Page 1

1/2” Heavy-duty Low Speed

®

VSR Drill

93632

ASSEMBLY AND OPERATING INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2006 by Harbor Freight Tools® . All rights reserved. No portion of this manual or any

artwork contained herein may be reproduced in any shape or form without the express written

consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

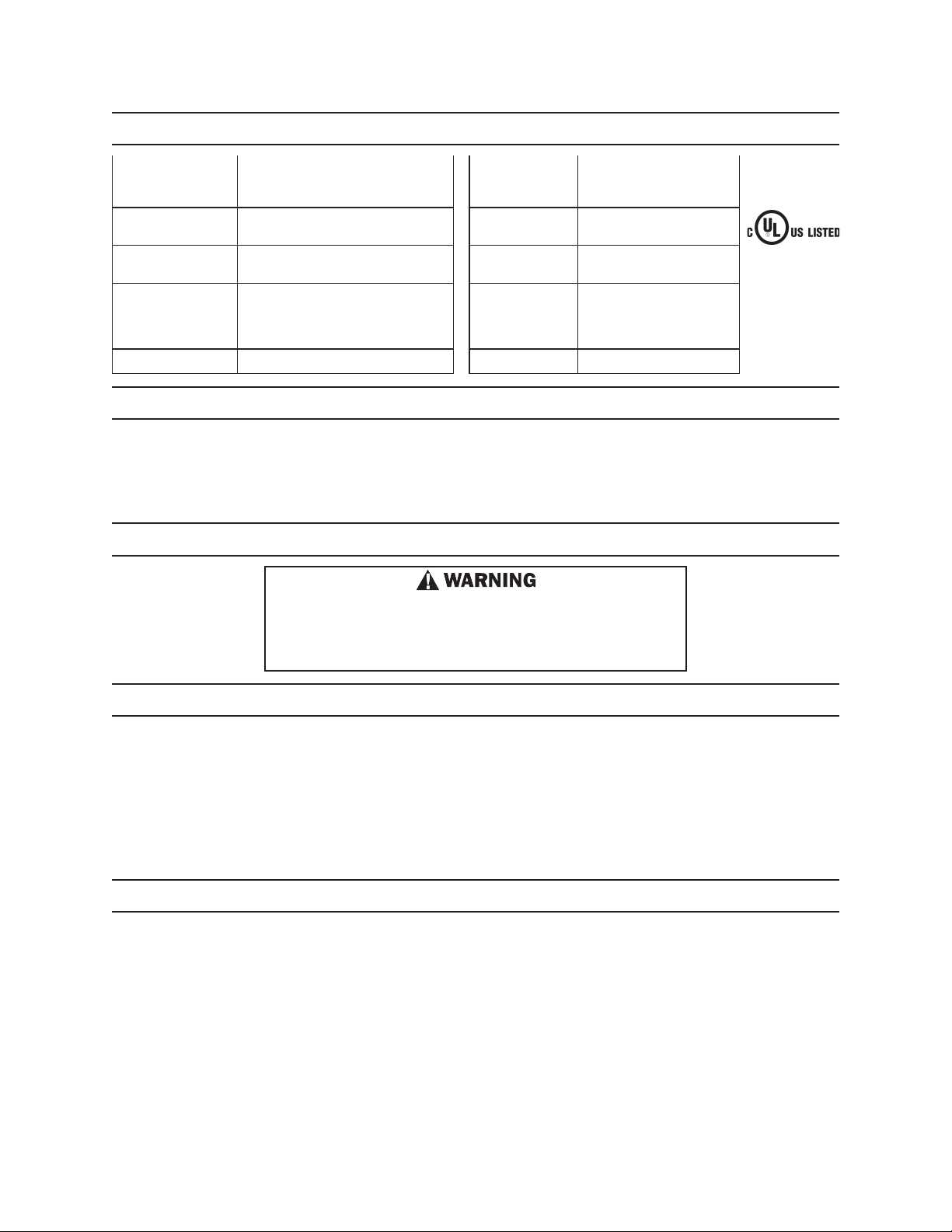

SPECIFICATIONS

:noitcurtsnoC

:epyTdnaeziSkcuhC

:deepSllirDMPR055-0:elbairaV:ytilibapaCgnillirD

:noitceriDgnillirDesreveR/drawroF

:snoisnemiDllarevOH"8/5-8xL"21xW"¾-3:thgieWteN.sbL5.7

,citsalPSBAdedloMnoitcejnI

dnamunimulAdloMtnenamreP

leetSnobraCdenihcaM

epyTyeKdewaJ-3yticapaC"2/1-"61/1

FNU02"½:daerhTeldnipS

:epyTrotoM

:

deriuqeRrewoP

dedulcnI

:seirosseccA

uhC

tupnIpmA5.7

zH06,CAV021

kcotSdooW"2

leetS

dliM"½

erawdraH

yeKkc

htiwrotoM

noitcudeRraeGelbuoD

daolrednuspmA2.6

E194601

htiweldnaHedapS

eldnaHyrallixuA

SAVE THIS MANUAL

You will need the manual for the safety warnings and precautions, assembly instructions, operating and

maintenance procedures, parts list and diagram. Keep your invoice with this manual. Write the invoice

number on the inside of the front cover. Keep the manual and invoice in a safe and dry place for future

reference.

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS.

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause

you to lose control. Protect others in the work area from debris such as chips and sparks. Provide

barriers or shields as needed.

ELECTRICAL SAFETY

4. Grounded tools must be plugged into an outlet properly installed and grounded in accordance

with all codes and ordinances. Never remove the grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt whether the

outlet is properly grounded. If the tool should electrically malfunction or break down, grounding provides

a low resistance path to carry electricity away from the user.

5. Double insulated tools are equipped with a polarized plug (one blade is wider than the other).

This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet.

Do not change the plug in any way. Double insulation eliminates the need for the three wire grounded

power cord and grounded power supply system.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 2

Page 3

6. Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators.

There is an increased risk of electric shock if your body is grounded.

7. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk

of electric shock.

8. Do not abuse the Power Cord. Never use the Power Cord to carry the tool or pull the Plug from an

outlet. Keep the Power Cord away from heat, oil, sharp edges, or moving parts. Replace damaged

Power Cords immediately. Damaged Power Cords increase the risk of electric shock.

9. When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”. These

extension cords are rated for outdoor use, and reduce the risk of electric shock.

10. Stay alert. Watch what you are doing, and use common sense when operating a power tool. Do

not use a power tool while tired or under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious personal injury.

11. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving

parts.

12. Avoid accidental starting. Be sure the Power Switch is off before plugging in. Carrying power tools

with your finger on the Power Switch, or plugging in power tools with the Power Switch on, invites accidents.

13. Remove adjusting keys or wrenches before turning the power tool on. A wrench or a key that is left

attached to a rotating part of the power tool may result in personal injury.

14. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables

better control of the power tool in unexpected situations.

15. Use safety equipment. Always wear eye protection. Dust mask, nonskid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

16. Use clamps (not included) or other practical ways to secure and support the work piece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

17. Do not force the tool. Use the correct tool for your application. The correct tool will do the job better

and safer at the rate for which it is designed.

18. Do not use the power tool if the Power Switch does not turn it on or off. Any tool that cannot be

controlled with the Power Switch is dangerous and must be replaced.

19. Disconnect the Power Cord Plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool

accidentally.

20. Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the

hands of untrained users.

21. Maintain tools with care. Keep cutting tools maintained and clean. Properly maintained tools are

less likely to bind and are easier to control. Do not use a damaged tool. Tag damaged tools “Do not use”

until repaired.

22. Check for misalignment or binding of moving parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged, have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

23. Use only accessories that are recommended by the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous when used on another tool.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 3

Page 4

SERVICE

24. Tool service must be performed only by qualified repair personnel. Service or maintenance performed

by unqualified personnel could result in a risk of injury.

25. When servicing a tool, use only identical replacement parts. Follow instructions in the “Inspection,

Maintenance, And Cleaning” section of this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

1. Hold tool by insulated gripping surfaces when performing an operation where cutting tools may

contact hidden wiring or its own cord. Contact with a ‘live’ wire will exposed metal parts on the

tool ‘live’ and shock the operator.

2. Maintain labels and nameplates on the tool. These carry important information. If unreadable or

missing, contact Harbor Freight Tools for a replacement.

3. Always wear ANSI-approved safety impact eye goggles and heavy work gloves when using the

tool. Using personal safety devices reduce the risk for injury. Safety impact eye goggles and heavy

work gloves are available from Harbor Freight Tools.

4. Maintain a safe working environment. Keep the work area well lit. Make sure there is adequate

surrounding workspace. Always keep the work area free of obstructions, grease, oil, trash, and other

debris. Do not use a power tool in areas near flammable chemicals, dusts, and vapors. Do not use this

product in a damp or wet location.

5. When using a handheld power tool, always maintain a firm grip on the tool with both hands to

resist starting torque. Always have one hand on the Handle, and the other either on the Spade

Handle or Side Handle.

6. Always keep the extension cord away from moving parts on the tool.

7. Avoid unintentional starting. Make sure you are prepared to begin work before turning on the Drill.

8. Make sure the Drill bit being used is free from burrs and any other foreign matter which could

damage the tool.

9. Never leave the tool unattended when it is plugged into an electrical outlet. Turn off the tool, and

unplug it from its electrical outlet before leaving.

10. Always unplug the Drill from its electrical outlet before performing any inspection, maintenance,

or cleaning procedures.

11. Let Bits cool before touching, changing or adjusting them. Bits heat up dramatically while in use,

and are capable of severe burns.

12. Do not force the Drill. This tool will do the work better and safer at the speed and capacity for which it

was designed.

13. Always secure the workpiece in a vise or other appropriate device; never attempt to hold the

workpiece in your hand while drilling.

14. If the drill bit jams, release the trigger immediately; drill torque can cause injury.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 4

Page 5

15. WARNING! People with pacemakers should consult their physician(s) before using this product.

Electromagnetic fields in close proximity to a heart pacemaker could cause interference to or failure of

the pacemaker.

In addition, people with pacemakers should adhere to the following:

• Avoid operating power tools alone.

• Don’t use a power tool with the power switch locked on.

• If powered via a power cord be certain that the tool is properly grounded. A ground fault interrupt

(GFCI) system is also a good precaution. This inexpensive device is a good safety measure because

it prevents a sustained electrical shock.

• Properly maintain and inspect all tools before use to avoid electrical shock.

16. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities, contain chemicals known (to the State of California) to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are: lead from lead-based paints, crystalline

silica from bricks and cement or other masonry products, arsenic and chromium from chemically treated

lumber. Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

(California Health & Safety Code § 25249.5,

et seq.

)

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric

shock. Check with a qualified electrician if you are in doubt as to whether the

outlet is properly grounded. Do not modify the power cord plug provided with

the tool. Never remove the grounding prong from the plug. Do not use the

tool if the power cord or plug is damaged. If damaged, have it repaired by a

service facility before use. If the plug will not fit the outlet, have a proper outlet

installed by a qualified electrician.

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

1. Tools marked with “Grounding Required” have a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If the

tool should electrically malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user, reducing the risk of electric

shock. (See Diagram A.)

2. The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool. The green wire in the cord must be the only

wire connected to the tool’s grounding system and must never be attached to an

electrically “live” terminal. (See Diagram A.)

3. Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

those in the following illustration. (See Diagram A.)

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 5

Page 6

DIAGRAM A

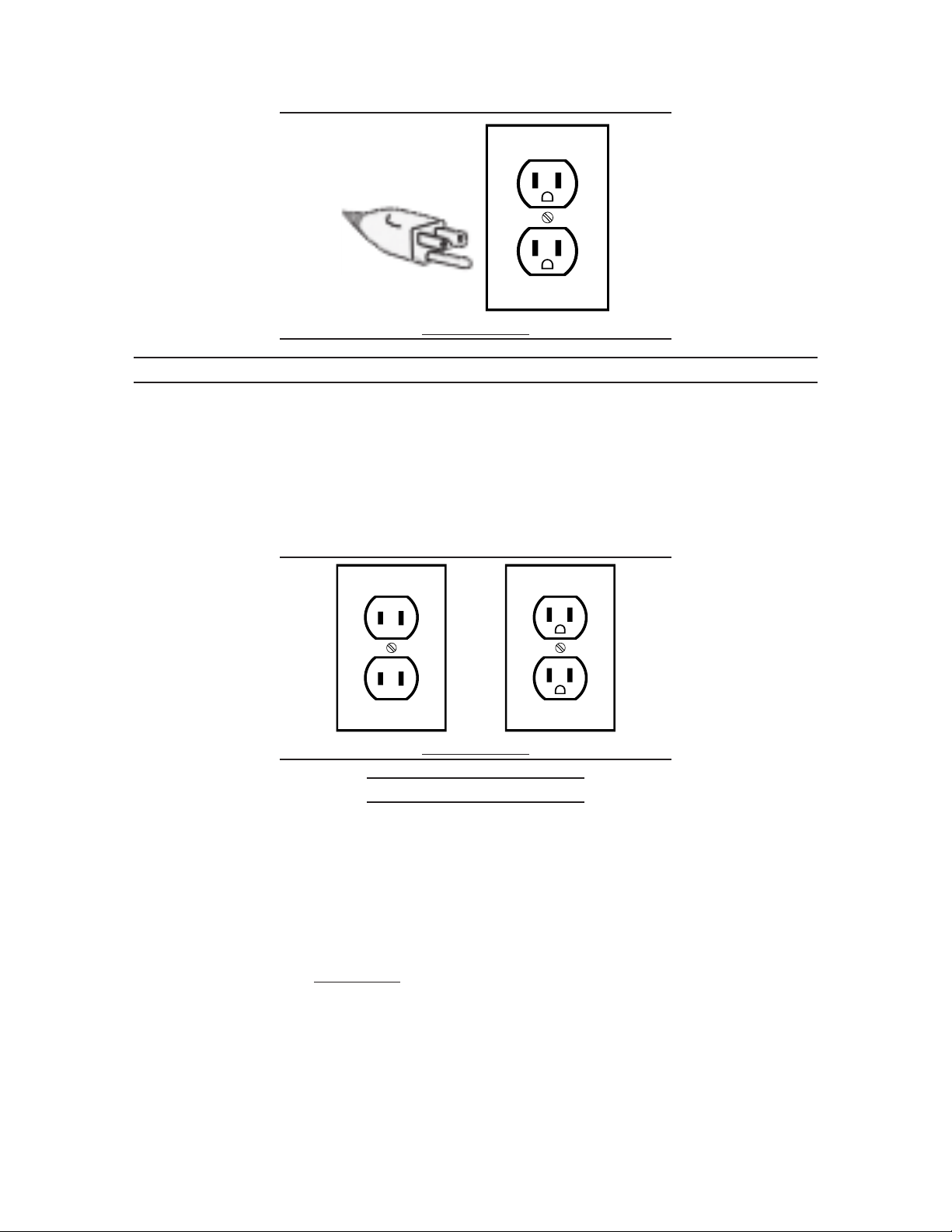

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

4. Tools marked “Double Insulated” do not require grounding. They have a special

double insulation system which satisfies OSHA requirements and complies with

the applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Diagram B.)

5. Double insulated tools may be used in either of the 120 volt outlets shown in the

following illustration. (See Diagram B.)

DIAGRAM B

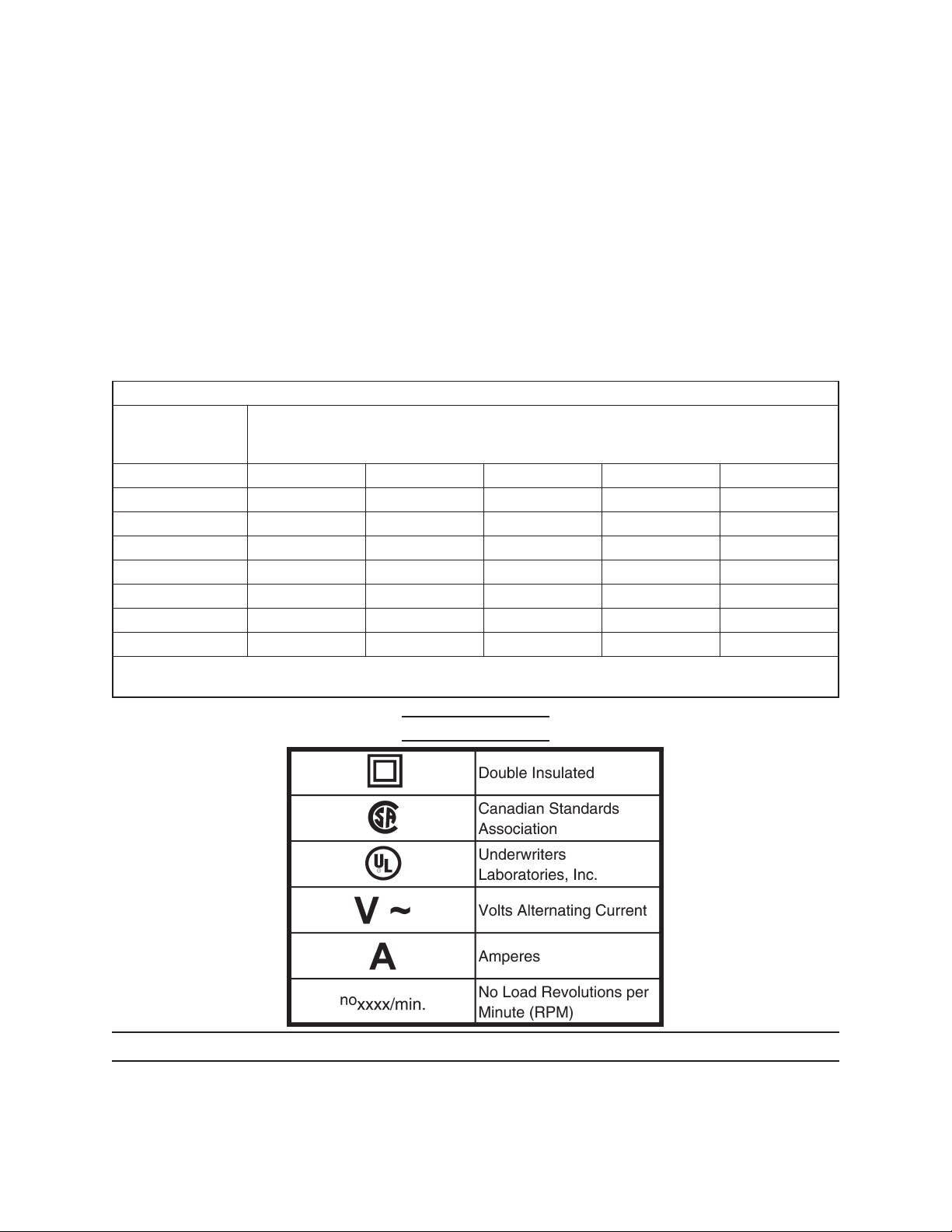

EXTENSION CORDS

1.

2. As the distance from the supply outlet increases, you must use a heavier gauge

3. The smaller the gauge number of the wire, the greater the capacity of the cord. For

4. When using more than one extension cord to make up the total length, make sure

SKU 93632 For technical questions, please call 1-800-444-3353.

Grounded

use either a two or three wire extension cord.

extension cord. Using extension cords with inadequately sized wire causes a serious

drop in voltage, resulting in loss of power and possible tool damage.

(See Diagram C,

example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Diagram C.)

each cord contains at least the minimum wire size required. (See Diagram C.)

tools require a three wire extension cord.

next page.)

Double Insulated

tools can

English

Page 6

Page 7

5. If you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum cord size.

(See Diagram C.)

6. If you are using an extension cord outdoors, make sure it is marked with the suffix

“W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

7. Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified

electrician before using it.

8. Protect your extension cords from sharp objects, excessive heat, and damp or wet

areas.

*SDROCNOISNETXEROFEGUAGERIWMUMINIMDEDNEMMOCER

ETALPEMAN

SEREPMA

)daoLlluFtA(

teeF52teeF

0.2-08181818161

4.3-1.28181816141

0.5-5.38181614121

0.7-1.58161412121

0.21-1.781412101-

0.61-1.21412101--

0.02-1.612101 ---

05teeF57teeF001teeF051

CERUGIF

HTGNELDROCNOISNETXE

evifotpordegatlovenilehtgnitimilnodesaB*

.serepmadetarehtfo%051tastlov

SYMBOLOGY

UNPACKING

When unpacking, check to make sure that the product is intact and undamaged.

If any parts are missing or broken, please call Harbor Freight Tools at the number on the cover of this manual.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 7

Page 8

OPERATING INSTRUCTIONS

Your Low Speed Heavy-duty Drill will usually be preassembled. In some cases, due to variations in packaging,

you may have to install the Spade Handle and Auxiliary Handle. Please refer to the assembly diagram on page

10.

CAUTION: Be sure the tool is unplugged from any power source before performing any installation

or adjustment of the tool.

1. Align the Spade Handle (31) with the Back Case (32). Insert the Spade Handle Knob (30) through the

Spade Handle into the Back Case. Tighten the Spade Handle Knob by turning clockwise until tight.

2. Insert the Screw (14) through the Side Handle (15). Position the Side Handle on the Gear Housing Cover

(22). Using a screwdriver (not included) tighten the Screw (14) until tight.

NOTE: Periodically check to be sure the handles remain tight. Never try to reposition the handles while

the tool is running.

About Low Speed Heavy-duty Drills:

While an extremely useful tool, heavy-duty drills can be dangerous if used improperly or in damaged

condition.

1. This tool incorporates a double gear reduction transmission to reduce drill speed while increasing torque.

This design improves performance when drilling large holes up to 2” in wood and 1/2” in mild steel. This

feature also helps prevent the tool from “bogging down” or stopping when under heavy load.

2. Drill Bits (not included) come in various sizes and types. Various types include low and high speed twist

bits for metals, spade or brad point bits for wood, forstner bits for flat bottomed holes in wood or plastic,

auger bits for boring through walls and floors, masonry bits for plaster and dry wall, etc. Always select the

proper bit type and size for the application at hand.

3. This drill can use drill bit shank sizes between 1/16” and 1/2” inclusive. Boring hole size may be larger

than the shank size. Do not attempt to use drill bits larger or smaller than this range.

4. Whenever installing a drill bit into the tool, first unplug the tool. By hand, rotate the outer ring of the Chuck

counterclockwise to open it enough to allow the bit to be inserted. Be sure the bit is centered in the

Chuck. By hand, rotate the outer ring of the Chuck clockwise to tighten on the bit. Check to be sure the

bit is centered in the jaws of the Chuck.

5. Insert the tip of the Chuck Key into one of the openings drilled into the side of the Chuck. Engage the

gears of the Chuck Key with the gear teeth on the outside of the Chuck. Turn the Chuck Key clockwise to

tighten the jaws of the Chuck firmly on the drill bit. CAUTION: Be sure the drill bit is centered and firmly

fixed in the Chuck before beginning work.

Power Switch Features

Note: The Power Switch (46) has a variable speed feature. Simply turn the dial below the Power Switch

to adjust the drill speed. The dotted lines on the dial are spaced from narrow to wide to indicate increasing

drill speed.

Note: The trigger lock button on the Power Switch, when activated, will allow the drill to run without

continuous finger pressure on the power switch. To release the trigger lock, simply press your finger on

the power switch.

1. Do not start the tool until you have observed all safety preparations and are ready to work.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 8

Page 9

2. Squeeze the Power Switch. The tool will start to operate. The speed of the drill will increase as the Trigger

is squeezed tighter. The speed will lessen as the Trigger is released.

3. Stop the tool by releasing the Power Switch.

Note: The Forward/Reverse button is located behind the Trigger (46). When button is pushed in on the left side

of housing (see photo on cover), the drill will rotate in Reverse (counterclockwise). When button is

pushed in on the right side of housing, the drill will rotate in a Forward clockwise direction.

Reversing Direction of the Drill

Caution: Never attempt to change direction of the drill while the drill is operating. Always wait for the drill

to come to a complete stop before changing direction.

1. Most drill bits are designed to work while turning in a clockwise direction. When drilling, confirm that you

are using a standard type drill bit and that the drill is set to turn in the correct direction.

2. Occasionally the drill bit may become stuck, or it is desired to reverse drill direction.

3. To reverse direction, wait for the drill to come to a complete stop. Press the Forward/Reverse button as

described in the Note above.

Using the Heavy Duty Drill

Before using the Heavy Duty Drill, be sure all work area safety precautions are being observed. Be sure

to wear ANSI-approved eye protection.

NOTE: The motor will heat up as it is used. To avoid motor burn out, do not use continually for more than

20 minutes at a time. Allow the tool to cool down for at least 10 minutes before resuming work.

1. Place the drill tip on the work piece, and Start the tool.

2. Apply light pressure on the tool to help it drill into the workpiece. Do not overload the tool. If the speed

noticeably slows down, release some downward pressure from the drill.

3. When the hole has been drilled, remove the bit from the hole and release pressure from the Trigger,

allowing the tool to stop operating.

4. Unplug the tool and store it in a safe place.

MAINTENANCE AND INSPECTION

1. The Armature (25) and Stator (29) comprise the main part of the tool. Protect these electrical components

from moisture or oil intrusion.

2. Inspect the Carbon Brushes (34) regularly. Replace them is they are more than 1/3 worn or are chipped or

cracked. When handling them, be careful not to damage them. To reduce wear after inspection, replace

them in exactly the same way as they were removed.

3. Regularly inspect all components and fasteners to be sure they are properly installed, not damaged, and

tight. Tighten any loose parts. Repair or replace any damaged components.

4. If the tool is damaged or does not function properly, take it to a qualified service technician.

5. Clean the tool after each use, and store it properly. Keep it out of reach of children and other unauthorized

persons. Protect it from moisture and corrosive materials.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 9

Page 10

TROUBLESHOOTING

1. Drill operates but hole is not effectively drilled.

Possible Cause:

Inappropriate or dull drill bit.

Solution:

Try a different drill bit.

2. Drill will not turn ON.

Possible Cause:

No power source.

Solution:

Check that the power cord is plugged into an appropriate live

outlet. Check that power cord is in good condition.

Possible Cause:

Damaged Carbon Brushes.

Solution:

Unplug tool. Remove and inspect Carbon Brushes.

If glazed, they can be cleaned with a pencil eraser. If chipped, cracked or worn out, they must be

replaced. Reinstall good Carbon Brushes. Plug in tool and try again.

Possible Cause:

Damaged or burned out Rotor or Stator.

Solution:

Take to a qualified service technician

for replacement or repair.

3. Drill bit “wobbles” in Chuck.

Possible Cause:

Loose or misaligned drill bit.

Solution:

Unplug tool from power supply. Loosen drill bit in

chuck, and reinstall carefully. Tighten securely.

Possible cause:

Chuck is loose on Spindle (12).

Solution:

Tighten the Chuck onto the Spindle by turning

clockwise.

PARTS LIST

#traPnoitpircseD.YTQ#traPnoitpircseD.YTQ

15mrehsaWgnirpS492rotatS1

2055x5TSwercS403bonKeldnaHedapS1

3yeKkcuhC113eldnaHedapS1

422x6mwercSdaeHpaC123esaCkcaB1

5kcuhC133paChsurB2

612mrehsaW143hsurBnobraC2

7gnisuoHraeG153redloHhsurB2

83mniP2638mtuNxeH1

9SR2006gn

01pilcriC183F61x4TSwercS4

1101x7.3x3myeK393gnisuoH1

21eldnipS104eveelSrebbuR1

31raeGtuptuO114gulPdnadro

4104x01mwercS124pilCdroC1

51eldnaHediS13461x4TSwercS2

6121mpilcriC144revoCeldnaH1

71214101KHgniraeBeldeeN154F81x4TSwercS2

81t

91raeGdnoceS174etalPepyT1

0221mpilcriC184055x4TSwercS2

12012180KHgniraeBeldeeN494etalPemaN1

22revoCgnisu

3201mpilcriC115gniR-O1

42reniateRgniraeB125gniRlaeS1

52erutamrA135raeGtsriF1

6272.806gniraeBllaB14

72gnihsuBgniraeB155teksaG1

82ediuGgnidniW1

iraeBllaB173tuNrofrevoC1

C1

fahSdnoceS164hctiwS1

oHraeG105Z2.0006gniraeBllaB1

5tfahStsriF1

NOTE: Some parts are listed and shown for illustration purposes only and are not available individually as

replacement parts.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 10

Page 11

ASSEMBLY DRAWING

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL AS A

REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO

THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE

MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER.

THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF RE-

PLACEMENT PARTS THERETO.

SKU 93632 For technical questions, please call 1-800-444-3353.

English

Page 11

Page 12

1

®

/2” la Vitesse de Variable de Faible Vitesse

Très Résistante la Foreuse Réversible

93632

ASSEMBLAGE ET MODE DE FONCTIONNEMENT

IMPORTANT!

Cette édition de langue

française est une traduction

du manuel anglais original

accompagnant ce produit. Si

une partie du manuel anglais

original est inconsistante

avec cette traduction, le

manuel anglais original

gouvernera.

En raison des améliorations continuantes, le produit réel peut différer légèrement du produit décrit ici.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visitez notre Site Internet à http://www.harborfreight.com

PRÉVENIR LA BLESSURE SÉRIEUSE, LUE ET

COMPRENDRE TOUS LES AVERTISSEMENTS ET

LES INSTRUCTIONS AVANT L’UTILISATION.

Le copyright© 2006 par le Harbor Freight Tools®. Tous droits réservés. Aucune portion de ce

manuel ou de n’importe quel travail d’art contenu ici ne peut être reproduite dans aucune forme

ou formulaire sans le consentement rapidement écrit de Harbor Freight Tools.

Pour les questions techniques et les pièces détachées, appelez-vous s’il

vous plaît 1-800-444-3353.

Page 13

SPÉCIFICATIONS

:noitcurtsnoC

:epyTteeziSnirdnaM

essetiVnim-rt055-0:elbairaV

:noitceriD

rénéG

:esueroFed

aledegaroF

snoisnemiD

:sela

,euqitsalPedeluoMedmuinimulA'lnoitcejni'L

énisU

epyTeléticapaCal"2/1-"61/1

FNU02"½:uaesuFedliF

l/reyovnE

eriartnoCe

H"8/5-8xL"21xW"¾-3:teNsdioPgk5.3~

enobracuareicA'lteéledoMSBAtnenamreP

étopap-3élC

:sulcnI

:elibomotuAepyT

:uluoVriovuoP

aledegaroF

:éticapaC

seriosseccA

zH06,CAV021

sioBedkcotS"2

xuodreicA'L"½

yeKnirdnaM

noitubirtnoCedruetoM5.7

noitcudéRalcevaerèpmA'd

elbuoDeganergnE'd

egrahcalsuosserèpmA2.6

E194601

leirétaMelcevaehcêbedeéngioP

eriatnemélppuSeéngioP

SAUVEZ CE MANUEL

Vous aurez besoin du manuel pour les avertissements de sécurité et les précautions, les instructions

d’assemblage, en opérant et les procédures de maintenance, la liste de parties et le diagramme. Gardez votre

facture avec ce manuel. Écrivez le nombre de facture sur l’intérieur de la couverture première. Gardez le

manuel et la facture dans un coffre-fort et un endroit sec pour la référence future.

RÈGLES RÉPANDUES DE SÉCURITÉ

AVERTISSEMENT!

LISEZ ET COMPRENEZ TOUTES LES INSTRUCTIONS.

L’échec de suivre toutes les instructions énumérées peut

ci-dessous s’ensuivre dans le décharge électrique, le feu

et-ou la blessure sérieuse.

SAUVEZ CES INSTRUCTIONS.

RÉGION DE TRAVAIL

1. Garder votre région de travail propre et bien allumé. Les bancs encombrés et les régions sombres

invitent des accidents.

2. Ne faire pas marcher d’instruments de pouvoir dans les atmosphères explosives, comme en

présence des liquides inflammables, les gaz, ou la poussière. Les instruments de pouvoir créent

des étincelles qui peuvent enflammer la poussière ou les exhalaisons.

3. Garder des spectateurs, des enfants et des visiteurs loin en faisant marcher un instrument de

pouvoir. Les distractions peuvent vous faire perdre le contrôle. Protégez d’autres dans la région de

travail des débris comme les frites et les étincelles. Fournissez des barrières ou des protecteurs comme

nécessaire.

SÉCURITÉ ÉLECTRIQUE

4. Les instruments mis à la terre doivent être branchés à une prise de courant murale correctement

installée et mise à la terre conformément à tous les codes et aux ordonnances. N’enlevez jamais

la dent d’installer à la terre ou modifiez la prise de courant de toute façon. N’utilisez pas de

prises de courant d’adaptateur. Vérifiez avec un électricien qualifié si vous êtes douteux si la

prise de courant murale est correctement mise à la terre. Si l’instrument devrait électriquement mal

fonctionner ou se décomposer, installer à la terre fournit un sentier de résistance faible pour emporter

l’électricité de l’utilisateur.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 2

Page 14

5. Les instruments isolés doubles sont équipés avec une prise de courant polarisée (une lame est

plus large que l’autre). Cette prise de courant correspondra dans une prise de courant murale

polarisée seulement à une voie. Si la prise de courant ne va pas complètement dans la prise de

courant murale, inverse la prise de courant. S’il ne va pas toujours, contactez un électricien

qualifié pour installer une prise de courant murale polarisée. Ne changez pas la prise de courant

de toute façon. L’isolation double élimine le besoin pour le trois fil a mis le cordon de pouvoir à la terre

et a mis le système d’alimentation électrique à la terre.

6. Éviter le contact de corps avec les surfaces mises à la terre comme les tuyaux, les radiateurs, les

variétés et les réfrigérateurs. Il y a un risque augmenté de décharge électrique si votre corps est mis

à la terre.

7. N’exposer pas d’instruments de pouvoir pour pleuvoir ou les conditions mouillées. L’eau entrant

dans un instrument de pouvoir augmentera le risque de décharge électrique.

8. N’abuser pas du Cordon de Pouvoir. N’utilisez jamais le Cordon de Pouvoir pour porter l’instrument

ou tirer la Prise de courant d’une prise de courant murale. Tenez le Cordon de Pouvoir à distance

de la chaleur, les bords de pétrole, pointus, ou les pièces bougeantes. Remplacez des Cordons

de Pouvoir faits tort immédiatement. Les Cordons de Pouvoir Faits tort augmentent le risque de

décharge électrique.

9. En faisant marcher un instrument de pouvoir à l’extérieur, utilisez “W-A” marqué d’un cordon

d’extension en plein air ou “W”. Ces cordons d’extension sont estimés pour l’utilisation en plein air et

réduisent le risque de décharge électrique.

10. Séjour vigilant. La surveillance que vous faites et utilisez le sens commun en faisant marcher un

instrument de pouvoir. N’utilisez pas d’instrument de pouvoir pendant que fatigué ou sous

l’influence de drogues, alcool, ou médication. Un moment d’inattention en faisant marcher des

instruments de pouvoir peut s’ensuivre dans la blessure personnalisée sérieuse.

11. Robe correctement. N’usez pas de vêtements desserrés ou de bijouterie. Contenez de longs

cheveux. Gardez vos cheveux, vêtements et gants loin de déplacer des pièces. Les vêtements

desserrés, la bijouterie, ou les longs cheveux peuvent être attrapés dans les pièces bougeantes.

12. Éviter le commencement accidentel. Soyez sûrs que l’Interrupteur de Pouvoir est éteient avant le

fait de brancher. Le fait de porter des instruments de pouvoir avec votre doigt sur l’Interrupteur de

Pouvoir, ou en branchant des instruments de pouvoir avec l’Interrupteur de Pouvoir sur, invite des

accidents.

13. Enlever des clés s’adaptant ou des tourne-à-gauche avant le fait d’allumer l’instrument de pouvoir.

Un tourne-à-gauche ou une clé qui est laissée attachée à une pièce tournante de l’instrument de pouvoir

peuvent s’ensuivre dans la blessure personnalisée.

14. Ne dépaser pas. Gardez la position nécessaire et l’équilibre à tous moments. La position nécessaire

et l’équilibre permettent le meilleur contrôle de l’instrument de pouvoir dans les situations inattendues.

15. Utiliser l’équipement de sécurité. Usez toujours la protection d’oeil. Le masque de filtre, les

chaussures de sécurité antidérapantes, le chapeau dur, ou l’audition de la protection doivent être utilisés

pour les conditions appropriées.

UTILISATION D’INSTRUMENT ET SOIN

16. Utiliser des attaches (non inclus) ou d’autres façons pratiques de stabiliser et soutenir la pièce

de travail à une plate-forme ferme. La possession du travail à la main ou contre votre corps est

instable et peut causer la perte de contrôle.

17. Ne forcer pas l’instrument. Utilisez l’instrument correct de votre application. L’instrument correct

fera le travail mieux et plus sûr au taux auquel il est conçu.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 3

Page 15

18. N’utiliser pas l’instrument de pouvoir si l’Interrupteur de Pouvoir ne l’allume pas ou éteie. N’importe

quel instrument qui ne peut pas être contrôlé avec l’Interrupteur de Pouvoir est dangereux et doit être

remplacé.

19. Débrancher la Prise de courant de Cordon de Pouvoir de la source de pouvoir avant le fait de

faire n’importe quels ajustages, accessoires changeants, ou le fait de conserver l’instrument. De

telles mesures de sécurité préventives réduisent le risque de commencer l’instrument par hasard.

20. Le magasin les instruments à l’arrêt hors de portée des enfants et d’autres personnes sans

formation. Les instruments sont dangereux dans les mains d’utilisateurs sans formation.

21. Maintenir des instruments avec le soin. Continuez à couper des instruments maintenus et propres.

Les instruments correctement maintenus se lieront moins probablement et sont plus faciles de contrôler.

N’utilisez pas d’instrument fait tort. L’étiquette a fait tort aux instruments “n’utilisent pas” jusqu’à ne

réparé.

22. Vérifier pour le défaut d’alignement ou le fait d’attacher de pièces bougeantes, la fracture de

pièces et d’autre condition qui peut affecter l’opération de l’instrument. Si fait tort, faites assurer

l’entretien de l’instrument avant l’utilisation. Beaucoup d’accidents sont causés par les instruments

pauvrement maintenus.

23. Utiliser seulement des accessoires qui sont recommandés par le fabricant pour votre modèle.

Les accessoires qui peuvent être convenables pour un instrument peuvent devenir les hasardeux quand

utilisé sur un autre instrument.

ENTRETIEN

24. L’entretien d’instrument doit être exécuté seulement par le personnel de réparation qualifié.

L’entretien ou la maintenance exécutée par le personnel disqualifié pourraient s’ensuivre dans un risque

de blessure.

25. En assurant l’entretien d’un instrument, utilisez des pièces détachées seulement identiques.

Suivez des instructions dans la “Inspection, la Maintenance Et la “ section Nettoyante de ce

manuel. L’utilisation de pièces faites sans autorisation ou d’échec de suivre les instructions de

maintenance peut créer un risque de décharge électrique ou de blessure.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

1. Tenir l’instrument par les surfaces de captage isolées en exécutant une opération où la coupure

des instruments peut contacter l’installation électrique cachée ou son propre cordon. Contact

avec un fil ‘de force’ ira faire des pièces en métal exposées sur l’instrument ‘vivre’ et choquer

l’opérateur.

2. Maintenir des étiquettes et des plaques sur l’instrument. Ceux-ci portent des renseignements

importants. Si illisible ou l’absence, contactez le Harbor Freight Tools pour un remplacement.

3. Usez toujours des lunettes de protection d’oeil d’impact de sécurité approuvées d’ANSI et de

lourds gants de travail en utilisant l’instrument. L’utilisation les artifices de sécurité personnalisés

réduit le risque pour la blessure. Les lunettes de protection d’oeil d’impact de sécurité et les lourds gants

de travail sont en vente du Harbor Freight Tools.

4. Maintenir un cadre de travail sûr. Gardez la région de travail bien allumée. Assurez-vous qu’il y a le

cadre de travail environnant adéquat. Gardez toujours la région de travail sans obstructions, graisse,

pétrole, déchets et d’autres débris. N’utilisez pas d’instrument de pouvoir dans les régions près des

produits chimiques inflammables, les poussières et les vapeurs. N’utilisez pas ce produit dans un

endroit humide ou mouillé.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 4

Page 16

5. En utilisant un instrument de pouvoir à main, maintenez toujours une prise ferme sur l’instrument

avec les deux mains pour résister au moment de torsion de départ. Ayez toujours on passe la

Poignée et l’autre sur la Poignée de Côté ou de Poignée de Bêche.

6. Tenez toujours le cordon d’extension à distance de déplacer des pièces sur l’instrument.

7. Éviter le commencement inconscient. Assurez-vous que vous êtes disposés à commencer le travail

avant le fait d’allumer la Foreuse.

8. Assurer que le morceau de Foreuse étant utilisé est libre des tesson en métaux et d’autre matière

étrangère qui pourrait faire tort à l’instrument.

9. Ne laissez jamais l’instrument sans surveillance quand il est branché à une prise de courant

murale électrique. Éteignez l’instrument et débranchez-le de sa prise de courant murale électrique

avant le départ.

10. Débranchez toujours la Foreuse de sa prise de courant murale électrique avant le fait d’exécuter

n’importe quelle inspection, maintenance, ou le fait de nettoyer des procédures.

11. Laisser des Morceaux frais avant l’attouchement, le changement ou le réglage d’eux. Les morceaux

chauffent radicalement pendant que dans l’utilisation et sont capables de sévères brûle.

12. Ne forcer pas la Foreuse. Cet instrument fera le travail mieux et plus sûr à la vitesse et à la capacité à

laquelle il a été conçu.

13. Stabilisez toujours la pièce de fabrication dans un étau d’établi ou d’autre artifice approprié;

jamais l’essai de tenir la pièce de fabrication dans votre main en forant.

14. Si le morceau de foreuse se bloque, lâchez la manette immédiatement; le moment de torsion de

foreuse peut causer la blessure.

15. AVERTISSEMENT! Les gens avec les stimulateurs cardiaques devraient consulter leur docteur (s) avant

le fait d’utiliser ce produit. Les champs électromagnétiques dans la proche proximité à un stimulateur

cardiaque du cœur pourraient causer l’interférence à ou l’échec du stimulateur cardiaque.

En plus, les gens avec les stimulateurs cardiaques devraient respecter la chose suivante :

• Éviter de faire marcher des instruments de pouvoir seuls.

• N’utiliser pas d’instrument de pouvoir avec l’Interrupteur de Pouvoir verrouillé.

• Si actionné via un cordon de pouvoir sont certain que l’instrument est correctement mis à la terre.

Une interruption de faute de terre (GFCI) le système est aussi une bonne précaution. Cet artifice bon

marché est une bonne mesure de sécurité parce qu’il évite un choc électrique suivi.

• Maintenez correctement et inspectez tous les instruments avant l’utilisation pour éviter le choc

électrique.

16. AVERTISSEMENT! Un peu de poussière créée par le fait d’éroder de pouvoir, le sciage, le grincement, le

forage et d’autres activités de construction, contient des produits chimiques connus (à l’État de Californie)

pour causer le cancer, les anomalies congénitales ou d’autre mal reproducteur. Quelques exemples de

ces produits chimiques sont : le plomb des peintures à base de plomb, la silice cristalline des briques et

le ciment ou d’autres produits de maçonnerie, l’arsenic et le chrome du bois de construction chimiquement

traité. Votre risque de ces expositions varie, selon combien de fois vous faites ce type de travail. Réduire

votre exposition à ces produits chimiques : le travail dans une région bien aérée et un travail avec

l’équipement de sécurité approuvé, comme ces masques de filtre qui sont spécialement conçus pour

éliminer des particules microscopiques.

(Le Code de Sécurité et de Santé de Californie § 25249.5

et seq.

)

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 5

Page 17

INSTALLER À LA TERRE

AVERTISSEMENT!

Improprement le branchement du fil d’installer à la terre peut s’ensuivre dans

le risque de décharge électrique. Vérifiez avec un électricien qualifié si vous

êtes douteux quant à si la prise de courant est correctement mise à la terre. Ne

modifiez pas la prise de courant de cordon de pouvoir fournie avec

l’instrument. N’enlevez jamais la dent d’installer à la terre de la prise de courant. N’utilisez pas l’instrument si le cordon de pouvoir ou la prise de courant

sont nuis. Si nui, faites-le réparer par un établissement d’entretien avant

l’utilisation. Si la prise de courant ne correspondra pas à la prise de courant,

faites installer une prise de courant nécessaire par un électricien qualifié.

INSTRUMENTS MIS À LA TERRE: INSTRUMENTS AVEC TROIS

PRISES DE COURANT DE DENT

1. Les instruments marqués avec “le Grounding Required” ont un trois cordon métallique et trois dent

mettant la prise de courant à la terre. La prise de courant doit être raccordée à une prise de courant

correctement mise à la terre. Si l’instrument devrait électriquement mal fonctionner ou se décomposer,

installer à la terre fournit un sentier de résistance bas pour emporter l’électricité de l’utilisateur, en réduisant

le risque de décharge électrique. (Voir le Diagramme A.)

2. La dent d’installer à la terre dans la prise de courant est raccordée par le fil vert à l’intérieur du cordon au

système d’installer à la terre dans l’instrument. Le fil vert dans le cordon doit être le seul fil raccordé au

système d’installer à la terre de l’instrument et ne doit jamais être attaché à un terminus électriquement

“vivant”. (Voir le Diagramme A.)

3. Votre instrument doit être branché dans une prise de courant appropriée, a correctement installé et a mis

à la terre conformément à tous les codes et aux ordonnances. La prise de courant et la prise de courant

devraient ressembler à ceux en illustration suivante. (Voir le Diagramme A.)

DIAGRAMME A

DOUBLEZ DES INSTRUMENTS ISOLÉS : INSTRUMENTS AVEC

DEUX PRISES DE COURANT DE DENT

4. Les instruments marqués “Double Isolé” n’exigent pas installer à la terre. Ils ont un système d’isolation

double spécial qui satisfait des exigences OSHA et se plie aux normes applicables d’Underwriters

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 6

Page 18

Laboratories, Inc., l’Association Standard canadienne et le Code Électrique national. (Voir le Diagramme

B.)

5. Les instruments isolés doubles peuvent être utilisés dans n’importe laquelle des prises de courant de

120 volts montrées en illustration suivante. (Voir le Diagramme B.)

DIAGRAMME B

CORDONS D’EXTENSION

1. Les instruments

doubles

2. Comme la distance des augmentations de prise de courant de réserves, vous devez utiliser un plus

lourd cordon d’extension de calibre. L’utilisation des cordons d’extension avec le fil insuffisamment de

grandeur cause une goutte sérieuse dans le voltage, en s’ensuivant dans la perte de pouvoir et de

dommage d’instrument possible.

(Voir le Diagramme C, la page suivante.)

3. Plus petit le nombre de calibre du fil, plus grand la capacité du cordon. Par exemple, un 14 cordon de

calibre peut porter un plus haut courant qu’un 16 cordon de calibre.

(Voir le Diagramme C.)

4. En utilisant plus qu’un cordon d’extension pour créer la longueur totale, assurez-vous que chaque cordon

contient au moins la grandeur métallique minimale exigée. (Voir le Diagramme C.)

5. Si vous utilisez un cordon d’extension de plus qu’un instrument, ajoutez les ampères de plaque et

utilisez la somme pour déterminer la grandeur de cordon minimale voulue.

(Voir le Diagramme C.)

6. Si vous utilisez un cordon d’extension dehors, assurez-vous qu’il est marqué avec le suffixe “W-A” (“W”

au Canada) pour indiquer que c’est acceptable pour l’utilisation en plein air.

7. Assurer que votre cordon d’extension est correctement télégraphié et dans la bonne condition électrique.

Remplacez toujours un cordon d’extension nui ou faites-le réparer par un électricien qualifié avant le fait

de l’utiliser.

8. Protéger vos cordons d’extension des objets pointus, la chaleur excessive et les régions humides ou

mouillées.

peuvent utiliser deux ou trois cordon d’extension métallique.

mis à la terre

exigent un trois cordon d’extension métallique. Les instruments

Isolés

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 7

Page 19

*SDROCNOISNETXE'LRUOPÉDNAMMOCERLAMINIMEUQILLATÉMERBILACEL

EUQALP

SERÈPMA

)egrahCenielPalÀ(

m5.7m51m5.22m03m54

0.2-08181818161

4.3-1.28181816141

0.5-5.38181614121

0.7-1.58161412121

0.21-1.781412101-

0.61-1.21412101--

-1.612101 ---

0.02

CEMMARGAID

ROCEDRUEUGNOL

NOISNETXE'DNOD

engiledegatlovelretimiledtiafelrusdesaB*

.séulavéserèpmased%051àstlovqnicàtnebmot

SYMBOLOGY

Double Isolé

Association de Normes

Canadienne

Underwriters Laboratories,

Inc.

V ~

A

no

xxxx/min.

Courant alternatif de Volts

Ampères

Aucune Révolution de Charge

par Minute (TR-MIN)

DÉFAISANT

En défaisant, vérifiez pour vous assurer que le produit est intact et non endommagé.

Si des parties manquent ou cassées, appelez s’il vous plaît le Harbor Freight Tools au nombre sur la couverture

de ce manuel.

LE FAIT DE FAIRE MARCHER DES INSTRUCTIONS

Votre Faible vitesse la Foreuse Très résistante sera d’habitude prérassemblée. Dans certains cas, en raison

des variations dans l’emballage, vous devriez installer la Poignée de Bêche et la Poignée Auxiliaire. Faites

s’il vous plaît allusion au diagramme d’assemblage sur la page 10.

PRUDENCE : Soyez sûrs que l’instrument est non branché de n’importe quelle source de pouvoir

avant le fait d’exécuter n’importe quelle installation ou ajustage de l’instrument.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 8

Page 20

1. Mettre en ligne la Poignée de Bêche (31) avec l’Arrière Cas (32). Insérez le Bouton de Poignée de Bêche

(30) par la Poignée de Bêche dans l’Arrière Cas. Serrez le Bouton de Poignée de Bêche en tournant dans

le sens des aiguilles d’une montre jusqu’à serrés.

2. Insérer la Vis (14) par la Poignée de Côté (15). Placez la Poignée de Côté sur la Couverture d’Habitation

de Matériel (22). L’utilisation d’un tournevis (non inclus) serre la Vis (14) jusqu’à serré.

NOTER: Vérifiez Périodiquement pour être sûr que les poignées restent serrées. N’essayez jamais de

replacer les poignées pendant que l’instrument court.

De la Faible vitesse Foreuses Très résistantes:

Pendant qu’un instrument extrêmement utile, les foreuses très résistantes peuvent être dangereuses si

utilisé improprement ou dans la condition nuie.

1. Cet instrument incorpore une transmission de réduction d’engrenage double pour réduire la vitesse de

foreuse en augmentant le moment de torsion. Ce design améliore la performance en forant de grands

trous en haut à 2” dans le bois et 1/2” dans l’acier doux. Cette caractéristique aide aussi à empêcher

l’instrument “d’être ralenti” ou s’arrêter quand sous la lourde charge.

2. Les Morceaux de Foreuse (non inclus) sont fournis dans les grandeurs différentes et les types. Choisissez

toujours le type de morceau nécessaire et la grandeur pour l’application à portée de la main.

3. Cette foreuse peut utiliser des grandeurs de manche de morceau de foreuse entre 1/16” et 1/2” tout

compris. La grandeur de trou peut être plus grande que la grandeur de manche. N’essayez pas d’utiliser

des morceaux de foreuse plus grands ou plus petits que cette variété.

4. En installant un morceau de foreuse dans l’instrument, débranchez d’abord l’instrument. À la main,

faites tourner l’anneau extérieur de Mandrin en sens inverse des aiguilles d’une montre pour l’ouvrir

assez pour permettre au morceau d’être insérés. Soyez sûrs que le morceau est centré dans Mandrin. À

la main, faites tourner l’anneau extérieur de Mandrin dans le sens des aiguilles d’une montre pour vous

serrer sur le morceau. Vérifiez pour être sûr que le morceau est centré dans les mâchoires de Mandrin.

5. Insérer le bout de Mandrin Key dans une des ouvertures forées dans le côté de Mandrin. Retenez les

engrenages de Mandrin Key avec les dents d’engrenage sur l’extérieur de Mandrin. Tournez Mandrin Key

dans le sens des aiguilles d’une montre pour serrer les mâchoires de Mandrin fermement sur le morceau

de foreuse. PRUDENCE : Soyez sûrs que le morceau de foreuse est centré et fixé fermement dans

Mandrin avant le travail commençant.

Caractéristiques d’Interrupteur de Pouvoir

Noter : l’Interrupteur de Pouvoir (46) a une caractéristique de vitesse variable. Tournez simplement le

bouton au-dessous de l’Interrupteur de Pouvoir pour régler la vitesse de foreuse. Les traits pointillés sur

le bouton sont espacés d’étroit à large pour indiquer la vitesse de foreuse augmentante.

Noter: Le bouton de serrure de manette sur l’Interrupteur de Pouvoir, quand activé, permettra à la foreuse

de courir sans pression de doigt continue sur l’interrupteur de pouvoir. Pour libérer la serrure de manette,

appuyez simplement sur votre doigt sur l’interrupteur de pouvoir.

1. Ne commencer pas l’instrument jusqu’à ce que vous ayez observé toutes les préparations de sécurité et

soyez prêts à travailler.

2. Serrer l’Interrupteur de Pouvoir. L’instrument commencera à opérer. La vitesse de la foreuse augmentera

comme la Manette est serrée plus serrée. La vitesse diminuera comme la Manette est libérée.

3. Arrêter l’instrument en libérant l’Interrupteur de Pouvoir.

Notez: Le bouton changeant de direction est trouvé derrière la Manette (46). Quand le bouton est poussé dans

sur le côté gauche d’habitation (voir la photo sur la couverture), la foreuse tournera en sens inverse (en

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 9

Page 21

sens inverse des aiguilles d’une montre). Quand le bouton est poussé dans sur le côté droit d’habitation,

la foreuse tournera dans un avancé, dans le sens des aiguilles d’une montre la direction.

L’Inversion de la Direction de la Foreuse

Prudence: N’essayez Jamais de changer la direction de la foreuse pendant que la foreuse opère. Attendez

toujours la foreuse pour venir à un arrêt complet avant la direction changeante.

1. La plupart des morceaux de foreuse sont conçus pour travailler en rendant dans le sens des aiguilles

d’une montre la direction. En forant, confirmez que vous utilisez un morceau de foreuse de type standard

et que l’on charge que la foreuse tourne dans la direction correcte.

2. De temps à autre le morceau de foreuse peut devenir coincé, ou vous pouvez vouloir inverser la direction

de foreuse.

3. Pour inverser la direction, attendez la foreuse pour venir à un arrêt complet. Appuyez sur la direction le

bouton changeant comme décrit dans la Note ci-dessus.

L’utilisation de la Foreuse Très résistante

Avant le fait d’utiliser la Foreuse Très résistante, soyez sûrs que toutes les précautions de sécurité de

région de travail sont observées. Soyez sûrs d’user{de porter} la protection d’oeil approuvée d’ANSI.

NOTER : Le moteur chauffera comme il est utilisé. Éviter le moteur incendient, n’utilisez pas constamment

depuis plus de 20 minutes à la fois. Permettez à l’instrument de refroidir depuis au moins 10 minutes

avant le travail reprenant.

1. Placer le bout de foreuse sur le morceau de travail et Commencer l’instrument.

2. Appliquer la pression douce sur l’instrument pour l’aider à forer dans la pièce de fabrication. Ne surchargez

pas l’instrument. Si la vitesse ralentit manifestement, n’appuyez pas sur la foreuse comme durement.

3. Quand le trou a été foré, enlève le morceau du trou et libère la pression de la Manette, en permettant à

l’instrument d’arrêter d’opérer.

4. Débrancher l’instrument et le conserver dans un endroit sûr.

MAINTENANCE ET INSPECTION

1. L’Armature (25) et le Stator (29) comprend la partie principale de l’instrument. Protégez ces composantes

électriques de l’humidité ou de l’intrusion de pétrole.

2. Inspecter les Balais de carbone (34) régulièrement. Remplacez-les s’ils sont plus que 1/3 usé{porté} ou

sont ébréchés ou craqués. En les manipulant, être prudent de ne pas leur nuire. Pour réduire l’usure après

l’inspection, remplacez-les d’exactement la même façon qu’ils ont été enlevés.

3. Inspectez régulièrement toutes les composantes et les fermetures pour être sûr qu’ils sont correctement

installés, ne pas nuis et serré. Serrez n’importe quelles parties desserrées. La réparation ou remplace

n’importe quelles composantes nuies.

4. Si l’instrument est nui ou ne fonctionne pas correctement, le prend à un technicien d’entretien qualifié.

5. Nettoyer l’instrument après chaque utilisation et conserver-le correctement. Gardez-le hors de portée des

enfants et d’autres personnes faites sans autorisation. Protégez-le de l’humidité et des matériaux corrosifs.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 10

Page 22

LE FAIT DE FIXER DES PROBLÈMES

1. La foreuse opère mais le trou n’est pas efficacement foré.

Cause Possible :

Morceau de foreuse incorrect ou émoussé.

Solution :

Essayez un différent morceau de

foreuse.

2. La foreuse ne commencera pas.

Cause Possible :

Aucune source de pouvoir.

Solution :

Vérifiez-le le cordon de pouvoir est branché dans

une prise de courant appropriée de force. Vérifiez ce cordon de pouvoir est en bon état.

Cause Possible :

Balais de carbone Diminués.

Solution :

Débranchez l’instrument. Enlevez et inspectez

des Balais de carbone. Si mis sous verre, ils peuvent être nettoyés avec une gomme de crayon. Si

ébréché, craqué ou épuisé, ils doivent être remplacés. Réinstallez de bons Balais de carbone. Branchez

l’instrument et essayer de nouveau.

Cause Possible :

Diminué ou a incendié le Rotor ou le Stator.

Solution :

Prenez à un technicien d’entretien

qualifié pour le remplacement ou la réparation.

3. Le morceau de foreuse “branle” dans Mandrin.

Cause Possible :

Morceau de foreuse desserré ou non mis en ligne.

Solution :

Débranchez l’instrument de

l’alimentation électrique. Desserrez le morceau de foreuse dans mandrin et réinstallez soigneusement.

Serrez-vous solidement.

Cause possible :

Mandrin est desserré sur le Fuseau (12).

Solution :

Serrez Mandrin sur le Fuseau en

tournant dans le sens des aiguilles d’une montre.

LISTE DE PARTIES

eitraPnoitpircseDétitnauQeitraPnoitpircseDétitnauQ

15merèinatnirPellednoR492rotatS1

2055x5TSsiV403ehcêBedeéngioPednot

3yeKnirdnaM113ehcêBedeéngioP1

422x6mtennoBedetêTedsiV123saCerèirrA1

5nirdnaM133ialaBedtennoB2

612mellednoR143enobraCedia

7eganergnE'dnoitatibaH153ialaBedruetnetéD2

83melgnipÉ2638menogaxeH'duorcÉ1

9SR2006sellibàtnemeluoR173uorcÉ'lruoper

01egacolbeduaennA183F61x4TSsiV4

1101x7.3x3mélC393noitatibaH1

21uaesuF104cuohctuoaCedettehcoP1

31tnemedneRedegane

rgnE114tnaruocedesirPtenodroC1

4104x01msiV124nodroCedruetnetéD1

51étôCedeéngioP13461x4TSsiV2

6121megacolbeduaennA144eéngio

71214101KHelliugia'dreilaP154F81x4TSsiV2

81stiuPemèixueD164ruetpurretnI1

91eganergnEemèixueD174euqalPalz

0221megacolbeduaennA184055x4TSsiV2

12012180KHelliugia'dreilaP494moNedeuqalP1

22eganergnE'dnoitatibaH'derutrevu

oC105Z2.0006sellibàtnemeluoR1

3201megacolbeduaennA115uaenna-O1

42noisivorPaledreilaP125tnioJeduaennA1

52erutamrA135reimerp

6272.806selliBàtnemeluoR145erbrAreimerP1

72esiotertnE'ledreilaP155tnioJ1

82ediuGudeganiboB1

uoB1

laB2

utrevuoC1

PederutrevuoC1

epaT1

eganergnE1

NOTEZ : Quelques parties sont énumérées et montrées pour les buts d’illustration seulement et ne sont pas

disponibles individuellement comme les pièces détachées.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 11

Page 23

DESSIN DE MONTAGE

LISEZ S’IL VOUS PLAÎT LE SUIVANT SOIGNEUSEMENT

LE FABRICANT ET-OU LE DISTRIBUTEUR A FOURNI LE DIAGRAMME DE PARTIES DANS CE MANUEL COMME

UN INSTRUMENT DE RÉFÉRENCE SEULEMENT. NI LE FABRICANT NI LE DISTRIBUTEUR NE FONT AUCUNE

REPRÉSENTATION OU GARANTIE DE N’IMPORTE QUELLE SORTE À L’ACHETEUR QU’IL OU ELLE EST

AUTORISÉ POUR FAIRE N’IMPORTE QUELLES RÉPARATIONS AU PRODUIT OU QU’IL OU ELLE EST AUTORISÉ

POUR REMPLACER N’IMPORTE QUELLES PARTIES DU PRODUIT. EN FAIT, LE FABRICANT ET-OU LE

DISTRIBUTEUR DÉCLARE EXPRESSÉMENT QUE TOUTES LES RÉPARATIONS ET LES REMPLACEMENTS

DE PARTIES DEVRAIENT ÊTRE ENTREPRIS PAR LES TECHNICIENS DIPLÔMÉS ET AGRÉÉS ET PAS PAR

L’ACHETEUR. L’ACHETEUR SUPPOSE TOUT LE RISQUE ET LA RESPONSABILITÉ SURVENANT DU FAIT DE

SES RÉPARATIONS AU PRODUIT ORIGINAL OU AUX PIÈCES DÉTACHÉES Y, OU SURVENANT DU FAIT DE

SON INSTALLATION DE PIÈCES DÉTACHÉES Y.

MODÈLE 93632 Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

Français

Page 12

Loading...

Loading...