Page 1

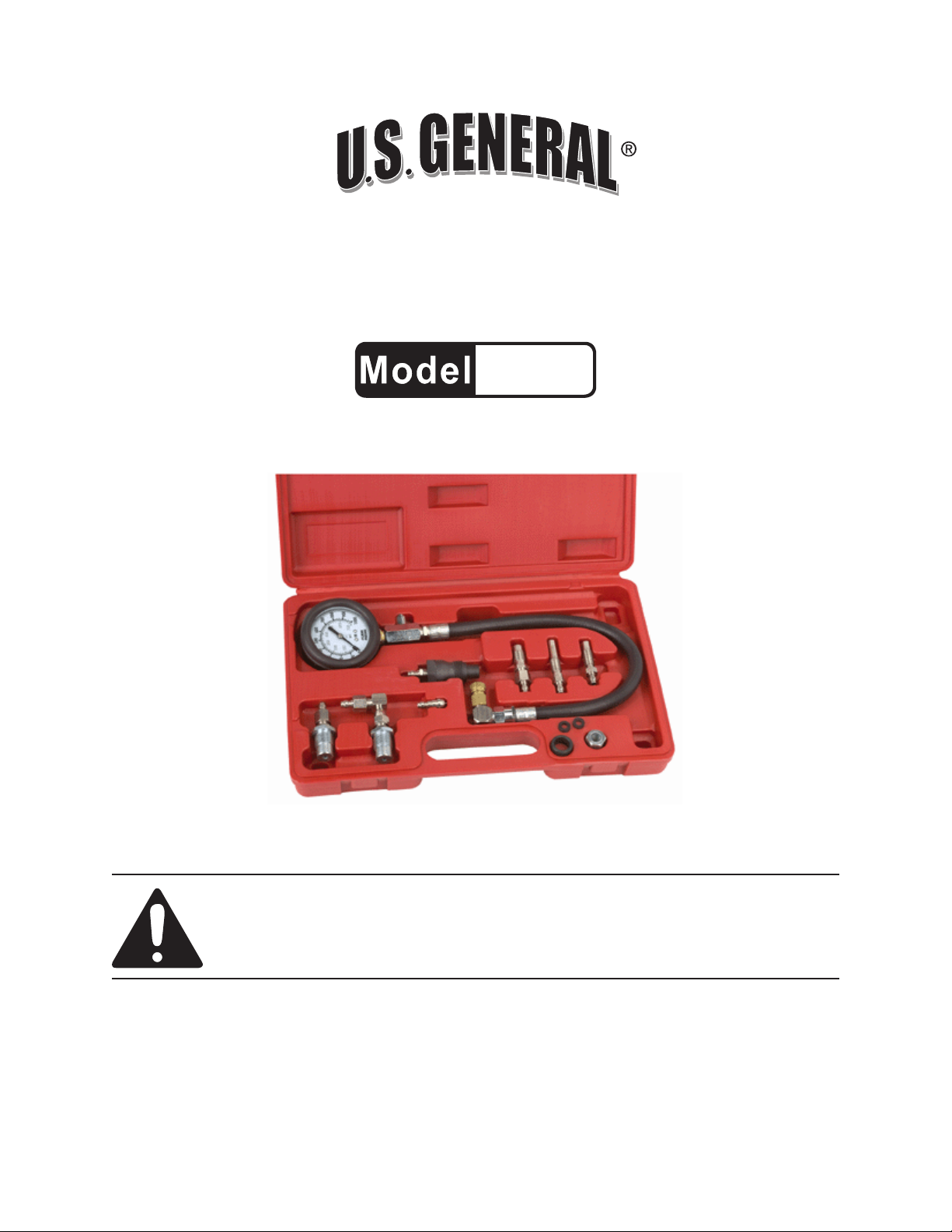

DIESEL ENGINE

COMPRESSION TESTER

93644

ASSEMBLY AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2005 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

Pressure Scale 0<->1000 PSI / 0<->7000 kPa

Gauge 2-9/16” Diameter / 2-5/8” Bezel Diameter / 1-1/8” Deep

Air Release Type Thumb Button Release

Maximum Working Pressure 1000 PSI

Hose Size 15/64” I.D. / 35/64” O.D. / 16” Long

Accessories Carrying Case

Weight 3.50 Pounds

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

UNPACKING

When unpacking, check to make sure all the parts shown in the Parts List on page 8

are included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the front cover of this manual as soon as possible.

GENERAL SAFETY RULES

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions detailed in this manual may

result in serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered and dark work areas invite

accidents.

SKU 93644 For technical questions, please call 1-800-444-3353. Page 2

Page 3

2. Keep bystanders, children, and visitors away while using the Compression

Tester. Distractions can cause you to lose control.

PERSONAL SAFETY

3. Stay alert. Watch what you are doing, and use common sense during use. Do

not use while tired or under the inuence of drugs, alcohol, or medication. A moment of inattention while operating may result in serious personal injury.

4. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving engine parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

5. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enable better control in unexpected situations.

6. Always wear eye and hand protection. Wear ANSI approved safety

impact goggles, non-skid safety shoes, and heavy duty work gloves

when using this product.

TOOL USE AND CARE

7. Store idle tools and equipment out of reach of children and other untrained

people. Tools and equipment are dangerous in the hands of untrained users.

8. Maintain the Compression Tester with care. Keep this product clean. A

properly maintained tool is easier to control. Do not use damaged tools and

equipment. Tag damaged tools and equipment “Do not use” until repaired.

9. Check for misalignment or binding of moving parts, loose or broken parts,

and any other condition that may affect the Compression Tester’s operation.

If damaged, have the tool serviced before using. Many accidents are caused by

poorly maintained tools and equipment.

10. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one product may become hazardous

when used on another product.

SERVICE

11. Tool service must be performed only by qualied service technician. Service

or maintenance performed by unqualied personnel could result in a risk of injury.

12. When servicing the Compression Tester, use only identical replacement parts.

Follow instructions in the “Inspection, Maintenance, And Cleaning” section of this

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of injury.

SKU 93644 For technical questions, please call 1-800-444-3353. Page 3

Page 4

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on the Compression Tester Kit. These carry

important information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

2. Use the right product for the job. There are certain applications for which this

product was designed. Do not use this product for a purpose for which it was not

intended.

3. Industrial applications must follow OSHA requirements.

4. Prior to using this product, make sure to read and understand all instructions

and safety precautions as outlined in the vehicle manufacturer’s manual and

engine diagnostic/repair manuals.

5. Use the Compression Tester in a well ventilated area. Do not operate

an engine in a closed area or in a poorly ventilated area. When running,

the Engine of a vehicle produces carbon monoxide, a colorless,

odorless, toxic fume that, when inhaled, can cause serious personal

injury or death. Early signs of carbon monoxide poisoning resemble the u, with

headaches, dizziness, or nausea. If you have these signs, get fresh air

immediately.

6. Do not exceed the maximum pressure capacity of this tool (1000 PSI).

Exceeding the maximum pressure capacity could cause personal injury and/or

property damage.

7. Always keep hands, ngers, and body away from the moving parts and hot

parts of the diesel engine.

8. When warming up a diesel engine in preparation for compression testing,

make sure the vehicle’s transmission is placed in “PARK”/“NEUTRAL” and

the emergency brake is applied.

9. WARNING! The brass components of this product contain lead, a chemical

known to the State of California to cause cancer and birth defects (or other

reproductive harm). (California Health & Safety Code § 25249.5, et seq.)

10. WARNING! People with pacemakers should consult their physician(s)

before using this product. Electromagnetic elds in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker. In addition,

people with pacemakers should adhere to the following: Caution is necessary

when near the coil or distributor of a running engine. The engine should always

be off if adjustments are to be made to the distributor.

11. WARNING! The warnings and cautions discussed in this manual cannot

cover all possible conditions and situations that may occur. It must be under-

stood by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator.

SKU 93644 For technical questions, please call 1-800-444-3353. Page 4

Page 5

OPERATING INSTRUCTIONS

1. NOTE: Refer to the Diesel Adapters chart to select the proper Adapter to be used

for the specic vehicle you will test. (See page #6.) After identifying the correct

adapter, assemble it securely as shown on the assembly diagram on page 8. Make

certain that the vehicle’s battery is fully charged before testing.

2. Prepare the engine for compression testing by starting the engine and allowing it

to warm up to its normal operating temperature. Then, switch off the engine.

3. Once the engine has been turned off, disconnect the fuel shutdown solenoid (refer

to the engine maintenance manual for location).

4. Remove all of the injectors or all of the glow plugs (depending on the connector used).

You may wish to label them for reassembly. (See Figure A.) Unless instructed

to do so by the engine manual, do not inject oil into the cylinders (a “wet”

test); the oil may not compress properly and damage the engine.

PRESSURE GAUGE (1)

INJECTORS/GLOW PLUGS

REMOVE

AIR RELEASE BUTTON (2)

FIGURE A

5. Using the proper Adapter, connect the Compression Tester to the rst cylinder of

the engine. Then, with the fuel pedal depressed completely, crank the engine for

eight revolutions. Do not continue to crank the engine; the engine’s starter may

overheat, causing damage to itself. (See Figure A.)

6. After cranking the engine, record the reading on the Pressure Gauge (1) of the

Compression Tester. (See Figure A.)

7. Once the maximum reading has been recorded, release the Gauge (1) pressure

on the Tester by depressing the Air Release Button (2). (See Figure A.)

8. Use caution, the engine will be hot! Remove the Compression Tester from the

rst cylinder. Then, repeat steps #5, #6, #7 for the remaining cylinders.

9. NOTE: Good engine cylinder compression will be indicated with a high initial

reading, and a progressive buildup to the nal maximum reading. Poor engine

cylinder compression will be indicated with a low initial reading and a much slower

buildup to the nal maximum reading. The compression readings for all of the

engine cylinders should not vary by more than 10%.

10. Reconnect the fuel injection solenoid and reinstall all glow plugs/injectors.

SKU 93644 For technical questions, please call 1-800-444-3353. Page 5

Page 6

DIESEL ADAPTERS

Manufacturer Engine Type Thread Adapter #

Audi Early models, see VW for TDI Injector 24 x 2.00 C

Mercedes-Benz Early models Injector 24 x 2.00 C

VW 1970’s Rabbit Injector 24 x 2.00 C

Volvo Early models except 30’s & 40’s Injector 24 x 2.00 C

BMW 2.4L Glow Plug 12 x 1.25 H

Chevette/Isuzu; Luv/Isuzu 1.8L, 2.2L Glow Plug 10 x 1.25 E

Deutz Many models Glow Plug 12 x 1.25 H

Ford/Mazda (1984-87) 2.0L;

Glow Plug 10 x 1.25 F

(1983-84) 2.2L Escort, Lynx,

Ranger, Tempo, Topaz

Ford/Mitsubishi (1985-87) Ranger 2.3L Glow Plug 10 x 1.25 F

Ford/Navistar 6.9L and 7.3L (up to 1994) Glow Plug 10 x 1.00 A

General Motors 4.3L V6, 4.3L V8, 5.7L V8 Glow Plug 10 x 1.00 A

Duramax 6.6L Turbo Diesel Glow Plug 10 x 1.25 E

Hummer Optimizer 6500 V8 Turbo Glow Plug 10 x 1.25 E

Isuzu/Isuzu Truck (1992-98) 4HE1-TC

Glow Plug 10 x 1.25 E

(1998-2005) 6HK1-TC

(1998-2005) 4HE1-TC

Glow Plug 12 x 1.25 HUI

(Up to 1998) 6HK1-TC

Kubota Some models Glow Plug 10 x 1.25 F

Lincoln, Mark VII/

Continental

2.4L used in 1984-85 autos Glow Plug 12 x 1.25 H

with Volvo engines Glow Plug 10 x 1.25 F

Mercedes-Benz (1988-89) 190E 2.5L Glow Plug 12 x 1.25 I

(1991-99) E300 Glow Plug 12 x 1.25 H

2005 E320 CDI Glow Plug 10 x 1.00 A

Mitsubishi 2 and 3 cylinder engines Glow Plug 10 x 1.25 F

Mitsubishi-Fuso Medium Glow Plug 10 x 1.25 F

Navistar/ International 6.9L and 7.3L Glow Plug 10 x 1.00 A

Nissan/ UD Truck 2.2L Glow Plug 10 x 1.25 F

Medium Glow Plug 10 x 1.25 F

Peugeot Most Glow Plug 12 x 1.25 H

Certain Models Glow Plug 18 x 1.50 H

Toyota 1.8L Glow Plug 10 x 1.25 E

2.2L Glow Plug 10 x 1.25 F

VW (1979-84) Rabbit,

Glow Plug 12 x 1.25 HUI

(1979-99) Jetta,

(1981-84) Pick-Up

(1987-99) Golf,

(1992-97) Passat,

(1992-98) Eurovan

(1995-97) Passat,

Glow Plug 10 x 1.00 A

(1997-05) Golf, Jetta & Jetta

Wagon,

(1998-05) New Beetle,

2004 Touareg

U

- Indicates that part 7 must be removed for these applications.

U

U

U

U

U

U

U

SKU 93644 For technical questions, please call 1-800-444-3353. Page 6

Page 7

INSPECTION, MAINTENANCE, AND CLEANING

1. Before each use, inspect the general condition of the Compression Tester Kit.

Check for cracked, worn or damaged Adapters, damaged Pressure Gauge and

Hose, and any other condition that may affect the tool’s safe operation. If a problem

occurs, have the problem corrected before further use. Do not use damaged

equipment.

2. To clean, use a damp cloth and a mild detergent.

3. When storing, keep the Compression Tester Kit in its Carrying Case and in a clean,

dry, safe location out of reach of children.

4. WARNING! All maintenance, service, and repairs not discussed in this manual

should only be performed by a qualied service technician.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE

MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF

ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES

THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED

AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISKS

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR

REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT PARTS THERETO.

PARTS LIST

Part Description Q’ty Part Description Q’ty

1 Pressure Gauge 1 10 ZG 1/8” (M) Male Quick Coupler 1

2 Air Release Button 1 11 ZG 1/8” (F)-M24X2 (M) Adapter 1

3 Rubber Hose 1 12 Adapter Sleeve 1

1

4

/8” NPT Quick Coupler 1 13 Quick Connect with Ball Tip 1

7

5

/16”-20(F) Quick Coupler 3 141/2” -19 Lock Nut 1

6 M12X1.25(M)-7/16”-20(M) Adapter 3 157/16”-20(M)-7/16”X20(F) 90° Connector 1

7 M12X1.25(F)-M18X1.5(M) Adapter 2 16 ZG 1/8” (M)-M24X1.5 (M) Adapter 1

8 M10X1.25 Short Adapter 1 17 M10X1(M) Adapter 1

9 M10X1.25 Long Adapter 1 18 Copper Washer 2

SKU 93644 For technical questions, please call 1-800-444-3353. Page 7

Page 8

ASSEMBLY DIAGRAM

Letters designate adapter assemblies.

NOTE: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

SKU 93644 For technical questions, please call 1-800-444-3353. Page 8

Page 9

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product

is free from defects in materials and workmanship for the period of 90 days from the date

of purchase. This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity,

improper installation, normal wear and tear, or to lack of maintenance. We shall in no event

be liable for death, injuries to persons or property, or for incidental, contingent, special

or consequential damages arising from the use of our product. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation

of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either

repair or replace the product at our election or we may elect to refund the purchase price

if we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

REV 09h

SKU 93644 For technical questions, please call 1-800-444-3353. Page 9

Loading...

Loading...