Page 1

Fuel Pump & Vacuum

Gauge Tester

93547 Pump / Gauge Tester

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at:

http://www.harborfreight.com

Read this material before

using this product.

Failure to do so can result

in serious injury.

SAVE THIS MANUAL.

When unpacking, make sure

that the product is intact and

undamaged.

If any parts are missing or broken,

please call 1‑800‑444‑3353

as soon as possible.

Copyright© 2011 by Harbor Freight Tools®.

All rights reserved. No portion of this document

or any artwork contained herein may be

reproduced in any shape or form without the

express written consent of Harbor Freight

Tools. Diagrams within this document may

not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly

from the product described herein. Tools required

for assembly and service may not be included.

For technical questions or replacement

parts, please call 1‑800‑444‑3353.

Page 2

Specications

Pressure

Gauge

Brass

Fittings

0~28 IN‑Hg (0~70 cm‑Hg) vacuum;

0~10 PSIG (0~0.7 kg/cm2) pressure

1/4”‑18 (male) x 1/8” ‑ 27 (female)

1/8”‑27 (male) x 7/32” (barbed)

1/8”‑27 (female) x 3/8” ‑ 18 (male)

Important Safety Information

WARNING!

READ AND UNDERSTAND ALL

INSTRUCTIONS

Failure to follow instructions listed

below may result in serious injury.

SAVE THESE INSTRUCTIONS

General Safety Rules

1. Keep bystanders, children, and

visitors away while operating the

Vacuum Pump. Distractions can

cause you to lose control. Protect

others in the work area from injury.

2. Stay alert. Watch what you are

doing, and use common sense

when operating the Vacuum Pump.

Do not use the tool while tired

or under the inuence of drugs,

alcohol, or medication. A moment

of inattention while operating the tool

may result in serious personal injury.

3. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

jewelry away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

4. Do not overreach. Keep proper

footing and balance at all

times. Proper footing and balance

enables better control of the power

tool in unexpected situations.

5. Use safety equipment. Wear

ANSI‑approved safety glasses

underneath a full face safety

shield. Nonskid safety shoes, hard

hat, or hearing protection must be

used for appropriate conditions.

6. Do not force the tool. Use the

correct tool for your application. The

correct tool will do the job better and

safer at the rate for which it is designed.

7. Store idle tools out of reach of

children and other untrained

persons. Tools are dangerous in

the hands of untrained users.

8. Maintain tools with care. Keep

tools dry and clean. Properly

maintained tools are less likely to

bind and are easier to control. Do not

use a damaged tool. Tag damaged

tools “Do not use” until repaired.

9. Check for misalignment or binding

of moving parts, breakage of

parts, and any other condition that

may affect the tool’s operation. If

damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

10. Use only accessories that are

recommended by the manufacturer

for your model. Accessories that may

be suitable for one tool may become

hazardous when used on another tool.

11. Tool service must be performed

only by qualied repair personnel.

Service or maintenance performed

by unqualied personnel could

result in a risk of injury.

12. When servicing a tool, use only

identical replacement parts. Use

of unauthorized parts or failure to

follow maintenance instructions

may create a risk of injury.

Page 2 For technical questions, please call 1‑800‑444‑3353. SKU 93547

Page 3

Specic Safety Instructions

1. Maintain a safe working

environment. Keep the work area

well lit. Make sure there is adequate

surrounding workspace. Keep the work

area free of obstructions, grease, oil,

trash, and other debris. Do not use

this product in a damp or wet location.

2. Maintain labels and nameplates

on this product. These carry

important information. If unreadable

or missing, contact Harbor Freight

Tools for a replacement.

3. Loosen gas cap and relieve fuel

pump pressure before testing.

4. Before use read and understand

all warnings, safety precautions,

and instructions as outlined in the

vehicle manufacturer’s service

manual. Every vehicle has specic

measurement values for vacuum

related readings. It is beyond the

scope of this manual to properly

describe the correct procedure

and test data for each vehicle.

5. Before testing fuel system,

verify all connections are

tight to eliminate leaking.

6. Carbon monoxide is produced

while a vehicle’s engine is

operating and is deadly in a closed

environment. Early signs of carbon

monoxide poisoning resemble the

u, with headaches, dizziness, or

nausea. If you have these signs,

the work area may not be vented

properly. Get fresh air immediately.

7. Prior to using the Fuel Pump/

Tester, make sure to place

the vehicle’s transmission

in “PARK” (if automatic) or

“NEUTRAL” (if manual). Then,

block the tires with chocks.

8. Be alert for hot engine parts

to avoid accidental burns.

9. Avoid accidental re and/or

explosion. Do not smoke near

engine fuel and battery components.

10. Do not allow gasoline to come

into contact with hot manifolds

or other engine components.

11. Do not change ttings

with engine running.

12. Do not drive vehicle while under test.

13. After testing, turn off engine

and depressurize system before

removing test components. Place

absorbing cloths around ttings before

disconnecting. Wipe up any spilled fuel

and place cloths in reproof container.

14. Clean all testing components of

residual fuel before storing.

15. People with pacemakers should

consult their physician(s) before

using this product on a running

engine. Electromagnetic elds in

close proximity to a heart pacemaker

could cause interference or failure of

the pacemaker. In addition, people

with pacemakers should adhere to

the following: Caution is necessary

when near the coil, spark plug cables,

or distributor of a running engine.

16. The brass components of this product

contain lead, a chemical known

to the State of California to cause

cancer and birth defects (or other

reproductive harm). (California Health

& Safety Code § 25249, et seq.)

17. The warnings, precautions, and

instructions discussed in this manual

cannot cover all possible conditions

and situations that may occur. The

operator must understand that common

sense and caution are factors which

cannot be built into this product, but

must be supplied by the operator.

Page 3For technical questions, please call 1‑800‑444‑3353.SKU 93547

Page 4

Setup Instructions

1. Park the vehicle in a well‑ventilated

area. If in a garage, park the car

so that the exhaust pipe faces

out the garage entrance. Leave

garage door open at all times.

2. Place the transmission in Park/Neutral

and set the vehicle emergency brake.

Operating Instructions

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of

this document including all

text under subheadings therein

before set up or use of

this product.

Fuel Pump Pressure Test

1. Relieve the fuel line pressure from the

vehicle fuel system.

Refer to the vehicle manufacturer’s

service manual for instructions

on relieving pressure from the

fuel line, testing procedures and

connection points, and normal

fuel pump pressure readings.

2. Disconnect the pump fuel

output line at the pump.

3. Use the various Adapters included

and Rubber Hose (2) to connect the

Vacuum / Pressure Gauge (1) directly

to the fuel pump.

Use a small amount of pipe compound

or pipe thread seal tape (not supplied)

on the connection threads to prevent

leaks. Tighten using a wrench (not

supplied).

WARNING! Make sure

all connections are tight

to avoid fuel leaks.

4. Start the engine and leave at idle

speed, and immediately check for

fuel leaks. If fuel leaks are found,

turn engine off and x leaks.

5. Read the Vacuum / Pressure Gauge

(1) for the correct pressure.

6. Turn off the engine. The current

reading should hold for one or two

minutes before going down to zero.

7. Wrap a cloth around the hose

connection point before relieving

the pressure from the fuel line and

remove testing components.

8. Reconnect vehicle’s fuel

line to the pump.

9. Wipe up any spilled fuel.

Dispose of fuel‑soaked rags

in a reproof container.

10. Start the engine and immediately

check for leaks. If fuel leaks are

found, turn engine off and x leaks.

11. Clean and store testing components.

Fuel Pump Vacuum Test

1. With the engine off, disconnect the

fuel pump inlet line that comes from

the fuel tank. Have a towel ready

to wipe up any spilled gasoline.

2. Connect the Vacuum / Pressure Gauge

(1) to the fuel pump inlet connector.

Use the Rubber Hose (2) and the

various adapters that t the pump

inlet connector. Do not kink Rubber

Hose. Do not allow air leaks.

3. Start the engine and immediately view

the Vacuum / Pressure Gauge (1).

If the gauge pointer rises to 10 IN/

Hg (the red zone), before the pump

Page 4 For technical questions, please call 1‑800‑444‑3353. SKU 93547

Page 5

goes dry and the engines dies, the

fuel pump is working properly.

4. Turn ignition off and reconnect

fuel line to the fuel pump.

Vacuum Testing

1. With the engine off, connect the

Vacuum / Pressure Gauge (1) as close

as possible to the intake manifold.

Use the Rubber Hose (2) and the

various adapters as needed. Do

not kink Rubber Hose. Do not allow

air leaks. Engines with two intake

manifolds have to be tested separately.

2. Start the engine and let it idle until

the engine temperature reaches its

normal operating temperature.

3. Adjust throttle buttery valve

and set idling speed to get

a smooth engine idle.

4. Take vacuum reading from the Vacuum

/ Pressure Gauge (1). Readings will

vary depending on altitude.

At idle engine speed, with a properly

adjusted carburetor, the gauge pointer

will remain xed between 17 and 22

IN/Hg (the green zone on the gauge),

19.5, optimum.

A slow, uctuation between 14 and

22 IN/Hg indicates that the carburetor

needs adjustment, or there are

other engine problems. Refer to the

vehicle’s service manual for normal and

abnormal readings, and adjustment or

repair procedures.

Other possible engine problems

can be diagnosed as follows:

• When the gauge pressure drops

intermittently about 4 IN/Hg, it could be

an indication of sticky valves. Remove

the Rubber Hose (2), add a few drops

of penetration oil to the manifold

and test again. If the valves stop

sticking, valves need to be cleaned.

• A constant low reading on the gauge

could indicate a burnt valve(s).

• If the gauge pointer pulsates

rapidly when the engine speed is

raised, it could indicate weak valve

springs or poorly seated valves.

• At idle engine speed the gauge pointer

pulsates, but at higher speeds the

pointer is steady, this could be an

indication of loose valve stem guides.

• When the gauge pointer drops slowly

when the engine is sped up several

times in secession, this could indicate

a clogged mufer. An unblocked

mufer will cause the gauge pointer

to momentarily drop to zero.

• When the gauge pointer remains

at 12 IN/Hg at any engine speed it

could indicate late valve timing.

• Test the choke by closing throttle all

the way and starting the engine. The

gauge pointer should immediately rise

to 22 IN/Hg (green zone). If the gauge

pointer stays around 3 to 6 IN/Hg this

may indicate a burnt riser tube, or the

failure of the throttle valve to close.

There could also be air leaks in the

intake manifold system.

Page 5For technical questions, please call 1‑800‑444‑3353.SKU 93547

Page 6

Maintenance and Servicing

1. Before each use: Inspect the

general condition of the Fuel Pump

and Vacuum Gauge Tester. Check

for misalignment or binding of moving

parts, cracked or broken parts,

damaged Hoses, loose connections,

and any other condition that may affect

its safe operation. If a problem occurs,

have the problem corrected before

further use.

Do not use damaged equipment.

2. When cleaning: Do not clean

the Vacuum Pump with cleaners

or other solvents not intended for

use with plastic components. Use

a clean cloth and, if necessary, a

mild detergent. Do not immerse

the Vacuum Pump in any liquid.

3. When storing: Do not store uid

in the Cup. Dispose of excess

uid properly, according to federal,

state, and local guidelines. Store

the Vacuum Pump in a clean, dry

location out of reach of children.

4. WARNING! All maintenance,

service, or repairs not listed in this

manual are only to be attempted by a

qualied service technician.

Record Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

PLEASE READ THE FOLLOWING CAREFULLY

NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR

WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE

ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR

HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR

ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 6 For technical questions, please call 1‑800‑444‑3353. SKU 93547

Page 7

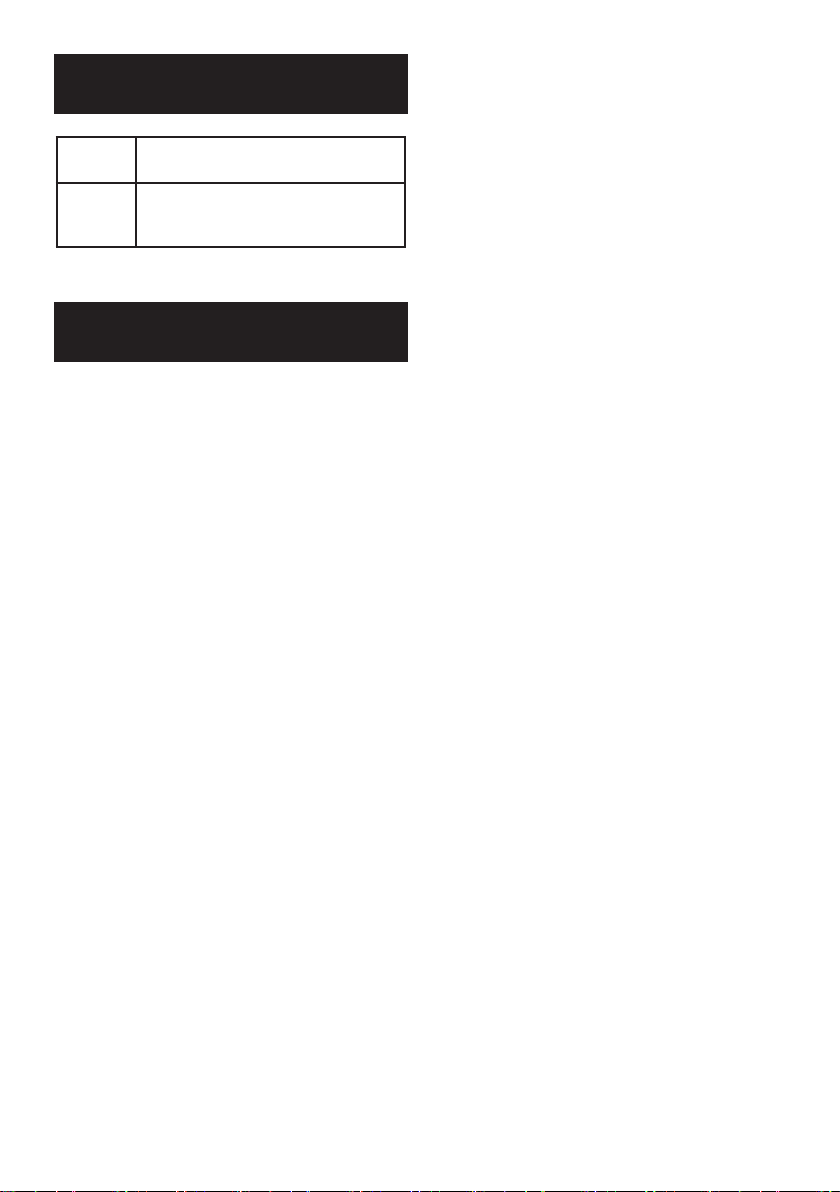

Parts List and Diagram

Part Description Qty

1 Vacuum / Pressure Gauge 1

2 Hose 1

3 Cone Adapter 1

4 Connector 1

1

Part Description Qty

51/4” Adapter (male/female) 1

61/8” Adapter (male/barbed) 1

71/8” Adapter (female/male) 1

87/32” T‑type Adapter

(not shown)

1

2

6

5

3

7

4

Page 7For technical questions, please call 1‑800‑444‑3353.SKU 93547

Page 8

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet

high quality and durability standards, and warrants to the original purchaser that this

product is free from defects in materials and workmanship for the period of 90 days

from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside

our facilities, criminal activity, improper installation, normal wear and tear, or to lack of

maintenance. We shall in no event be liable for death, injuries to persons or property,

or for incidental, contingent, special or consequential damages arising from the use

of our product. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to

us with transportation charges prepaid. Proof of purchase date and an explanation

of the complaint must accompany the merchandise. If our inspection veries

the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you

with a replacement. We will return repaired products at our expense, but if we

determine there is no defect, or that the defect resulted from causes not within the

scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may

also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Page 8 For technical questions, please call 1‑800‑444‑3353. SKU 93547

Loading...

Loading...