Harbor Freight Tools 94623 Product manual

2-IN-1

94623

PIPE BENDER

ASSEMBLY AND OPERATION

Visit our website at: http://www.harborfreight.com

SAVE THESE INSTRUCTIONS. READ ALL PRECAUTIONS

AND INSTRUCTIONS.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this document or any artwork contained

herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this document may not be drawn proportionally. Due to continuing improvements, actual product

may differ slightly from the product described herein. Tools required for assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

SPECIFICATIONS

Product Applications

Pipe Size Capacity 1/2” to 7/8” Diameter tubing.

Maximum Bend Up to 180°

Construction

Accessories Bending dies (Qty. 2)

Designed for bending copper

and aluminum pipe.

Cast iron and steel tube.

Steel rollers. Aluminum hardware.

UNPACKING

When unpacking, check to make sure that

the item is intact and undamaged. If any parts are

missing or broken, please call Harbor Freight Tools

at the number shown on the cover of this document

as soon as possible.

IMPORTANT SAFETY

INFORMATION

Assembly Precautions

Assemble only according to these instruc-1.

tions. Improper assembly can create haz-

ards.

Revised Manual 10k

Wear ANSI-approved safety goggles and 2.

heavy-duty work gloves during assembly.

Keep assembly area clean and well lit.3.

Keep bystanders out of the area during as-4.

sembly.

Do not assemble when tired or when under 5.

the inuence of drugs or medication.

Use Precautions

This product is not a toy. Do not allow chil-1.

dren to play with or near this item.

Use for intended purpose(s) only.2.

Inspect before use; do not use if product is 3.

damaged.

Maintain product labels and nameplates. 4.

These carry important safety information.

If unreadable or missing, contact Harbor

Freight Tools for a replacement.

This tool is designed to bend soft metal pipe 5.

or tubing, such as copper or aluminum. Do

not attempt to bend hard metal pipe, such as

black iron pipe. You may damage the tool.

Do not attempt to bend brittle materials, such 6.

as glass or hard plastic. Those materials

may shatter and potentially cause injury. Always wear ANSI-approved safety impact eye

goggles and heavy duty work gloves when

using the Tube Bender.

As the pipe or tubing is being bent, there is 7.

a signicant pinch hazard created. Keep

hands, ngers, feet, and any item which may

be injured or damaged away from the Tube

Bender and hinge point areas of this tool

when in operatoin.

ASSEMBLY & OPERATION

INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this document including

all text under subheadings therein

before set up or use of this product.

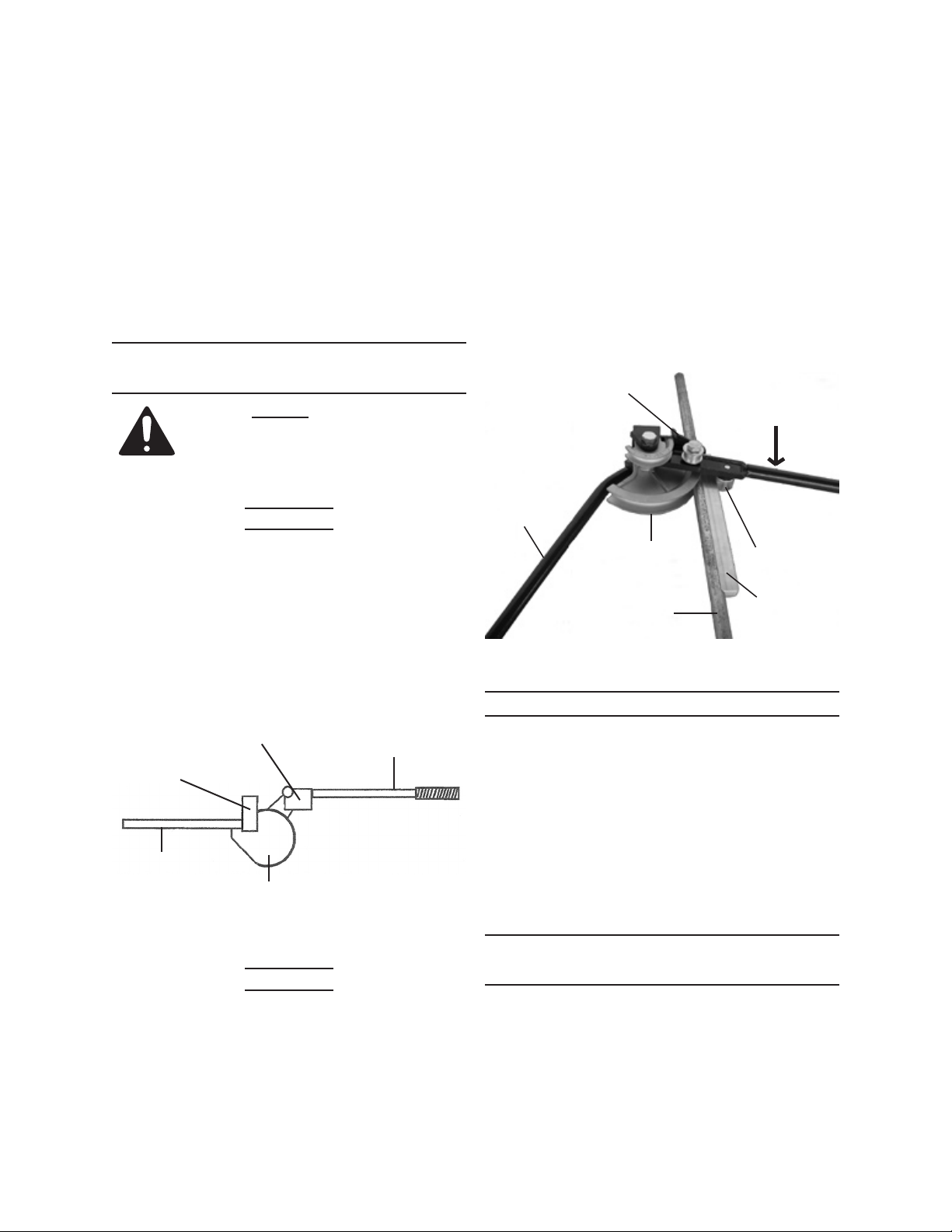

Assembly

Insert the Handle (4) through the Tube Hold-1.

er (1). Screw the Handle into the threaded

hole of the Tubing Bender (2) by turning

clockwise until tight. (See Figure A.)

Insert the Handle with Grip (5) into the Con-2.

necting Plate Assembly (3). (See Figure A.)

Insert the tubing along the Handle (4). Move 3.

the Tube Holder (1) to allow the tube to slide

under it, and position the Tube Holder (1) to

hold the tube in place. (See Figure B.)

While holding the tube along the Handle (4), 4.

pull down on the Handle with Grip (5). The

tube will be formed along the Tubing Bender

(2). Continue pulling until the desired bend

has been achieved, from 0 to 180 degrees.

(See Figure B.)

When completed, remove the bent tube from 5.

the tool.

TUBE HOLDER

(1)

HANDLE WITH GRIP

(PULL DOWN TO

BEND TUBE)

FIGURE B

HANDLE

(4)

TUBING BENDER

(2)

TUBING

(NOT INCLUDED)

(5)

CONNECTING

PLATE ASSY.

(3)

5/8” OR 7/8”

BENDING DIE

(6, 7)

TUBE HOLDER

(1)

CONNECTING

PLATE ASSY.

(3)

HANDLE WITH GRIP

(5)

Before each use, inspect the Pipe Bender for 1.

bent or damaged components.

Periodically, lubricate the hinge points of the 2.

MAINTENANCE

tool with a medium weight oil.

FIGURE A

HANDLE

(4)

TUBING BENDER

(2)

Regularly wipe down and clean the tool to 3.

keep it in best condition.

When not in use, store the tool in a clean, 4.

dry, safe location out of reach of children and

other unauthorized persons.

PLEASE READ THE FOLLOWING

Operation

Select the proper bending die (5/8” or 7/8”) 1.

to suit the diameter of tubing you wish to

bend.(See Figure B.)

Rotate the Handle with Grip (5) around the 2.

Tubing Bender (2) until it is in a straight line

with the other Handle (4). (See Figure B.)

SKU 94623 For technical questions, please call 1-800-444-3353 Page 2

THE MANUFACTURER AND/OR DISTRIBUTOR HAS

PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN

THIS DOCUMENT AS A REFERENCE TOOL ONLY. NEITHER

THE MANUFACTURER OR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE

BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY

REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT.

CAREFULLY

Loading...

Loading...