Page 1

PLASMA AIR CUTTERPLASMA AIR CUTTER

®

PLASMA AIR CUTTER

PLASMA AIR CUTTERPLASMA AIR CUTTER

230 VOL230 VOL

230 VOL

230 VOL230 VOL

TECHNOLOGYTECHNOLOGY

TECHNOLOGY

TECHNOLOGYTECHNOLOGY

TT

, INVER, INVER

T

, INVER

TT

, INVER, INVER

TERTER

TER

TERTER

92652

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 MISSION OAKS BLVD., CAMARILLO, CA 93011

VISIT OUR WEB SITE AT HTTP://WWW.HARBORFREIGHT.COM

Copyright

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

©

2005 by Harbor Freight Tools®. All rights reserved. No portion of this

Page 2

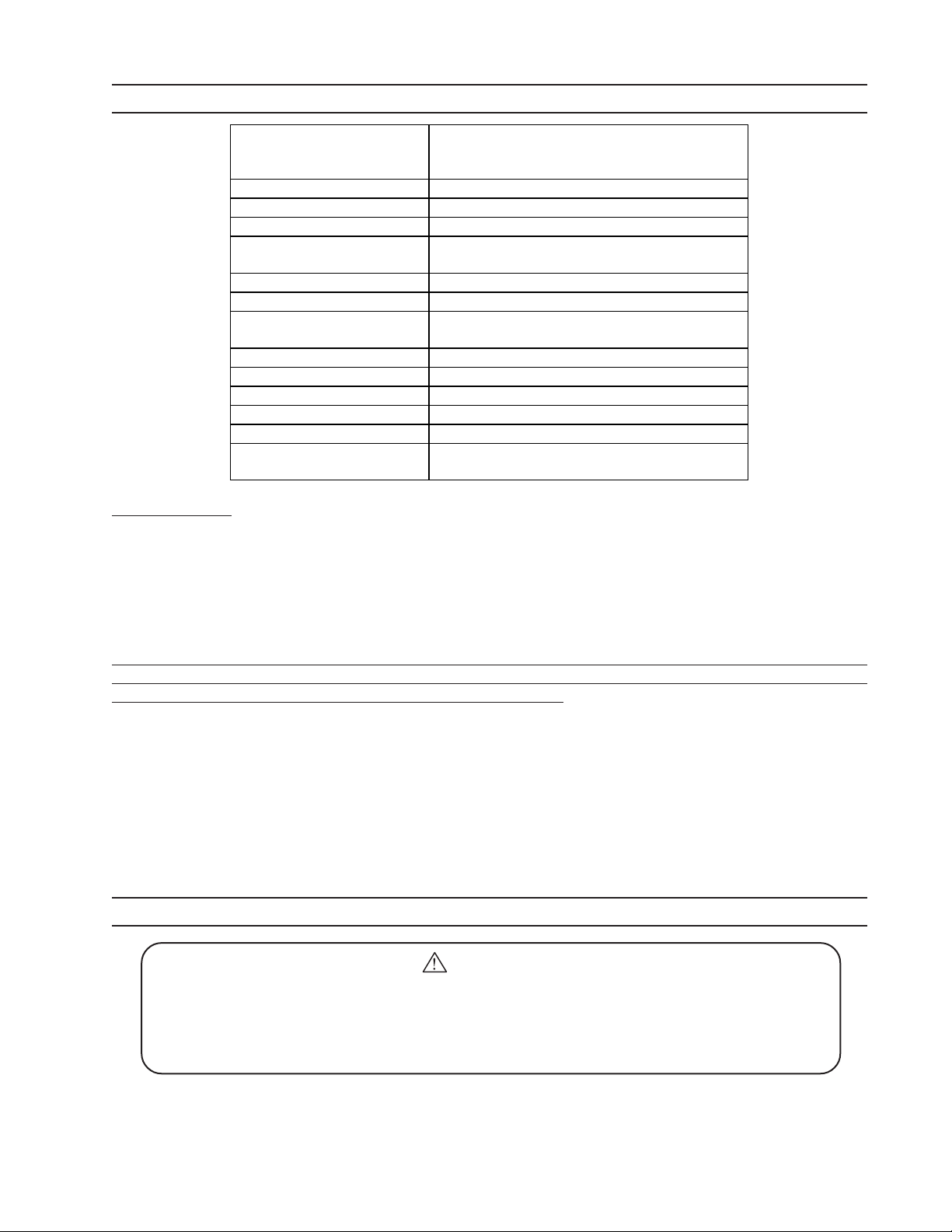

SPECIFICATIONS

Power Consumption 230 VAC, 50/60 Hz, single phase,

40 amp dedicated circuit required for

maximum output

Cutting Capacity Plate Steel 5/64” to 1/2"

Cutting Current 15 to 40 Amps

Rated Duty Cycle 35% at 40 Amps

Line Cord 7’ 5” (L) (without 220 VAC twist plug);

12 AWG x 3-C

Arc Torch Cable 16’ (L)

Ground Cable 9’ 7-3/4” (L) with clamp

Air Requirement 60 to 100 PSI, (maximum), dry compressed

air, 3.5 CFM

Arc Striking System Pilot arc

Power Switch Rocker type, lighted

Fuse Internal: 0.5A

Overall Dimensions 16-3/4” (L) x 14-3/4” (H) x 8-1/8” (W)

Weight 36.6 lb.

Accessories - Inlet air regulator

- Shoulder strap

DUTY CYCLE is a welding or cutting, equipment specification, which defines the number of

minutes, within a 10-minute period, that a given piece of equipment can safely weld or cut at

its rated load without overheating.

For example, if a welder or cutting type piece of equipment is rated at a 40% duty cycle at 36

amps, that particular piece of equipment must be “rested” for at least 6 minutes after 4 minutes

of continuous welding or cutting.

Failure to carefully observe duty cycle limitations can easily over stress the power

generation systems of a piece of equipment contributing to the premature failure of that

piece of equipment and the voiding of the warranty.

SAVE THIS MANUAL

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow all instructions

listed below may result in electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

REV 08/05; 10/06

Page 2SKU 92652 For technical questions, please call 1-800-444-3353

Page 3

Work Area

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control. Protect others in the work area from debris

such as chips and sparks. Provide barriers or shields as needed.

Electrical Safety

4. Avoid body contact with grounded surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

5. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

6. Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any way. Do not use any adapter plugs. Check with

a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

7. Do not abuse the Power Cord. Never use the Power Cord to carry the tools or

pull the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp

edges, or moving parts. Replace damaged Power Cords immediately. Damaged

Power Cords increase the risk of electric shock.

8. When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These extension cords are rated for outdoor use, and reduce the risk of

electric shock.

Personal Safety

9. Stay alert. Watch what you are doing, and use common sense when operating a

power tool. Do not use a power tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may

result in serious personal injury.

10. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from arc. Loose clothes, jewelry, or long hair

can catch fire.

11. Avoid accidental starting. Be sure the Power Switch is off before plugging in.

Carrying power tools with your finger on the Power Switch, or plugging in power tools

with the Power Switch on, invites accidents.

Page 3SKU 92652 For technical questions, please call 1-800-444-3353

Page 4

12. Remove adjusting keys or wrenches before turning the power tool on. A wrench

or a key that is left attached to a rotating part of the power tool may result in personal

injury.

13. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

14. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

15. Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

16. Do not force the tool. Use the correct tool for your application. The correct tool

will do the job better and safer at the rate for which it is designed.

17. Do not use the power tool if the Power Switch does not turn it on or off. Any tool

that cannot be controlled with the Power Switch is dangerous and must be replaced.

18. Disconnect the Power Cord Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

19. Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

20. Maintain tools with care. Keep tools in good repair. Properly maintained tools will

get the job done better. Do not use a damaged tool. Tag damaged tools “Do not use”

until repaired.

21. Check for breakage of parts, and any other condition that may affect the tool’s

operation. If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

22. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous when

used on another tool.

Service

23. Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

24. When servicing a tool, use only identical replacement parts. Follow instructions

in the

unauthorized parts or failure to follow maintenance instructions may create a risk of

electric shock or injury.

“Inspection, Maintenance, And Cleaning”

section of this manual. Use of

Page 4SKU 92652 For technical questions, please call 1-800-444-3353

Page 5

SPECIFIC SAFETY RULES FOR THIS PRODUCT

1. Maintain labels and nameplates on the Air Plasma Cutter. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a replacement.

2. Maintain a safe working environment. Keep the work area well lit. Make sure there

is adequate surrounding workspace. Always keep the work area free of obstructions,

grease, oil, trash, and other debris. Do not use a power tool in areas near flammable

chemicals, dusts, and vapors. Do not use this product in a damp or wet location.

3. Avoid unintentional starting. Make sure you are prepared to begin work before

turning on the Air Plasma Welder/Cutter.

4. Unplug before performing maintenance. Always unplug the Plasma Welder/Cutter

from its electrical outlet before performing and inspection, maintenance, or cleaning

procedures.

5. Never leave the Plasma Welder/Cutter unattended while energized. Turn power off

if you have to leave the Air Plasma Cutter.

6. Maintain a safe working environment. Keep the work area well lit. Make sure there

is adequate surrounding workspace. Always keep the work area free of obstructions,

grease, oil, trash, and other debris.

7. Prevent eye injury and burns. Wearing and using ANSI approved personal safety

clothing and safety devices reduce the risk for injury.

• Wear ANSI approved safety impact eye goggles with a welding helmet featuring at

least a number 10 shade lens rating.

• Leather leggings, fire resistant shoes or boots should be worn when using this

product. Do not wear pants with cuffs, shirts with open pockets, or any clothing that

can catch and hold molten metal or sparks.

• Keep clothing free of grease, oil, solvents, or any flammable substances. Wear dry,

insulating gloves and protective clothing.

• Wear an approved head covering to protect the head and neck. Use aprons, cape,

sleeves, shoulder covers, and bibs designed and approved for welding and cutting

procedures.

• When welding/cutting overhead or in confined spaces, wear flame resistant ear

plugs or ear muffs to keep sparks out of ears.

8. Prevent accidental fires. Remove any combustible material from the work area.

• When possible, move the work to a location well away from combustible materials.

If relocation is not possible, protect the combustibles with a cover made of fire

resistant material.

• Remove or make safe all combustible materials for a radius of 35 feet (10 meters)

around the work area. Use a fire resistant material to cover or block all open doorways, windows, cracks, and other openings.

Page 5SKU 92652 For technical questions, please call 1-800-444-3353

Page 6

• Enclose the work area with portable fire resistant screens. Protect combustible

walls, ceilings, floors, etc., from sparks and heat with fire resistant covers.

• If working on a metal wall, ceiling, etc., prevent ignition of combustibles on the other

side by moving the combustibles to a safe location. If relocation of combustibles is

not possible, designate someone to serve as a fire watch, equipped with a fire

extinguisher, during the cutting process and for at least one half hour after the cutting is completed.

• Do not weld or cut on materials having a combustible coating or combustible inter-

nal structure, as in walls or ceilings, without an approved method for eliminating the

hazard.

• Do not dispose of hot slag in containers holding combustible materials. Keep a fire

extinguisher nearby and know how to use it.

• After welding or cutting, make a thorough examination for evidence of fire. Be

aware that easily visible smoke or flame may not be present for some time after the

fire has started. Do not weld or cut in atmospheres containing dangerously reactive

or flammable gases, vapors, liquids, and dust. Provide adequate ventilation in work

areas to prevent accumulation of flammable gases, vapors, and dust. Do not apply

heat to a container that has held an unknown substance or a combustible material

whose contents, when heated, can produce flammable or explosive vapors. Clean

and purge containers before applying heat. Vent closed containers, including

castings, before preheating, welding, or cutting.

• Only use compressed air to operate the Plasma Welder/Cutter. Never use other

compressed gases. Don’t exceed maximum PSI for this product as stated on the

specification table on page 2.

9. Avoid overexposure to fumes and gases. Always keep your head out of the fumes.

Do not breathe the fumes. Use enough ventilation or exhaust, or both, to keep fumes

and gases from your breathing zone and general area.

Page 6SKU 92652 For technical questions, please call 1-800-444-3353

Page 7

• Where ventilation is questionable, have a qualified technician take an air sampling

to determine the need for corrective measures. Use mechanical ventilation to

improve air quality. If engineering controls are not feasible, use an approved respirator.

• Work in a confined area only if it is well ventilated, or while wearing an air-supplied

respirator.

• Follow OSHA guidelines for Permissible Exposure Limits (PEL’s) for various fumes

and gases.

• Follow the American Conference of Governmental Industrial Hygienists recommen-

dations for Threshold Limit Values (TLV’s) for fumes and gases.

• Have a recognized specialist in Industrial Hygiene or Environmental Services

check the operation and air quality and make recommendations for the specific

welding or cutting situation.

10. Always keep hoses away from welding/cutting spot. Examine all hoses and

cables for cuts, burns, or worn areas before each use. If any damaged areas are

found, replace the hoses or cables immediately.

11. Read and understand all instructions and safety precautions as outlined in the

manufacturer’s manual for the material you will weld or cut.

12. Proper cylinder care. Secure cylinders to a cart, wall, or post, to prevent them from

falling. All cylinders should be used and stored in an upright position. Never drop or

strike a cylinder. Do not use cylinders that have been dented. Cylinder caps should be

used when moving or storing cylinders. Empty cylinders should be kept in specified

areas and clearly marked “empty.”

13. Never use oil or grease on any inlet connector, outlet connector, or cylinder

valves.

14. Use only supplied Torch on this Air Plasma Welder/Cutter. Using components from

other systems may cause personal injury and damage components within.

WARNING! This product, when used for welding and similar applications, contains

or produces a chemical known to the State of California to cause cancer and birth defects (or other reproductive harm). (California Health & Safety Code § 25249.5,

WARNING! People with pacemakers should consult their physician(s) before using this product. Electromagnetic fields in close proximity to a heart pacemaker could

cause interference to, or failure of the pacemaker.

et seq.

GROUNDING

)

This Air Plasma Cutter requires a 3-prong, 230 VAC, polarized, twist-lock plug (not supplied). This plug must be installed by a qualified electrician.

Page 7SKU 92652 For technical questions, please call 1-800-444-3353

Page 8

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord provided with the tool or

product. Never remove the grounding prong from the plug. Do not use the tool if

the power cord or plug is damaged. If damaged, have it repaired by a service

facility before use. If the plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

EXTENSION CORDS

If an extension cord is to be used with this product, it must be rated to handle 230 VAC,

single phase at 40 amps (minimum), and have a twist-lock plug.

1. Grounded, 230 VAC tools require a three wire extension cord.

2. As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a serious

drop in voltage, resulting in loss of power and possible tool damage.

3. The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 10 gauge cord can carry a higher current than a 12 gauge cord.

4. When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required.

5. If you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum cord size.

6. If you are using an extension cord outdoors, make sure it is marked with the suffix “W-

A” (“W” in Canada) to indicate it is acceptable for outdoor use.

7. Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified

electrician before using it.

8. Protect your extension cords from sharp objects, excessive heat, and damp or wet

areas.

Page 8SKU 92652 For technical questions, please call 1-800-444-3353

Page 9

SYMBOLOGY

Table B

UNPACKING

When unpacking, check to make sure that all the parts are included. Refer to the Assembly

section, and the Assembly Drawing and Parts List at the end of this manual. If any parts are

missing or broken, please call Harbor Freight Tools at the number on the cover of this

manual as soon as possible.

Carrying Strap (46)

Valve Body (4)

230 VAC Line Cord (44)

without plug

Air Regulator (43)

Grounding Clamp/Cable (45)

Air Plasma Cutter

Torch and Cable (47)

ASSEMBLY INSTRUCTIONS

1. Connect a 3-prong, 230 VAC, polarized, twist-lock plug (not supplied) to the Line Cord.

This plug must be installed by a qualified electrician.

2. Insert the Air Regulator (43) into the Valve Body (4) (unit rear) using the snap-lock.

Page 9SKU 92652 For technical questions, please call 1-800-444-3353

Page 10

REAR VIEW

OPERATING INSTRUCTIONS

Controls and Indicators

FRONT VIEW

Air Switch (49)

Line Cord (44)

Power Switch

with Light (30)

Air

Regulator (43)

Valve

Body (4)

LED Indicators:

Grn. - Power On

Yel.- Energized Torch

Red - Thermal Fault

Yel.+Red - Air Pressure Fault

Grounding Cable (45)

Quick Coupler

Air Pressure Gauge (5)

Current

Adjustment

Knob (48)

Torch

Trigger

(2A)

Quick

Coupler (34)

Air Plasma Cutting

Before beginning, please read and understand all the safety precautions starting on

page 2, and especially the section “Specific Safety Rules” starting on page 4.

1. Mount the metal to be cut to the metal welding-cutting table. It should be mounted so

that the cutting debris falls to the cement floor.

2. Place the Air Plasma Cutter unit no closer than six feet from the workpiece to be cut.

3. Connect an air hose and coupling (not supplied) from the air supply tank to the Air

Regulator (43) at the rear of the unit. See photo on page 9, bottom.

The Air Regulator (43) output must be regulated to between 60 and 100 PSI as read

on the Air Pressure Gauge (5). The air supply must be dry. It is recommended to install

a moisture filter (not included) on the compressor. Do not use an air oiler.

4. Connect the Torch Cable (47) plug into the twist-lock connector on the unit front. Twist

to lock. See photo on page 9, bottom.

5. Plug in the Grounding Cable (45) into the Ground Cable Quick Coupler. Twist to lock.

6. Securely place the clamping end of the Grounding Cable Clamp (45) to a part of the

workpiece or metal table that is clean of paint, oil, or dirt.

Clamp as close as possible to the workpiece without damaging the cable during

cutting.

7. Verify that the Power Switch (30) is in the Off (O) position, then plug the 220 VAC line

cord plug into a 230 VAC, 40 amp outlet.

8. Turn the Current Adjustment Knob (48) to the desired current (15 to 40 amps).

Page 10SKU 92652 For technical questions, please call 1-800-444-3353

Page 11

Maximum current is required to cut 1/2 inch steel.

9. Press up on the Air Switch (49) to turn on air without activating the Torch Handle.

Adjust air pressure by turning the knob on the rear Air Regulator (43). Read pressure

on Pressure Gauge (5).

10. When everything is in place for cutting, press the Power Switch to the On (I) position.

The green Power Indicator lights, but the Torch (47) is not energized yet.

11. Orient yourself to one side of the area to be cut, and hold the Arc Shaded Face Shield

(not included) over your eyes.

12. Squeeze (and hold) the Torch Handle Trigger (2A) to energize the Torch Electrode

(4A). The air output is delayed a few seconds to enable a proper arc to begin.

Warning: The Torch handle is now energized. Be careful not to touch anything else with

the Torch Body (3A) except the workpiece to be cut.

Warning: Never look at the ignited arc without ANSI approved, arc shaded, eye protection in a full face shield. Permanent eye damage or blindness can occur. Skin burns can

occur. Never breath arc fumes.

13. Bring the Electrode (4A) of the Torch Body (3A) close enough to the starting point of

the cut to create an arc. The yellow Cutter Indicator lights.

14. Lightly tap the Torch Electrode (4A) into the cutting surface to ignite the arc, then pull

back slightly. If the arc is not started within two seconds, the unit goes into standby

mode. Release the Trigger once and squeeze to reset to arc mode.

15. Slowly move the Torch Handle (1A) at a slight angle along the cutting line with the

Torch tip trailing.

The air causes the molten metal to fall away from the workpiece being cut. If proper

cutting is not achieved, adjust the Current Adjustment Knob (48) to a higher level, and/

or increase air flow. To increase air flow, press the Power Switch (30) to the Off (O)

position, then adjust the air pressure at the Air Regulator (43). The air will continue to

come out of the Torch Handle (1A) for 30 seconds once the trigger is released.

Note: If too much current is drawn from the Plasma Cutter (i.e., short circuit), the Thermal

Switch, an overload protector, will activate and the red Overheat indicator will light. The Plasma

Cutter will turn off until it cools down. It will automatically reset. Press Trigger (2A) to begin

cutting again.

16. When finished cutting:

A. Release the Torch handle trigger and lift the Torch handle from the workpiece,

B. press the Power Switch (30) to the Off (O) position,

C. set the Torch handle down on the metal workbench,

D. turn the air supply off,

E. unplug the line cord from the electrical outlet.

Page 11SKU 92652 For technical questions, please call 1-800-444-3353

Page 12

INSPECTION, MAINTENANCE, AND CLEANING

WARNING! Make sure the Power Switch (30) of the Plasma Cutter is in its “OFF”

position and that the tool is unplugged from the electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

1. Before each use, inspect the general condition of the Air Plasma Cutter. Check for

loose cable connections, misalignment or binding of the fan, cracked or broken parts,

damaged electrical wiring, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use. Do

not use damaged equipment.

2. Periodically recheck all nuts, bolts, and screws for tightness.

3. Periodically blow the dust from the cooling vents with compressed air.

4. Verify that the cooling fan is operational before cutting.

5. If an odd smell comes from the unit during operation, stop all use. Have the Air Plasma

Cutter inspected and repaired by a qualified service technician.

6. Store the welder and accessories in a clean and dry location.

7. Periodically disassemble and clean the Torch Head components with steel wool.

Replace burnt, cracked, distorted, or coated components. Refer to the assembly

drawing on page 14.

8. To gain access to the internal components of the unit, remove six screws from each

Panel (35), and two side screws from the Cover (27). Any repairs should be completed

by a qualified technician.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE

IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES

ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT

OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF

REPLACEMENT PARTS THERETO.

Page 12SKU 92652 For technical questions, please call 1-800-444-3353

Page 13

MAIN UNIT PARTS LIST

metInoitpircseDyt'QmetInoitpircseDyt'Q

1emarfesab1235.9*9.3TSwercs04

2BCP133lenaptnorf1

3BCP143relpuockciuq1

4ydobevlav153lenap2

5eguagerusserpria1634rehsaw4

6lanimrethcro

7etalpdim1835rehsawkcol21

831*8.4TSwercs49331*9.3TSwercs21

91rotcelfeddim1044rehsawkcol63

015.9*8.4

11gniriwretlif124gniriwgnilpuocycneuqerfhgih1

21troppus234rotalugerria1

31retrevid244drocrewo

41BCPyradnoces154elbacdnapmalcgnidnuorg1

51)rewop(rotaidar164partsgniyrrac1

61remrofsnartretrevni174elbacdnahcrot1

71)r

81eceipgnitcennoc294hctiwsria1

912rotcelfed1

02dutsreppoc4

tgnidlew1734rehsawgnirps4

TSwercs814BCPlortnocmargorp1

p1

etrevni(rotaidar184bonkgnitsujdatnerruc1

MAIN UNIT EXTERNAL PARTS

12BCPyramirp1

224Mtun8

3

2BCPmargorp1

DRAWING

425.9*9.2TSwercs3

5257*4Mtlob4

62draobgninil2

72revoc1

82lenapraer1

92temmorgdrocrewop1

03hctiwsrewop1

13nafrewol

b1

REV 03/05; 11/06

Page 13SKU 92652 For technical questions, please call 1-800-444-3353

Page 14

MAIN UNIT INTERNAL ASSEMBLY DRAWING

NOTE: Some parts are listed and shown for illustration purposes only and are

not available individually as replacement parts.

REV 03/05

Page 14SKU 92652 For technical questions, please call 1-800-444-3353

Page 15

TORCH HANDLE PARTS LIST

traPnoitpircseD

A1eldnaH

A2reggirT

A3ydoB

A4edortcelE

A5resuffiDgnitalusnI

A6elzzoN

A7elzzoN,redloH

TORCH HANDLE ASSEMBLY DRAWING

REV 03/05

Page 15SKU 92652 For technical questions, please call 1-800-444-3353

Page 16

CIRCUIT DIAGRAM

Page 16SKU 92652 For technical questions, please call 1-800-444-3353

Loading...

Loading...