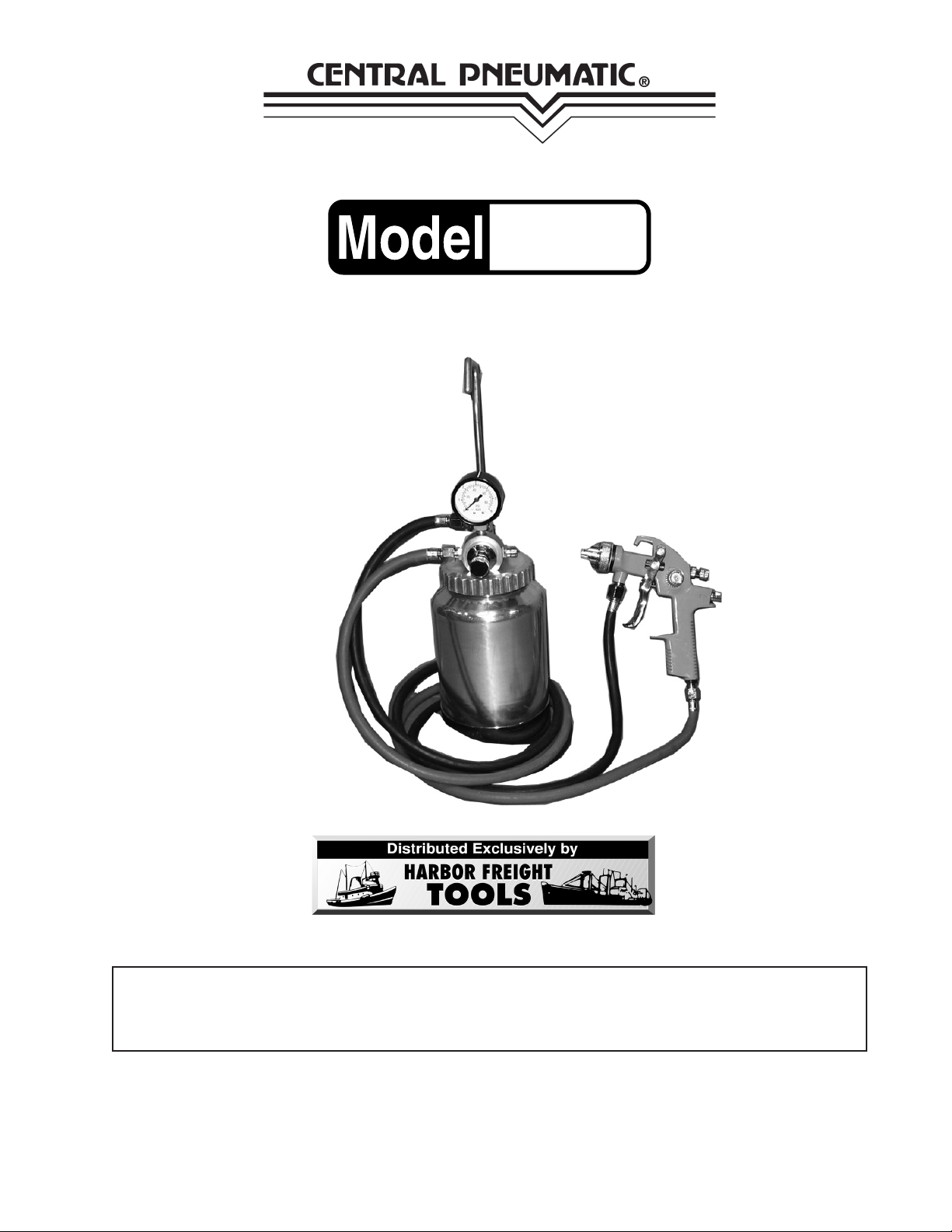

Page 1

®

HVLP SPRAY GUN KIT

93305

ASSEMBLY and OPERATING

INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools® . All rights reserved. No portion of this manual or any

artwork contained herein may be reproduced in any shape or form without the express written

consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

IMPORTANT: Before using for the rst time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

Contents

Specications ................................................................................................. 3

Safety Warnings and Precautions ................................................................ 3

Unpacking ....................................................................................................... 5

Air Connection ................................................................................................ 6

Control Layout ................................................................................................ 6

A Comparison: Conventional versus HVLP Spray Guns ............................ 7

Preparation...................................................................................................... 8

Fan Direction and Pattern Adjustment ......................................................... 8

Techniques .................................................................................................... 10

Maintenance ...................................................................................................11

Parts List ...................................................................................................... 12

Assembly Diagram ....................................................................................... 13

Troubleshooting ........................................................................................... 14

Limited 1 Year Warranty ............................................................................... 16

SKU 93305 Page 2

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 3

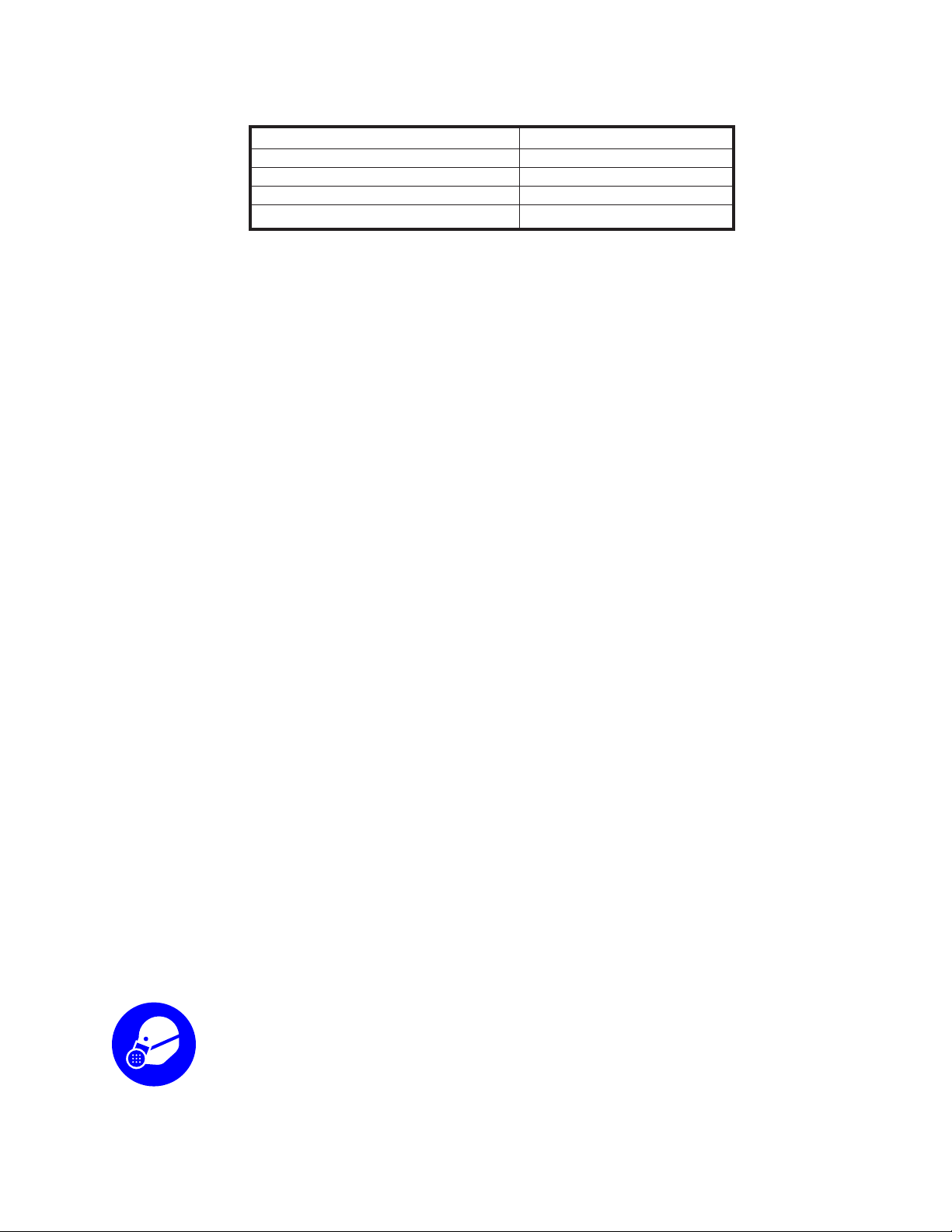

Specications

Inlet PSI 30 - 43 PSI, 43 PSI MAX

Average Air Consumption 10 CFM @ 40 PSI

Paint Capacity 2 Quart

Air Inlet 1/4” - 18 NPS

Nozzle Size .057”

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lit. Do not use air tools in the

presence of ammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, extension cords, or air hoses.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. Use the right tool for the job. Do not attempt to force a small tool or attachment

to do the work of a larger industrial tool. There are certain applications for which this

tool was designed. It will do the job better and more safely at the rate for which it was

intended. Do not modify this tool and do not use this tool for a purpose for which it was

not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes and nonskid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

7. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Always wear an ANSI approved dust mask or respirator when using this Spray

Gun.

SKU 93305 Page 3

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 4

8. Do not overreach. Keep proper footing and balance at all times. Do not reach over

or across running machines or air hoses.

9. Maintain tools with care. Keep tools clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords and air hoses

periodically and, if damaged, have them repaired by an authorized technician. The

handle must be kept clean, dry, and free from oil and grease at all times.

10. Disconnect air supply. Disconnect air hose when not in use, when changing

accessories, and during maintenance.

11. Remove adjusting wrenches. Check that adjusting wrenches are removed from the

tool before attaching to the air source.

12. Avoid unintentional starting. Be sure the trigger is in the Off position when not in

use and before attaching to the air source. Do not carry any tool with your nger on

the trigger, whether it is attached to the air compressor or not.

13. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

14. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting xtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualied technician. Do

not use the tool if the trigger does not operate properly.

15. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

16. Do not operate tool if under the inuence of alcohol or drugs. Read warning labels

if taking prescription medicine to determine if your judgement or reexes are impaired

while taking drugs. If there is any doubt, do not operate the tool.

17. Use proper size and type extension cord. If an extension cord is required for the

compressor, it must be of the proper size and type to supply the correct current to the

compressor without heating up. Otherwise, the extension cord could melt and catch

re, or cause electrical damage to the compressor. Check your compressor’s manual

for the appropriate size cord.

18. Maintenance. For your safety, maintenance should be performed regularly by a qualied

technician and the unit must be thoroughly cleaned out after every use. Improper

cleaning of the Spray Gun is a common reason for the Spray Gun to jam or not

perform properly.

19. Compressed air only. Never use combustible gas as a power source. Never exceed

the recommended operating pressure of the any of the parts (i.e. hoses, ttings, gun)

SKU 93305 Page 4

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 5

of the Sprayer system.

20. Do not spray near open ames, pilot lights, stoves, heaters, the air compressor, or

any other heat source. Most solvents and coatings are highly ammable, particularly

when sprayed. Maintain a distance of at least 25 feet from the air compressor. If possible,

locate the air compressor in a separate room. Do not smoke while spraying.

21. Read all of the information concerning coating products and cleaning solvents.

Chlorinated solvents (e.g. 1-1-1 Trichlorethylene and Methylene Chloride, also known

as methyl chloride) can chemically react with aluminum and may explode. Many paint

sprayers contain aluminum. If you have any doubt about potential chemical reactions,

contact the solvent or coating manufacturer.

22. Materials used when painting or cleaning may be harmful or fatal if inhaled or

swallowed. Only use in an area with adequate ventilation. Use a respirator or mask

when painting or using cleaning solvents.

23. Never release the sprayer lid while the cup is pressurized.

24. Industrial applications must follow OSHA requirements.

25. Never point a spray gun at a person or animal. Serious injury could occur.

26. Spraying hazardous materials may result in serious injury or death. Do not spray

pesticides, acids, corrosive materials, fertilizers, and toxic chemicals.

27. WARNING: The brass components of this product contain lead, a chemical known to

the State of California to cause birth defects (or other reproductive harm).

(California Health & Safety Code § 25249.5, et seq.)

Note: Performance of the compressor (if powered by line voltage) may vary depending

on variations in local line voltage. Extension cord usage may also affect tool perfor-

mance.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator.

Unpacking

When unpacking, check to make sure the product is intact and undamaged. If any parts

are missing or broken, please call Harbor Freight Tools at the number on the cover of this

manual as soon as possible.

SKU 93305 Page 5

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 6

Air Connection

For best service you should incorporate a regulator and inline lter, as shown in the diagram

above. Hoses, couplers, regulators, and lters are all available at Harbor Freight Tools.

Note: Compressor pumps discharge condensed water, oil, or other contaminants along with

the compressed air. Condensation causes “sh eyes” to appear in paint patterns. To avoid

this problem, install water/oil removal lters and controls (not included) as close to the Spray

Gun as possible. If run through the Gun, water and oil will cause damage.

1. You will need to prepare a 1/4” air connector (sold separately) to connect to the air inlet

on the Spray Gun. First, wrap the 1/4” air connector (not included) with pipe thread

seal tape before threading it into the Air Inlet (36). Connect the Red Air Hose (41) to

the Air Outlet Connector (36). Attach the other end of the Red Air Hose (41) to the Air

Inlet (80) on the Gun.

2. Set the air pressure on your compressor to 30-43 PSI. Do not exceed the maximum

air pressure of 43 PSI. Also, set the air pressure on the Air Regulator to 10-30 PSI, as

shown on the Gauge (38).

3. Check the air connection for leaks and then disconnect the tool from the air source.

Control Layout

Air Adjustment Knob (73)

FIGURE 1

Air Cap Set (45)

Fluid Inlet

Trigger (78)

Pattern Control Knob (57)

Fluid Control Knob (67)

Air Inlet (80)

SKU 93305 Page 6

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 7

IMPORTANT: Before using for the rst time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

FIGURE 2

Fluid Outlet (39)

Safety Valve (2)

Fluid Flow Knob (11)

Air Outlet Connector (36)

Air Inlet Connector (36)

Air Regulator (24)

A Comparison: Conventional versus HVLP Spray Guns

Because conventional spray guns require a much higher air cap pressure to atomize

the paint than HVLP Spray Guns, conventional guns have lower transfer efciencies

and more overspray.

This translates to a signicant paint/material savings for HVLP guns, in addition to

making them more environmentally friendly.

To qualify as HVLP, the dynamic air pressure going in the Air Cap must be a maximum

of 10 PSI. The lower the air pressure, the less bounce back and overspray.

Note: Due to the viscosity of latex and other water-based paints, they are not

recommended for use with this or other HVLP (High Volume Low Pressure) sprayers.

See FIGURE 3 below.

FIGURE 3

SKU 93305 Page 7

For technical questions, please call 1-800-444-3353;

Conventional

HVLP

Troubleshooting section at end of manual.

Page 8

IMPORTANT: Before using for the rst time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

Preparation

Note: Proper paint material mixture helps to ensure less problems. Be sure to follow the manu-

facturer’s directions. Most materials will spray readily if they are thinned properly.

General tips for Preparation:

1. Mix and thin the paint/materials thoroughly according to the manufacturer’s

directions.

2. Carefully strain the paint/material through a paint strainer or piece of cheese cloth.

3. Remove (un-thread) the Cup (16) from the Unit. Fill the Cup (16) to approximately 3/4

full. Thread it back onto the unit. Connect the Fluid Hose (40) form the Fluid Outlet

(39) to the Fluid Inlet on the Spray Gun.

4. Start the air compressor.

5. To adjust the spray pattern, set up a piece of scrap material to practice on. While

practicing on the scrap material, check to see that the material you are spraying has

the appropriate consistency. If it appears to thin, add a very small amount of thinner

(not included). BE CAREFUL when thinning. Proceed slowly, adding very minimal

amounts. NEVER exceed the manufacturer’s thinning recommendations.

Fan Direction and Pattern Adjustment

Fan Direction

To change the direction of the fan from horizontal to vertical, loosen the Lock Ring and

turn the Air Cap (45) 90 degrees. After the adjustment, tighten the Lock Ring by hand.

See FIGURE 4 below.

Lock Ring

FIGURE 4

Air Cap

Horizontal Fan

Vertical Fan

SKU 93305 Page 8

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 9

IMPORTANT: Before using for the rst time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

Pattern Adjustment

Warning!! Never exceed the Maximum Inlet PSI of 43 PSI.

1. Adjust the Gauge (38) pressure to 10-30 PSI using the Air Regulator (24). If you need

to reduce the air pressure for specic areas, adjust the Air Adjustment Knob (73).

2. To set the pattern size specic to the job, use the Pattern Control Knob (57) (see FIG-

URE 1 on page 6). By turning it counterclockwise (all the way open), the pattern will

atten. Turn the Pattern Control Knob (57) clockwise for a round pattern.

See FIGURE 5 below.

FIGURE 5

Flat/Open Round/Closed

3. Close the Fluid Control Knob (67) and fully open the Fluid Flow Knob (11). See FIGURE

1 on page 6.

4. After setting up a piece of scrap material, squeeze the Trigger (78) in short bursts while

turning the Fluid Control Knob (67) counterclockwise and observe the spray patterns

until you see the pattern you want. Also, look at the pattern for consistency. Too much

air may cause the spray to come out too ne. Reduce the air pressure or allow more

material to come out by opening the Fluid Control Knob (67). If the spray appears too

thick (you see globs of paint), close down the Fluid Control Knob (67) slowly, checking

the mixture after each adjustment.

See FIGURE 6 below.

FIGURE 6

Too Coarse

(Tighten)

Correct

Too Fine

(Loosen)

SKU 93305 Page 9

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 10

IMPORTANT: Before using for the rst time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

Techniques

Note: Before spraying, mask all objects you do not want sprayed and lay cloths (not included)

on the oors.

1. Always keep the gun at right angles to the workpiece (See FIGURE 7). Pull the Trigger

(78) slowly and move the Spray Gun in parallel strokes to the object being painted.

Keep the distance from the object being painted at 6” to 9”. This may slightly differ

depending on the ow adjustment and the material being sprayed. Do not stop the

gun movement while spraying. If you stop the gun for even just a slight pause while

spraying, the paint will build up and run down the workpiece.

FIGURE 7

(Heavier coat on one

side, uneven coverage)

Incorrect

(Even coverage)

Correct (90o)

2. To ensure you don’t allow paint to build up, start moving the Spray Gun before you

Squeeze the Trigger (78). When you are nished spraying, release the Trigger (78)

before you stop moving the Spray Gun. Doing so will eliminate distinct overlaps,

producing a blended (feathered) affect. See FIGURE 8 below.

Begin

Stroke

Squeeze

Trigger (78)

FIGURE 8

(Top View)

Release

Trigger (78)

End

Stroke

Note: The speed of the stroke, the adjustment of the Fluid Control Knob (67), and the distance

from the workpiece, will determine how much paint is being applied. To get the best

results, try to apply two thin coats of paint versus one thick coat.

3. Clean out the gun thoroughly after EVERY use, according to the instructions

found on the next page.

SKU 93305 Page 10

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 11

Maintenance

SOLVENT SELECTION

Always follow the paint manufacturer’s recommendations for cleaning,

solvent type, and disposing of used solvent.

Note: Due to the viscosity of latex and other water-based paints, they are not recom-

mended for use with this or other HVLP (High Volume Low Pressure) sprayers.

Oil Based Paints: Use mineral spirits.

IF A FLAMMABLE SOLVENT NEEDS TO BE USED, ADHERE TO THE FOLLOWING:

1. Follow all of the solvent manufacturer’s clean up instructions and

safety precautions at all times.

2. Always ush the Spray Gun a full hose length from the air compressor.

3. If collecting ushed solvents into a metal container, transfer into a larger

nonmetal container, and ush the metal container.

4. Work far away from any ignition sources in a vapor free area.

After each use:

1. Empty the Paint Cup (16) and clean it with the solvent.

2. Fill the Paint Cup (16) with solvent and spray it through the Gun into a container, while

shaking the gun. Once the Paint Cup (16) is empty, repeat the process until the solvent

comes out clean.

Disconnect from the air source. After disconnecting, be aware that air pressure

may still remain in the Spray Gun. Point the Gun into the spent solvent container and

squeeze the Trigger again to make sure no air remains.

3. Remove the Air Cap and soak it in solvent until it is clean. Use an old toothbrush and

toothpicks to remove any material. Do not use metal objects to clean the Air Cap

or you may damage the drilled passages. Inspect the uid needle and make sure

it is not bent. If it is bent, have it replaced by a certied service technician.

Warning!! Do not immerse the Spray Gun Body in solvent!

4. Use the appropriate solvent (depending on the material sprayed) to wipe down the Gun

body.

5. Always lubricate the Spray Gun after cleaning. You may use a non-silicon oil or a light

lubricant on all threaded connections prior to storing the unit.

6. Disposal: After cleaning your Spray Gun, properly dispose of your cleaning solutions

according to the solution manufacturer’s direction and local hazardous waste

standards.

SKU 93305 Page 11

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 12

Parts List

Part Description Part Description

1 Handle 40 Fluid Hose

2 Safety Valve 41 Air Hose (Red)

3 Lock Nut 42 Ring

4 Spring 43 Lock Ring

5 Valve 44 Gasket

6 Valve Gasket 45 Air Cap Set

7 Valve Seat 46 Fluid Nozzle

8 Connector 47 Seat

9 Screw 48 Sealing Gasket

10 Nut 49 Packing Nut

11 Fluid Flow Knob 50 Sealing Screw

12 Spring 51 Gasket

13 Cap 52 Gun Body

14 Suction Tube 53 Needle

15 Gasket 54 Needle Adapter

16 Cup 55 Spring

17 Rivet 56 Fixed Screw

18 Gasket 57 Pattern Control Knob

19 Tube 58 Rivet

20 Screw 59 Gasket

21 Spring 60 Sealing Screw

22 Rivet (Qty. 2) 61 Adjusting Level

23 E-clip 62 Valve Seat

24* Air Regulator 63 Spring

25* Lock Nut 64 Rivet

26* Air Adjusting Seat 65 Air Adjusting Valve

27* Spring Seat 66 O-ring

28* Air Adjusting Seat 67 Fluid Control Knob

27* Spring Seat 68 Gasket

28* Air Adjusting Screw 69 E-clip

29* Sealing Nut 70 Fan Adjusting Screw

30* Sealing Gasket 71 Fan Adjusting Stopper

31* Valve Gasket 72 O-ring

32* Nut 73 Air Adjustment Knob

33* Needle Seat 74 Rivet

34* Air Needle 75 E-clip

35* Spring 76 Trigger Stud

36 Connector (Qty. 2) 77 Trigger Stud

37* Gauge Seat 78 Trigger

38 Gauge 79 Fluid Connector

39 Fluid Outlet Valve 80 Air Inlet

*Parts 24 through 35 and 37 are available as a kit.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED

AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 93305 Page 12

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 13

Assembly Diagram

80

40

41

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

SKU 93305 Page 13

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

REV 01/07

Page 14

Troubleshooting

Spray Pattern Diagnosis

The Patterns below resemble symptoms of spray pattern problems. Please refer to

the accompanying possible problems if you are experiencing similar difculties. The

solution to each problem follows the problem in parentheses.

Problem 1:

1. The Pattern Control Knob (57) is partially closed. (Open Pattern Control Knob (57).)

2. The material is too thick. (Thin material according to the manufacturer’s instructions.)

3. The air pressure is too low. (Increase air pressure. Make sure air pressure feeding into

the pot is within the proper range (30-43 PSI) & air pressure as shown on the Gauge (38)

is within the proper range (10-30 PSI).)

Problem 2:

1. High air pressure. (Reduce air pressure at gun.)

2. Not enough uid. (Increase uid.)

3. Pattern Control Knob (57) open too much. (Partially close Pattern Control Knob (57).)

Problem 3:

1. Air Cap plugged. (Clean the Air Cap.)

2. Air cap loose or dirty seat. (Clean and tighten.)

3. Dried material on uid tip. (Use a nonmetallic point to clean the Air Cap.)

Problem 4:

1. Dirt on one side of the uid tip. (Clean the uid tip.)

2. Holes on one side of the Air cap are plugged. (Clean the Air cap with a nonmetallic

point.)

If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualied technician.

For technical questions, please call 1-800-444-3353.SKU 93305 Page 14

Page 15

Troubleshooting (continued)

Problem Cause Solution

Sputtering Spray Low material level1.

Will Not Spray No pressure at gun1.

Overspray Improper application speed1.

Fluid Tip Leakage Dirty tip1.

Air Leaking from Air Cap Dirty air valve/seat1.

Fluid Leaking from Packing Nut Packing Nut loose1.

Cup tipped too far2.

Clogged Air Vent3.

Loose uid inlet connections4.

Dry or loose uid needle 5.

Packing Nut

Loose/damaged uid tip/seat6.

Fluid control not open enough2.

Fluid too thick3.

Improper distance from 2.

workpiece

Too much pressure3.

Tight Packing Nut2.

Broken uid needle spring3.

Worn or damaged tip4.

Sticking air valve2.

Damaged air valve spring3.

Worn/damaged air valve/seat 4.

Bent valve stem5.

Packing worn or dry2.

Rell1.

Hold upright2.

Clean vent hole3.

Tighten4.

Lubricate and/or tighten5.

Adjust or replace6.

Check air hoses1.

Open uid control2.

Thin uid or increase pressure 3.

(within Maximum range)

Move moderately and parallel1.

Adjust distance 2.

Reduce air pressure3.

Clean1.

Loosen Packing Nut2.

Replace3.

Replace tip and/or needle4.

Clean1.

Lubricate2.

Replace3.

Replace 4.

Replace5.

Tighten without restricting1.

Replace or lubricate (non-2.

silicone)

If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualied technician.

For technical questions, please call 1-800-444-3353.SKU 93305 Page 15

Page 16

LIMITED 1 YEAR WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is

free from defects in materials and workmanship for the period of one year from the date of

purchase (90 days if used by a professional contractor or if used as rental equipment). This

warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence

or accidents, repairs or alterations outside our facilities, normal wear and tear, or to lack

of maintenance. We shall in no event be liable for death, injuries to persons or property,

or for incidental, contingent, special or consequential damages arising from the use of our

product. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation of exclusion may not apply to you. THIS WARRANTY IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection veries the defect, we will either repair

or replace the product at our election or we may elect to refund the purchase price if we

cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then you must bear the cost of returning the

product.

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

SKU 93305 Page 16

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

REV 08c

Loading...

Loading...