Page 1

BACKPACK SPRAYER

12 VOLT - 4.8 GAL. CAPACITY

Model

94573

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2006 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 10d

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings

and precautions, assembly, operating,

inspection, maintenance and cleaning

procedures. Write the product’s serial number

in the back of the manual near the assembly

diagram (or month and year of purchase if

product has no number). Keep this manual

and the receipt in a safe and dry place for

future reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling, and

all other information provided with

this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that follow

this symbol to avoid possible

injury or death.

DANGER indicates a

hazardous situation

which, if not avoided, will result

in death or serious injury.

WARNING indicates a

hazardous situation

which, if not avoided, could

result in death or serious injury.

CAUTION, used with

the safety alert

symbol, indicates a hazardous

situation which, if not avoided,

could result in minor or moderate

injury.

NOTICE is used to

address practices not

related to personal injury.

CAUTION, without the

safety alert symbol, is

used to address practices not

related to personal injury.

GENERAL SAFETY RULES

WARNING Read all safety warnings

and instructions. Failure to follow the

warnings and instructions may result

in electric shock, re and/or serious

injury.

Save all warnings and instructions

for future reference.

WORK AREA

Keep your work area clean and well 1.

lit. Cluttered and dark work areas invite

accidents.

Keep bystanders, children, and 2.

visitors away while operating the

Sprayer. Distractions can cause you to

lose control.

PERSONAL SAFETY

Stay alert. 1. Watch what you are doing,

and use common sense when operating

a power tool. Do not use the Sprayer

while tired or under the inuence of

drugs, alcohol, or medication. A moment

of inattention while operating power tools

may result in serious personal injury.

Dress properly. 2. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves

away from moving parts. Loose clothes,

jewelry, or long hair can be caught in

moving parts.

Page 2 For technical questions, please call 1-800-444-3353. SKU 94573

Page 3

Do not overreach. 3. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

Sprayer in unexpected situations.

Wear eye, breathing, and skin 4.

protection. Wear ANSI approved safety

impact goggles, a NIOSH-approved

respirator, latex gloves, and proper

safety clothing when using this product.

TOOL USE AND CARE

Do not force the Sprayer. 1. Use the

correct product for your application. The

correct product will do the job better and

safer at the rate for which it is designed.

SERVICE

Product service must be performed 1.

only by qualied service technician.

Service or maintenance performed by

unqualied personnel could result in a

risk of injury.

When servicing the Sprayer, use 2.

only identical replacement parts.

Follow instructions in the “Inspection,

Maintenance, And Cleaning” section

of this manual. Use of unauthorized

parts or failure to follow maintenance

instructions may create a risk of electric

shock or injury.

Store idle tools and equipment out of 2.

reach of children and other untrained

people. Tools and equipment are

dangerous in the hands of untrained

users.

Maintain the Sprayer with care. 3.

Keep this product clean. A properly

maintained tool is easier to control. Do

not use damaged tools and equipment.

Tag damaged tools and equipment “Do

not use” until repaired.

Check for misalignment or binding 4.

of moving parts, loose or broken

parts, and any other condition that

may affect the Sprayer’s operation.

If damaged, have the Sprayer serviced

before using. Many accidents are

caused by poorly maintained tools and

equipment.

Use only accessories that are 5.

recommended by the manufacturer

for your model. Accessories that may

be suitable for one product may become

hazardous when used on another

product.

SPECIFIC SAFETY RULES

Maintain labels and nameplates on 1.

the Sprayer. These carry important

information. If unreadable or missing,

contact Harbor Freight Tools for a

replacement.

Use the right product for the job. 2.

There are certain applications for which

this product was designed. Do not use

small tools, equipment, or attachments

to do the work of larger industrial tools,

equipment, or attachments. Do not use

this product for a purpose for which it

was not intended.

Industrial applications must follow 3.

OSHA requirements.

Store idle tools. 4. When not in use, store

the Sprayer in a clean, dry, safe location

out of reach of children.

This Sprayer is intended to be used 5.

only with water, liquid fertilizers,

liquid herbicides, and liquid

pesticides. Never attempt to spray

ammable, combustible, or corrosive

liquids with the Sprayer.

Page 3For technical questions, please call 1-800-444-3353.SKU 94573

Page 4

Always follow all chemical label 6.

precautions and local EPA regulations

when using liquid chemicals. Do

not touch harmful chemicals. After

use, clean the Sprayer thoroughly with

agents recommended by the chemical

manufacturer.

the tool to make sure ice has not

formed. Do not store the Sprayer

where the temperature will fall below 32°

Fahrenheit.

Do not keep water or any liquid 16.

chemicals in the Sprayer after use.

Never point the nozzle of the Spray 7.

Gun Assembly at yourself, other

people, pets and animals, or property.

A note on Chemicals disposal: 8. Never

attempt to burn unused fertilizers,

herbicides, pesticides, or any other types

of chemicals. Make sure to check with

your local solid waste authorities for

proper disposal procedures.

Always make sure children and 9.

animals do not have access to

chemically treated areas.

Dry running will cause damage to 10.

the inner seals. Make sure the water

or liquid chemical supply used for the

Sprayer is not dirty or sandy.

Do not pull or carry the Sprayer by its 11.

Spray Gun Assembly. Use the Handle

on the Sprayer to move the tool from one

location to another.

The work area should have adequate 12.

drainage to reduce the possibility of a

fall due to slippery surfaces.

Make sure to clean the Filter of the 17.

Sprayer before each use.

Never leave the Sprayer unattended.18.

When nished using the Sprayer, empty

the unit. Thoroughly clean the unit and

store it in a clean, dry, safe location out

of reach of children.

The warnings and cautions discussed 19.

in this manual cannot cover all possible

conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

People with pacemakers should consult 20.

their physician(s) before using this

product. Electromagnetic elds in close

proximity to a heart pacemaker could

cause interference to or failure of the

pacemaker.

SAVE THESE INSTRUCTIONS

GROUNDING

This product is designed for outdoor 13.

use only.

Keep the Cap and Spray Gun 14.

Assembly of the Sprayer connected

to the tool while the system is

pressurized. Prior to relling or

emptying the Tank, squeeze the

Trigger on the Spray Gun Assembly to

completely depressurize the system.

Prior to starting the Sprayer in cold 15.

weather, check all of the parts of

Page 4 For technical questions, please call 1-800-444-3353. SKU 94573

TO PREVENT

ELECTRIC SHOCK

AND DEATH FROM INCORRECT

GROUNDING WIRE

CONNECTION:

Check with a qualied electrician

if you are in doubt as to whether

the outlet is properly grounded.

Do not modify the power cord

plug provided with the tool.

Never remove the grounding

prong from the plug. Do not use

Page 5

the tool if the power cord or plug

is damaged. If damaged, have it

repaired by a service facility

before use. If the plug will not t

the outlet, have a proper outlet

installed by a qualied

electrician.

Double Insulated Tools: Tools with

Two Prong Plugs

V~

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

Volts Alternating Current

Outlets for 2-Prong Plug

Tools marked “Double Insulated” do 1.

not require grounding. They have a

special double insulation system which

satises OSHA requirements and

complies with the applicable standards

of Underwriters Laboratories, Inc., the

Canadian Standard Association, and the

National Electrical Code. (See Outlets

for 2-Prong Plug.)

Double insulated tools may be used in 2.

either of the 120 volt outlets shown in the

preceding illustration. (See Outlets for

2-Prong Plug.)

A

n0 xxxx/min.

Amperes

No Load Revolutions per Minute

(RPM)

Extension Cords

Note: Extension cords must not be used with

this item’s charger.

Page 5For technical questions, please call 1-800-444-3353.SKU 94573

Page 6

SPECIFICATIONS

Charger Input 120 V~ / 60 Hz

Charger Output 12 VDC

Battery Type Rechargeable 12V / 10 Ah

Charge Time 8 Hours

Charger Cord/Plug 58-1/2” L, 2-Prong

Spray Time Output Approximately 9 to 10 Hours

(Full Charge)

Tank Capacity 4.8 Gallons

Flow Rating 0.7 Gallons Per Minute

Maximum

Pressure

Unit Dimensions 7” Long x 15” Wide x 23-5/8” High

Spray Rod

Dimensions

Unit Weight

(Empty)

Accessories Conical Mist Nozzle

Additional

Features

65 PSI

28” Long x 3/8” Diameter

17.5 lb.

Four Hole Adjustable Nozzle

Mist Nozzle / 30° Dual Nozzle

Diaphragm Pump

Triple Screen Water Filtration

FIGURE E

CHARGER

(63)

CHARGING

PLUG

CHARGE FOR 8 HOURS

(DO NOT OVERCHARGE)

2. To charge the Battery (51), Turn the

Power Switch (58) to its “OFF” position.

(See Figure E.)

Insert the chrome Charging Plug of 3.

the Charger (63) into the Charging

Receptacle of the Sprayer. Make sure

to screw the chrome Charging Plug onto

the Receptacle rmly. (See Figure E.)

POWER

SWITCH

(58)

UNPACKING

When unpacking, make sure all that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon as

possible.

CHARGING INSTRUCTIONS

The Battery (51) for the Sprayer must 1.

be fully charged before using the tool.

When charging for the rst time, and all

subsequent charges, the charge time is

8 hours. Never charge the Battery (51)

for longer than 8 hours, as damage to

the Battery and/or Sprayer will occur.

Plug the Power Cord Plug of the Charger 4.

(63) into the nearest, 120 volt, grounded,

electrical outlet. (See Figure E.)

Charge the Battery (51) for 5. 8 hours.

IMPORTANT: The Charger (63) will not

automatically shut off when the Battery

(51) is fully charged. Avoid Battery/

tool damage by removing power to the

Charger at the end of 8 hours charge

time. (See Figure E.)

Keep children and pets away from the 6.

Battery while it is charging. Regularly

check the Battery to make sure it is

charging properly.

When nished charging, disconnect the 7.

Charger (63) from the electrical outlet.

Then, unscrew and remove the chrome

Charging Plug of the Charger (63) from

the Charging Receptacle of the Sprayer.

(See Figure E.)

On a full charge, the Sprayer will operate 8.

approximately 9 to 10 hours.

REV 06j

Page 6 For technical questions, please call 1-800-444-3353. SKU 94573

Page 7

ASSEMBLY AND OPERATING

INSTRUCTIONS

CAUTION! Wear eye, breathing, and skin

protection. Wear ANSI-approved safety

impact goggles, a NIOSH-approved

respirator, latex gloves, and proper

safety clothing when using this product.

Nozzle Selection And Assembly:

The Sprayer is equipped with the 1.

following Nozzle types:

30° DUAL NOZZLE

(60)

FIGURE F

a. 30° Dual Nozzle (60): Designed

for wider spray areas on short crops

and the spraying of herbicides and

pesticides. Follow the wind and move

in a parallel manner on one side while

spraying. (See Figure F.)

FOUR HOLE

ADJUSTABLE

NOZZLE (62)

FIGURE H

c. Four Hole Adjustable Nozzle (62):

Designed for spraying high crops

and fruit trees and the spraying of

pesticides. However, the Adjustable

Nozzle may result in signicant

overspray of pesticides.

(See Figure H.)

CONICAL MIST

NOZZLE (65)

FIGURE I

d. Conical Mist Nozzle (65): Designed

for spraying low crops and the spraying

of herbicides and pesticides. Allows for

a conical spray pattern. Follow the wind

and move in a parallel manner on one

side while spraying. (See Figure I.)

NOZZLE

(60, 61, 62, 65)

NOZZLE

NUT (1)

MIST

NOZZLE

(61)

FIGURE G

b. Mist Nozzle (61): Designed for narrow

spray areas on low crops and the

spraying of herbicides and pesticides.

Follow the wind and move in a parallel

manner on one side while spraying.

(See Figure G.)

NOZZLE GASKET

RING (4)

FIGURE J

SPRAY GUN ASSY.

2. To attach a Nozzle (60, 61, 62, 65) to

the Spray Gun, check to make sure

the Nozzle Gasket Ring (4) is properly

seated in the Nozzle Nut (1). Then,

screw the desired Nozzle into the Nozzle

Nut. (See Figure J.)

Page 7For technical questions, please call 1-800-444-3353.SKU 94573

Page 8

TANK

CAP (41)

TANK

FILTER (42)

FIGURE K

To Fill The Tank:

TANK

(64)

be sprayed. Then, squeeze the Trigger

to begin spraying. (See Figure L.)

NOTE: The Trigger (17) of the Spray Gun

Assembly may be locked in a continuous

run position with the Trigger Lock

(16). To do so, move the Trigger Lock

backward toward the Handle (21). To

return to manual operation, move the

Trigger Lock forward toward the Spray

Rod (9). (See Figure L.)

1. Prior to lling the Tank (64) of the

Sprayer with liquid, remove the Tank

Cap (41) and check to make sure the

Tank Filter (42) is clear of dirt and debris.

If necessary, remove the Filter and

thoroughly clean. (See Figure K.)

Next, insert the Tank Filter back into the 2.

opening of the Tank.

Fill the Tank with up to 4.8 gallons of 3.

liquid. Then, replace the Tank Cap on

the Tank.

To Operate The Sprayer:

CAUTION! Make sure other adults, children,

and animals do not have access to the

spray area(s).

NOTE: The Sprayer is heavy when

completely lled with liquid. Strap the

Sprayer on with assistance. Adjust the

Back Strap (45) as needed.

TRIGGER

TRIGGER

LOCK (16)

SPRAY

ROD (9)

FIGURE L

1. Grip the Handle (21) of the Spray Gun

Assembly rmly. Then, turn the Power

Switch (58) to its “ON” position.

(See Figures E and L.)

Point the Nozzle (60, 61, 62) of the 2.

Spray Gun Assembly toward the area to

(17)

HANDLE

(21)

As you spray, the system will begin to 3.

depressurize. When the distance of the

spray diminishes you will need to stop

spraying momentarily. Allow the Sprayer

to re-pressurize its system before

spraying again.

If it becomes necessary to rell the 4.

Tank (64) of the Sprayer, turn the Power

Switch (58) to its “OFF” position.

Continue squeezing the Trigger (17) on

the Spray Gun Assembly to completely

de-pressurize the system. Remove the

Tank Cap (41) from the Tank. Check to

make sure the Tank Filter (42) is clear

of dirt and debris. Rell the Tank with

liquid, and replace the Tank Cap. Turn

the Power Switch to its “ON” position

to pressurize the system, and continue

spraying. (See Figures E and K.)

When nished spraying, turn the Power 5.

Switch (58) to its “OFF” position.

Continue squeezing the Trigger (17) on

the Spray Gun Assembly to completely

depressurize the system. Remove the

Tank Cap (41) from the Tank (64), and

empty any remaining liquid into a safe

and secure container. Clean the Sprayer

thoroughly with agents recommended

by the chemical manufacturer. Allow the

unit to air-dry. Replace the Tank Cap

(41), and store the Sprayer in a clean,

dry, safe location out of reach of children

and other unauthorized people.

Page 8 For technical questions, please call 1-800-444-3353. SKU 94573

Page 9

INSPECTION, MAINTENANCE,

AND CLEANING

CAUTION! Make sure the Power Switch

(58) is in its “OFF” position and

unplugged from its Charger (63).

Then, de-pressurize the system

before performing any inspection,

maintenance, or cleaning of the

Sprayer.

Before each use,1. inspect the general

condition of the Sprayer. Check for

misalignment or binding of moving parts,

damaged or loose parts, dirt or debris in

the Filter and Nozzle, damaged electrical

wiring, and any other condition that

may affect the tool’s safe operation. If

abnormal noise or vibration occurs, have

the problem corrected before further use.

Do not use damaged equipment.

To clean: 2. If using liquid chemicals,

ush the interior and clean the exterior

of the Sprayer and its Spray Gun

Assembly thoroughly with cleaning

agents recommended by the chemical

manufacturer. Then, allow to air-dry. Do

not use solvents.

When storing: 3. Always completely

empty the Sprayer of liquid. Frost will

damage the Sprayer if the unit contains

liquid. Store the Sprayer in an indoor

area such as a garage or shed. Make

sure to store the Sprayer and any

chemicals in a safe, dry, clean

location out of reach of children and

other unauthorized people.

CAUTION! 4. All maintenance, service,

and repairs not discussed in this manual

should only be performed by a qualied

service technician.

TROUBLESHOOTING

Problem Possible Solution

Unit does not spray. Fully charge the battery.1.

Fill the tank.2.

Firmly tighten the Tank Cap and secure all connections on the tank and 3.

the spray gun assembly.

Clear the Nozzle on the Spray Gun assembly of dirt and debris.4.

The spray pattern is

undesirable.

Use the proper Nozzle for the job at hand.1.

Clear the Nozzle on the Spray Gun assembly of dirt and debris.2.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE

MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY

OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISKS AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 9For technical questions, please call 1-800-444-3353.SKU 94573

Page 10

PARTS LIST

Part Description Qty.

1 Nozzle Nut 1

2 Conical Mist Spraying Sheet 1

3 Splitting Sheet 1

4 Nozzle Gasket Ring 1

5 Elbow 1

6 Spray Rod O-Ring 2

7 Opening Cover 2

8 Spray Rod Nut 3

9 Spray Rod 1

10 Switch Main Unit 1

11 Switch Gasket 1

12 Valve Cartridge O-Ring 1

13 Valve Cartridge 1

14 Spring 1

15 Switch Nut 1

16 Trigger Lock 1

17 Trigger 1

18 Switch Pin 1

19 Handle Gasket Ring 1

20 Switch Filter Screen 1

21 Handle 1

22 Opening Cover 1

23 Tube Sleeve 1

24 Hose 1

25 Caster 4

26 Screw (M5 x 20) 4

27 Flat Washer (#5) 4

28 Nut (M5) 4

29 Protection Cover 1

30 Base 1

31 Countersink Screw (M5 x 15) 1

32 Tube Clamp 1

33 Inlet Tube 1

Part Description Qty.

34 Mini-Pump 1

35 Tube Coupling 1

36 O-Ring 1

37 Inlet Coupling 1

38 Screen Frame 1

39 Screen Cover 1

40 Vent Valve 1

41 Tank Cap 1

42 Tank Filter 1

43 Barrel 1

44 Strap Clamp 2

45 Back Strap 2

46 Shoulder Cushion 2

47 Strap Button 2

48 Strap Hook 2

49 Self Tapping Screw (3.7 x 10) 1

50 Alarm 1

51 Battery 1

52 Anchor Ear 1

53 Self Tapping Screw (3.7 x 18) 2

54 Power Cable 7

55 Nylon Tier 3

56 Countersink Screw (M3 x 10) 2

57 Nut (M3) 2

58 Power Switch 1

59 Socket 1

60 Dual Nozzle 1

61 Mist Nozzle 1

62 Adjustable Nozzle 1

63 Charger 1

64 Tank 1

65 Conical Mist Nozzle 1

Page 10 For technical questions, please call 1-800-444-3353. SKU 94573

Page 11

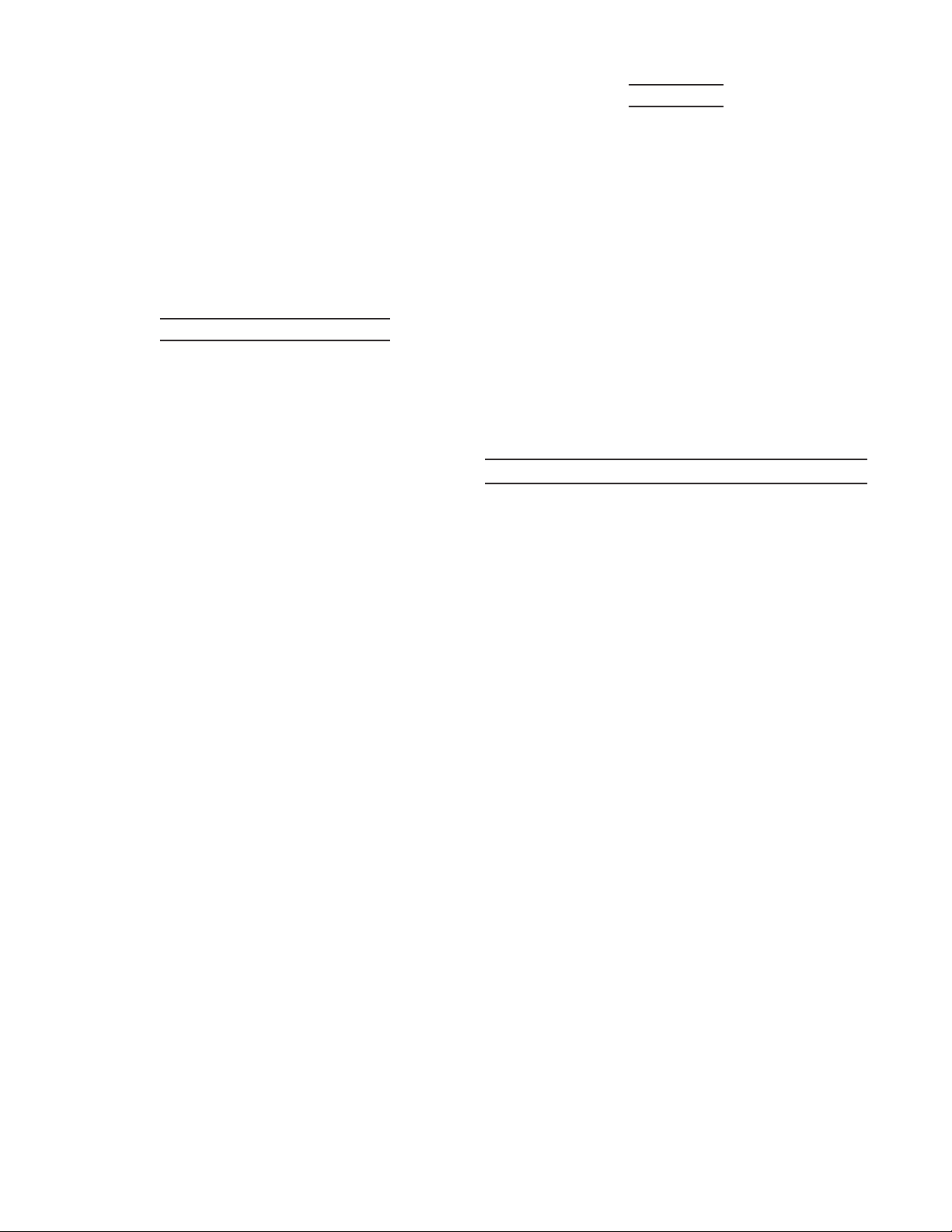

ASSEMBLY DIAGRAM

40

65

60

61

62

63

48

46

47

59

50

58

49

45

44

51

52

55

57, 56

54

53

41

33

42

43

31

38

37

36

35

39

32

29

34

30

64

10

1

2

3

4

5

6

7

8

9

14

12

11

18

19

20

21

22

23

24

13

15

16

17

25

28, 27, 26

NOTE: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

Rev 10d

Page 11For technical questions, please call 1-800-444-3353.SKU 94573

Loading...

Loading...