Page 1

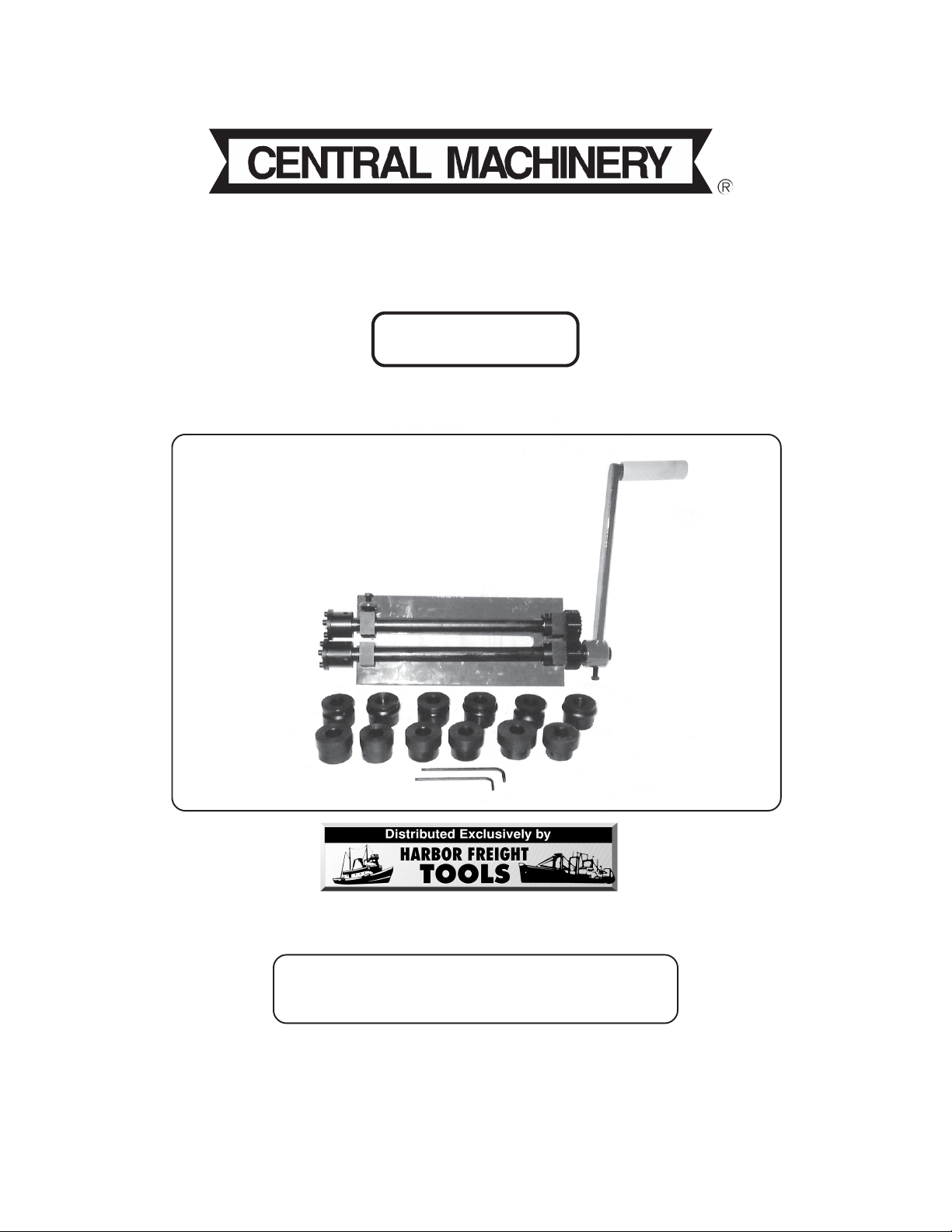

12” BEAD ROLLER KIT

®

Model 93364

ASSEMBLY AND OPERATING INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright 2005 by Harbor F reight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

©

without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

Item Description

Maximum Throat Depth Capacity 12”

Maximum Thickness Capacity 18 Gauge

Accessories 1/4”, 3/8”, 1/2” Bead Rollers

1/16”, 1/8”, 1/4” Flange Rollers

Rolling Shear

Shearing Mandrel

Base Dimensions 14-5/8” L x 6-3/8” W

Unit Weight 38.3 Pounds

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram. K eep

your invoice with this manual. Write the invoice number on the inside of the front cover.

Keep this manual and in voice in a safe and dry place for future reference.

GENERAL SAFETY RULES

When unpacking, check to mak e sure all the parts shown in the Parts List on page 11 are

included. If any parts are missing or broken, please call Harbor Freight T ools at the n umber

shown on the front cover of this manual as soon as possible.

GENERAL SAFETY RULES

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions detailed in this manual may

result in serious personal injury .

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered and dark work areas invite

accidents.

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 2

Page 3

2. Keep bystanders, children, and visitors away while operating the Bead

Roller Kit. Distractions can cause you to lose control.

PERSONAL SAFETY

3. Stay alert. W atch what you are doing, and use common sense when operating a

power tool. Do not use a power tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may

result in serious personal injury.

4. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

5. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the Bead Roller Kit in unexpected

situations.

6. Always wear ey e and hand pr otection. Wear ANSI approved safety impact

goggles and heavy duty work gloves when assembling and using this product.

TOOL USE AND CARE

7. Do not force the Bead Roller Kit. Use the correct product for your application.

The correct product will do the job better and safer at the rate for which it is

designed.

8. Store idle tools and equipment out of reach of children and other untrained

people. Tools and equipment are dangerous in the hands of untrained users.

9. Maintain the Bead Roller Kit with care. Keep this product clean. A properly

maintained tool is easier to control. Do not use damaged tools and equipment.

Tag damaged tools and equipment “Do not use” until repaired.

10. Check for misalignment or binding of moving parts, loose or broken parts,

and any other condition that may affect the Bead Roller Kit’s operation. If

damaged, have the Bead Roller Kit serviced before using. Many accidents are

caused by poorly maintained tools and equipment.

11. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one product may become hazardous

when used on another product.

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 3

Page 4

SERVICE

12. Bead Roller Kit service must be performed only by qualified service

technician. Service or maintenance performed by unqualified personnel could

result in a risk of injury .

13. When servicing the Bead Roller Kit, use only identical replacement parts.

Follow instructions in the

manual. Use of unauthorized parts or failure to follow maintenance instructions

may create a risk of electric shock or injury .

“Inspection, Maintenance, And Cleaning”

section of this

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on the Bead Roller Kit. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

2. Use the right product for the job. There are certain applications for which this

product was designed. Do not use small tools, equipment, or attachments to do

the work of larger industrial tools, equipment, or attachments. Do not use this

product for a purpose for which it was not intended.

3. Avoid moving parts during operation. Keep fingers and hands away from

gears, rollers, dies , cutting plates , and all moving parts.

4. T wo person operation. Two people are needed to operate the Bead Roller

machine. One person is needed to feed the sheet metal, while a second person

cranks the Bead Roller’s handle.

5. 18 Gauge limit. Do not use the Bead Roller on metal thicker than 18 gauge.

6. During set up and operation. Use a standard shop vise (not included) to hold

the Bead Roller assembly (see Figure A, page 5). Make sure the vise is bolted

or permanently fastened to a flat, lev el, sturdy workbench capab le of supporting

the weight of the Bead Roller, vise, workpieces, and any additional tools.

7. Industrial applications must follow OSHA requirements.

8. Store idle tools. When not in use, store the Bead Roller Kit in a clean, dry, saf e

location out of reach of children.

9. WARNING! The warnings and cautions discussed in this manual cannot

cover all possib le conditions and situations that may occur. It must be understood

by the operator that common sense and caution are factors which cannot be built

into this product, but must be supplied by the oper ator .

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 4

Page 5

INSTALLATION AND ASSEMBLY INSTRUCTIONS

1. CAUTION! The Bead Roller is heavy. Always use

two

people when lifting or

moving the tool.

2. Use a standard shop vise (not included) to securely hold the Bead Roller. Make

sure the vise is bolted or permanently fastened to a flat, level, sturdy workbench

capable of supporting the weight of the Bead Roller, vise, workpieces, and any

additional tools. (See Figure A.)

3. Once the Bead Roller is secured in a vise, align the flat inner edge of the Handle

(12) with the flat edge of the Active Roller (3). Then, slide the Handle onto the

Active Roller. (See Figure A.)

4. Use a 3/8” open end wrench to firmly tighten the Bolt (11). (See Figure A.)

ACTIVE R OLLER (3)

BOL T (11)

VISE

(NOT INCLUDED)

HANDLE (12)

FIGURE A

ALIGNMENT

NOTE: The Bead Roller has been factory pre-aligned. Howev er, depending on

use the Bead Roller may eventually require re-alignment. Poor alignment will

affect the quality of metal forming and the ability of the tool to cut sheet metal. If

you experience either of these problems, perform the following alignment steps:

1. Set up the Bead Roller with Cutting Dies (10-1, 10-2) and Cutting Plates (9) as

shown in the illustration. (See Figure B, next page.)

2. Inspect the Cutting Plates (9). When the Bead Roller is properly aligned, the

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 5

Page 6

edges of the Cutting Plates should be touching (or almost touching). If they are

not, perform the following steps:

3. Use the 4mm He x Key Wrench (27) to loosen the two He x Bolts (16) that secure

the Gear (5) and Collar (6) to the Active Roller (3). (See Figure B.)

4. Slide the Active Roller (3) until the edges of the Cutting Plates (9) are touching.

(See Figure B.)

5. By hand, move the Collar (6) so its edge is touching the Roll Block (2). Then,

re-tighten its Hex Bolt (16). (See Figure B.)

6. Mo v e the Gear (5) so its side is touching the Roll Bloc k (2). Then, re-tighten its

Hex Bolt (16). (See Figure B.)

7. NOTE: If the edges are touching and the Bead Roller does not cut material

properly, adjust the roller tension as discussed in the section

Tension”

on page 8 of this manual.

ROLL BLOCK (2)

“Adjusting Roller

CUTTING PLA TES

(9)

CUTTING DIES

(10-1, 10-2)

COLLAR (6)

GEAR (5)

FIGURE B

CHANGING ROLLERS

NOTE: The Bead Roller Kit comes with a variety of Bead Dies and Flange Dies,

as well as the Cutting Dies and Cutting Plates that are assembled onto the tool

beforeshipping. Use the following instructions when you change Dies:

To remove the Cutting Dies (10-1, 10-2) and Cutting Plates (9):

1. Use a 3/8” wrench to loosen the Thickness Adjusting Bolt (15).

(See Figure C, next page.)

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 6

Page 7

2. Use the 5mm (26) He x Key Wrench to remove the eight Hex Bolts (18) securing

the Cutting Plates (9) to the Cutting Dies (10-1, 10-2). (See Figure C.)

3. Remove the Cutting Plates (9). (See Figure C.)

4. Use a 14mm wrench to remove the two End Bolts (14) securing the Cutting Dies

(10-1, 10-2) to the Active Roller (3) and P ositiv e Roller (4). Then, remov e the

Washers (13). (See Figure C.)

5. Use the 4mm Hex Ke y Wrench (27) to loosen the Hex Bolts (16) that loc k the

Cutting Dies (10-1, 10-2) onto the Active Roller (3) and Positive Roller (4).

(See Figure C.)

6. Remove the Cutting Dies (10-1, 10-2). (See Figure C.)

THICKNESS ADJUSTING BOL T (15)

CUTTING DIES

(10-1, 10-2)

HEX

BOLTS

(18)

CUTTING

PLATES

(9)

WASHERS

(13)

ACTIVE R OLLER (3)

POSITIVE ROLLER (4)

FIGURE C

Installing Bead And Flange Dies:

1. Select the correct Bead Dies (19-1 thru 21-2) or Flange Dies (22-1 thru 24-2) for

the job you are going to perform.

2. Slide both Dies onto the Activ e Roller (3) and Positive Roller (4) at the same time.

Make sure the Hex Bolts (16) on the Dies are positioned over the flat edges of the

Active Roller and Positive Roller. (See Figure D, next page.)

3. By hand, install the tw o End Bolts (14). Then, tighten the End Bolts with a 14mm

wrench. (See Figure D.)

4. Make sure to tighten the two Hex Bolts (16) on the Dies. (See Figure D.)

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 7

Page 8

END

BOLTS

(14)

WASHERS

(13)

(19-1 THRU 24-2)

THICKNESS ADJUSTING BOL T

(15)

ACTIVE

ROLLER

(3)

ROLL BLOCK

(2)

DIES

POSITIVE

ROLLER

(4)

FIGURE D

Adjusting Roller Tension:

1. Adjust the Thickness Adjusting Bolt (15) only finger tight. (See Figure E.)

2. Use a 3/8” wrench to tighten the Thic kness Adjusting Bolt (15) 1 to 3 turns, depending on desired results. (See Figure E.)

THCKNESS ADJUSTING BOL T (15)

FIGURE E

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 8

Page 9

OPERATING INSTRUCTIONS

1. CAUTION! Do not exceed the maximum thickness capacity (18 gauge) of

the Bead Roller.

2. Always use two people to operate the Bead Roller. One person should guide the

metal along the Roller while a second person cranks the Handle (12) of the tool.

Metal forming typically requires good communication between the person

cranking the Handle and the person guiding the metal, particularly on corners.

NOTE: It is recommended to practice all cutting/beading pr ocedures first on

scrap metal. (See Figure F .)

3. Mark your rib , flange pattern, or cut-line on the workpiece. (See Figure F.)

4. Insert and guide the workpiece through the Cutting Dies or Flange Dies while

another person cranks the Handle (12) of the tool. (See Figure F.)

5. When finished using the Bead Roller Kit, make sure to store the tool and its

accessories in a clean, dry , saf e location out of reach of children.

PERSON #1

CRANKS

HANDLE

(15)

PERSON #2)

FEEDS

WORKPIECE

FIGURE F

INSPECTION, MAINTENANCE, AND CLEANING

1. Before each use, inspect the general condition of the Bead Roller Kit. Check for

misalignment or binding of moving parts, damaged or loose parts, dull or worn

Cutting Dies and Flange Dies, and any other condition that ma y affect the tool’s

safe operation. If abnormal noise or vibration occurs, have the problem cor

rected before further use. Do not use damaged equipment.

2. Periodically, use grease to lubricate all moving parts of the Bead Roller.

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 9

Page 10

3. T o clean, use a clean cloth and mild detergent or non-flammable solvent. Then,

dry.

4. CAUTION! All maintenance, service, and repairs not discussed in this

manual should only be performed by a qualified service technician.

TROUBLESHOOTING

Problem Possible Solution

Tool not cutting properly or not

forming a proper bead.

Handle turns with difficulty. Check to make sure workpiece is no thicker than 18 gauge.

Check to make sure workpiece is no thicker than 18 gauge.

Check Cutting Dies/Flange Dies for proper alignment.

Make sure all Hex Bolts are tightened.

Check Collars for proper setting and adjustment.

Check for worn Cutting Plates/Flange Dies. If necessary, replac e

Cutting Plates/Flange Dies.

Lubricate all moving parts.

Check for proper adjustment of Thickness Adjusting Bolt.

Check for damaged parts (Gears, Rollers, Dies, Flanges, etc.)

Lubricate all moving parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR W ARRANTY OF ANY KIND T O THE BUYER THAT HE

OR SHE IS QUALIFIED TO REPLA CE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUF A CTURER

AND/OR DISTRIBUTOR EXPRESSLY ST A TES THA T ALL REP AIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NO T BY THE BUYER. THE BUYER

ASSUMES ALL RISKS AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERET O, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT P AR TS THERET O.

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 10

Page 11

PARTS LIST

Part # Description Qty. Part # Description Qty.

1 Base 1 17 Bushing 1

2 Roll Block 4 18 Hex Bolt (M6x10) 8

3 Active Roller 1 19-1 ½” Half-Round Die (Convex) 1

4 Positive Roller 1 19-2 ½” Half-Round Die (Concave) 1

5 Gear 2 20-1 3/8” Half-Round Die (Convex) 1

6 Collar 2 20-2 3/8” Half-Round Die (Concave) 1

7 Roll Block Bolt (M14x30) 4 21-1 ¼” Half-Round Die (Convex) 1

8 Flat Washer (14mm) 4 21-2 ¼” Half-Round Die (Concave) 1

9 Cutting Plate 2 22-1 ¼” Flange Die 1

10-1 Long Cutting Die 1 22-2 ¼” Flange Die 1

10-2 Short Cutting Die 1 23-1 1/8” Flange Die 1

11 Bolt (M10x30) 1 23-2 1/8” Flange Die 1

12 Handle 1 24-1 1/16” Flange Die 1

13 Washer (10mm) 2 24-2 1/16” Flange Die 1

14 End Bolt (M10x20) 2 25 Spring Washer (6mm) 8

15 Thickness Adjusting Bolt (M10x30) 1 26 Hex Key Wrench (5mm) 1

16 Hex Bolt (M8x10) 18 27 Hex Key Wrench (4mm) 1

PART SELECTION GUIDE

Note: Items are larger than shown in this illustration.

1/4” HALF-ROUND DIE

(21-1, 22-2)

1/16” FLANGE DIE

(24-1, 24-2)

3/8” HALF-ROUND DIE

(20-1, 20-2)

1/8” FLANGE DIE

(23-1, 23-2)

1/2” HALF-ROUND DIE

(19-1, 19-2)

1/4” FLANGE DIE

(22-1, 22-2)

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 11

Page 12

ASSEMBLY DIAGRAM

NOTE:

and are not available individually as replacement parts.

Some parts are listed and shown for illustration purposes only ,

SKU 93364 For technical questions, please call 1-800-444-3353 PAGE 12

Loading...

Loading...