Page 1

METAL CUTTING BANDSAW

Model

97009

7” X 12”

SET UP AND OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

TABLE OF CONTENTS

Important Safety Information ...................................................................3

General Safety Rules.................................................................................4

Specic Safety Rules.................................................................................6

Grounding...................................................................................................8

Extension Cords.........................................................................................9

Symbology.................................................................................................10

Product Specications.............................................................................10

Set Up Instructions....................................................................................11

Operating Instructions..............................................................................12

Maintenance and Servicing......................................................................25

Troubleshooting Guide.............................................................................29

Parts Lists..................................................................................................30

Assembly Diagrams..................................................................................38

Electrical Schematics...............................................................................43

Warranty Information................................................................................46

Page 2SKU 97009 For technical questions, please call 1-800-444-3353.

Page 3

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number

in the back of the manual near the assembly diagram (or month and year of purchase if

product has no number). Keep this manual and the receipt in a safe and dry place for

future reference.

IMPORTANT SAFETY INFORMATION

In this manual, on the labeling, and all other information

provided with this product:

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGERDANGER

WARNINGWARNING

CAUTIONCAUTION

NOTICENOTICE

CAUTIONCAUTION

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION, used with the safety alert

symbol, indicates a hazardous situation

which, if not avoided, could result in minor

or moderate injury.

NOTICE is used to address practices not

related to personal injury.

CAUTION, without the safety alert symbol,

is used to address practices not related to

personal injury.

Page 3SKU 97009 For technical questions, please call 1-800-444-3353.

Page 4

GENERAL SAFETY RULES

WARNING! Read all instructions

Failure to follow all instructions listed below may result in electric shock,

re, and/or serious injury. The term “power tool” in all of the warnings listed

below refers to your line-operated (corded) power tool.

SAVE THESE INSTRUCTIONS

1.

2.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

a.

Do not operate power tools in explosive atmospheres, such as in the

b.

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool.

c.

Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way.

a.

Do not use any adapter plugs with grounded power tools. Unmodied plugs

and matching outlets will reduce risk of electric shock.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges

b.

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

Do not expose power tools to rain or wet conditions. Water entering a power

c.

tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

d.

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

3.

When operating a power tool outdoors, use an extension cord suitable for

e.

outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating

a.

a power tool. Do not use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

Use safety equipment. Always wear eye protection. Safety

b.

equipment such as dust mask, heavy duty work gloves, or

hearing protection used for appropriate conditions will reduce

personal injuries.

Page 4SKU 97009 For technical questions, please call 1-800-444-3353.

Page 5

Avoid accidental starting. Ensure the switch is in the off-position before

c.

plugging in.

Remove any adjusting key or wrench before turning the power tool on. A

d.

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

Do not overreach. Keep proper footing and balance at all times. This

e.

enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

f.

clothing and gloves away from moving parts. Loose clothes, jewelry or long

hair can be caught in moving parts.

4.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application.

a.

The correct power tool will do the job better and safer at the rate for which it

was designed.

Do not use the power tool if the switch does not turn it on and off. Any power

b.

tool that cannot be controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source and/or the battery pack from the

c.

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of children and do not allow people

d.

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts,

e.

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with

f.

sharp cutting edges are less likely to bind and are easier to control.

5.

Use the power tool and accessories in accordance with these instructions

g.

and in the manner intended for the particular type of power tool, taking into

account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a

hazardous situation.

Service

Have your power tool serviced by a qualied repair person using only

a.

identical replacement parts. This will ensure that the safety of the power tool

is maintained.

Page 5SKU 97009 For technical questions, please call 1-800-444-3353.

Page 6

SPECIFIC SAFETY RULES

1.

2.

3.

4.

5.

6.

7.

8.

Maintain labels and nameplates on the tool. These carry important safety

information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

Make sure the Bandsaw is located on a at, level, sturdy surface capable of

supporting the weight of the tool, accessories, and workpieces. Always “chock”

the Wheels to prevent the Bandsaw from accidentally moving.

Make sure the Table of the Bandsaw and surrounding area are clear with the

exception of the workpiece to be cut.

Before using the Bandsaw, check to make sure the Saw Blade is properly

mounted and in good condition.

Never stand on the Bandsaw. Serious injury could result if the Bandsaw is tipped

or if the rotating Saw Blade is accidentally contacted.

Never attempt to cut more than one workpiece at a time.

When cutting a large workpiece, make sure its entire length is properly

supported. If necessary, use a roller stand (not included).

Do not lean on the Bandsaw when the tool is in its upright position.

9.

10.

11.

12.

13.

14.

15.

16.

When moving the Bandsaw, always have its Head lowered to its horizontal

position.

Allow the Saw Blade to rotate to full speed before feeding the Blade into a

workpiece. When turning off the Bandsaw, allow the Saw Blade to spin down

and stop on its own. Do not press against the Saw Blade to stop it.

To avoid injury, always wear ANSI-approved safety goggles and heavy duty work

gloves when changing the Saw Blade.

The Saw Blade becomes hot while cutting. Allow the Blade to completely cool

before handling.

Do not force the Saw Blade into the workpiece when cutting. Apply moderate

pressure, allowing the Blade to cut without being forced.

Turn off the Bandsaw and allow the Saw Blade to completely stop if the Blade is

to be backed out of an incomplete cut.

Never attempt to remove material stuck in the moving parts of the Bandsaw while

it is plugged in and running.

Keep all safety guards in place and in proper working order.

17.

Always adjust and position the Blade Guide Arm before starting the cut.

Page 6SKU 97009 For technical questions, please call 1-800-444-3353.

Page 7

18.

When cutting magnesium, use soluble oils or emulsions (oil/water mix) as water

only will greatly intensify any accidental magnesium chip re. See your industrial

coolant supplier for specic coolant recommendations when cutting magnesium.

19.

20.

21.

22.

23.

24.

Avoid unintentional starting. Prepare to begin work before turning on the tool.

Do not leave the tool unattended when it is plugged into an electrical outlet. Turn

off the tool, and unplug it from its electrical outlet before leaving.

Use the Vise or other practical ways to secure and support the workpiece to the

Support Plate. Holding the work by hand or against your body is unstable and

may lead to loss of control, and personal injury.

This product is not a toy. Keep it out of reach of children.

The brass components of this product contain lead, a chemical known to the

State of California to cause birth defects (or other reproductive harm). California

Health & Safety Code 25249.5, et seq.)

People with pacemakers should consult their physician(s) before use.

Electromagnetic elds in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure. In addition, people with

pacemakers should:

• Avoid operating alone.

• Do not use with power switch locked on.

• Properly maintain and inspect to avoid electrical shock.

• Any power cord must be properly grounded. Ground Fault Circuit Interrupter

(GFCI) should also be implemented – it prevents sustained electrical shock.

25.

26.

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities, contains chemicals known [to the State of California] to

cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

Lead from lead-based paints

Crystalline silica from bricks and cement or other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that

are specially designed to lter out microscopic particles. (California Health &

Safety Code § 25249.5, et seq.)

The warnings, precautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

Page 7SKU 97009 For technical questions, please call 1-800-444-3353.

Page 8

SAVE THESE INSTRUCTIONS.

GROUNDING

WARNINGWARNING

1.

2.

Tools marked with “Grounding Required” have a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If

the tool should electrically malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user, reducing the risk of electric

shock. (See 3-Prong Plug and Outlet.)

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool. The green wire in the cord must be the

only wire connected to the tool’s grounding system and must never be attached

to an electrically “live” terminal. (See 3-Prong Plug and Outlet.)

Improperly connecting the grounding wire can result in

electric shock.

Check with a qualied electrician if you are in doubt as to

whether the outlet is properly grounded. Do not modify

the power cord plug provided with the tool. Never remove

the grounding prong from the plug. Do not use the tool if

the power cord or plug is damaged. If damaged, have it

repaired by a service facility before use. If the plug will not

t the outlet, have a proper outlet installed by a qualied

electrician.

Grounded Tools: Tools with Three Prong Plugs

3.

The tool must be plugged into an appropriate outlet, properly installed and

grounded in accordance with all codes and ordinances. The plug and outlet

should look like those in the following illustration.

(See 3-Prong Plug and Outlet.)

3-Prong Plug and Outlet

Outlets for 2-Prong Plug

Page 8SKU 97009 For technical questions, please call 1-800-444-3353.

Page 9

Double Insulated Tools: Tools with Two Prong Plugs

1.

2.

1.

2.

3.

Tools marked “Double Insulated” do not require grounding. They have a special

double insulation system which satises OSHA requirements and complies

with the applicable standards of Underwriters Laboratories, Inc., the Canadian

Standard Association, and the National Electrical Code.

(See Outlets for 2-Prong Plug.)

Double insulated tools may be used in either of the 120 volt outlets shown in the

preceding illustration. (See Outlets for 2-Prong Plug.)

EXTENSION CORDS

Grounded tools require a three wire extension cord. Double Insulated tools can

use either a two or three wire extension cord.

As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool damage.

(See Table A.)

The smaller the gauge number of the wire, the greater the capacity of the cord.

For example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Table A.)

4.

5.

6.

7.

8.

When using more than one extension cord to make up the total length, make

sure each cord contains at least the minimum wire size required. (See Table A.)

If you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum cord size.

(See Table A.)

If you are using an extension cord outdoors, make sure it is marked with the

sufx “W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

Make sure the extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualied

electrician before using it.

Protect the extension cords from sharp objects, excessive heat, and damp or wet

areas.

Page 9SKU 97009 For technical questions, please call 1-800-444-3353.

Page 10

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS* (120/240 VOLT)

NAMEPLATE

EXTENSION CORD LENGTH

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

TABLE A

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

* Based on limiting the line voltage drop to ve volts at 150% of the rated amperes.

SYMBOLOGY

Double Insulated

Canadian Standards Association

V~

A

Volts Alternating Current

Amperes

Underwriters Laboratories, Inc.

n0 xxxx/min.

No Load Revolutions per Minute

(RPM)

SPECIFICATIONS

Electrical Requirements 120 V~ / 60 Hz / 16 Amps

1 HP Single Phase Motor / 1720 RPM

Power Switch Type: Toggle

Circuit Breaker: 18 Amps (Resettable)

Power Cord Type: 14 AWG x 3C

Plug Type: 120 Volt / 3-Prong / Grounded

Stock Capacity at 90° 7” (Round) / 7” x 12” (Rectangle)

Blade Speeds

(Feet Per Minute)

Blade Size

Teeth Per Inch

Belt Type 3V-270

Miter Slot Width / Depth 11/16” Wide / 9/16” Deep

Hydraulic Ram Travel 5-5/8”

Base Mounting Holes 3/8” Diameter (Qty. 4)

Wheel Dimensions 5” Diameter x 1” Wide

90 FPM / 135 FPM / 195 FPM / 255 FPM

0.75” x 0.031” x 93” (Carbon Steel Blade)

6 TPI

Page 10SKU 97009 For technical questions, please call 1-800-444-3353.

Page 11

UNPACKING

When unpacking, check to make sure that the item is intact and undamaged. If

any parts are missing or broken, please call Harbor Freight Tools at the number shown

on the cover of this manual as soon as possible.

SET UP INSTRUCTIONS

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this manual including all text under subheadings therein

before set up or use of this product.

WARNINGWARNING

Note: For additional information regarding the parts listed in the following pages, refer

to the Assembly Diagrams near the end of this manual.

Risk of accidental starting; resulting in serious personal

injury. Turn the Power Switch of the tool to its “OFF”

position and unplug the tool from its electrical outlet before

assembling or making any adjustments to the tool.

Assembly

1.

2.

3.

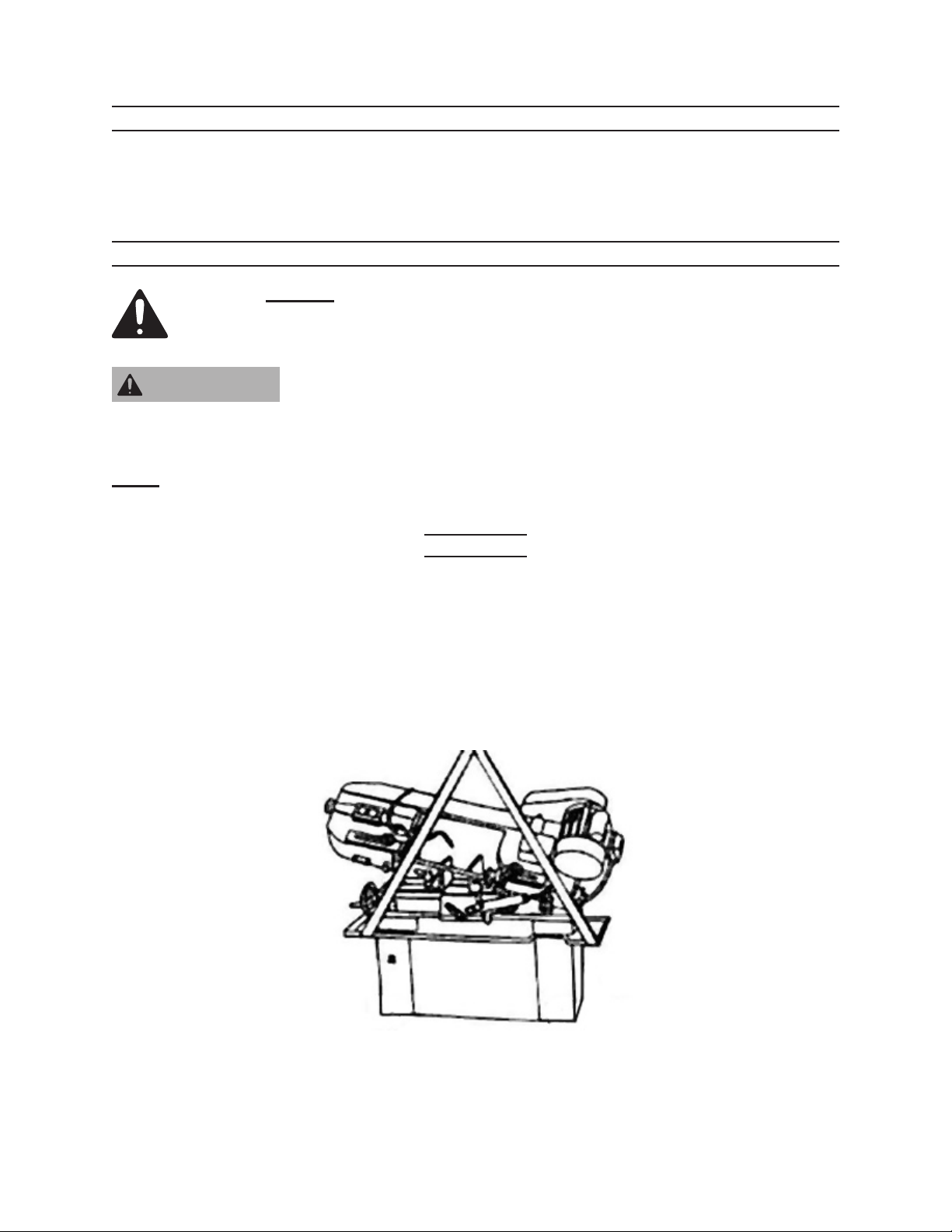

NOTE: To assemble and locate the Bandsaw will require additional assistance

and a proper lifting device.

After the Bandsaw and its accessories are unpacked, make sure its Head is

lowered to its horizontal position. (See Figure A.)

With a proper lifting device, raise the Bandsaw approximately six inches off the

oor surface. (See Figure A.)

FIGURE A

4.

Once the Bandsaw is lifted, insert the Wheel Rod (92-4) through the two holes

located at the bottom/right side of the Stand (77S). Slide one Wheel (92-2) on

each end of the Wheel Rod. Place one Washer (92-1) on each end of the Wheel

Page 11SKU 97009 For technical questions, please call 1-800-444-3353.

Page 12

Rod. Insert one Cotter Pin (92-3) through the hole in each end of the Wheel Rod.

Make sure to bend the Cotter Pins to secure the Wheels in place.

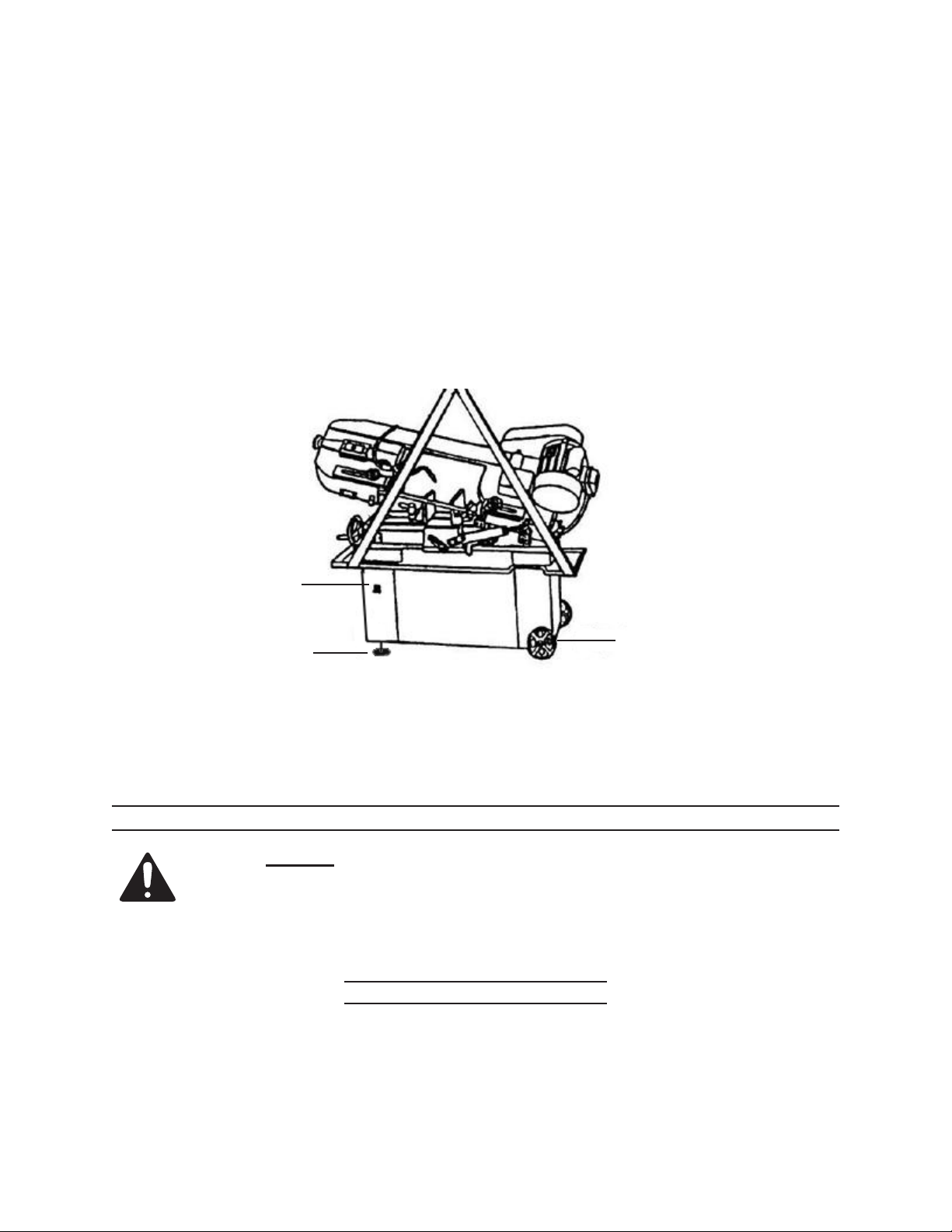

(See Figure B.)

5.

6.

7.

Screw in the two Levelers (93) into the two threaded mounting holes located

underneath the bottom/left side of the Stand (77S). (See Figure B.)

Carefully lower the Bandsaw to the oor surface. Then turn the two Levelers (93)

clockwise or counterclockwise to properly level the Stand (77S).

(See Figure B.)

Attach the Hand Rod (98-1) to the Stand Assembly (77S) using Screw (98-2),

washer (98-3) and Hex Nut (98-4). See Diagram on page 39.

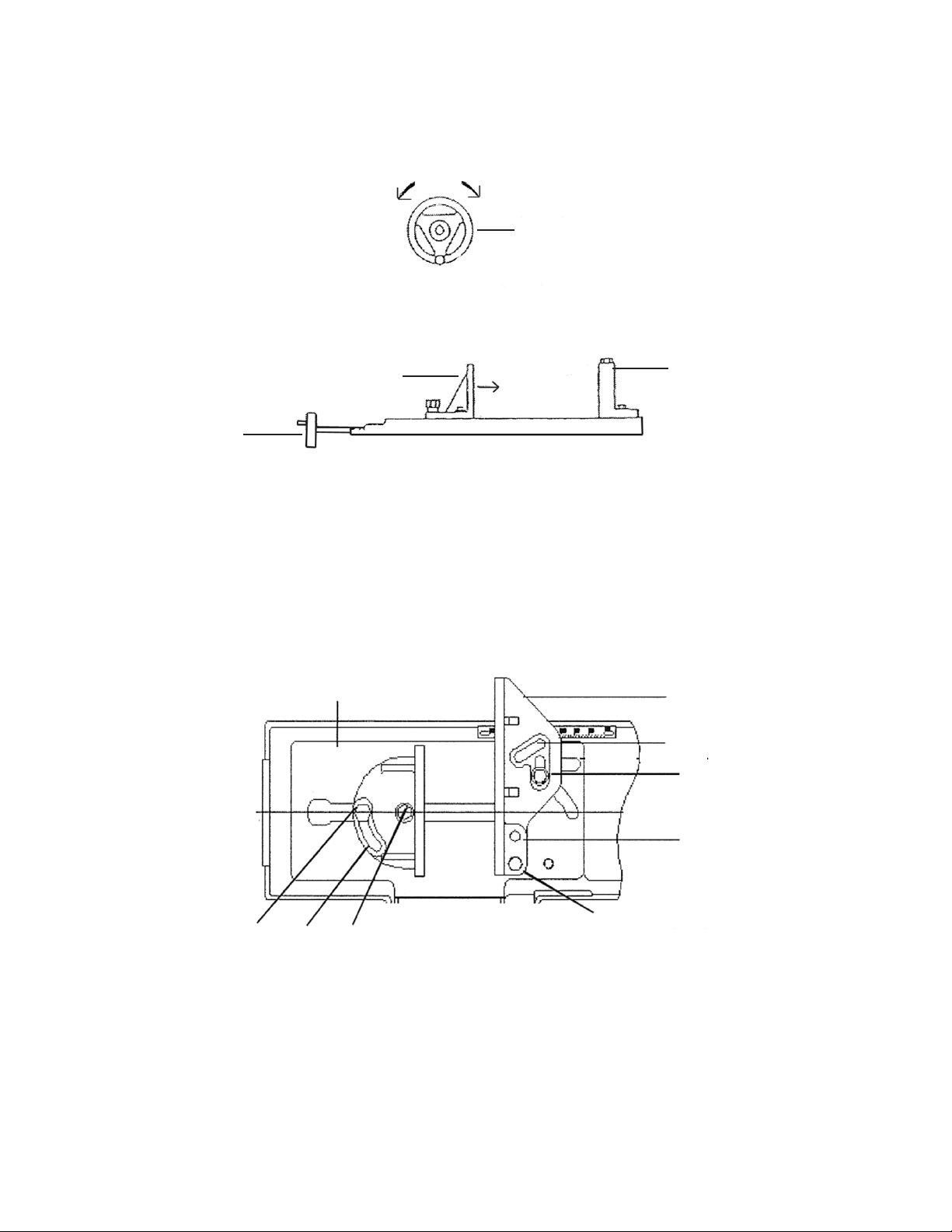

FIGURE B

STAND (77S)

WHEEL ROD (92-4)

WHEEL (92-2)

LEVELER (93)

WASHER (92-1)

COTTER PIN (92-3)

8.

NOTE: The Bandsaw is factory pre-wired to operate on a grounded, 120 volt

system. However, if rewired, the Bandsaw is also designed to operate on a

grounded, 240 volt system. For information about how to switch the electrical

system from 120 volt to 240 volt, refer to the “Electrical Schematics” toward the

end of this manual. WARNING! Only a qualied electrician should attempt

to rewire the Bandsaw.

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this manual including all text under subheadings therein

before set up or use of this product.

Caution: Even though the unit is equipped with wheels and a carrying handle,

always seek help when wheeling the unit around the shop.

TO USE THE QUICK VISE

1.

2.

Place the workpiece between the Vise Jaws (9, 22) with the amount to be cut off

extending out past the Saw Blade (251). (See Figure C, next page.)

The Bandsaw is equipped with a quick action Vise Jaw mechanism which allows

you to instantly position the moveable Front Vise Jaw (9). (See Figure C.)

Page 12SKU 97009 For technical questions, please call 1-800-444-3353.

Page 13

3.

To operate, turn the Hand Wheel (5S) counterclockwise 1/2 turn and move the

Front Vise Jaw (9) to the desired position. Then tighten the Front Vise Jaw

against the workpiece by turning the Hand Wheel clockwise. (See Figure C.)

HAND WHEEL (5S)

FIGURE C

HAND WHEEL (5S)

4.

Setting up the Quick Vise for a straight (0°) cut:

Loosen the Screws (H) and (G) of Front Vise Jaw (F).

•

Turn the Hand Wheel (5S) counterclockwise by half a turn and slide back the

•

Front Vise Jaw (9).

Loosen Screw (A and B) and note that Screw (A) should be in the slot which is

•

parallel with the Rear Vise Jaw.

Rear Vise Jaw at the scale side should be aligned with the zero (0) on the rule.

•

Tighten Screws (A and B). (See Figure D.)

FRONT VISE JAW (9)

FIGURE D

BASE (1)

REAR VISE JAW (22)

22

Note: Make

C

A

D

sure “C” slot is

free of casting

ush so the

vise can be

positioned in

all angles.

5.

B

G

9

H

ORIGINAL POSITION (FOR 0° CUTTING)

Setting up the Quick Vise an angle:

Remove Screws (A and B) from base of the Rear Vise Jaw (22).

•

Position (D) over (B) and attach the Screw and Washer (19 and 22) and attach Screw

•

(B).

Attach Carriage Screw (17) onto Slot (C) through the curved slot in the Base (1).

•

Align edge of the Rear Vise Jaw with the indexing rule and tighten Screws at (B and

•

C). (See Figure E.)

Page 13SKU 97009 For technical questions, please call 1-800-444-3353.

Page 14

FIGURE E

THE POSITION FOR AN ANGLE (90°) CUT.

A

D

B

6.

Setting up the Quick Vise for cutting a 12” workpiece:

Remove both fasteners from the Rear Vise Jaw (22).

•

Position (B) over the outer threaded hole on the Base (1).

•

Position Slot (A) over the small rectangular opening across the Base (1).

•

Attach Screws (A and B). Align the lower edge of the Rear Vise Jaw (22) with

•

the “0” index mark adjacent to the 16° degree setting. Tighten the screws.

(See Figure F)

FIGURE F

A

D

B

TO ADJUST THE STOP BLOCK

For repeated cuts of pre-set lengths

1.

2.

Loosen the Thumb Screw (38) that holds the Stop Block (41) to the Stock Stop

Rod (40). (See Figure G)

Adjust the Stop Block (41) to the desired length position. Then re-tighten the

Thumb Screw (38). (See Figure G)

Page 14SKU 97009 For technical questions, please call 1-800-444-3353.

Page 15

FIGURE G

THUMB SCREW

(38)

STOCK

STOP ROD

(40)

STOP BLOCK

(41)

WORKPIECE

(NOT INCLUDED)

TO CONVERT THE BANDSAW FOR VERTICAL USE

1.

2.

NOTE: Notching, slitting, and contour work is best done with the Bandsaw in its

vertical position.

Raise the Saw Head to its full vertical position, making sure it locks into position

by turning the Cylinder’s (216) on/off valve to its “OFF” position (the spoke to be

positioned cross the cylinder). (See Figure H.)

FIGURE H

CYLINDER (216)

Page 15SKU 97009 For technical questions, please call 1-800-444-3353.

Page 16

3.

Remove the two Screws (266-7), and remove the Deector Plate (266-3).

(See Figure I.)

DEFLECTOR PLATE (266-3)

SAW BLADE (251)

SCREWS (266-7)

FIGURE I

4.

Guide the Saw Blade (251) through the slot in the Vertical Saw Table (55-2), and

secure it in position with the two Screws (266-7).

(See Figure J.)

VERTICAL SAW TABLE (55-2)

1.

When using the Bandsaw, always change the Saw Blade (251) speed to best suit

the material being cut. The illustration below shows several settings for several

types of materials. (See Figure K.)

Material Speed

Stainless Alloy Steels

Bearing Bronze

Medium to High Carbon Steels

Hard Brass or Bronze

Low to Medium Carbon Steel

Soft Brass

Aluminum

Plastic

SCREWS (266-7)

FIGURE J

TO ADJUST THE BLADE SPEED

Belt Groove Used

(Feet Per Minute)

90 FPM Small Largest

135 FPM Medium Large

195 FPM Large Medium

255 FPM Largest Small

Motor Pulley Saw Pulley

FIGURE K

Page 16SKU 97009 For technical questions, please call 1-800-444-3353.

Page 17

2.

To adjust the Saw Blade (251) speed, loosen the two Hex Nuts (304) and Hex

Screws (307-2). Slide the Motor (300) forward to release tension on the Belt

(208). (See Figure L.)

BELT (208)

FIGURE L

3.

(REMAINING 3 HEX NUTS NOT SHOWN)

HEX NUT (304)

MOTOR MOUNT PLATE (303)

Remove the Belt (208) from its two Pulleys (206, 296). Place the Belt onto the

two Pulleys according to the Saw Blade (251) speed desired. Then move the

Motor (300) back to its original position and secure in place by tightening the

previously loosened two nuts and two screws. (See Figures L and M.)

Saw Pulley Motor Pulley Speed

(Feet Per Minute)

90 FPM

135 FPM

195 FPM

255 FPM

FIGURE M

4.

1.

Verify belt tension by pressing the belt between the pulleys. Deection should

be about 3.8”. In time, the belt will stretch and loose its tension. Loosen the Hex

Nut (302) and back off the Belt Tension Limiter Bolt (301). Turn the Belt Tension

Limiter Bolt (301) against the Motor Mount Bracket (307) and tighten the Hex Nut

(302).

TO ADJUST THE BLADE GUIDE BEARINGS

IMPORTANT: Blade Guide Bearings (266-10) adjustment is a critical factor in

the performance of the Bandsaw. It is always best to try a new Saw Blade (251)

to see if it will correct poor cutting quality before attempting to adjust the Blade

Guide Bearings. For example, if a Saw Blade becomes dull on one side sooner

Page 17SKU 97009 For technical questions, please call 1-800-444-3353.

Page 18

than the other, it will begin cutting crooked. A Saw Blade replacement will correct

this problem, whereas Blade Guide Bearings adjustment will not.

2.

If a new Saw Blade (251) does not correct the problem, check the clearance

between the Saw Blade and Blade Guide Bearings (266-10) to obtain proper

clearance. NOTE: There should only be a maximum of 0.001 clearance

between the Saw Blade and Blade Guide Bearing. To obtain this clearance,

adjust as follows:

The Blade Guide Bearings (266-10) are mounted to the Guide Pivot Assemblies

•

(270S) and can be adjusted. (See Figure N.)

Loosen the Hex Socket Head Screw (269-9) while holding the Guide Pivot

•

Assembly (270S) with an allen wrench (not included). (See Figure N.)

Position the Guide Pivot Assembly (270S) by turning it to the desired position of

•

clearance. Then re-tighten the Hex Head Socket Screw (269-9).

(See Figure N.)

Adjust the second Blade Guide Bearing (266-10) in the same manner.

•

SAW BLADE

(251)

GUIDE PIVOT ASSY.

(270S)

HEX SOCKET HEAD SCREW (269-9)

BLADE GUIDE BEARING (266-10)

1.

2.

3.

4.

BLADE GUIDE BEARING (266-10)

FIGURE N

TO ADJUST THE BLADE TRACKING

Raise the Bandsaw to its full vertical position, making sure it locks in position by

turning the Cylinder (216) to its “OFF” position. (See Figure H.)

Turn on the Bandsaw. The Saw Blade (251) is tracking properly when the back

of the Blade is just touching the edge of the Idler Wheel (250-1) ange. The back

of the Blade should not be rubbing against the ange.

(See Figure O, next page.)

If adjustment is necessary, the Blade Guide Bearings (266-10) shoud be clear of

the Saw Blade (251). (See Figure N.)

Loosen the upper Hex Head Screw (243) to a point where it is just barely snug.

(See Figure O, next page.)

Page 18SKU 97009 For technical questions, please call 1-800-444-3353.

Page 19

5.

With the Bandsaw running, turn the Adjusting Hex Head Screw (240) until the

Saw Blade (251) is tracking properly, making sure Blade tension is maintained by

turning the Adjustable Blade Knob (245) clockwise. (See Figure O.)

6.

Make sure to retighten the upper Hex Head Screw (243) when adjusment is

complete. (See Figure O.)

BLADE TENSIONER

KNOB (245)

FIGURE O

HEX HEAD SCREW

(243)

ADJUSTING

HEX HEAD SCREW

(240)

TO ADJUST THE BLADE TENSION

1.

Turn the Blade Tensioner Knob (245) clockwise to increase tension on the Saw

Blade (251). Turn the Knob counterclockwise to decrease tension on the Saw

Blade. Correct tension is aquired when the Saw Blade does not slip on the Drive

and Idler wheels (231S and 250-1). (See Figure O.)

2.

NOTE: When the Bandsaw is not in use over long periods of time, release the

tension on the Saw Blade (251).

TO ADJUST THE FEED RATE

Note: Feed rate is adjusted by the Bleed Valve above on/off valve of the cylinder.

Turning the wheel clockwise slows down the arm’s movement.

Page 19SKU 97009 For technical questions, please call 1-800-444-3353.

Page 20

TO ADJUST THE BLADE GUIDE BRACKETS

1.

2.

3.

The Adjustable Blade Guide Knob (261) is adjusted by loosening the Knob and

sliding the Adjustable Bracket (269S) up or down to accommodate the width of

the workpiece. (See Figure Q.)

The Adjustable Bracket (269S) should be set as close as possible to the

workpiece, without interfering with the workpiece. (See Figure Q.)

Once the adjustment is made, make sure to retighten the Adjustable Blade Guide

Knob (261). (See Figure Q.)

ADJUSTABLE BRACKET (269S)

FIGURE Q

ADJUSTABLE BLADE GUIDE

KNOB (261)

1.

2.

3.

4.

5.

TO FILL THE COOLANT TANK

NOTE: When cutting magnesium, use soluble oils or emulsions (oil/water mix)

as water only will greatly intensify any accidental magnesium chip re. See your

industrial coolant supplier for specic coolant recommendations when cutting

magnesium.

Remove the Hose (78) at the top of the Coolant Tank (82). Then slide the

Coolant Tank out from under the Stand (77S) of the Bandsaw. (See Figure R.)

Fill the Coolant Tank to about 80% capacity with a clean, water-soluble coolant

(not included). (See Figure R.)

Slide the Coolant Tank (82) back under the Stand (77S) of the Bandsaw. Then

re-insert the Hose (78) through the top of the Coolant Tank. (See Figure R.)

IMPORTANT: The water-soluble coolant should be replaced as often as is

necessary to keep metal debris in the coolant from clogging the hoses.

Page 20SKU 97009 For technical questions, please call 1-800-444-3353.

Page 21

FIGURE R

HOSE (78)

COOLANT TANK (82)

BASIC BANDSAW OPERATION - VERTICAL POSITION

1.

2.

3.

WARNING!

Always wear ANSI-approved safety impact eye goggles when operating

•

the Bandsaw. Never wear loose tting clothin.

When operating the machine, keep the Bandsaw Blade enclosure closed.

•

Do not plug the Power Cord into an electrical outlet until all necessary

•

adjustments (as previously discussed in this manual) have been made.

Cut only at workpieces when the Bandsaw is in its vertical position.

•

Never attempt to cut pipes or other round objects with the Bandsaw in its

vertical position.

Before cutting, turn on the Bandsaw and check for excessively loose Saw

•

Blade (251) tension or machine vibration. If this is found, turn off the

Bandsaw and correct the problem before using.

Always keep hands and ngers safely away from the cutting area.

•

Raise the Saw Head Assembly to its full vertical position, making sure it locks in

place by turning the Cylinder (216) to its “OFF” position. (See Figure S.)

Check to make sure the Motor Toggle Switch (750S4) and Coolant Pump Toggle

Switch (750S2) are both in their “OFF” positions. (See Figure S.)

4.

Plug the Power Cable (500) into the nearest 120 volt, grounded, electrical

outlet. NOTE: If the Bandsaw has been re-wired to operate on a 240 volt

system then plug the Power Cord into the nearest 240 volt, grounded, electrical

outlet.

Page 21SKU 97009 For technical questions, please call 1-800-444-3353.

Page 22

5.

Turn the Coolant Pump Fitting (91S) to its “OPEN” position. Then turn the

Coolant Pump Toggle Switch (750S2) to its “ON” position. (See Figure S.)

6.

7.

8.

9.

10.

Turn the Motor Toggle Switch (750S4) to its “ON” position. (See Figure S.)

Set the workpiece on the Vertical Saw Table (55-2), making sure to keep

downward pressure on the workpiece throughout the cutting process. (See

Figure S.)

When cutting a large workpiece, make sure its entire length is properly

supported. If necessary, use a roller stand (not included) with a large workpiece.

Allow the Saw Blade (251) to turn up to full speed before feeding the workpiece

into the Blade. (See Figure S.)

Feed the workpiece into the Saw Blade (251) gradually. Do not force the

Bandsaw to remove material faster than it is designed to cut. (See Figure S.)

SAW HEAD ASSY.

FIGURE S

COOLANT PUMP FITTING (91S)

MOTOR TOGGLE SWITCH (750S4)

COOLANT PUMP

TOGGLE SWITCH

(750S2)

SAW BLADE (251)

VERTICAL SAW TABLE (55-2)

CYLINDER (216)

Page 22SKU 97009 For technical questions, please call 1-800-444-3353.

Page 23

11.

Never attempt to remove material stuck in the moving parts of the Bandsaw

while it is plugged in and running. Turn off the Bandsaw if the workpiece is to be

backed out of an uncompleted cut.

12.

13.

14.

1.

Once the cut is made, turn the Motor Toggle Switch (750S4) to its “OFF”

position. Turn the Coolant Pump Toggle Switch (750S2) to its “OFF” position.

Turn the Coolant Pump Fitting (91S) to its “CLOSED” position. The unplug the

Power Cord (500) from its electrical outlet. (See Figure S.)

Wait until the Saw Blade (251) comes to a complete stop. Then remove the

workpiece and scrap material from the Vertical Saw Table (55-2).

(See Figure S.)

Turn the Cylinder (216) to its “ON” position. Slowly lower the Saw Head

Assembly to its horizontal position. Then turn the Cylinder to its “OFF” position

to lock the Saw Head Assembly in place. (See Figure S.)

BASIC BANDSAW OPERATION - HORIZONTAL POSITION

WARNING!

Always wear ANSI-approved safety impact eye goggles when operating

•

the Bandsaw.

When operating the machine, keep the Bandsaw Blade enclosure closed.

•

2.

3.

4.

5.

Do not plug the Power Cord into an electrical outlet until all necessary

•

adjustments (as previously discussed in this manual) have been made.

Before cutting, turn on the Bandsaw and check for excessively loose Saw

•

Blade (251) tension or machine vibration. If this is found, turn off the

Bandsaw and correct the problem before using.

Always keep hands and ngers safely away from the cutting area.

•

Turn the Cylinder (216) to its “ON” position, and raise the Saw Head to its full

vertical position. Then turn the Cylinder to its “OFF” position to lock the Saw

Head in place. (See Figure T, next page.)

Secure the workpiece in the Vise (9, 22) assembly. When cutting a large

workpiece, make sure its entire length is properly supported. If necessary, use a

roller stand (not included) with a large workpiece. (See Figure T, next page.)

If cutting several workpieces at the same length, you may wish to adjust the Stop

Block (41) to the desired position. (See Figure T, next page.)

Check to make sure the Motor Toggle Switch (750S4) and Coolant Pump Toggle

Switch (750S2) are both in their “OFF” positions. (See Figure T, next page.)

Page 23SKU 97009 For technical questions, please call 1-800-444-3353.

Page 24

6.

Plug the Power Cable (500) into the nearest 120 volt, grounded, electrical

outlet. NOTE: If the Bandsaw has been re-wired to operate on a 240 volt

system then plug the Power Cord into the nearest 240 volt, grounded, electrical

outlet.

7.

8.

9.

10.

11.

12.

Turn the Coolant Pump Fitting (91S) to its “OPEN” position. Then turn the

Coolant Pump Toggle Switch (750S2) to its “ON” position. (See Figure T.)

Turn the Motor Toggle Switch (750S4) to its “ON” position. (See Figure T.)

Turn the Cylinder to its “ON” position, and slowly lower the Saw Head until the

Saw Blade (251) is just above the workpiece cut line. (See Figure T.)

Allow the Saw Blade (251) to turn up to full speed before feeding the Blade into

the workpiece. (See Figure T.)

Through the Hydraulic Feed System, allow the Saw Arm to lower, while it

gradually feeds the Saw Blade (251) into the workpiece. Do not force the

Bandsaw to remove material faster than it was designed to cut. NOTE: The

speed at which the Saw Arm moves downward may be increased or decreased

by adjusting the Bleed Valve on the Cylinder (216). (See Figure T.)

Never attempt to remove material stuck in the moving parts of the Bandsaw

while it is plugged in and running. Turn off the Bandsaw if the workpiece is to be

backed out of an uncompleted cut.

COOLANT PUMP FITTING

(91S)

SAW HEAD ASSY.

FIGURE T

MOTOR

TOGGLE SWITCH

(750S4)

COOLANT PUMP TOGGLE SWITCH

(750S2)

CYLINDER (216)

Page 24SKU 97009 For technical questions, please call 1-800-444-3353.

Page 25

13.

IMPORTANT: When in the horizontal cutting mode only, the Motor Toggle Switch

(750S4) will automatically turn to its “OFF” position and shut off the Bandsaw’s

Motor when the cut has been completed. (See Figure T.)

14.

15.

16.

Once the cut is made, and the motor is switched off, turn the Coolant Pump

Toggle Switch (750S2) to its “OFF” position. Turn the Coolant Pump Fitting

(91S) to its “CLOSED” position. Then unplug the Power Cable (500) from its

electrical outlet. (See Figure T.)

Wait until the Saw Blade (251) comes to a complete stop. Then raise the Saw

Head to its full vertical position. Turn the Cylinder (216) to its “OFF” position

to lock the Saw Head in place. Remove the workpiece from the Vise (9, 22)

assembly and scrap material from the Base (1) of the Bandsaw. (See Figure T.)

Turn the Cylinder (216) to its “ON” position. Slowly lower the Saw Head to its

horizontal position. Then turn the Cylinder to its “OFF” position to lock the Saw

Head in place. (See Figure T.)

WARNINGWARNING

MAINTENANCE AND SERVICING

Risk of serious personal injury from accidental starting or

electric shock. Turn the Power Switch of the Bandsaw to its

“OFF” position and unplug the tool from its electrical outlet

before performing any inspection, maintenance, or cleaning

procedures.

1.

2.

Damaged equipment can fail, causing serious personal

injury. Do not use damaged equipment. If abnormal noise or

vibration occurs, have the problem corrected before further

use.

INSPECTION, MAINTENANCE, AND CLEANING

Before each use, inspect the general condition of the Bandsaw. Check for

loose screws, misalignment or binding of moving parts, cracked or broken

parts, damaged electrical wiring, and any other condition that may affect its safe

operation. Do not use damaged equipment.

Before each use, inspect the Saw Blade (251). Using a dull Saw Blade will

cause excessive wear on the Motor of the Bandsaw and will not produce a

satisfactory cut. Replace with a new Saw Blade when needed. To replace the

Saw Blade:

NOTE: Make sure to wear heavy duty work gloves to avoid accidental injury

•

from the Saw Blade (251) when performing this procedure.

Page 25SKU 97009 For technical questions, please call 1-800-444-3353.

Page 26

Turn the Cylinder (216) to its “ON” position, and raise the Saw Head to its full

•

vertical position. Then turn the Cylinder to its “OFF” position to lock the Saw

Head in place. (See Figure U.)

Open the Blade Back Cover (286S). (See Figure U.)

•

Release Saw Blade (251) tension by turning the Adjustable Blade Knob (261).

•

(See Figure U.)

Slip the old Saw Blade (251) off the Idler Wheel (250S), Drive Wheel (231S),

•

and Guide assemblies. (See Figure U.)

Place the new Saw Blade (251) between each of the Guide assemblies and

•

around the Idler Wheel (250S) and Drive Wheel (231S). IMPORTANT: The

teeth must be pointing downward toward the Motor. (See Figure U.)

Tighten the tension on the new Saw Blade (251) by turning the Adjustable

•

Blade Tensioner Knob (261) in a clockwise direction. (See Figure U.)

Close the Blade Back Cover (286S). (See Figure U.)

•

ADJUSTABLE BLADE KNOB (261)

IDLER WHEEL

(250S)

FIGURE U

3.

UPPER GUIDE ASSY.

SAW

BLADE

(251)

LOWER GUIDE ASSY.

DRIVE WHEEL

(231S)

BLADE

BACK

COVER

(286S)

To lubricate the Worm Gear Shaft Assembly: The Worm Gear Shaft Assembly

(202S) runs in an oil bath Gear Box Assembly (201S) and should not require an

oil change more than once a year, unless the oil becomes contaminated or a leak

occurs due to improper replacement of the Gear Box Cover. To change oil in the

Gear Box Assembly:

Position the Saw Arm in the horizontal position.

•

Remove the four Hex Socket Head Screws, Gear Box Cover, and Gear Box

•

Gasket. (See Figure V.)

Page 26SKU 97009 For technical questions, please call 1-800-444-3353.

Page 27

Remove the old oil from inside the Gear Box Assembly (201S) and replace the

•

oil using 140 weight gear oil (not included). The new oil should just come to the

edge of the Gear Box (202-1). Do not overll. (See Figure V.)

Replace the Gear Box Gasket, Gear Box Cover, and four Hex Socket Head

•

Screws. (See Figure V.)

HEX SOCKET HEAD SCREWS

GEAR BOX COVER

GEAR BOX GASKET

4.

To replace the coolant: Remove the Hose (78) at the top of the Coolant

Tank (82). Then slide the Coolant Tank out from under the Stand (77S) of the

Bandsaw. (See Figure W.)

Fill the Coolant Tank to about 80% capacity with a clean, water-soluble coolant

•

(not included). (See Figure W.)

Slide the Coolant Tank (82) back under the Stand (77S) of the Bandsaw. Then

•

re-insert the Hose (78) through the top of the Coolant Tank. (See Figure W.)

FIGURE V

&

GEAR BOX ASSY. (201S)

IMPORTANT: The water-soluble coolant should be replaced as often as is

•

necessary to keep metal debris in the coolant from clogging the hoses.

FIGURE W

HOSE (78)

COOLANT TANK (82)

Page 27SKU 97009 For technical questions, please call 1-800-444-3353.

Page 28

5.

To clean the exterior parts of the Bandsaw, use only a clean cloth and mild

detergent or mild solvent to clean the body of the Saw. Do not immerse any

electrical part of the machine in liquid.

6.

CAUTION! All maintenance, service, and repairs not mentioned in this

manual must only be performed by a qualied technician.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE

MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF

ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO

THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES

THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED

AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR

REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT PARTS THERETO.

Page 28SKU 97009 For technical questions, please call 1-800-444-3353.

Page 29

TROUBLESHOOTING

Adjust the speed and/or feed for the material being cut.

3.

4.

5.

6.

3.

4.

5.

6.

Page 29SKU 97009 For technical questions, please call 1-800-444-3353.

Page 30

PARTS LIST

Part

Description

Specications

Qty.

Page 30SKU 97009 For technical questions, please call 1-800-444-3353.

Page 31

PARTS LIST - CONTINUED

Part

Description Specication

Qty.

Page 31SKU 97009 For technical questions, please call 1-800-444-3353.

Page 32

PARTS LIST - CONTINUED

Part Description Specications Qty.

Leveler

Page 32SKU 97009 For technical questions, please call 1-800-444-3353.

Page 33

PARTS LIST - CONTINUED

Part

Description Specications Qty.

Page 33SKU 97009 For technical questions, please call 1-800-444-3353.

Page 34

PARTS LIST - CONTINUED

Part Description Specications

Qty.

Blade Tensioner Knob

0.032” x 3/4” x 93” - 10T

Page 34SKU 97009 For technical questions, please call 1-800-444-3353.

Page 35

PARTS LIST - CONTINUED

Part

259

Description

Specications Qty.

Page 35SKU 97009 For technical questions, please call 1-800-444-3353.

Page 36

PARTS LIST - CONTINUED

Part

Description Specications Qty.

Belt Tension Limiter Bolt

Page 36SKU 97009 For technical questions, please call 1-800-444-3353.

Page 37

PARTS LIST - CONTINUED

Part

Description Specications Qty.

Page 37SKU 97009 For technical questions, please call 1-800-444-3353.

Page 38

ASSEMBLY DIAGRAM

Page 38SKU 97009 For technical questions, please call 1-800-444-3353.

Page 39

ASSEMBLY DIAGRAM - CONTINUED

Page 39SKU 97009 For technical questions, please call 1-800-444-3353.

Page 40

ASSEMBLY DIAGRAM - CONTINUED

Page 40SKU 97009 For technical questions, please call 1-800-444-3353.

Page 41

ASSEMBLY DIAGRAM - CONTINUED

Page 41SKU 97009 For technical questions, please call 1-800-444-3353.

Page 42

ASSEMBLY DIAGRAM - CONTINUED

Page 42SKU 97009 For technical questions, please call 1-800-444-3353.

Page 43

ELECTRICAL SCHEMATIC

Yellow

240 VOLT

240 VOLT

White

Yellow

120 VOLT

120 VOLT

Page 43SKU 97009 For technical questions, please call 1-800-444-3353.

Page 44

ELECTRICAL SCHEMATIC - CONTINUED

Page 44SKU 97009 For technical questions, please call 1-800-444-3353.

Page 45

ELECTRICAL SCHEMATIC - CONTINUED

Page 45SKU 97009 For technical questions, please call 1-800-444-3353.

Page 46

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product

is free from defects in materials and workmanship for the period of 90 days from the date

of purchase. This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity,

improper installation, normal wear and tear, or to lack of maintenance. We shall in no event

be liable for death, injuries to persons or property, or for incidental, contingent, special

or consequential damages arising from the use of our product. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation

of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either

repair or replace the product at our election or we may elect to refund the purchase price

if we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

Page 46SKU 97009 For technical questions, please call 1-800-444-3353.

Loading...

Loading...