Page 1

TRAILER WITH TAILGATE

®

5’ x 8’ WITH RAMP

MODEL 93747

ASSEMBLY AND OPERATING INSTRUCTIONS

WARNING!

IMPORTANT INFORMATION

This trailer’s Hitch Coupler MUST be properly secured to the hitch ball of the towing vehicle. After assembly and

attachment, pull up and down on the Hitch Coupler to make sure the hitch ball is fitting snugly in the Hitch Coupler.

There must be no play between the hitch ball and Hitch Coupler. If there is play, tighten the Adjustment Nut until

no play is present. If the Adjustment Nut is too tight, the Handle will not lock. Carefully read and follow the

complete instructions in this manual BEFORE setup or use.

If the Coupler is not secured properly, the ball could come loose while the trailer is in motion, possibly

causing property damage, SERIOUS PERSONAL INJURY, or DEATH.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http//www.harborfreight.com

TO PREVENT SERIOUS INJURY OR DEATH,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2006 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts,

please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

Item Description

Maximum Weight Capacity 1,500 Pounds

Maximum Towi ng Speed 55 MPH

Overall Dimensions 137” L x 76” W x 73-1/4” @ Top of Raised Ramp

137” L x 76” W x 31-1/2” @ Top of Rails

Main Frame Dimensi ons 95” L x 57-1/2” W x 12” H @ Top of Side/Front Rails

Ramp Dimensions 53-5/8” L x 57-3/8” W x 1-1/2” Thick

Ground Clearance 14” @ Tongue / 16-3/4” @ Rear / 9-1/4” @ Axle

Tires Qty. 2 / DOT Approved

Required Tire Pres sur e: 80 PSI

Load Range Rating: C

Type: Tubeles s

Size: 5.30-12 x 4” Wide

Hitc h Ty pe Cla s s II

Ball Si z e 2”

Light Voltage Requi re ment 12 Volts DC Negative Grou nd

Weight 398 Pounds

UNPACKING

When unpacking, make sure all the par ts and hardware shown on the Parts List/Hardware List (pag es 22, 23) are included. If any parts are missing or broken, please call

Harbor Freight Tools at the number shown on the cover of this man ual as soon as possible.

SA VE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

Read and adhere to the following instructions. Failure to read and obey all of the

following instructions COMPLETELY will void the warranty and can result in dam-

age to the Trailer, property damage, SERIOUS PERSONAL INJURY, or DEATH.

SAVE THESE INSTRUCTIONS.

Page 2SKU 93747 For technical questions, please call 1-800-444-3353.

Page 3

WORK AREA

1. Keep work area clean and dry . Cluttered, damp, or wet w o rk areas invite inju-

ries.

2. Keep children away from work area. Do not allow children to play in, climb on

or ride in this product.

3. Store idle equipment. When not in use, tools and equipment should be stored in

a dry location to inhibit rust. Always lock up tools and equipment, and keep out of

reach of children.

4. Do not setup or use this product if under the influence of alcohol or drugs.

Read warning labels on prescriptions to determine if your judgement or reflexes

are impaired while taking drugs. If there is any doubt, do not attempt to setup or

use this product.

5. Use ey e protection. Wear ANSI-approved safety impact eye goggles when

assembling this product. ANSI-approved safety impact eye goggles are available

from Harbor F reight Tools.

6. Dress safely. Do not wear loose clothing or jew elry, as they can become caught

in moving parts. W ear a protective hair covering to prev ent long hair from becoming caught in moving part s. If wearing a long-sleeve shirt, roll sleeves up above

elbows.

7. Do not overreach. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etc.

8. Industrial applications must follow OSHA requirements.

9. Stay alert. W atch what you are doing at all times. Use common sense. Do not

setup or use this product when you are tired or distracted from the job at hand.

EQUIPMENT USE AND CARE

1. Check for damaged parts. Before using this product, carefully check that it will

operate properly and perform its intended function. Check for damaged parts and

any other conditions that may affect the operation of this product. Replace or

repair damaged or worn parts immediately.

2. Replacement parts and accessories: When servicing, use only identical replacement parts. Only use accessories intended for use with this product. Approved accessories are available from Harbor Freight Tools.

Page 3SKU 93747 For technical questions, please call 1-800-444-3353.

Page 4

3. Maintain this product with care. Keep this product clean and dry for better and

safer performance.

4. Maintenance: For your saf ety, service and maintenance should be performed

regularly by a qualified technician.

5. Use the right equipment for the job. Do not attempt to force small equipment to

do the work of larger industrial equipment. There are certain applications for

which this product was designed. It will do the job better and more safely at the

capacity for which it was intended. Do not modify this product, and do not use this

product for a purpose for which it was not intended.

SERVICE

1. Equipment service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel could result in a risk

of injury .

2. When servicing equipment, use only identical replacement parts. Follow

instructions in the

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of personal injury.

“Inspection, Maintenance, and Cleaning”

section of this

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. T o avoid personal injury and/or property damage, do not exceed the T railer’s

maximum weight capacity of 1,500 pounds, evenly distributed.

Be aware of dynamic loading! Suddenly dropping or moving a load onto the

trailer bed or ramp may create, for a brief instant, an excess load which may result

in damage to the product and/or personal injury .

2. Before each use, always examine the Trailer for proper Tire air pressure (80

PSI), damaged tail lights, damaged side running lights, loose bolts and nuts,

structural cracks and bends, and any other condition that may affect its safe

operation. Do not use the Trailer even if minor damage appears.

3. Never allow adults, children, or pets to ride in or play on the T railer.

4. Before each use, alwa ys attach the Saf ety Chain of the Trailer to the towing

vehicle. Make sure the Safety Chain is attached to the towing vehicle with the

same length for each side. Do not allow the Safety Chain to drag on the ground.

Page 4SKU 93747 For technical questions, please call 1-800-444-3353.

Page 5

5. Always check to make sure the payload being transported is properly and

safely secured in the T railer. Load the Trailer evenly from side to side with 60%

of the load forward of the Axle.

6. Prior to using the Trailer, make sure to read and understand all instructions

and safety precautions as outlined in the owner’s manual for the towing

vehicle. Make sure the towing vehicle is capable of towing the Trailer and its

payload. Make sure the hitch on the towing vehicle is capable of towing the

Trailer and its payload. The towing capacity of the hitch is typically stamped on

the hitch dra wbar.

7. Make sure the Coupler and the vehicle’ s ball hitch (not included) are of

equal mating size (2”) and are rated equal to or greater than the weight of

the Trailer and its payload.

8. Do not exceed 55 miles per hour when towing the Trailer. Excess speed is a

major cause of vehicle-trailer accidents.

9. The Tail Light Bulbs supplied with this Trailer are f or a 12 v olt DC electrical

system only. Do not attempt to power the Light Bulbs with any other type or

voltage electrical current.

10. Whenever possible, park the Trailer on a flat, le vel, paved, surface and choc k

both Tires to keep the Trailer from accidently moving.

11.

12. Maintain labels and nameplates on the T railer. These carry important informa-

13. Reporting safety defects: If you believe your Trailer has a def ect which could

CA UTION! Care must be taken when backing up the Trailer. Onl y back

up the Trailer on a straight path. If the Trailer is allowed to turn off the straight

path while backing up, the Trailer could jackknife, causing severe damage to the

Trailer and towing vehicle.

tion. If unreadab le or missing, contact Harbor Freight Tools for a replacement.

cause a crash or could cause injury or death, you should immediately inform the

National Highway Traffic Safety Administration (NHTSA) in addition to notifying

the manufacturer, Changzhou Nanxiashu Tool Company. If NHTSA receives

similar complaints, it may open an investigation, and if it finds that a safety defect

exists in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you,

Harbor Freight Tools, or the manufacturer. To contact NHTSA, you may either call

the Auto Safety Hotline toll-free at 1-800-424-9393 or 202-366-0123 or write

NHTSA, U.S. Department, 400 7th Street SW NSA-11, W ashington, D.C. 20590.

Page 5SKU 93747 For technical questions, please call 1-800-444-3353.

Page 6

14. T railer licensing notice: Some states may consider this Trailer a vehicle requir-

ing registration, licensing, and titling. Check with your State Department of Motor

Vehicles for information and guidance on registering, licensing, and titling the

Trailer.

15. WARNING: The warnings, precautions, and instructions discussed in this manual

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied by the operator.

16. This Trailer must be securely connected to the towing vehicle bef ore loading.

17. Do not use this trailer on rough terrain. Excessively rough terrain, especially

when coupled with high speeds, could cause the trailer to become damaged or

cause the hitch coupler to fail.

ASSEMBLY INSTRUCTIONS

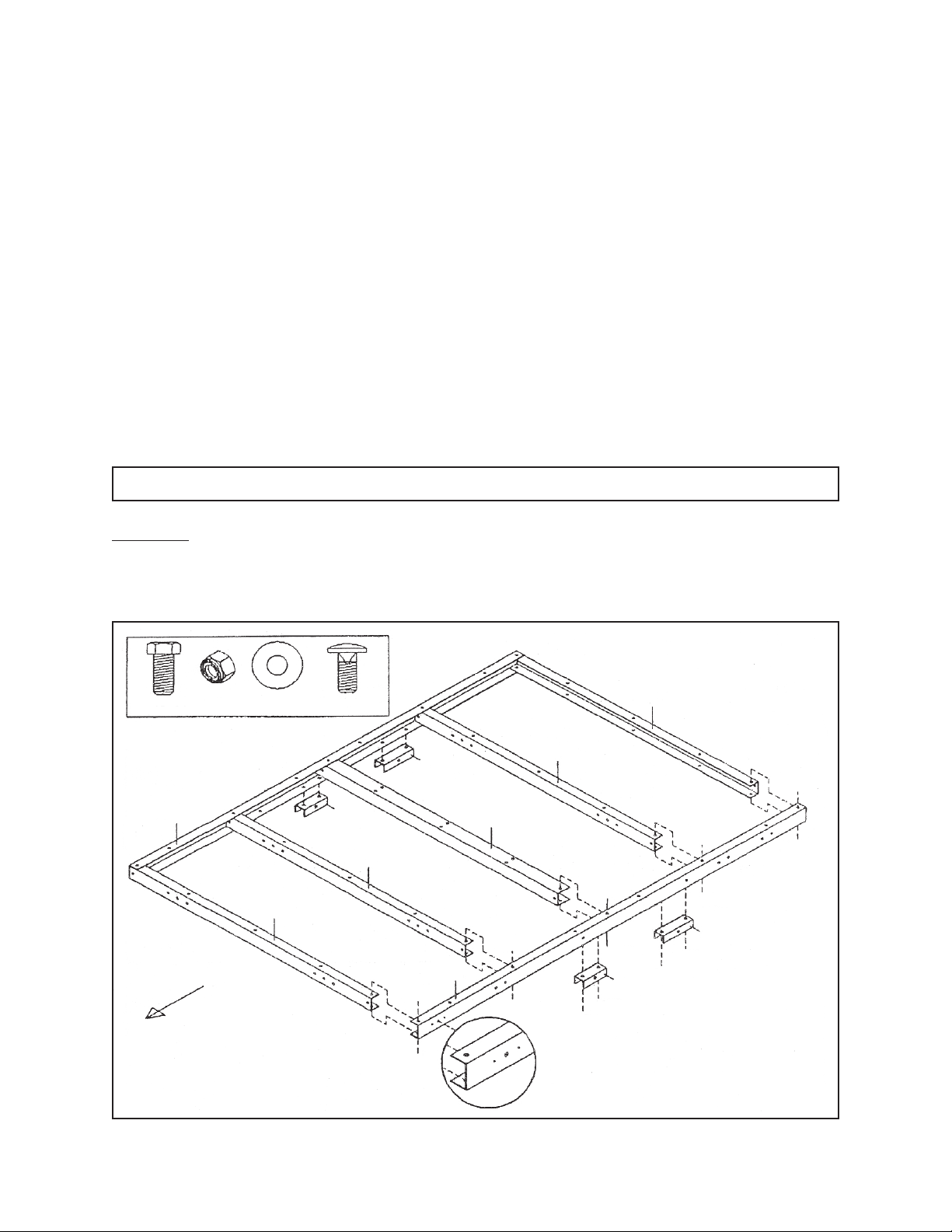

Phase 1:

1. Lay out the Right Side Rail (1R), Left Side Rail (1L), four Cross Members (2), and

Center Cross Member (3). (See Figure A.)

ACB

7

2

FCB

ACB

FCB

ACB

ACB

ACB

8

A: 3/8” x 1” B: 3/8” C: 3/8” F: 3/8” x 7/8”

1R

2

FRONT

7

2

ACB

8

3

ACB

1L

ACB

2

ACB

FCB

FCB

ACB

Page 6SKU 93747 For technical questions, please call 1-800-444-3353.

Page 7

2. IMPORTANT: There is a larger hole between two smaller holes located on one

end of the Left Side Rail (1L) and one end of the Right Side Rail (1R). The ends

of the Side Rails with the three holes must be positioned toward the

front

of the

Trailer.

(See circle illustration in Figure A.)

3. Attach the Side Rails (1L, 1R) to the four Cross Members (2) and Center Cross

Member (3), using the Hex Bolts (A), Flat Washers (C), and Nylon Nuts (B) as

shown in the illustration. (See Figure A.)

4. Attach the shorter Front Spring Hanger (7) and longer Rear Spring Hanger (8) to

the bottom of the Left Side Rail (1L) and Right Side Rail (1R), using the Carriage

Bolts (F), Flat Washers (C), and Nylon Nuts (B) as shown in the illustration.

(See Figure A.)

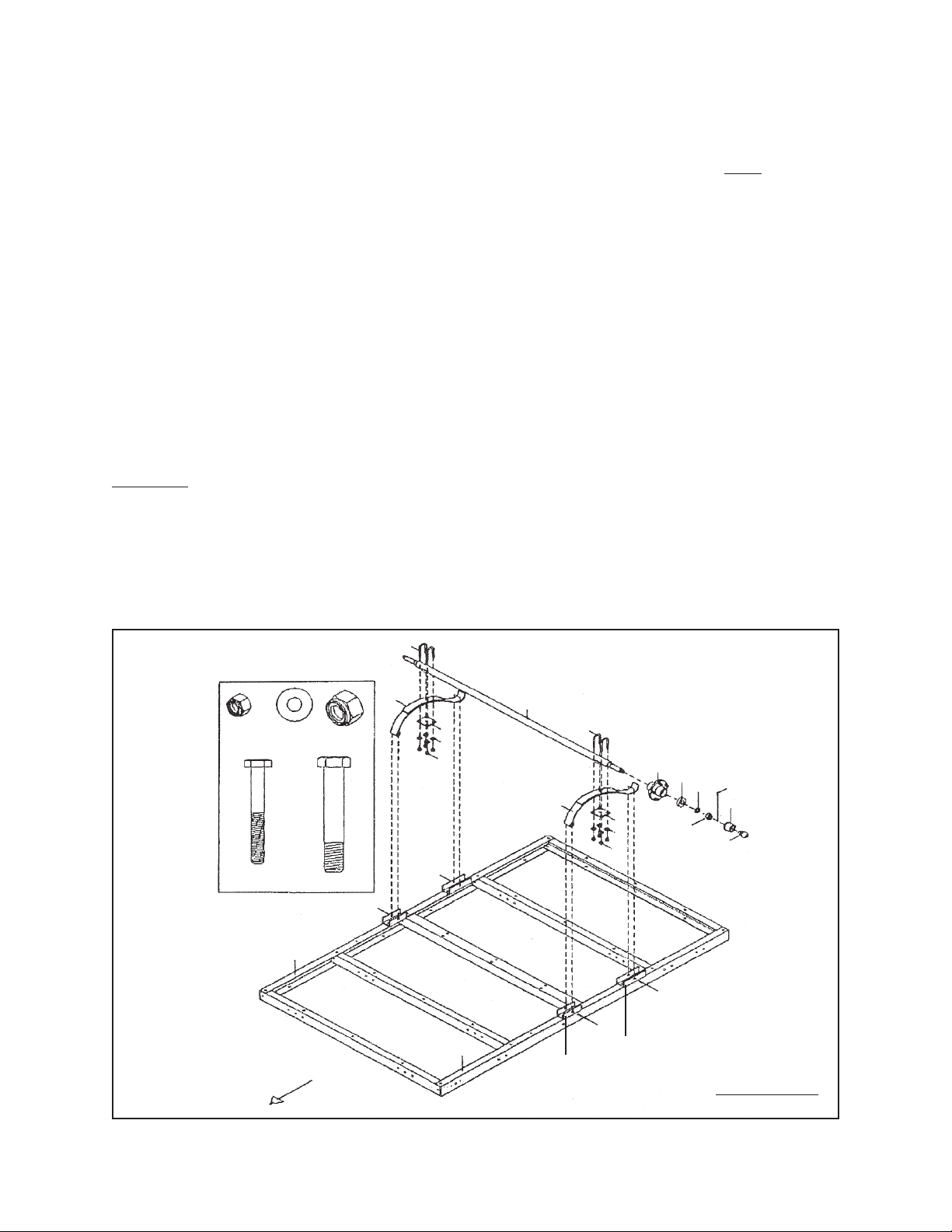

Phase 2:

1. With assistance, turn the Trailer upside down.

2. Place a Leaf Spring (20) on the Spring Hangers (7, 8) with the

forward. Secure the Leaf Spring to the Spring Hangers, using the Hex Bolts (G)

19

B: 3/8” C: 3/8”

E: 3/8” X 3”

G: 9/16” X 3-1/4”

1L

H: 9/16”

20

18

C

B

EB

GH

10

20

19

B

18

C

26

EB

spring eye

27

T

U

29

28

R

facing

FRONT

1R

GH

8

7

FIGURE B

Page 7SKU 93747 For technical questions, please call 1-800-444-3353.

Page 8

and Nylon Nuts (H) at the front portion. Use the Hex Bolts (E) and Nylon Nuts (B)

for the rear portion. Then, repeat this procedure for the remaining Leaf Spring.

(See Figure B.)

3. Place the Axle (10) on the Leaf Springs (20) with the grease fitting hole at each

end of the Axle facing

and place two U-Bolts (19) over each end of the Axle and through each Spring

Plate (18). Then secure the Axle to the Leaf Springs, using the Flat W ashers (C)

and Nylon Nuts (B). (See Figure B.)

4. IMPORTANT: Whenever a Hub (26) on a new Trailer requires assembly (or if a

Hub is disassembled for maintenance) the following procedures MUST be followed:

A. Using a suitable solvent, thoroughly clean the Hub Set (26), Outer Bearings

(27), Castle Nut (28), Dust Cap (29), and the rest of the parts of the Hub Assembly of all grease, dirt, metal shavings, and all other foreign objects. These

parts must be cleaned, even if they are new or appear to be clean.

(See Figure B.)

B. Allow all parts to dry completely.

downward

away from the Springs. Center the Axle (10)

C. Make sure your hands are clean and the bearing packer (not included) is

clean.

D. Place fresh, clean bearing grease in the bearing packer.

E. With the grease-filled bearing packer in one hand and the Outer Bearing (27)

in the other, press the Bearing into the grease, forcing the grease inside the

slots in the Bearing. Continue doing this until every slot in the Bearing is

completely full of grease. (See Figure B.)

F. Finish assembling the Hub Assembly as explained below, making sure not to

get dirt or debris on any part of the assembly.

5. Carefully slide the Hub Sets (26) over the spindles at each end of the Axle (10).

Insert the Outer Bearings (27) and Flat Washers (U) on the spindles. Screw a

Castle Nut (28) tightly onto each spindle. Then bac k the Castle Nut off slightly so

that the Hubs can just move freely. (See Figure B.)

6. Insert a Cotter Pin (T) through the Castle Nut (28) and hole at the end of each

spindle, and spread the Cotter Pins. (See Figure B.)

7. Fill the Dust Caps (29) with bearing grease. Then, press each Dust Cap onto the

Hub Sets (26). (See Figure B.)

8. Install a Grease Fitting (R) into each hole located at the ends of the Axle (10).

(See Figure B.)

Page 8SKU 93747 For technical questions, please call 1-800-444-3353.

Page 9

Phase 3:

1. Attach a Tow Bar (5) to the Left Side Rail (1L), Right Side Rail (1R), and front

Cross Member (2).

NO TE: The ends of the Tow Bars, with three square holes, must be facing toward

the front of the Trailer. Secure the Tow Bars, using the Hex Bolts (A), Flat Washers

(C), and Nylon Nuts (B) as shown in the illustration.

(See Figure C.)

2. Place the Stand Base (16) on the front of the two Tow Bars (5). Align the mounting holes in the Stand Base with the three square holes in the Tow Bars. Then

secure the Stand Base to the Tow Bars, using the Carriage Bolts (F), Flat Washers

(C), and Nylon Nuts (B). (See Figure C.)

16

FCB

5

ACB

FRONT

ACB

ACB

C: 3/8”B: 3/8”A: 3/8” X 1”

ACB

5

F: 3/8” X 7/8”

FIGURE C

Page 9SKU 93747 For technical questions, please call 1-800-444-3353.

Page 10

Phase 4:

1. With assistance, turn the Trailer right-side-up.

2. Attach the Spare Tire Bar (6) to both T o w Bars (5), using the Carriage Bolts (F),

Flat W ashers (C), and Nylon Nuts (B). (See Figure D.)

3. Attach the Coupler Base (15) to the front ends of both Tow Bars (5), using the

Carriage Bolts (F), Flat W ashers (C), and Nylon Nuts (B). (See Figure D.)

4. Locate the center link in the Safety Chain (17). Attach the Chain to the bottom of

the Coupler Base (15) by inserting a Carriage Bolt (D) downward through the

Coupler Base and through the center link in the Chain. Secure the Chain to the

Coupler Base, using a Flat Washer (C) and Nylon Nut (B). (See Figure D.)

N

17

DCB

14

Q

LK

FCB

JLK

IL

FCB

F: 3/8” X 7/8”

J: 1/2” X 1”

15

FCB

FCB

B: 3/8”

K: 1/2”

C: 3/8”

D: 3/8” X 1-1/2”

N

L: 1/2”

5

I: 1/2” X 3-3/4””

Q

6FRONT

FIGURE D

Page 10SKU 93747 For technical questions, please call 1-800-444-3353.

Page 11

5. Slide the Hitch Coupler (14) onto the Coupler Base (15), and align the two top

mounting holes of the Hitch Coupler with the two top mounting holes of the Coupler Base. Secure the Hitch Coupler to the Coupler Base, using the Hex Bolts (I),

Flat W ashers (L), and Nylon Nuts (K). (See Figure D.)

6. Lock the Coupler’s (14) Trigger by inserting the Safety Pin (N) through the hole in

the Trigger. Then, insert the “R” Pin (Q) through the hole in the Safety Pin.

(See Figure D.)

Phase 5:

1. Attach a Fender Bracket (30), with a Hole Spacer (9), in

the Left Side Rail (1L), using the Hex Bolts (O), Flat Washers (C), and Nylon Nuts

(B). Attach a Fender Bracket (31), with a Hole Spacer (9),

the Left Side Rail (1L), using the Hex Bolts (O), Flat Washers (C), and Nylon Nuts

(B). (See Figure E,

2. Attach a Fender Bracket (31), with a Hole Spacer (9), in

the Right Side Rail (1R), using the Hex Bolts (O), Flat Washers (C), and Nylon

Nuts (B). Attach a Fender Bracket (30), with a Hole Spacer (9),

(10) on the Right Side Rail (1R), using the Hex Bolts (O), Flat Washers (C), and

Nylon Nuts (B). (See Figure E,

3. Attach a Fender (11) to the Fender Brackets (30, 31) on the Left Side Rail (1L),

using the Hex Bolts (A), W ashers (C), and Nylon Nuts (B).

(See Figure E,

4. Attach the remaining Fender (11) to the Fender Brackets (30, 31) on the Right

Side Rail (1R), using the Hex Bolts (A), Washers (C), and Nylon Nuts (B).

(See Figure E,

5. Install a Tire/Wheel (12) assembly on each Hub Set (26). Then, secure the Tire/

Wheel assemblies, using the Lug Nuts (M).

next page.)

next page.)

next page.)

next page.)

front

of the Axle (10) on

behind

front

the Axle (10) on

of the Axle (10) on

behind

the Axle

NOTE: Use a lug wrench (not included) to tighten the Lug Nuts (in a crisscross

star pattern) to 90 Ft./Lbs.

Page 11SKU 93747 For technical questions, please call 1-800-444-3353.

Page 12

A: 3/8” X 1”

B: 3/8”

C: 3/8”

O: 3/8” X 1-1/4”

M: 1/2”

FRONT

FIGURE E

31

11

30

12

9

31

M

11

9

9

30

31

30

OCB

ACB

OCB

Phase 6:

1. Assemble the Tail Light Brackets (23) to the rear of the Left Side Rail (1L) and

Right Side Rail (1R), using the Hex Bolts (A), Flat Washers (C), and Nylon Nuts

(B). (See Figure F,

next page.)

2. Attach the License Plate Brack et (13) with the Left Tail Light (21) to the Left Side

Rail (1L), using the Hex Bolts (A), Flat W ashers (C), and Nylon Nuts (B).

NO TE: The Left T ail Light has a

(See Figure F ,

next page.)

clear

window at the bottom.

3. Attach the Right Tail Light (22) to the Right Side Rail (1R), using the Hex Bolts

(A), Flat W ashers (C), and Nylon Nuts (B). (See Figure F,

next page.)

Page 12SKU 93747 For technical questions, please call 1-800-444-3353.

Page 13

4. Open the Lens of the Side Running Lights (25). Run the Wire Lead of a Side

Running Light through the

center

hole located at the front end of the Left Side Rail

(1L). Then attach the Side Running Light to the Left Side Rail, using the Self

Tapping Screw (S). (See Figure F.)

5. Run the Wire Lead of the remaining Side Running Light (25) through the

hole located at the front end of the Right Side Rail (1R). Then attach the Side

Running Light to the Right Side Rail, using the Self Tapping Screw (S).

(See Figure F.)

6. Reinstall the Lens on the two Side Running Lights (25).

(See Figure F.)

22

ACB

23

25

center

13

23

ACB

21

FIGURE F

25

S

B: 3/8”

A: 3/8” X 1”

C: 3/8”

S

Page 13SKU 93747 For technical questions, please call 1-800-444-3353.

Page 14

Phase 7:

1. Have a qualified service technician install a 4-wire, 12 volt DC, Connector in the

trunk area of your vehicle.

2. Locate the vehicle’s Connector Plug near the Trailer’s Coupler (14) and lay out the

T railer’s Wiring Harness wires. (See Figure G.)

3. Connect the Brown Wire to the vehicle’s Left Tail Light by stripping, wrapping, and

taping the Connector Plug. (See Figure G.)

4. Connect the Yellow Wire to the vehicle’s Left Signal and Stop Light Wire.

(See Figure G.)

5. Connect the Green Wire to the vehicle’s Right Signal and Stop Light Wire.

6. NO TE: Some f oreign vehicles may require an adaptor to conve rt their 5-wire

system to a 4-wire vehicle Connector Plug. (See Figure G.)

7. Attach the White Ground Wire at the plug end of the Wiring Harness to the small

hole on the Coupler Base (15) with a 1/4” Tapping Screw (not included).

(See Figure G.)

SIDE RUNNING LIGHT (BROWN)

GROUND (WHITE)

GROUND (WHITE)

BROWN/YELLOW

D

E

D

D

D

C

D

LEFT STOP & TURN SIGNAL (YELLOW)

RIGHT STOP & TURN SIGNAL (GREEN)

E

BROWN/GREEN

D

D

D

D

D

D

D

E

WIRE CLIP

C

D

C

D

BROWN WIRE

WIRE (FROM SIDE LIGHT)

CONNECTOR

WIRE HARNESS

WIRE HARNESS

&

WIRE FROM TAIL LIGHT

FIGURE G

CONNECTOR

Page 14SKU 93747 For technical questions, please call 1-800-444-3353.

Page 15

8. Leave about 18” of wire beyond the Coupler (14). Then lay out the remaining

wires along the Tow Bars (5) and Left and Right Side Rails (1L, 1R).

(See Figure G.)

9. Secure the wires to the Tow Bars (5) and Left and Right Side Rails (1L, 1R), using

the Clips provided. (See Figure G,

Circle D

.)

10. Connect the Wire Lead from the Side Running Light (25) on each side of the

Trailer to the Brown Wire of the Wiring Harness, using a Wire Connector.

(See Figure G,

Circle E

.)

11. Strip about 3/4” of the ends of the Yellow/Brown and Green/Brown wires.

(See Figure G.)

12. Make the following connections (per color code). (See Figure G,

Circle C

.)

Left Side Right Side

Yellow-Red Wire Green-Red Wire

Brown-Two Black Wires Brown-Two Black Wires

Phase 8:

1. To install a Bed for the Trailer, cut tw o pieces of 3/4” thick plywood (not included)

to 48” x 60”. NOTE: It ma y be necessary to slightly trim the plywood to fit.

(See Figure H.)

FIGURE H

48”

48”

3/4” THICK PLYWOOD

60”

3/4” THICK PLYWOOD

PLYWOOD

*3/8”

HARDWARE

(NOT INCLUDED)

3/8”

CARRIAGE BOLT*

3/8”

WASHER*

3/8”

LOCK WASHER*

3/8”

NUT*

Page 15SKU 93747 For technical questions, please call 1-800-444-3353.

Page 16

2. Mark 7 locations in each piece of plywood to correspond with the 14 mounting

holes located on the front and rear Cross Members (2) and Left and Right Side

Rails (1L, 1R). Set the plywood aside, and drill the 14 marked locations with a

7/16” bit. Then, replace the plywood on the Trailer frame.

(See Figure H.)

W ARNING: Do not drill ad ditional Holes thr ough the ramp or structure of the Trailer.

Additional holes may weaken the structure of the Ramp, potentially causing it

to fail.

3. Secure the two pieces of plywood to the front and rear Cross Members (2) and

Left and Right Side Rails (1L, 1R), using 3/8” diameter, rust-resistant Carriage

Bolts, Washers, Lock W ashers, and Nuts (none included). Mak e sure the bolt

threads do not protrude up through the plywood. (See Figure H.)

Phase 9:

1. Lay out and assemble the Front Rack (1), Front Left Side Rack (2FL), Rear Left

Side Rack (3LR), Front Right Side Rack (2FR), and Rear Right Side Rack (3RR),

using the Hex Bolts (D), Flat Washers (E), and Nylon Nuts (F). (See Figure I.)

3FR

ABC

1

ABC

3RR

2FL

DEF

DEF

ABC

3RL

ABC

FIGURE I

Page 16SKU 93747 For technical questions, please call 1-800-444-3353.

Page 17

2. With assistance, set the Rack assembly on the Trailer and align the mounting

holes in the vertical supports on the Rack assembly with the mounting holes

located on the outer edges of the Trailer frame. Then secure the Rack assembly

to the Trailer frame, using the He x Bolts (A), Flat W ashers (B), and Nylon Nuts (C).

(See Figure I.)

Phase 10:

1. Lay out the Left Side Ramp (4L) and Right Side Ramp (4R) with their brackets on

the same end. Bolt each side together , using the Hex Bolts (A), Flat W ashers (B),

and Nylon Nuts (C).

(See Figure J.)

2. Attach the Angle Irons (8) to the assembled Ramp, using the Hex Bolts (A), Flat

Washers (B), and Nylon Nuts (C). (See Figure J.)

ABC

8

4R

ABC

ABC

ABC

ABC

ABC

8

4L

Phase 11:

1. Insert a Bushing (6) into each hinge of the Connecting Brackets (5).

(See Figure K,

next page.)

FIGURE J

2. Attach the Brackets (5) to the rear Cross Member (2), using the Hex Bolts (A), Flat

Washers (B), and Nylon Nuts (C). (See Figure K.)

Page 17SKU 93747 For technical questions, please call 1-800-444-3353.

Page 18

3. With assistance, raise the bottom of the Ramp assembly up to both hinges on the

rear Cross Member (2). Then insert a Hex Bolt (G) through the Ramp hinges and

Bushings (6) in the Connecting Bracket (5). Secure the Hex Bolts (6) to the rear

Cross Member, using the Nylon Nuts (C). (See Figure K.)

4. Raise the Ramp assembly all the way up. Insert a Lock Pin (7) through the side

bracket on each side of the Ramp and the Left and Right Rear Side Racks (3RL,

3RR). Then insert an “R” Safety Pin (H) through each of the Lock Pins.

(See Figure K.)

W ARNING:

Additional holes may weaken the structure of the Ramp, potentially causing it

to fail.

Do not drill additional Holes thr ough the ramp or structure of the Trailer.

7

ABC

H

5

GC

6

5

GC

6

7

H

ABC

FIGURE K

Page 18SKU 93747 For technical questions, please call 1-800-444-3353.

Page 19

OPERATING INSTRUCTIONS

WARNING!

IMPORTANT INFORMATION

This trailer’s Hitch Coupler MUST be properly secured to the hitch ball of the towing vehicle. After assembly and attachment, pull up and down on the Hitch Coupler to make sure

the hitch ball is fitting snugly in the Hitch Coupler. There must be no play between the

hitch ball and Hitch Coupler. If there is play, tighten the Adjustment Nut until no play is

present. If the Adjustment Nut is too tight, the Handle will not lock. Carefully read and

follow the complete instructions in this manual BEFORE setup or use.

If the Coupler is not secured properl y , the ball could come loose while the trailer is in

motion, possib ly causing property damage, SERIOUS PERSONAL INJUR Y , or DEATH.

1. Only use a 2” Ball Hitch (not included) on the towing vehicle. (See Figure L.)

2. NO TE: To reduce friction between the 2” Ball Hitch and Trailer Coupler (14), apply a

layer of heavy grease over the Ball Hitch. (See Figure L.)

3. Temporarily remove the “ R” Pin (Q) and Saf ety Pin (N). Then, pull

up on the Trigger and lift up on the Handle. (See Figure L.)

4. With assistance, place the Hitch Coupler (14) over the vehicle’s

Hitch Ball and, while holding the trigger, push down on the Handle

until the Trigger locks in the slot.

5. Pull up and down on the Coupler to make sure the Hitch Ball is

fitting snugly in the Coupler. There should be no pla y between the

Hitch Ball and Coupler . If there is pla y, tighten the Adjustment Nut

until no play is present. If the Adjustment Nut is too tight, the Handle

will not lock. (See Figure L.)

“R” PIN

HANDLE

SAFETY PIN

TRIGGER

Trigger on

locking handle

MUST latch in

place before

inserting

safety pin.

COUPLER

(14)

SLOT

ADJUSTMENT

NUT

2” BALL

HITCH

FIGURE L

HITCH

Page 19SKU 93747 For technical questions, please call 1-800-444-3353.

Page 20

6. Pull up on the handle without squeezing the trigger to ensure that it is properly

locked in place. Reinstall the Safety Pin (N) and “R” Pin (Q). (See Figure L.)

7. Make sure to attach each side of the Safety Chain (17) equally to the towing

vehicle’ s rear bumper or frame. (See Figure L.)

8. Connect the Tail Light Wiring Assembly to the towing vehicle’s 12 Volt DC wiring

connector.

vehicle for proper connection instructions.

NOTE: Make sure to consult the operator’ s manual of the towing

9.

10. When towing the Trailer over long distances, stop and check the tightness of all

11. Carry emergency flares and fire extinguisher, if required for operation in y our

12. It is recommended to carry extra b ulbs and fuses if towing the Trailer at night over

1. Ensure that the ramp is used only while the coupler is properly attached securely

2. The ramp must be used only on a solid, level surface that is stable enough to

CA UTION! Care must be taken when backing up the Trailer. Onl y back

up the Trailer on a straight path. If the Trailer is allowed to turn off the straight

path while backing up, the Trailer could jackknife, causing severe damage to the

Trailer and to the towing vehicle.

connections, Side Running Lights (25), and Tail Lights (21, 22)

miles.

state.

long distances.

RAMP USAGE

to the towing vehicle.

properly support the trailer’s wieght, the towing vehicle’s weight, and the weight of

any load to be placed on the trailer.

at least

every 100

3. Proper loading procedures and hazards associated with loading will vary

widely depending on the application that this trailer is used for . Follow all

loading instructions provided with vehicles, and always make sure that the

load is distributed evenly while loading or towing.

Page 20SKU 93747 For technical questions, please call 1-800-444-3353.

Page 21

INSPECTION, MAINTENANCE, AND CLEANING

1. The Chart below ser ves as a basic guideline for scheduling your trailer maintenance. Maintenance may be different based on your local conditions, trailer use

application, and frequency of trailer use.

2.

CAUTION! All maintenance, service, or repairs listed in this manual are only

to be attempted by a qualified service technician.

relpuoC

cehC

sleehW .gnillatsniretfaselim05tsrifretfadna,esuhcaeerofebstungulkcehC

/sbuH

ylretrauqsgniraebotesaergddA

sgniraeB

seriT

auqefildaertkcehC

/lacirtcelE

gnithgiL

aeerofebsthgilekarbkcehC

ELUDEHCSECNANETNIAM

.relpuocfotifreporperusneesuhcaeerofeB

.reliartfoegarotsretfa/erofebdnaylretrauqnoitacirbulrofk

.egarotsretfadna

.egarotserofebdnayllaunnasgniraebkcapeR

eerofeb)ISP08(erusserpehtkcehC

.esuhcaeretfadnaerofebserittcepsniyllausiV

.egarotsretfa/erofebdnaylretr

.egarotsretfadnaesuhcaeerofebsthgilliatkcehC

.egarotsretfadnaesuhc

.esuhcaeerofebgniriwdnuorglacirtcelekcehC

.egarotsretfa/erofebdnaesuhca

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST

AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY.

NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION

OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND

LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT

OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 21SKU 93747 For technical questions, please call 1-800-444-3353.

Page 22

PARTS LIST & ASSEMBLY DIAGRAM - TRAILER

Par t # Desc ript ion Qty . Pa rt # Descri ption Qty .

1L Left Side Rail 1 27 Outer Bearing 2

1R Right Side Rail 1 28 Castle Nut 2

2 Cross Member 4 29 Dust Cap 2

3 Center Cross Member 1 30 Fender Brack et (A) 2

5 Tow Bar 2 31 Fender Bracket (B) 2

6 Spare Tire Bar 1 A 3/8” x 1” Hex Bolt 36

7 Front Spring Hanger (Short) 2 B 3/8” Nylon Nut 71

8 Rear Spring Hanger (Long) 2 C 3/8” Flat Washer 69

9 Hole Spacer (6mm) 4 D 3/8” x 1-1/2” Carriage Bolt 1

10 Axle 1 E 3/8” x 3” Hex Bolt 2

11 Fender 2 F 3/8” x 7/8” Carriage Bolt 20

12 Tire/Wheel Assy. 2 G 9/16” x 3-1/4” Hex Bolt 2

13 License Plate Bracket 1 H 9/16” Nylon Nut 2

14 Coupler 1 I 1/2” x 3-3/4” Hex Bolt 2

15 Coupler Base 1 J 1/2” x 1” Hex Bolt 1

16 St and Base 1 K 1/2” Nylon Nut 3

17 Safety Chain 1 L 1/2” Flat Washer 6

18 Spring Plate 2 M 1/2” Lug Nut 10

19 U-Bolt 4 N Safety Pin 1

20 Leaf Spring 2 O 3/8” x 1-1/4” Hex bolt 4

21 Left Tail Light 1 Q 2m m R Pin 1

22 Right Tail Light 1 R Grease Fitting 2

23 Tail Light Bracket 2 S 4m m Self Tapping Screw 4

25 Side Running Light 2 T 5/32” Cotter Pin 2

26 Hub Set 2 U 3/4” Flat Washer 2

ILK

JLK

FCB

ABC

ABC

ACB

ACB

ACB

FCB

ACB

ACB

ACB

NOTE:

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

ACB

U

T

R

Page 22SKU 93747 For technical questions, please call 1-800-444-3353.

Page 23

PARTS LIST & ASSEMBLY DIAGRAM - RAMP

Par t # Desc ript ion Qty. Part # De scr ipt ion Qty.

1 Front Rack 1 8 Angle Iron 2

2FR Front Right Side Rack 1 A 3/8” x 1” Hex Bolt 24

2FL Front Left Side Rack 1 B 3/8” Flat Washer 24

3RR Rear Right Side Rack 1 C 3/8” Nylon Nut 26

3RL Rear Left Side Rail 1 D 5/16” x 3” Hex Bolt 8

4R Right Side Ramp 1 E 5/16” Flat Washer 8

4L Left Side Ramp 1 F 5/16” Nylon Nut 8

5 Connecting Bracket 2 G 3/8” x 3” Hex Bolt 2

6 Bushing 2 H 3mm R Safety Pin 2

7 L Lock Pin 2

NOTE: If or dering parts for the Ramp assembly belo w,

make sure to specify “Ramp Part Numbers”.

H

ABC

GC

ABC

GC

H

Page 23SKU 93747 For technical questions, please call 1-800-444-3353.

Page 24

WARRANTY

LIMITED 90 DAY

WARRANTY

Harbor Freight T ools Co . makes e ve ry effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for

the period of ninety days from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, or to lack of

maintenance. W e shall in no ev ent be liable f or death, injuries to persons or property , or f or incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the abov e limitation of exclusion may not apply to you.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take adv antage of this warranty, the product or par t must be retur ned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint m ust accompan y the merchandise. If our

inspection verifies the defect, w e will either repair or replace the product at our election or we may elect to

refund the purchase price if we cannot readily and quickly provide you with a replacement. We will return

repaired products at our expense, but if we determine there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty giv es you specific legal rights and y ou may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-33533491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-33533491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Page 24SKU 93747 For technical questions, please call 1-800-444-3353.

Loading...

Loading...