Harbor Freight Tools 93980 Product manual

Bearing Separator

and Puller Set

Item 93980

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at:

http://www.harborfreight.com

Read this material before

using this product.

Failure to do so can result

in serious injury.

SAVE THIS MANUAL.

When unpacking, make sure

that the product is intact and

undamaged.

If any parts are missing or broken,

please call 1‑800‑444‑3353

as soon as possible.

Copyright© 2011 by Harbor Freight Tools®.

All rights reserved. No portion of this document

or any artwork contained herein may be

reproduced in any shape or form without the

express written consent of Harbor Freight

Tools. Diagrams within this document may

not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly

from the product described herein. Tools required

for assembly and service may not be included.

For technical questions or replacement

parts, please call 1‑800‑444‑3353.

Specications

or missing, contact Harbor

Freight Tools for a replacement.

Bearing

Splitter Sizes

Push ‑ Puller

Leg Dimensions

Yoke 6 IN. With Center Adapter

2 IN. / 3 IN.

2 sets with 2 extension

legs each; 4 IN. / 5 IN.

Important Safety Information

Assembly Precautions

1. Assemble only according to

these instructions. Improper

assembly can create hazards.

2. Wear ANSI‑approved safety

goggles and heavy‑duty work

gloves during assembly.

3. Keep assembly area

clean and well lit.

4. Keep bystanders out of the

area during assembly.

5. Do not assemble when tired

or when under the inuence

of drugs or medication.

Use Precautions

1. This product is not a toy. Do

not allow children to play

with or near this item.

2. Use as intended only.

3. Inspect before every use; do not

use if parts are loose or damaged.

4. Maintain product labels and

nameplates. These carry important

safety information. If unreadable

Specic Safety

Precautions

1. Be certain that the separator

jaws are evenly set between

bearing halves before

attempting to separate.

2. Lead Screw (5) should be centered

on the shaft where the bearings

are being pulled to avoid damaging

shaft or bearing housing.

3. Avoid pinching or scraping the

bearing shaft by securely (and

squarely) placing the Jaws

around the bearing housing.

4. Use care when removing the Lead

Screw from the Case to avoid

damaging the threads. Pry up

from the ends of the Lead Screw.

Operating Instructions

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of

this document including

all text under subheadings

therein before set up or

use of this product.

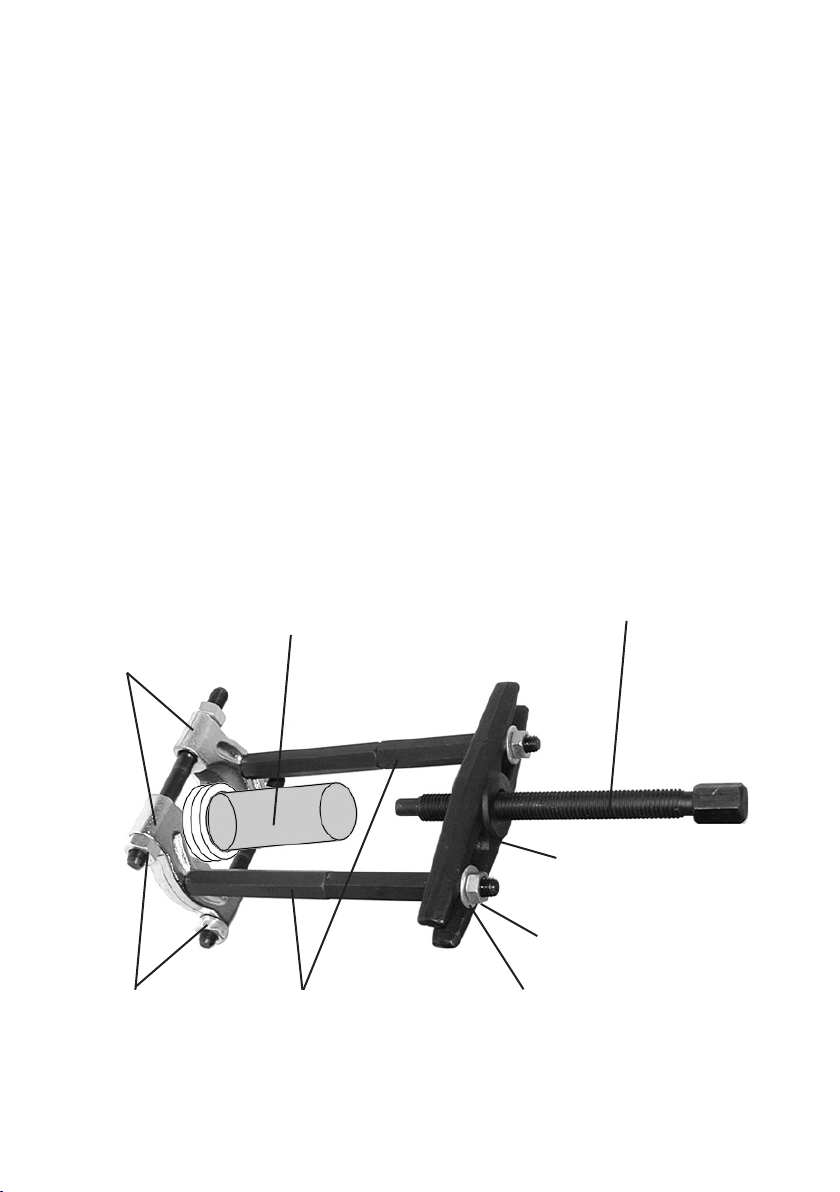

Pulling Bearings

off Shaft

1. Select the proper size Bearing

Separator Jaw (2 or 14) for the

bearing size (2.2 IN. ~ 3 IN. or 2

IN.) being removed from the shaft.

Page 2 For technical questions, please call 1‑800‑444‑3353. SKU 93980

2. Loosen the Separator Jaw Nuts

(3) sufciently to allow the jaws to

catch behind the bearing housing.

3. Using a wrench (not included),

begin to evenly tighten the Nuts

until the jaws are securely set

behind the bearing housing.

4. Screw in both Extension Screws

of the same length (4 / 12 or 6 / 9)

into the Bearing Separator Jaws as

shown below.

NOTE: Do not use Extension

Screws of different lengths.

5. Place the 6 inch Yoke (16)

over the Extension Screws

and tightly secure with

Washers (7) and Nuts (3).

6. Screw in Lead Screw (5) into

the Yoke until it touches the

center of the shaft where the

bearings are mounted.

7. Using a wrench, turn the

Lead Screw clockwise until

the bearing housing begins

to move off the shaft.

8. Continue turning the Lead

Screw until the bearing

housing is off the shaft.

9. Remove the Lead Screw by

turning it counterclockwise.

10. Remove bearing housing.

Bearing

Separator Jaw

(2 or 14)

Nut (3)

Shaft

(4/12 or 6/9)

Lead Screw (5)

Yoke (16)

Nut (3)

Washer (7)Extension Screws

Page 3For technical questions, please call 1‑800‑444‑3353.SKU 93980

Loading...

Loading...