Page 1

CORDLESS 18V CIRCULAR SAW

®

WITH LASER

Model 93808

ASSEMBLY AND OPERATING INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools® . All rights reserved. No portion of this manual or

any artwork contained herein may be reproduced in any shape or form without the express

written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

rotoMtloV81,MPR0024

snoitacificepSedalB

selgnAdnashtpeDgnittuC

yrettaB

thgieWyrettaBhtiw.sbl5.9

tupnIesaBregrahCz

1

6

/

2

5

xretemaiD"

/

1

1;°09@"2

8

/

4

H06,CAV011

°54@"

leveBmumixaM°05

,yrettaBhMiNtloV81

emiTegrahCruoHenO

/MPR0005/piTedibraCT42

robrA"

E194601

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and assembly

diagram. Keep your invoice with this manual. Write the invoice number on the inside of the

front cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES FOR ALL BATTERY OPERATED TOOLS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may

result in electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite

the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 2

English

Page 3

ELECTRICAL SAFETY

1. Do not abuse the cord. Never use the cord to carry the tool. Keep cord away

from heat, oil, sharp edges, or moving parts. Replace damaged cords

immediately. Damaged cords may create a fire.

2. A battery operated tool with integral batteries or a separate battery pack must

be recharged only with the specified charger for the battery. A charger that may

be suitable for one type of battery may create a risk of fire when used with another

battery.

3. Use battery operated tool only with specifically designated battery pack. Use

of any other batteries may create a risk of fire.

PERSONAL SAFETY

1. Stay alert, watch what you are doing, and use common sense when operating

a power tool. Do not use tool while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating power tools may result in

serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

3. Avoid accidental starting. Be sure switch is in the locked or off position before

inserting battery pack. Carrying tools with your finger on the switch or inserting

the battery pack into a tool with the switch on invites accidents.

4. Remove adjusting keys or wrenches before turning the tool on. A wrench or a

key that is left attached to a rotating part of the tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enable better control of the tool in unexpected situations.

6. Use safety equipment. Always wear eye protection. Dust mask, nonskid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

1. Use clamps or other practical way to secure and support the workpiece to a

stable platform. Holding the work by hand or against your body is unstable and

may lead to loss of control.

2. Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed.

3. Do not use tool if switch does not turn it on or off. A tool that cannot be controlled

with the switch is dangerous and must be repaired.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 3

English

Page 4

4. Disconnect battery pack from tool or place the switch in the locked or off

position before making any adjustments, changing accessories, or storing

the tool. Such preventive safety measures reduce the risk of starting the tool

accidentally.

5. Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

6. When battery pack is not in use, keep it away from other metal objects like:

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery terminals

together may cause sparks, burns, or a fire.

7. Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with sharp cutting edge are less likely to bind and are easier to control.

8. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tool’s operation. If damaged, have the

tool serviced before using. Many accidents are caused by poorly maintained tools.

9. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may create a risk of injury

when used on another tool.

SERVICE

1. Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel may result in a risk of injury.

2. When servicing a tool, use only identical replacement parts. Follow instructions

in the Maintenance section of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of shock or injury.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 4

English

Page 5

SPECIFIC SAFETY RULES

1. DANGER! Keep hands away from cutting area and blade. Keep your second

hand on auxiliary handle or motor housing. If both hands are holding the saw,

they cannot be cut by the blade.

Keep your body positioned to either side of the saw blade, but not in line with

the saw blade. KICKBACK could cause the saw to jump backwards. (See

KICKBACK)

Do not reach underneath the work. The guard can not protect you from the blade

below the work.

2. Check lower guard for proper closing before each use. Do not operate saw if

lower guard does not move freely and close instantly. Never clamp or tie the

lower guard into the open position. If saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with the Retracting Handle and make sure it

moves freely and does not touch the blade or any other part, in all angles and depths

of cut.

3. Check the operation and condition of the lower guard spring. If the guard and

the spring are not operating properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged parts, gummy deposits, or a buildup

of debris.

4. Lower guard should be retracted manually only for special cuts such as

“Pocket Cuts” and “Compound Cuts.” Raise lower guard by Retracting Handle.

As soon as blade enters the material, lower guard must be released. For all

other sawing, the lower guard should operate automatically.

5. Always observe that the lower guard is covering the blade before placing saw

down on bench or floor. An unprotected, coasting blade will cause the saw to

walk backwards, cutting whatever is in its path. Be aware of the time it takes for the

blade to stop after switch is released.

6. NEVER hold piece being cut in your hands or across your leg. It is important to

support the work properly to minimize body exposure, blade binding, or loss of

control.

7. Hold tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring. Contact with a “live” wire will also

make exposed metal parts of the tool “live” and shock the operator.

8. When ripping always use a rip fence or straight edge guide. This improves the

accuracy of cut and reduces the chance for blade binding.

9. Always use blades with correct size and shape (diamond vs. round) arbor

holes. Blades that do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 5

English

Page 6

10. Never use damaged or incorrect blade washers or bolts. The blade washers

and bolt were specially designed for your saw, for optimum performance and safety

of operation.

11. Causes and Operator Prevention of Kickback:

Kickback is a sudden reaction to a pinched, bound, or misaligned saw blade, causing

an uncontrolled saw to lift up and out of the workpiece toward the operator. When

the blade is pinched or bound tightly by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back toward the operator. If the blade

becomes twisted or misaligned in the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood causing the blade to climb out of the kerf

and jump back toward the operator.

Kickback is the result of tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below:

12. Maintain a firm grip on the saw and position your body and arm in a way that

allows you to resist KICKBACK forces. KICKBACK forces can be controlled by

the operator, if proper precautions are taken.

13. When blade is binding, or when interrupting a cut for any reason, release the

trigger and hold the saw motionless in the material until the blade comes to a

complete stop. Never attempt to remove the saw from the work or pull the saw

backward while the blade is in motion or KICKBACK may occur. Investigate

and take corrective actions to eliminate the cause of blade binding.

14. When restarting a saw in the workpiece, center the saw blade in the kerf and

check that teeth are not engaged into the material. If saw blade is binding, it

may walk up or KICKBACK from the workpiece as the saw is restarted.

15. Support large panels to minimize the risk of blade pinching and KICKBACK.

Large panels tend to sag under their own weight. Supports must be placed under

the panel on both sides, near the line of cut and near the edge of the panel.

16. Do not use dull or damaged blade. Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade binding, and KICKBACK.

17. Blade depth and bevel adjusting locking levers must be tight and secure before

making cut. If blade adjustment shifts while cutting, it will cause binding and

KICKBACK.

18. Use extra caution when making a “Pocket Cut” into existing walls or other

blind areas. The protruding blade may cut objects that can cause KICKBACK.

19.

20.

WARNING! People with pacemakers should consult their physician(s) before

using this product. Operation of electrical equipment in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker.

WARNING! Some dust created by power sawing, grinding, drilling, and other

construction activities, contain chemicals known (to the State of California) to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 6

English

Page 7

are: lead from lead-based paints, crystalline silica from bricks and cement or other

masonry products, arsenic and chromium from chemically treated lumber. Your risk

from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles. (California Health & Safety Code §

25249.5,

et seq.

)

21.

WARNING! The warnings, precautions, and instructions discussed in this manual

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors which cannot be built

into this product, but must be supplied by the operator.

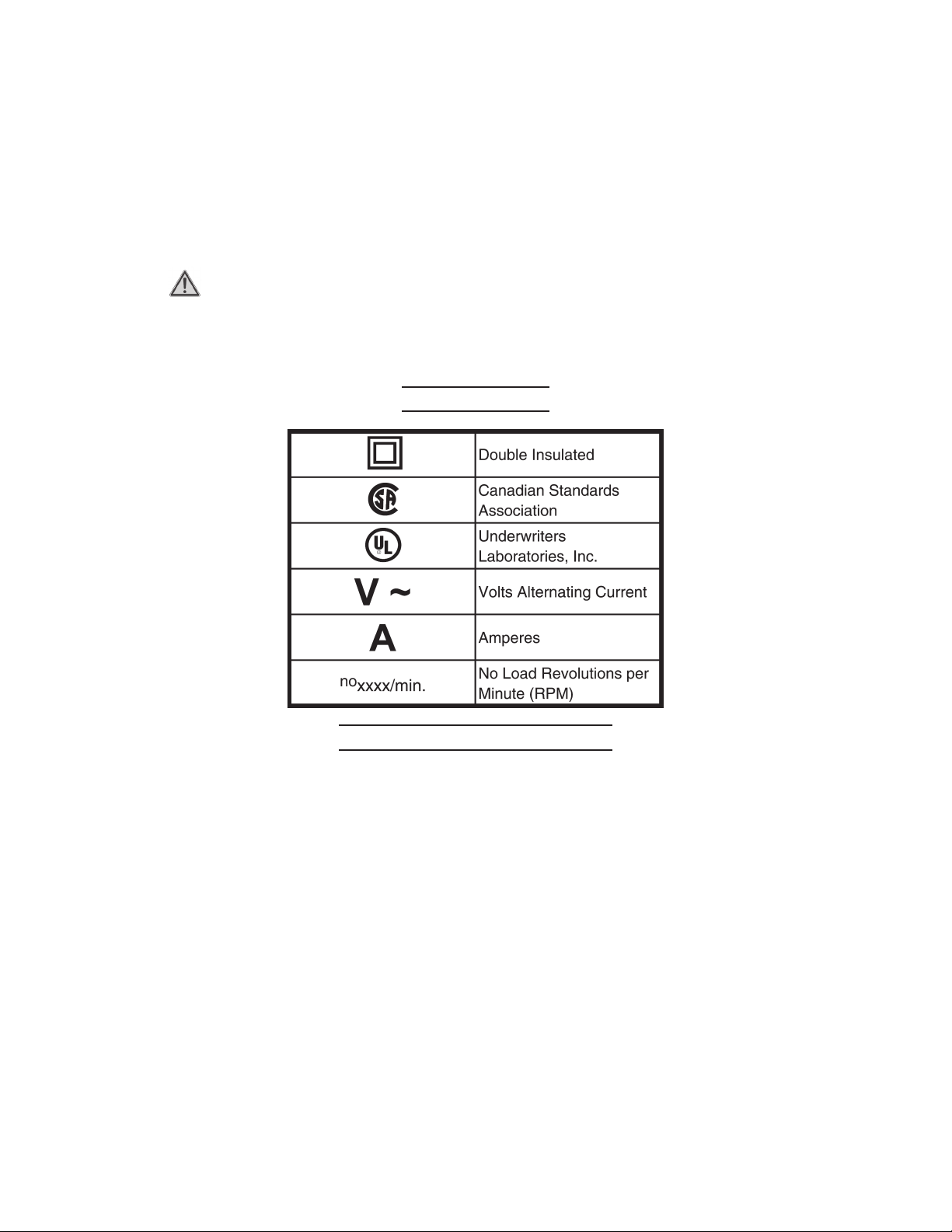

SYMBOLOGY

BATTERY PRECAUTIONS

1. Proper Battery Care: Battery (H) leakage may occur under extreme usage or

temperature conditions. If Battery fluid comes in contact with skin, wash with soap

and water and rinse with lemon juice and vinegar. If the fluid comes in contact with

eyes, flush with water for several minutes and contact a doctor immediately. Never

burn the Battery, as it can explode in a fire. Do not attempt to charge a leaking

Battery. Contact local solid waste authorities for instructions on correct disposal or

recycling of the Battery.

2. Do not allow children to handle or play with these products.

3. Industrial applications must follow OSHA requirements.

4. Check for damaged parts. Before using these products, carefully check that they

will operate properly and perform their intended function. Check for damaged parts

and any other conditions that may affect the safe operation of these products. Replace

or repair damaged or worn parts immediately.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 7

English

Page 8

5. Replacement parts and accessories: When servicing, use only identical

replacement parts. Only use accessories intended for use with this product.

6. Use the right tool or attachment for the right job. There are certain applications

for which this product was designed. It will do the job better and more safely at the

rate for which it was intended. Do not modify this product, and do not use this product

for a purpose for which it is not intended.

7. NEVER charge the Battery (H) more than

8. Always switch to a fresh Battery when tool performance begins to diminish.

Severe heat is most destructive to a Battery. The more heat generated, the faster the

Battery loses power. A Battery that gets too hot can be permanently damaged. Never

over-discharge a Battery by using the tool even after tool performance is decreasing.

Never attempt to discharge a tool’s Battery by continuing to pull the tool trigger.

When tool performance begins to diminish stop the tool, recharge the Battery and

use the fresh Battery for optimal performance.

9. Read all instructions and warnings on the battery before charging the battery.

10. To avoid accidents, charge the supplied battery only. Do not use a different

charger with this battery.

11. Do not expose the battery to rain or wet conditions.

12. To avoid damage of cable and plug, never pull the cable to disconnect the

charger.

13. Do not use the charger if the cable or plug are damaged.

14. Repairs should be carried out only by qualified service technicians.

15. Do not touch the battery poles with any conductive source.

two hours continuously.

16. Do not store the battery in a box with other metal objects.

17. NiMh Battery must be recycled or disposed of properly. Do not throw the battery

in a fire.

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List and the

assembly diagram on page 21 and 22 are included. If any parts are missing or broken,

please call Harbor Freight Tools at the number listed on the front cover of this manual.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 8

English

Page 9

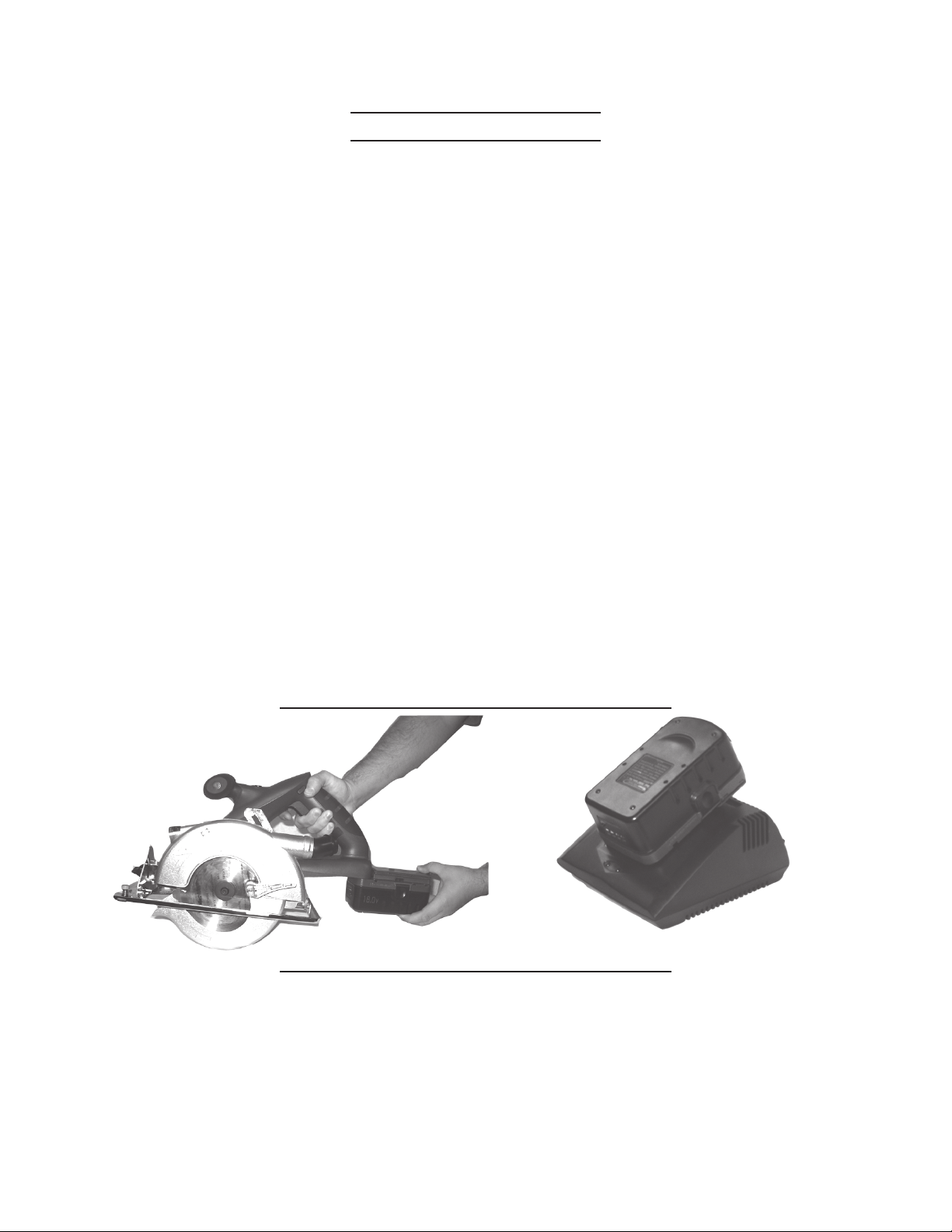

CHARGING BATTERY

NOTE: Refer to page 18, Figure 3 to help identify parts discussed below. Use the

part numbers in the Parts List on page 21 and shown on the Assembly Diagram

on page 22 to identify and order replacement parts.

NOTE: The Battery does not come charged from the factory. Charge before using.

Charging room temperature: 50°

1. Plug the Charger Base (O) into a wall socket. Note: The Charger Base (O) has both

an ON red light, and an OFF green light.

2. When the Charger Base (O) is plugged into a wall socket, the RED light will come

on and stay on steadily. This shows that all circuitry is working properly and the

Charger Base is ready to charge.

3. Slide the Battery (H) forward until it firmly seats into the Charger Base (O). The

GREEN light will go on and begin to flash. This indicates the battery is charging.

4. The charging period takes approximately one hour for a fully discharged battery

and less for a battery not fully discharged. When the Battery (H) has been fully

charged the Charger Base (O) will beep once and the GREEN light will stay on

steadily.

F - 104° F.

5. Remove the Battery (H) from the Charger Base (O) and insert the Battery (H) into

the base of the tool.

6. Press the test button on the Battery (H) to verify the battery is fully charged.

7. All four lights lit represent a full charge of the Battery.

FIGURE 1 FIGURE 2

Charger Base

INSTALLING & REMOVING THE BATTERY PACK

Warning! Do not touch the Trigger Switch (B) or the Trigger Release Button (A) while

installing the Battery.

Insert the Battery (H) into the saw body as shown in Fig. 1. Fig. 2 shows the Battery (H)

correctly inserted in the Charger Base (O).

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 9

English

Page 10

NOTE: When removing the Battery Pack from the saw body, press in on the two locking

tabs located on each side of the Battery Pack and pull straight out from the body.

Warning! If two or more batteries are to be charged, allow the Charging Base time

to cool down between charges.

WORK LIGHT AND LASER GUIDE

Your 18 Volt Cordless Circular Saw has an integrated Work Light and a Laser Guide.

The Work Light (F) is activated and deactivated by depressing the Work Lamp Switch (C)

located on the top of the saw. The Laser Guide (E) is activated by pulling the trigger and

can be activated no other way.

NOTE: The Work Light and Laser Guide are aids and are not intended to function in

any manner other than that described in this manual.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 10

English

Page 11

OPERATION

Install the Saw Blade. Prepare and secure the material to be cut before turning on

saw. The Battery (H) should have a full charge before using saw. Remove battery before

making any adjustments. Refer to Figure 3, on page 18.

INSTALLING CUTTING BLADE

NOTE: The Lock Bolt is a reverse thread.

1. Remove The Battery (O) before making any adjustments.

2. Press on the Spindle Lock Button (J) to keep the Saw Blade from moving while

turning the Blade Bolt (I).

3. Using the Hex Key (P), loosen and remove Lock Bolt (I) and Outer Flange (I).

4. Rotate the Lower Blade Guard (K), counterclockwise to allow entry of the Saw Blade.

5. Insert Saw Blade through the Base Plate (M) until blade fits on the motor spindle.

Notice the arrow on the Lower Blade Guard (K) and the arrow on the Saw

Blade. They should be pointing in the same direction.

6. Replace the Outer Flange (I) and Blade Bolt (I). Tighten with the Hex Key (P) while

pressing on the Spindle Lock Button (J). Verify that the Spindle Lock Button (J) is

in the up (unlocked) position.

7. Replace the Hex Key (P) to its storage hole in the housing of the saw.

ADJUSTING THE SAW PRIOR TO CUTTING

1. To adjust the angle of blade, loosen the Bevel Cut Adjustment Knob (G) and move

Base Plate (M) while observing the degree scale located next to the Bevel Cut

Adjustment Knob (G).

2. To adjust the depth of the cut, loosen the Depth Adjustment Knob (N), which is

located next to the motor housing, and move the Base Plate (M) while observing the

amount of Saw Blade exposed under Base Plate. Tighten the Depth Adjustment

Knob (N) after making the adjustment.

3. Rip Fence installation and adjustment:

The Rip Fence can be inserted into either the left or right side at the toe of the Base

Plate (M). Insert the Rip Fence into the fence guides until it contacts the Retention

Bolt (Q). Loosen the Retention Bolt (Q) until the fence can slide through then secure

it by turning the Retention Bolt (Q) clockwise. The Rip Fence is adjustable from 0”5”. ( Refer to Page 18, Fig. 3)

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 11

English

Page 12

FUNCTIONS

The 18 Volt Cordless Circular Saw has the following features, as shown

in Fig. 3 below.

(A) Trigger Release Button

(B) Trigger Switch

(C) Work Lamp Switch

(D) Off hand handle

(E) Laser Guide

(F) Work Light

(G) Bevel Cut Adjustment Knob

(H) 18 volt NiMh Battery

(I) Blade Flange and bolt

(J) Spindle Lock for blade change

(between saw body and upper

blade guard)

D

(K) Lower Blade Guard

(L) Light Holder

(M) Base Plate

(N) Depth Adjustment Knob

(next to the motor of the saw

not shown)

(O) Charger Base (shown on

page 16)

(P) Hex Key (Inserted in Saw

Body next to motor)

(Q) Retention Bolt

(R) Dust Port

C

N

A

B

Figure 3

J

P

E

L

G

Q

I

F

SKU 93808 For technical questions, please call 1-800-444-3353.

K

R

H

Page 12

English

Page 13

PREPARE MATERIAL BEFORE CUTTING

1. Support large panels to minimize risk of blade pinching and saw kickback.

2. Use a rip fence or secured straight edge guide when ripping material.

3. Securely clamp material to be cut to work bench.

4. Make sure saw does not cut into supports or workbench.

5. Use the appropriate type of blade for the material you are cutting.

CUTTING

Warning: The user can be seriously injured if the tool is not used properly.

Read this entire manual before using. Verify that the Saw Blade is securely

tightened and both angle and height adjustment knobs are tight before

proceeding. See Page 17.

1. Mark the line you will be cutting.

2. Place the Base Plate (M) on material to be cut. Align the front notch of the Base

Plate (right edge aligns with saw blade) on the cut line. Make Sure the Saw Blade

is NOT touching the material you will be cutting at this point or the saw will

kickback!

3. To start the saw, depress the Trigger Release Button ( A) and squeeze the Trigger

Switch (B).

4. With the saw at full speed, move the saw slowly forward to complete the cut.

5. When the cut is complete, release the Trigger Switch (1) and the electric brake will

stop the blade instantly. Do not set the saw down until the blade stops turning.

6. Once the blade stops and work is complete, remove the battery and store the Circular

Saw in a safe location, out of reach of children.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 13

English

Page 14

INSPECTION, MAINTENANCE, AND CLEANING

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS

THERETO.

WARNING! Always make sure the Trigger Switch (2) is in its “OFF” position,

and remove the Battery before performing any inspection, adjustments,

maintenance, or cleaning.

1. Keep the Circular saw clean; remove all sawdust that has accumulated.

2. Regularly inspect all mounting screws and knobs to ensure that they are properly

tightened.

3. Keep saw blades clean and sharp. Sharp blades minimize stalling and kickback.

4. Keep guards in good working order.

5. Keep motor air vent clean of dust and debris. Vacuum periodically.

6. If the tool is not operating normally, making unusual noises, appears defective or if

any other problem with the tool exists, stop using it immediately and get it repaired

by a qualified service technician.

7. Clean tool with a damp cloth and light detergent. Do not use solvents as they can

damage and crack the plastic parts.

8. If the tool does not start or operate at full power with a fully charged battery pack,

contacts on the battery pack may need to be cleaned.

9. Check for cracks or damage to the tool before using it.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 14

English

Page 15

PARTS LIST

traPnoitpircseD.ytQtraPnoitpircseD.ytQ

1wercSkcoL144bonKhsuP2

2egnalFedistuO154ydoBtfeL1

3edalB164kcaRhsurBnobraC1

nI174ecneFediuG1

4egnalFedis

5revoCdrauGdexiF184eriWkcalB1

6gnirpS194revoC1

7drauGedalBrewoL105draoBBCP1

8gnirpS115nottuBthgiL1

9rebbuRelffaB125no

01eveelSrebbuR135hctiwS1

11thgiLresaL145nottuBkcoLeldnipS1

21drauGedalBreppU155kcoLeldnipS1

31wercS465eriWdeR1

S475eriWkcalB1

41werc

51etalPeriW185kcaPyrettaB1

61wercS195gnirpS2

71wercS406esaBnoitcennoC1

81revoCxoBraeG116eloPrebbuR1

91gniraeB126etalPed

02sixAtuptuO136noiP1

12revoCthgiL146esaBthgiL1

22thgiL156wercS1

32wercSkcoL166rennapSmm61

42rehsaW176raeGgiB2

52bonK186nottuBsi

62wercS196troPtsuD1

72tuN107wercS1

82wercS117DEL1

92etalPesaB127thgiLrotatS1

03wercS137gnirpS1

13tuN147lebaLraeR1

23gniraeB157lebaLpoT1

3naFrotoM167eriW1

3

43rotoRrotoM177eriWkcalB1

53gniraeB187erIWdeR1

63reffuBrebbuR197etalPtnorF1

73rebbuR/wydoBthgiR108etalPediuG1

rcS518lebaLtfeL1

83we

93wercS228lebaLtfeL1

04revoCkcaB138rebbuR/wydoBtfeL1

14bonK148ebuT1

24hsurBnobraCroFrotatS258pirGtfoSthgiR1

34werc

SydoB868pirGtfoStfeL1

ttuBresaL1

onAthgiL1

xAkcoL1

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 15

English

Page 16

ASSEMBLY DIAGRAM

NOTE: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

SKU 93808 For technical questions, please call 1-800-444-3353.

Page 16

English

Page 17

SANS CORDON 18V LE SCIER

®

CIRCULAIRE A VEC LE LASER

Modèle 93808

ASSEMBLAGE ET MODE DE FONCTIONNEMENT

En raison des améliorations continuantes, le produit réel peut différer légèrement du produit décrit ici.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visitez notre Site Internet à http://www.harborfreight.com

PRÉVENIR LA BLESSURE SÉRIEUSE,

LISEZ ET COMPRENEZ TOUS LES AVERTISSEMENTS

ET LES INSTRUCTIONS AVANT L’UTILISATION.

Le Copyright © 2005

de n’importe quel travail d’art contenu ici ne peut être reproduite dans aucune forme ou formulaire sans le

consentement rapidement écrit de Harbor Freight Tools.

Pour les questions techniques et les pièces détachées, appelez-vous s’il vous

par le Harbor Freight Tools ®. Tous droits réservés. Aucune portion de ce manuel ou

plaît 1-800-444-3353.

Page 18

SPÉCIFICATIONS DE PRODUIT

ruetoMstlov81,nim-rt0024

emaLedsnoitacificépS

selgnAsedtesruednoforPsederupuoCaL

eirettaB

sdioPeirettaBalcevagk3.4

ruegrahCedesaBednoitcudorpedruetcaFH06,CAV011

mm561

°54mm23;°09mm05

etuaesiBmumixaM°05

,stlov81edhMiN

egrahCedspmeTnU

erueH'd

SAUVEZ CE MANUEL

Vous aurez besoin de ce manuel pour les avertissements de sécurité et les

précautions, l’assemblage, le fait de faire marcher, l’inspection, la maintenance et le

nettoyage des procédures, la liste de parties et le diagramme d’assemblage. Gardez votre

facture avec ce manuel. Écrivez le nombre de facture sur l’intérieur de la couver ture de

dev ant. Gardez ce manuel et f acture dans un coffre-f ort et un endroit sec pour la référence

future.

/nim-rt0005/tneDederubraCedtuoB42

ellennoTal"8/5xertèmaiDel

E194601

RÈGLES DE SÉCURITÉ GÉNÉRALES POUR TOUS LES

OUTILS À BATTERIE

AVERTISSEMENT ! VOUS DEVEZ LIRE ET COMPRENDRE

TOUTES LES INSTRUCTIONS.

Le non-respect, même partiel, des instructions ci-après

entraîne un risque de choc électrique, d’incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS

Aire de travail

1. Veillez à ce que l’aire de travail soit propre et bien éclairée. Le désordre et le

manque de lumière favorisent les accidents.

2. N’utilisez pas d’outilsélectriques dans une atmosphère explosive, par exemple

en présence de liquides, de gaz ou de poussières inflammables. Les outils

électriques créent des étincelles qui pourraient enflammer les poussières ou les

vapeurs.

3. Tenez à distance les curieux, les enfants et les visiteurs pendant que vous

travaillez avec un outil électrique. Ils pourraient vous distraire et vous faire faire

une fausse manoeuvre.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 2

Français

Page 19

Sécuritéélectrique

1. Ne maltraitez pas le cordon. Ne transportez pas l’outil par son cordon.

N’exposez pas le cordonà la chaleur , à des huiles, à des arêtes vives ou à des

pièces en mouvement. Remplacez immédiatement un cordon endommagé.

Un cordon endommagé peut constituer un risque d’incendie.

2. Un outil à bloc-batterie amovible ou à batterie intégrée ne doitêtre rechargé

qu’avec le chargeur prévu pour la batterie. Un chargeur qui convient à tel type

de batterie peut présenter un risque d’incendie avec tel autre type de batterie.

3. N’utilisez un outil qu’avec un bloc-batterie conçu spécifiquement pour lui.

L’emploi d’un autre b loc-batterie peut créer un risque d’incendie.

Sécurité des personnes

1. Restez alerte, concentrez-v ous sur v otre travail et faites preuve de jugement.

N’utilisez pas un outil électrique si vous êtes fatigué ou sous l’influence de

drogues, d’alcool ou de médicaments. Un instant d’inattention suffit pour entr aîner

des blessures graves.

2. Habillez-vous convenablement. Ne portez ni vêtements flottants ni bijoux.

Confinez les cheveux longs. N’approchez jamais les cheveux, les vêtements

ou les gants des pièces en mouvement. Des vêtements flottants, des bijoux ou

des cheveux longs risquent d’être happés par des pièces en mouvement.

3. Méfiez-vous d’un démarrage accidentel. Avant d’insérer un bloc-batterie,

assurez-vous que l’interrupteur de l’outil est sur ARRÊT. Le fait de transporter

un outil avec le doigt sur la détente ou d’insérer un b loc-batterie alors que l’interrupteur

est en position MARCHE peut mener tout droit à un accident.

4. Enlevez les clés de réglage ou de serra ge avant de démarrer l’outil. Une clé

laissée dans une pièce tournante de l’outil peut provoquer des blessures.

5. Ne vous penchez pas trop en avant. Maintenez un bon appui et restez en

équilibre en tout temps. Un bonne stabilité vous permet de mieux réagirà une

situation inattendue.

6. Utilisez des accessoires de sécurité. Portez toujours des lunettes ou une

visière. Selon les conditions , portez aussi un masque antipoussière, des bottes de

sécurité antidérapantes, un casque protecteur et/ou un appareil antibruit.

Utilisation et entretien des outils

1. Immobilisez le matériau sur une surface stable au moyen de brides ou de

toute autre façon adéquate. Le fait de tenir la pièce a vec la main ou contre votre

corps offre une stabilité insuffisante et peut amener un dérapage de l’outil.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 3

Français

Page 20

2. Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil correct fonctionne

mieux et de façon plus sécuritaire. Respectez aussi la vitesse de travail qui lui est

propre.

3. N’utilisez pas un outil si son interrupteur est bloqué. Un outil que vous ne

pouvez pas commander par son interrupteur est dangereux et doit être réparé.

4. Retirez le bloc-batterie ou mettez l’interrupteur sur ARRÊT ou en position

verrouillée avant d’eff ectuer un réglage, de changer d’accessoire ou de ranger

l’outil. De telles mesures préventives réduisent le risque de démarrage accidentel

de l’outil.

5. Rangez les outils hors de la portée des enfants et d’autres personnes

inexpérimentées. Les outils sont dangereux dans les mains d’utilisateurs novices .

6. Lorsque le bloc-batterie n’est pas en service, tenez-le à l’écart d’autres objets

métalliques (trombones, pièces de monnaie, c lés, c lous, vis, etc.) susceptibles

d’établir un contact électrique entre les deux bornes. La mise en court-circuit

des bornes de la batterie peut produire des étincelles et constitue un risque de

brûlures ou d’incendie.

7. Prenez soin de bien entretenir les outils. Les outils de coupe doivent être

toujours bien affûtés et propres. Des outils bien entretenus, dont les arêtes sont

bien tranchantes, sont moins susceptibles de coincer et plus faciles à diriger.

8. Soyez attentif à tout désalignement ou coincement des pièces en mouvement,

à tout bris ou à toute autre condition préjudiciable au bon fonctionnement de

l’outil. Si vous constatez qu’un outil est endommagé, faites-le réparer avant

de vous en ser vir. De nombreux accidents sont causés par des outils en mauvais

état.

9. N’utilisez que des accessoires que le fabricant recommande pour votre modèle

d’outil. Certains accessoires peuvent conv enir à un outil, maisêtre dangereux avec

un autre.

Réparation

1. La réparation des outils électriques doit être confiée à un réparateur qualifié.

L’entretien ou la réparation d’un outilélectrique par un amateur peut avoir des

conséquences grave s.

2. Pour la réparation d’un outil, n’employez que des pièces de rechange d’origine.

Suivez les directives données à la section « Réparation» de ce manuel. L’emploi

de pièces non autorisées ou le non-respect des instructions d’entretien peut créer

un risque de choc électrique ou de blessures.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 4

Français

Page 21

Règles de Sécurité Particulières

1. DANGER ! N’approchez pas les mains de la zone de coupe ou de la lame.

Gardez l’autre main sur la poignée auxiliaire ou sur le carter du moteur. En

tenant l’outil avec vos deux mains, vous mettez celles-ci à l’abri de la lame.

Placez-vous d’un côté ou de l’autre de la lame, mais non vis-à-vis celle-ci. En

cas de RECUL, la scie pourrait sauter vers l’arrière. (Voir «RECUL».)

N’étendez pas la main sous le matériau à scier. Le protecteur inférieur de l’outil

est inopérant à cet endroit.

2. Av ant chaque utilisation, assurez-v ous que le protecteur inférieur se referme

correctement. N’utilisez pas la scie si le protecteur inférieur ne bouge pas

librement et ne se referme pas instantanément. Ne bloquez jamais le pr otecteur

inférieur en position ouverte. Si la scie tombe par terre accidentellement, le

protecteur inférieur peut être gauchi : escamotez le protecteur inférieur avec sa

manette et assurez-vous qu’il bouge librement et qu’il ne touche pas la lame ni

aucun autre élément de l’outil, quels que soient les réglages d’angle et de profondeur

de coupe.

3. Vérifiez l’état et le bon fonctionnement du ressort du protecteur inférieur. Si

le protecteur ou son ressort ne fonctionnent pas correctement, il faut les

réparer av ant d’utiliser l’outil. Le protecteur inférieur peut être lent à se refermer

à cause de pièces endommagées, de dépôts collants ou d’une accumulation de

débris.

4. V ous ne devez escamoter manuellement le protecteur inférieur que pour des

opérations spéciales comme le défonçage d’ouvertures en plein bois et les

coupes de rainurage ou à onglets. Escamotez le protecteur inférieur au mo yen

de sa manette puis, dès que la lame attaque le matériau, lâchez le protecteur.

Pour toute autre tâche de sciage, laissez le protecteur inférieur fonctionner

automatiquement.

5. Assurez-vous toujours que le protecteur inférieur couvre bien la lame avant

de déposer l’outil sur l’établi ou sur le sol. Si la lame n’est pas protégée et n’a

pas fini de tourner, elle entraînera la scie vers l’arrière en coupant tout sur son

passage. Soyez conscient du temps nécessaire pour que la lame s’arrête après

que vous avez lâché la détente.

6. Ne maintenez jamais le matériau à scier dans vos mains ou sur v otre jambe. Il

importe de soutenir le matériau correctement, afin de ne pas vous e xposer inutilement

et de réduire le risque de coincement de la lame ou de dérapage de l’outil.

7. Tenez l’outil par ses surfaces de prise isolées pendant toute opération où

l’outil de coupe pourrait venir en contact avec un câblage dissimulé. En cas

de contact avec un conducteur sous tension, les pièces métalliques à découv ert de

l’outil transmettraient un choc électrique à l’utilisateur.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 5

Français

Page 22

8. Lorsque que vous refendez, utilisez toujours un guide longitudinal. Cela

améliore la précision de la coupe et réduit le risque de coincement de la lame.

9. Employez toujours une lame de diamètre approprié et dont le trou central est

de forme correcte (angulaire ou ronde). Une lame dont le trou ne correspond pas

à la forme du moyeu de fixation de la scie risque de tourner de façon excentrique et

de vous faire perdre la maîtrise de l’outil.

10. N’utilisez jamais un boulon ou une rondelle de lame endommagé ou incorrect.

Les boulons et rondelles de fixation de la lame sont conçus spécialement pour

votre scie et jouent un rôle essentiel dans le bon fonctionnement et la sécurité de

l’outil.

11. Causes du retour d’outil et prévention par l’utilisateur :

Le « retour d’outil » est une brusque réaction au pincement, au coincement ou au

désalignement de la lame de scie, qui amène la scie à sauter hors du matériau vers

l’utilisateur.

Lorsque la lame est pincée ou coincée par le rétrécissement du trait de scie, la

lame se bloque et la réaction du moteur projette l’outil avec force vers l’utilisateur.

Si la lame se trouve désalignée dans le trait de scie, ses dents arrière peuvent

mordre dans le dessus du matériau, ce qui amène la lame à sortir brutalement du

trait de scie en direction de l’utilisateur.

Le RECUL résulte d’une utilisation incorrecte de l’outil ou de mauvaises conditions

d’utilisation. On peut le prévenir en prenant les précautions adéquates ci-après:

12. T enez fermement la scie et placez votre corps et v os bras de manière à pouvoir

résister à la force d’un RECUL éventuel. L’utilisateur est capable de maîtriser un

RECUL s’il a pris les précautions adéquates.

13. Lorsque la lame se coince ou que vous interrompez une coupe pour une

raison quelconque, lâchez la détente et maintenez la scie immobile dans le

trait de scie jusqu’à ce que la lame s’arrête complètement. Ne cherc hez jamais

à sortir la scie du matériau ou à reculer la scie pendant que la lame est encore

en mouvement, car vous vous exposeriez à un RECUL. Si la lame a tendance à

se coincer, recherchez-en la cause et apportez les correctifs appropriés.

14. Lorsque vous redémarrez l’outil dans un trait de scie, centrez la lame dans

celui-ci et assurez-vous que les dents de la lame ne mordent pas dans le

matériau. Si lame est coincée, l’outil risque de reculer ou de sauter en arrière au

moment du démarrage de l’outil.

15. Soutenez adéquatement les grands panneaux afin de réduire au minimum le

risque de pincement de la lame et de RECUL. Les grands panneaux ont tendance

à s’affaisser sous leur propre poids. Placez des points d’appui sous le panneau des

deux côtés, près de la ligne de coupe et près des bords du panneau.

16. N’utilisez jamais une lame émoussée ou endommagée. Une lame mal affûtée

ou mal avo yée produit un trait de scie étroit qui donne lieu à un frottement excessif ,

au coincement de la lame età un RECUL.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 6

Français

Page 23

17. Les manettes de profondeur et d’angle de coupe doivent être bien bloquées .

Si ces manettes se débloquent pendant la coupe, il peut en résulter un coincement

et un retour d’outil.

18. Soyez particulièrement prudent lorsque vous découpez une ouverture dans

une cloison existante ou tout autre matériau dont l’arrière n’est pas visible.

La lame pourrait rencontrer un objet dur, ce qui provoquerait un RECUL.

19.

20. AVERTISSEMENT! Un peu de poussière créée par le sciage de pouvoir, le

21.

AVERTISSEMENT! Les gens avec les stimulateurs cardiaques devraient

consulter leur docteur (s) avant le f ait d’utiliser ce produit. L’opération d’équipement

électrique dans la proche proximité à un stimulateur cardiaque du cœur pourrait

causer l’interférence ou l’échec du stimulateur cardiaque.

grincement, le forage et d’autres activités de construction, contient des produits

chimiques connus (à l’État de Californie) pour causer le cancer, les anomalies

congénitales ou d’autre mal reproducteur. Quelques exemples de ces produits

chimiques sont : le plomb des peintures à base de plomb, la silice cristalline des

briques et le ciment ou d’autres produits de maçonnerie, l’arsenic et le chrome du

bois de construction chimiquement traité. Votre risque de ces expositions vari e,

selon combien de fois vous faites ce type de travail. Réduire v otre exposition à ces

produits chimiques : le travail dans une région bien aérée et un travail avec

l’équipement de sécurité approuvé, comme ces masques de poussière qui sont

spécialement conçus pour éliminer des particules microscopiques. (Le Code de

Sécurité et de Santé de Califo rnie § 25249.5

AVERTISSEMENT! Les avertissements, les précautions et les instructions

discutées dans ce manuel ne peuv ent pas couvrir toutes les conditions possibles et

les situations qui peuvent se produire. L’opérateur doit comprendre que le sens

commun et la prudence sont des facteurs qui ne peuvent pas être introduits dans

ce produit, mais doivent être fournis par l’opérateur.

et seq.

)

Modèle

93808

SYMBOLOGY

Double Isolé

Association de Normes

Canadienne

Underwriters L abora tories,

Inc.

V ~

A

no

xxxx/min.

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Cou r ant alt er nat if de Volts

Ampères

A ucune Révolut ion de Charge

par Minute (TR-MIN)

Page 7

Français

Page 24

PRÉCAUTIONS DE BATTERIE

1. Soin de Batterie Nécessaire : la Batterie (H) la fuite peut se produire dans l’usage

extrême ou les conditions de tempér ature . Si le liquide de Batterie entre en contact

avec la peau, se laver av ec le sav on et l’eau et le rinçage av ec le jus jaune citron et

le vinaigre. Si le liquide entre en contact avec les yeux, la rougeur av ec l’eau depuis

plusieurs minutes et contact un docteur immédiatement. Ne brûlez jamais la Batterie,

comme il peut exploser dans un f eu. N’essayez pas de charger une Batterie qui fuit.

Contactez des autorités inutilisées solides locales pour les instructions sur la

disposition correcte ou le recyclage de la Batterie.

2. Ne permettre pas aux enfants de manipuler ou jouer avec ces produits.

3. Les applications industrielles doivent suivre des exigences d’OSHA.

4. Vérifier pour les parties nuies. Avant le fait d’utiliser ces produits, vérifiez

soigneusement qu’ils opèrent correctement et exécuteront leur fonction voulue.

Vérifiez pour les parties nuies et autres conditions qui peuvent affecter l’opération

sûre de ces produits. Remplacez ou réparez des parties nuies ou portées

immédiatement.

5. Pièces détachées et accessoires: en assurant l’entretien, utilisez des pièces

détachées seulement identiques. Utilisez seulement des accessoires destinés de

l’utilisation avec ce produit.

6. Utiliser l’instrument bon ou l’attachement pour l’emploi bon. Il y a de certaines

applications auxquelles ce produit a été conçu. Il fera le tr av ail mieux et plus bien au

taux pour lequel il a été destiné. Ne modifiez pas ce produit et n’utilisez pas ce

produit d’un but pour lequel il n’est pas destiné.

7. Ne chargez JAMAIS la Batterie (H) plus de deux heures constamment.

8. Échangez toujours à une Batterie fraîche quand la performance d’instrument

commence à diminuer. La chaleur sévère est la plus destructive à une Batterie.

Plus de chaleur a produit, plus vite la Batterie perd le pouvoir. Une Batterie qui

devient trop chaude peut être en permanence nuie. Ne surrenvoyez jamais une

Batterie en utilisant l’instrument même après que la performance d’instrument

diminue. N’essa yez jamais de renvo yer la Batterie d’un instrument en continuant à

tirer la manette d’instrument. Quand la performance d’instrument commence à

diminuer l’arrêt l’instrument, recharger la Batterie et utiliser la Batterie fraîche de la

performance optimale.

9. Lire toutes les instructions et les avertissements sur la batterie avant le fait

de charger la batterie.

10 . Pour éviter des accidents, c hargez la batterie fournie seulement. N’utilisez pas

de différent chargeur avec cette batterie.

11 . N’exposer pas la batterie pour pleuvoir ou les conditions mouillées.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 8

Français

Page 25

12. Pour éviter le dommage de câble et de prise de courant, ne tirez jamais le

câble pour débrancher le c hargeur.

13. N’utiliser pas le chargeur si le câble ou la prise de courant sont nuis.

14. Les réparations devraient être réalisées seulement par les techniciens de

service qualifiés.

15 . Ne toucher pas les pôles de batterie a vec aucune source conductrice.

16 . Ne garder pas la batterie dans une boîte avec d’autres objets en métal.

17. La Batterie de NiMh doit être recyclée ou disposée correctement. Ne lancez

pas la batterie dans un feu .

Défaisant

En défaisant, vérifiez pour v ous assurer que toutes les parties montrées sur la Liste

de Parties et le diagramme d’assemblage sur la page 21 et 22 sont incluses. Si des parties

manquent ou cassées, appelez s’il vous plaît le Harbor Freight Tools au nombre énuméré

sur la couverture première de ce manuel.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 9

Français

Page 26

Le fait de Charger la Batterie

NOTEZ: Faites allusion à la page 18, le chiffre 3 pour aider à identifier des parties

discutées ci-dessous. Utilisez les nombres de partie dans la Liste de Parties

sur la page 21 et montré sur le Diagramme d’Assemblage sur la page 22 pour

identifier et ordonner des pièces détachées.

NOTEZ: La Batterie ne vient pas chargée de l’usine. Charge av ant l’utilisation. Le fait

de charger la température de pièce : 10° - 40° C.

1. Brancher la Base de Chargeur (O) à une douille murale . Notez : la Base de Chargeur

(O) a tant un SUR le feu rouge, qu’UN de la lumière verte.

2. Quand la Base de Chargeur (O) est branchée dans une douille murale, le FEU

ROUGE prendra et rester a constamment. Cela montre que tout l’ensemble de circuits

travaille correctement et la Base de Chargeur est prête à charger.

3. F aire glisser la Batterie (H) en avant jusqu’à ce qu’il prenne fermement place dans

la Base de Chargeur (O). La lumière VERTE prendr a et commencera à briller. Cela

indique que la batterie charge.

4. La période chargeante prend environ une heure pour une batterie complètement

renv oyée et moins pour une batterie pas complètement renvoyée . Quand la Batterie

(H) a été complètement chargée la Base de Chargeur (O) bipera une fois et la

lumière VERTE prendra constamment.

5. Enlever la Batterie (H) de la Base de Chargeur (O) et insérer la Batterie (H) dans la

base de l’instrument.

6. Appuyer sur le bouton d’essai sur la Batterie (H) pour vérifier que la batterie est

complètement chargée.

7. T outes les quatre lumières allumées représentent une charge complète de la Batterie.

CHIFFRE

1

LE FAIT D’INSTALLER ET LE FAIT D’ENLEVER LE PAQUET DE BATTERIE

Avertissement! Ne touchez pas le Changement de Manette (B) ou le Bouton de

Libération de Manette (A) en installant la Batterie.

CHIFFRE

2

Base de

Chargeur

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 10

Français

Page 27

Insérez la Batterie (H) dans le corps de scier comme montré dans le chiffre 1. Le chiffre 2

montre la Batterie (H) correctement inséré dans la Base de Chargeur (O).

NOTEZ : En enlevant le P aquet de Batterie du corps de scier, appuyez dans sur les deux

étiquettes se bloquant trouvées sur chaque côté du Paquet de Batterie et tirez

directement du corps.

Av ertissement! Si au moins deux batteries doivent être char gés, permettent au temps

Basé Chargeant de refroidir entre le fait de charger.

TRAVAILLEZ LE GUIDE CLAIR ET À LASER

V otre Scier Circulaire Sans cordon de 18 volts a une Lumière de Tra vail intég rée et

un Guide À laser. La Lumière de Travail (F) est allumée et désamorcée en déprimant le

Changement de Lampe de Travail (C) trouvé sur le haut du scier. Le Guide À laser (E) est

allumé en tirant la manette et ne peut être allumé aucune autre voie.

NOTEZ: La Lumière de Travail et le Guide À laser sont des outils et ne sont pas

destinés pour fonctionner dans n’importe quelle manière autre que cela décrit

dans ce manuel.

OPÉRATION

Installez la Lame de Scier. Préparez et protégez la matière à être coupée avant le

fait d’allumer le scier . La Batterie (H) de vrait av oir une charge complète av ant le fait d’utiliser

le scier. Enlevez la batterie avant le fait de faire n’importe quels ajustages. Faites allusion

au chiffre 3, sur la page 18.

LE FAIT D’INSTALLER LA LAME COUPANTE

NOTEZ : Le Verrou de Serrure est un fil contraire.

1. Enlever la Batterie (O) avant le fait de faire n’importe quels ajustages.

2. Appuyer sur le Bouton de Serrure de Fuseau (J) pour empêcher la Lame de Scier

de bouger en tournant le Verrou de Lame (I).

3. L’utilisation de la Clé d’Hexagone (P), desserrez et enlevez le Verrou de Serrure (I)

et la Bride Extérieure (I).

4. F aire tourner la Garde de Lame Plus basse (K), en sens inverse des aiguilles d’une

montre permettre l’entrée de la Lame de Scier.

5. La Lame de Scier d’Insertion par la Plaque de fond (M) jusqu’à la lame va sur le

fuseau automobile. Remarquez la flèche sur la Garde de Lame Plus basse (K)

et la flèche sur la Lame de Scier. Ils devraient être orientés dans la même

direction.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 11

Français

Page 28

6. Remplacer la Bride Extérieure (I) et le Verrou de Lame (I). Serrez-vous avec la Clé

d’Hexagone (P) en appuyant sur le Bouton de Serrure de Fuseau (J). Vérifiez que

le Bouton de Serrure de Fuseau (J) est dans la position en haut (déverrouillée).

7. Remplacer la Clé d’Hexagone (P) à son trou de stoc kage dans l’habitation du scier .

LE RÉGLAGE DU SCIER AVANT LA COUPURE

1. Pour régler l’angle de lame, desserrez le Bouton d’Ajustage de Coupe Biseaute

(G) et déplacez la Plaque de fond (M) en observant l’échelle de degré trouvée à

côté du Bouton d’Ajustage de Coupe Biseaute (G).

2. Pour régler la profondeur de la coupe, desserrez le Bouton d’Ajustage de

Profondeur (N), qui est trouvé à côté de l’habitation automobile et du mouvement la

Plaque de fond (M) en observant la quantité{le montant} de Lame de Scier exposée

sous la Plaque de fond. Serrez le Bouton d’Ajustage de Prof ondeur (N) après le fait

de faire l’ajustage.

3. Installation de Clôture d’Accroc et ajustage :

La Clôture d’Accroc peut être insérée dans le laissé ou dans le côté droit à l’ortei l

de la Plaque de fond (M). Insérez la Clôture d’Accroc dans les guides de clôture

jusqu’à ce qu’il contacte le V errou de Rétention (Q). Desserrez le Verrou de Rétention

(Q) jusqu’à ce que la clôture puisse glisser le protègent par alors en tournant le

V errou de Rétention (Q) dans le sens des aiguilles d’une montre. La Clôture d’Accroc

est ajustable de 0–127mm. (Faites allusion à la Page 18, le chiffre 3.)

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 12

Français

Page 29

Fonctions

Le Scier Circulaire Sans cordon de 18 volts a les caractéristiques suivantes,

comme montré dans le chiffre 3 ci-dessous.

(A) Bouton de Libér ation de Manette

(B) Changement de Manette

(C) Changement de Lampe de T r avail

(D) De la poignée de mains

(E) Guide À laser

(F) Lumière de travail

(G) Biseauter le Bouton d’Ajustage

de Coupe

(H) Batterie de NiMh de 18 volts

(I) Bride de Lame et verrou

(J) La Serrure de Fuseau pour le

changement de lame

(entre le corps de scier et la garde

de lame supérieure)

(K) Garde de Lame Plus basse

(L) Titulaire Clair

D

(M) Plaque de fond

(N) Bouton d’Ajustage de Prof ondeur

(à côté du moteur du scier non

montré)

(O) La Base de Chargeur (montré sur

la page 16)

(P) La Clé d’Hexagone

(Inséré dans le Scier Le corps à

côté du moteur)

(Q) Verrou de Rétention

(R) Port de Poussière

Chiffre 3

J

P

L

G

Q

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

N

E

F

C

A

B

R

H

K

I

Page 13

Français

Page 30

PRÉPAREZ LA MATIÈRE AVANT LA COUPURE

1. Soutenir de grands panneaux pour minimiser le risque de lame serrante et de recul

de scier.

2. Utiliser une clôture d’accroc ou un guide de bord droit protégé en déchirant la matière.

3. Serrez solidement la matière à être coupée pour travailler le banc.

4. Assurer que le scier n’a pas coupé dans les soutiens ou l’établi.

5. Utiliser le type approprié de lame pour la matière que vous coupez.

COUPURE

Av ertissement : l’utilisateur peut être sérieusement blessé si l’instrument n’est

pas utilisé correctement. Lisez ce manuel entier avant l’utilisation. Vérifiez

que la Lame de Scier est solidement serrée et tant angle que les boutons

d’ajustage de hauteur sont serrés avant la procédure. Voir la Page 17.

1. Marquer la ligne que vous couperez.

2. Placer la Plaque de fond (M) sur la matière à être coupée. Mettez en ligne l’entaille

première de la Plaque de fond (le bord bon met en ligne avec la lame de scier) sur

la ligne de coupe.

que vous couperez à ce point ou le scier ira faire recul!

Assurez-vous que la Lame de Scier ne touc he pas la matière

3. Pour commencer le scier , déprimez le Bouton de Libération de Manette (A) et serrez

le Changement de Manette (B).

4. Avec le scier à la vitesse complète , bougez le scier envoient lentement pour accomplir

la coupe.

5. Quand la coupe est complète, libérez le Changement de Manette (1) et le breake

électrique arrêtera la lame immédiatement. Ne déposez pas le scier jusqu’à ce que

la lame arrête de tourner.

6. Une fois les arrêts de lame et le trav ail est complet, enlever la batterie et conserver

le Scier Circulaire dans un endroit sûr, loin des enfants.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 14

Français

Page 31

L’INSPECTION, LA MAINTENANCE ET LE NETTOYAGE

LISEZ S’IL VOUS PLAÎT LE SUIVANT SOIGNEUSEMENT

LE FABRICANT ET-OU LE DISTRIBUTEUR A FOURNI LE DIAGRAMME DE PARTIES DANS

CE MANUEL COMME UN INSTRUMENT DE RÉFÉRENCE SEULEMENT. NI LE FABRICANT NI LE

DISTRIBUTEUR NE FONT AUCUNE REPRÉSENTATION OU GARANTIE DE N’IMPORTE QUELLE

SORTE À L’ACHETEUR QU’IL OU ELLE EST AUTORISÉ POUR FAIRE N’IMPORTE QUELLES

RÉPARATIONS AU PRODUIT OU QU’IL OU ELLE EST AUTORISÉ POUR REMPLACER N’IMPORTE

QUELLES PARTIES DU PRODUIT. EN FAIT, LE FABRICANT ET-OU LE DISTRIBUTEUR DÉCLARE

EXPRESSÉMENT QUE TOUTES LES RÉPARATIONS ET LES REMPLACEMENTS DE PARTIES

DEVRAIENT ÊTRE ENTREPRIS PAR LES TECHNICIENS DIPLÔMÉS ET AGRÉÉS ET PAS PAR

L’ACHETEUR. L’ACHETEUR SUPPOSE TOUT LE RISQUE ET L’OBLIGATION SURVENANT DU FAIT

DE SES RÉPARATIONS AU PRODUIT ORIGINAL OU AUX PIÈCES DÉTACHÉES Y, OU SURVENANT

DU FAIT DE SON INSTALLATION DE PIÈCES DÉTACHÉES Y.

A VERTISSEMENT! Assurez-v ous toujours que le Changement de Manette

(2) est dans son de la position et enlever la Batterie avant le fait d’exécuter

n’importe quelle inspection, ajustages, maintenance, ou nettoya ge.

1. Garder le scier Circulaire propre; enlevez toute la sciure qui a accumulé.

2. Inspectez régulièrement toutes les vis montantes et les boutons pour garantir qu’ils

sont correctement serrés.

3. Garder des lames de scier propres et pointu. Les lames pointues minimisent le fait

de caler et recul.

4. Garder des gardes en bon état de marche.

5. Garder la bouche aérienne automobile propre de poussière et de débris. Vide

périodiquement.

6. Si l’instrument n’opère pas normalement, en faisant des bruits inhabituels, semble

vicié ou si autre problème a vec l’instrument existe, arrêtez de l’utiliser immédiatement

et le faire réparer par un technicien de service qualifié.

7. L’instrument propre avec un tissu humide et un détersif doux. N’utilisez pas de

solvants comme ils peuvent nuire et faire craquer les parties de plastique.

8. Si l’instrument ne commence pas ou opère à la pleine puissance avec un paquet

de batterie complètement chargé, les contacts sur le paquet de batterie peuvent

dev oir être nettoyés.

9. Vérifier pour les craquements ou le dommage à l’instrument avant le fait de l’utiliser.

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 15

Français

Page 32

LISTE DE PARTIES

traPnoitpircseD.ytQtraPnoitpircseD.ytQ

1erurreSedsiV144eéssuoPednotuoB2

2edirBaledrueirétxe'lÀ154ehcuaGsproC1

3emaL164enobr

4edirBaledrueirétni'lÀ174ediuGederutôlC1

5eéxiFedraGederutrevuoC184rioNliF1

6spmetnirP194erutrev

7essabsulPemaLededraG105BCPedehcnalP1

8spmetnirP115xuenimulnotuoB1

9cuohctuoaCudretneiroséD125resalÀnotuoB1

01cuohctu

11resalàerèimuL145uaesuFederurreSednotuoB1

21erueirépuSemaLededraG155uaesuFederurreS1

31siV46

41siV475rioNliF1

51euqillatéMeuqalP185eirettaBedteuqaP1

61siV195spmetnirP2

71siV406noixennoCedesaB1

81leirétaMedetîoBe

91troppaR126erialCedonA'deuqalP1

02noitcudorPedexA136noiP1

12erialCerutrevuoC146erialCesaB1

22erèimuL156siV1

32erurreSedsiV166sertèmillim6edegarresedélC1

42revalàenihcaM176leirétaMdnarG2

52notuoB186erurreSedexA'dnot

62siV196erèissuoPedtroP1

72xioN107siV1

82siV117DEL1

92dnofedeuqalP127rotatsederèimuL1

03siV137spmetnirP1

13xioN147erèirrAetteuqitÉ1

23t

33elibomotuAnaF167liF1

43elibomotuArotoR177rioNliF1

53troppaR187eguorLIF1

63cuohctuoaCednopmate

73cuohctuoaCelcevatiorDsproC108ediuGedeuqalP1

83siV518ehcuaGetteuqitÉ1

93siV228ehcuaGetteuqitÉ1

04er

14notuoB148ebuT1

24enobraCedessorBalruoProtatS258etiorDelloMesirP1

34sproCedsiV868ehcuaGelloMesirP1

roppaR157erueirépuSetteuqitÉ1

rioméM197erèimerPeuqalP1

oaCedettehcoP135tnemegnahC1

5eguoRliF1

derutrevuoC116cuohctuoaCedelôP1

utrevuocedemèirtauQ138cuohctuoaCelcevaehcuaGsproC1

uoC1

uoB1

aCedessorBedriottuogÉ1

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 16

Français

Page 33

DIAGRAMME D’ASSEMBLAGE

NOTEZ : Quelques parties sont énumérées et montrées pour les buts d’illustration

seulement et ne sont pas disponibles individuellement comme les pièces détachées .

Modèle

93808

Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Page 17

Français

Loading...

Loading...