tighten all Hose Clamps (4) securely.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25). At-7.

tach the female quick coupler on the Pressure Testing and Bleed-off Assembly

(25) to the male quick coupler on the Adapter (7).

Start the engine and allow it to idle. Check all connections for leaks. Read the 8.

Gauge (1) and compare the result with the pressure values in the service manual.

Stop the engine and turn the ignition OFF.9.

With free end of bleed-off hose in a suitable container, press button on side of 10.

bleed-off assembly slowly to de-pressurize the fuel system. Refer to the General

Safety Rules section before removing tester from vehicle.

Reconnect vehicle’s fuel line and tighten all clamps securely. Check all connec-11.

tions for leaks.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 19

Page 20

Bosch Continuous Injection System (CIS) Testing - FIGURE N:

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTERS

(10, 11, 12, 13, 15, 16, 18, 19, 20, 21, 22, 23, OR 24)

AND

“O-RINGS”

CIS TESTING ASSEMBLY

WITH

BALL VALVE

(31)

FIGURE N

1. Turn off the ignition.

Clean the top of the fuel distributor to keep dirt from entering the fuel system.2.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-3.

sure relief procedures.

The CIS system has a primary circuit with pressure regulated at the fuel distribu-4.

tor. This is known as supply pressure, primary pressure, or line pressure. The

side of the tester without the ball valve is connected to this circuit. The other

circuit is known as the control circuit. This contains the control pressure regulator, known as the warm-up compensator. The side of the test with the ball valve

is connected to this circuit.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).5.

Install Adapter(s) (10, 11, 12, 13, 15, 16, 18, 19, 20, 21, 22, 23, or 24) and “O-6.

Ring” to the engine as required. Hand tighten only. Then connect Hoses to

Adapters.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 7.

(1) to the male quick coupler on the CIS Testing Assembly with Ball Valve (31).

With free end of bleed-off hose in a suitable container, press button on side of

bleed-off assembly slowly to release any air in the test Hose.

Refer to the 8. General Safety Rules section before removing tester from vehicle.

Remove tester and Adapters from vehicle. Reconnect vehicle’s fuel injection

lines to original condition. Start the vehicle and check for leaks.

Start the engine and check for leaks. Read the fuel pressure. Compare the 9.

value on the Gauge (1) to the value in the service manual.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 20

Page 21

Constant Injection System Electronic (CISE) - European Vehicles - FIGURE O:

GAUGE

(1)

PRESSURE TESTING

AND

BLEED-OFF ASSY.

(25)

ADAPTERS

(10, 11, 12, 13, 15, 16, 18, 19, 20, 21, 22, 23, OR 24)

AND

“O-RINGS”

FIGURE O

1. Turn off the ignition.

Clean the top of the fuel distributor to keep dirt from entering the fuel system.2.

Relieve the fuel pressure. Refer to the vehicle’s service manual for specic pres-3.

sure relief procedures.

Connect the Gauge (1) to the Pressure Testing and Bleed-off Assembly (25).4.

Install Adapter(s) (10, 11, 12, 13, 15, 16, 18, 19, 20, 21, 22, 23, or 24) and “O-5.

Ring” to the engine as required.

Attach the female quick coupler on the Pressure Testing and Bleed-off Assembly 6.

(1) to the male quick coupler on the Adapter.

Start the engine and allow it to idle. Check for leaks. Read the fuel pressure. 7.

Compare the value on the Gauge (1) to the value in the service manual.

With free end of bleed-off hose in a suitable container, press button on side of 8.

bleed-off assembly slowly to release any air in the test Hose. Refer to the Gen-

eral Safety Rules section before removing tester from vehicle.

Remove tester and Adapter(s) from vehicle.9.

Reconnect vehicle’s fuel injection lines to original condition.10.

Start vehicle and check for leaks.11.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 21

Page 22

INSPECTION, MAINTENANCE, AND CLEANING

1. CAUTION! Make sure to wear ANSI-approved safety impact goggles before

performing any inspection, maintenance, or cleaning of Pressure Test Kit.

Before each use: 2. Inspect the general condition of the Pressure Test Kit. Check

for damaged parts, and any other condition that may affect this product’s safe

operation. If a problem occurs, have the problem corrected before further use.

Do not use damaged equipment.

To clean: 3. Use a clean, soft, damp cloth, and mild detergent. Then, allow to air-

dry. Do not use solvents.

4. CAUTION! All maintenance, service, and repairs not discussed in this manual

should only be performed by a qualied service technician.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER.

THE BUYER ASSUMES ALL RISKS AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 22

Page 23

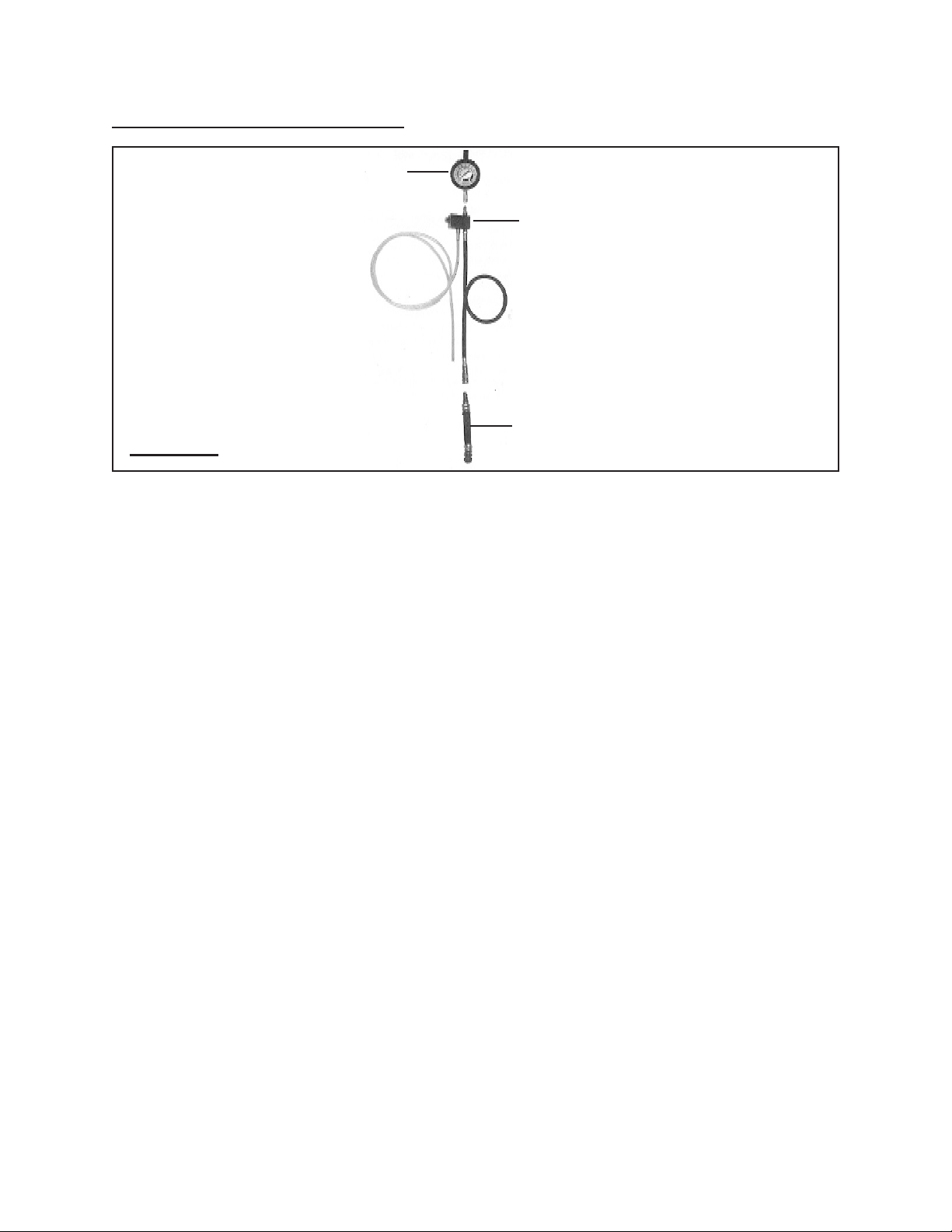

PARTS LIST AND ASSEMBLY DIAGRAM

Part Description

1 0-100 PSI (0-7.0 Bar) Gauge w/Boot & Hang-Up Hook

2 GM 2.5L & 5.7L Fuel Injection Pressure Test Adapter

3 GM 2.2L Fuel Injection Pressure Test Adapter

4 Hose Clamps & Hoses

5 GM Throttle Body Injection (TBI) Fuel Pressure

Adapter

6 Seals, Tank Valve & Gasket

7 Double End Barbed Hose Adapter

8 Single End Barbed Hose Adapter

9 6mm-1.00 Honda & Acura Multi-Port (PGM-FI)

Adapter

10 8mm-1.00 Banjo Bolt Adapter

11 10mm-1.00 Banjo Bolt Adapter

12 12mm-1.25 Banjo Bolt Adapter

13 12mm-1.50 Banjo Bolt Adapter

14 14mm-1.50 Banjo Bolt Adapter

15 8mm-1.00 Long Adapter

16 8mm-1.00 Female Adapter

33: CARRYING CASE NOT SHOWN.

Part Description

17 8mm-1.00 Male Adapter w/O-Ring (1 Pieces)

18 8mm-1.00 Male Adapter (Long)

19 10mm-1.00 Female Adapter

20 10mm-1.00 Male Adapter

21 12mm-1.50 Female Swivel Adapter (2 Pieces)

22 14mm-1.50 Male & Female Swivel Adapter

23 1/4” BSPT Male & Female Swivel Adapter

24 16mm-1.50 Male & Female Swivel Adapter

25 Pressure Testing & Bleed-Off Assy.

26 Small Schrader Valve Test Adapter for Ford

27 Large Schrader Valve Test Adapter for GM & Chrysler

28 5/16” Hair Pin Adapter for Ford CFI

29 3/8” Hair Pin Adapter for GM & Chrysler

30 Spring Lock Adapter for Ford EFI

31 CIS Testing Assy. w/Ball Valve

32 Instruction Manual

33 Carrying Case

2

3

4

5

1

18

9

10

11

12

13

8

6

14

15

16

7

17

21

22

23

24

19

20

25

26

31

27

28

29

30

NOTE:

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 23

Page 24

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from

the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from the use of our product. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us

with transportation charges prepaid. Proof of purchase date and an explanation of the

complaint must accompany the merchandise. If our inspection veries the defect, we

will either repair or replace the product at our election or we may elect to refund the

purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that

the defect resulted from causes not within the scope of our warranty, then you must

bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

SKU 97706 For technical questions, please call 1-800-444-3353. PAGE 24

Loading...

Loading...