Page 1

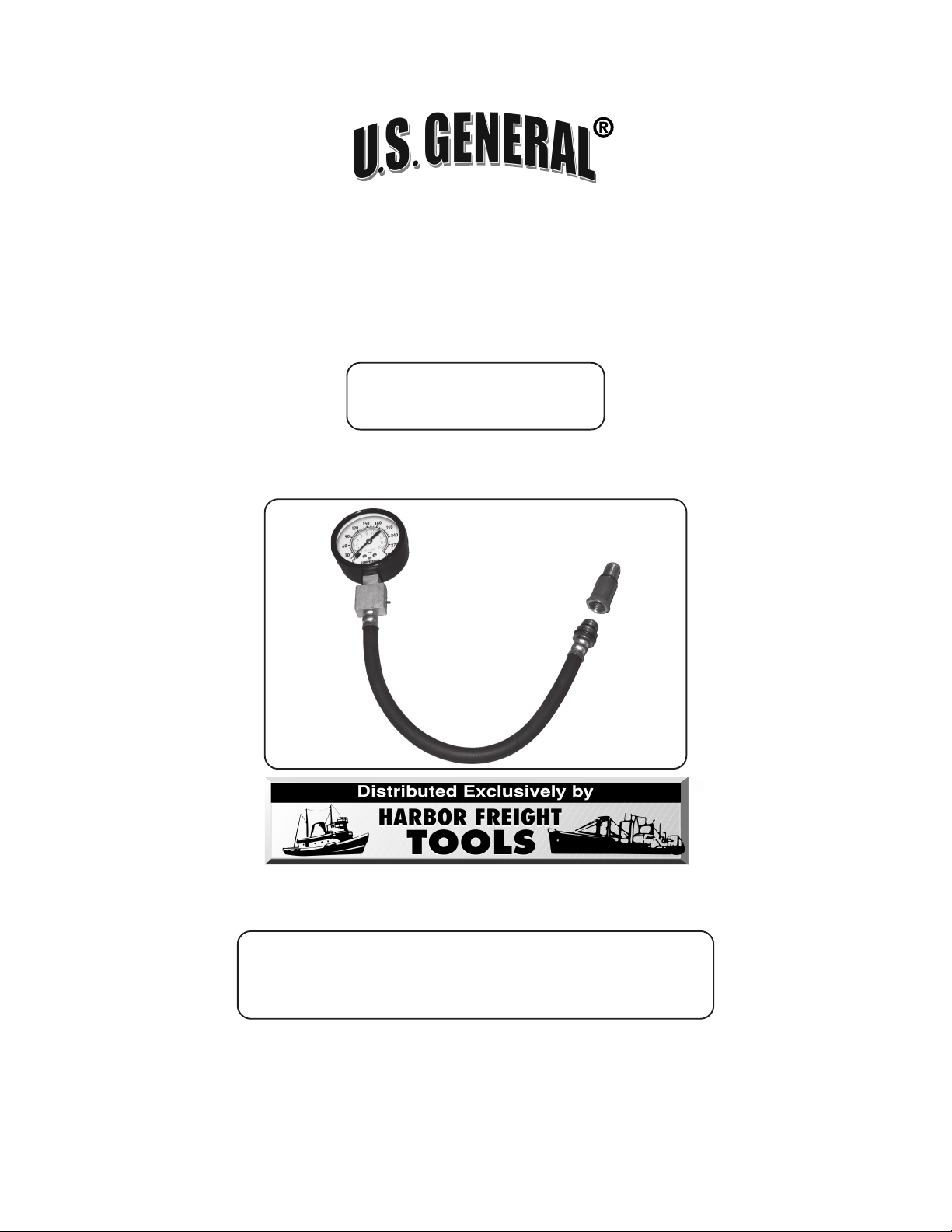

FLEX DRIVE

®

COMPRESSION TESTER

Model 92697

OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor F reight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

PRODUCT SPECIFICATIONS

metInoitpircseD

elacSerusserPISP003>-<0

epyTesaeleRriAnottuBhsuP

retemaiDeguaG-2

gnittiFesoHgniR-Ohtiw)elam(52.1-41M

retpadA ;gnir-Ohtiw)elam(5.1-81M/)elameF(52.1-41M:retpadAtrohS

eziSesoH

thgieWtinUsdnuoP7.0

9

/

61

1

/

4

5

-2/retemaiD"

/

8

gnoL"21x"

retemaiDlezeB"

gniR-Ohtiw)elaM(52.1-41M/)elameF(52.1-41M:retpadAgnoL

Note: Accuracy of the Gauge is ± 2%.

UNPACKING

When unpacking, check to mak e sure all the parts shown on the Figure A on page 5 are

included. If any parts are missing or broken, please call Harbor Freight T ools at the n umber

shown on the cover of this manual as soon as possible.

SAVE THIS MANUAL

You will need this manual for the safety war nings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY PRECAUTIONS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed in the following

pages may result in serious injury.

SA VE THESE INSTRUCTIONS

REV 05/05

Page 2SKU 92697 For technical questions, please call 1-800-444-3353.

Page 3

GENERAL SAFETY RULES

1. Keep your work area clean and well lit. Cluttered work areas invite accidents.

2. Do not operate tools and equipment in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. T ools and equipment create

sparks which may ignite flammables.

3. Keep bystanders, children, and visitors away while operating tools and

equipment. Distractions can cause you to lose control. Protect others in the work

area. Provide barriers or shields as needed.

4. Stay alert. Watch what y ou are doing, and use common sense when operat-

ing tools and equipment. Do not use tools and equipment while tired or

under the influence of drugs, alcohol, or medication. A moment of inattention

while operating tools and equipment may result in serious personal injury.

5. Dress properly. Do not wear loose c lothing or jewelry. Contain long hair .

Keep your hair, clothing, and gloves away from mo ving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

6. Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the tool in unexpected situations.

7. Use safety equipment. Always wear ANSI approved safety impact goggles

when using this product.

8. Do not force the tool. Use the correct tool for your application. The correct

tool will do the job better and safer at the rate for which it is designed.

9. Store idle tools and equipment out of reach of children and other untrained

persons. Tools and equipment are dangerous in the hands of untrained users .

10. Maintain tools with care. Do not use a damaged tool. Tag damaged tools “Do

not use” until repaired.

11. If damaged, have the tool serviced before using. Check for loose screws,

misalignment or binding of moving parts, loose mounting, cracked or broken

parts, and any other condition that may affect its saf e oper ation. Many accidents

are caused by poorly maintained tools.

12. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous

when used on another tool.

Page 3SKU 92697 For technical questions, please call 1-800-444-3353.

Page 4

13. Tool service must be perf ormed onl y by qualified repair per sonnel. Service

or maintenance performed by unqualified personnel could result in a risk of injury.

14. When servicing a tool, use only identical replacement parts. Follow instruc-

tions in the

Use of unauthorized parts or failure to follow maintenance instructions may create

a risk of injury.

“Inspection, Maintenance, And Cleaning”

section of this manual.

SPECIFIC SAFETY RULES

1. WARNING! Do not e xceed the maxim um pressure capacity of this tool

(300 PSI). Exceeding the maximum pressure capacity could cause serious

personal injury and/or property damage.

2.

3. Maintain labels and nameplates on the Compression Tester . These carry

4. Prior to using the Compression Tester, make sure to read and understand all

5. When warming up an engine in preparation for compression testing, make

6. Always keep hands and fingers away from the moving parts and hot parts of

7. WARNING! The br ass components of this product contain lead, a chemical

WARNING! Use the Compression T ester onl y in well ventilated areas. A

running gasoline engine produces carbon monoxide. Carbon monoxide fumes

are a colorless, odorless, gas that, if inhaled, can cause serious injury or

death.

important information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

warnings, safety precautions, and instructions as outlined in the

manufacturer’ s instruction manual for the engine y ou will test.

sure the vehicle’ s transmission is placed in “PARK”, (or neutral for a manual

transmission) and the emergency brake is applied.

the vehicle’ s engine.

known to the State of California to cause cancer and birth defects (or other reproductive harm). (California Health & Safety Code § 25249.5,

et seq.

)

8. WARNING! People with pacemakers should consult their physician(s) before

using this product. Electromagnetic fields in close proximity to a heart pacemaker

could cause interference to or f ailure of the pacemak er. In addition, people with

pacemakers should adhere to the following: Caution is necessary when near the

coil, spark plug cables, or distributor of a running engine. The engine should

always be off if adjustments are to be made to the distrib utor .

Page 4SKU 92697 For technical questions, please call 1-800-444-3353.

Page 5

9. WARNING! The warnings, precautions, and instructions discussed in this

manual cannot cover all possible conditions and situations that may occur. The

operator must understand that common sense and caution are factors, which

cannot be built into this product, but must be supplied b y the operator.

OPERATING INSTRUCTIONS

1. NOTE: Performing a compression test requires the work of

two

individuals; one

person to operate the vehicle’s ignition switch while the other person operates the

Compression T ester .

2. The Compression Tester features a Hose Fitting that may be used for 18mm spark

plug holes and an adapter to allow it to fit 14mm holes. (See Figure A.)

3. To perf orm a typical compression test, prepare the engine for compression testing

by starting the engine and allowing it to warm up to its normal operating temperature.

Then, switch off the ignition.

WARNING! Avoid carbon monoxide poisoning! Never run a gasoline engine in an enclosed garage or other contained area.

4. Once the engine has been turned off, disconnect both coil wires from the coil of

the engine, and remove all of the spark plugs. Note: Insulate coil wires or route

them away from each other and all metal surfaces. Make note of which spark plug

wires go to each spark plug locations. (See Figures B and C, next page.)

GA UGE

FIGURE A

AIR RELEASE

BUTTON

HOSE

14mm

ADAPTER

18mm

FITTING

Page 5SKU 92697 For technical questions, please call 1-800-444-3353.

Page 6

5. If desired, attach the Adapter to the Hose Fitting. (See Figure A.)

6. Connect the Compression Tester to the first cylinder of the engine. With the fuel

pedal depressed all the way down, crank the engine for at least eight revolutions.

(See Figure C.)

7. While cranking the engine, observe and record the maximum reading on the

Gauge of the Compression Tester. (See Figure C.)

8. Once the maximum reading has been recorded, discontinue cranking the engine.

Then, release the air pressure in the Gauge by pressing the Air Release Button.

(See Figure C.)

9. Remo v e the Compression Tester from the first engine cylinder. Then repeat Steps

#6, #7, #8 for the remaining engine cylinders. (See Figures B and C.)

10. NOTE: Good engine cylinder compression will be indicated with a high initial

reading, and a progressive b uildup to the final maximum reading. Poor engine

cylinder compression will be indicated with a low initial reading, and a much

slower buildup to the final maximum reading. The compression readings for all of

the engine cylinders should not vary by more than 10%. Note: Check your

owner’s or maintenance manual for acceptable pressure ranges.

FIGURE B

REMOVE

SP ARK PLUGS

FIGURE C

COIL

COIL WIRES

GAUGE

AIR RELEASE BUTTON

Page 6SKU 92697 For technical questions, please call 1-800-444-3353.

Page 7

INSPECTION, MAINTENANCE, AND CLEANING

1. Before each use, inspect the general condition of the Compression Tester.

Check for broken, cracked, or bent parts, loose or missing parts, and any condition that may affect the proper operation of the product. If a problem occurs,

have the problem corrected before further use.

Do not use damaged equipment.

2. When cleaning, use a clean cloth with a mild detergent. Do not use solvents,

as damage to the Compression Tester ma y result. Do not immerse the Gauge in

any liquid. Then, store the Compression Tester in a safe, dry location out of reach

of children and other unauthorized people.

3.

WARNING! All maintenance, service, or repairs not listed in this manual

are only to be attempted by a qualified service technician.

Replacement parts are not available for this item.

Page 7SKU 92697 For technical questions, please call 1-800-444-3353.

Loading...

Loading...