Page 1

7-INCH V7-INCH V

7-INCH V

7-INCH V7-INCH V

POLISHER / SANDERPOLISHER / SANDER

POLISHER / SANDER

POLISHER / SANDERPOLISHER / SANDER

ARIABLE SPEEDARIABLE SPEED

ARIABLE SPEED

ARIABLE SPEEDARIABLE SPEED

92623

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 MISSION OAKS BLVD., CAMARILLO, CA 93011

VISIT OUR WEB SITE AT HTTP://WWW.HARBORFREIGHT.COM

Copyright© 2004 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Manual Revised 03/06

Page 2

SPECIFICATIONS

Item Description

Power Requirement 120 VAC, 10 amps (input), 60 Hz

Speed 200 to 3377 RPM; Variable

Disc Size 7 inches

Spindle Size 5/8 inches – 11 TPI

Line Cord 6 feet; Two-prong polarized plug

Weight 6.6 lbs.

Accessories 2 – Sanding Disks: 60 and 240 grit

1 – Foam Pad

1 – Terry Towel

1 – Polishing Bonnet

1 – Polishing Pad

E194601

SAVE THIS MANUAL

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow all instructions

listed below may result in electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTION

Work Area

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control. Protect others in the work area from debris

such as chips and sparks. Provide barriers or shields as needed.

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 2

Page 3

Electrical Safety

4. Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any way. Do not use any adapter plugs. Check with

a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

5. Double insulated tools are equipped with a polarized plug (one blade is wider

than the other). This plug will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change the plug in any

way. Double insulation

cord and grounded power supply system.

6. Avoid body contact with grounded surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

7. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

eliminates the need for the three wire grounded power

8. Do not abuse the Power Cord. Never use the Power Cord to carry the tools or

pull the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp

edges, or moving parts. Replace damaged Power Cords immediately. Damaged

Power Cords increase the risk of electric shock.

9. When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These extension cords are rated for outdoor use, and reduce the risk of

electric shock.

Personal Safety

10. Stay alert. Watch what you are doing, and use common sense when operating a

power tool. Do not use a power tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may

result in serious personal injury.

11. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

12. Avoid accidental starting. Be sure the Power Switch is off before plugging in.

Carrying power tools with your finger on the Power Switch, or plugging in power tools

with the Power Switch on, invites accidents.

13. Remove adjusting keys or wrenches before turning the power tool on. A wrench

or a key that is left attached to a rotating part of the power tool may result in personal

injury.

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 3

Page 4

14. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

15. Use safety equipment. Always wear eye protection. Dust mask, nonskid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

16. Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

17. Do not force the tool. Use the correct tool for your application. The correct tool

will do the job better and safer at the rate for which it is designed.

18. Do not use the power tool if the Power Switch does not turn it on or off. Any tool

that cannot be controlled with the Power Switch is dangerous and must be replaced.

19. Disconnect the Power Cord Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

20. Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

21. Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with a sharp cutting edge are less likely to bind and are easier to control. Do not

use a damaged tool. Tag damaged tools “Do not use” until repaired.

22. Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

23. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous when

used on another tool.

Service

24. Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

25. When servicing a tool, use only identical replacement parts. Follow instructions

in the

unauthorized parts or failure to follow maintenance instructions may create a risk of

electric shock or injury.

“Inspection, Maintenance, And Cleaning”

section of this manual. Use of

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 4

Page 5

SPECIFIC SAFETY RULES FOR POLISHER / SANDER

1. Accessories must be rated for at least the speed recommended on the tool

warning label. Wheels and other accessories running over rated speed can fly apart

and cause injury.

2. Hold tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a “live”

wire will make exposed metal parts of the tool “live” and shock the operator.

3. Maintain labels and nameplates on the Polisher/ Sander. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a replacement.

4. Always wear ANSI-approved safety impact eye goggles and heavy work gloves

when using the Polisher/ Sander. Using personal safety devices reduce the risk for

injury. Safety impact eye goggles and heavy work gloves are available from Harbor

Freight Tools.

5. Maintain a safe working environment. Keep the work area well lit. Make sure there is

adequate surrounding workspace. Always keep the work area free of obstructions,

grease, oil, trash, and other debris. Do not use a power tool in areas near flammable

chemicals, dusts, and vapors. Do not use this product in a damp or wet location.

6. Make sure to read and understand all instructions and safety precautions as

outlined in the manufacturer’s manual for the vehicle you will wax/polish.

7. When using a handheld power tool, always maintain a firm grip on the tool with

both hands to resist starting torque.

8. Always keep the extension cord away from moving parts on the tool. Keep it off the

ground and away from water.

9. Avoid unintentional starting. Make sure you are prepared to begin work before turning

on the Polisher/ Sander.

10. Do not force the Polisher/Sander. This tool will do the work better and safer at the

speed and capacity for which it was designed. Do not force the pads into the vehicle

being waxed/polished. Apply moderate pressure, allowing the Bonnet to rotate freely

without being forced.

11. When waxing/polishing a vehicle, do not operate the vehicle’s engine in an enclosed

area. Carbon monoxide is a colorless, odorless, vapor emitted from a vehicle’s

(1)

running engine that may cause severe injury or death if inhaled.

12. Never lay the Polisher/Sander down until the Polishing Pad (2) has come to a full

stop. The Backing Pad can grab the surface and pull the tool out of your control.

13. Make sure the vehicle being waxed/polished is free from burrs and any other foreign

matter which could damage the tool.

14. Never leave the Polisher/ Sander unattended when it is plugged into an electrical

outlet. Turn off the tool, and unplug it from its electrical outlet before leaving.

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 5

Page 6

15. Always unplug the Polisher/ Sander from its electrical outlet before performing

any inspection, maintenance, or cleaning procedures.

16. When sanding, only use 7” sanding pads with a hook and loop back that attaches

securely to the Backing Pad.

17. Connect to a GFCI. Always connect the Line Cord to a Ground Fault Circuit Interrupter

(GFCI) protected electrical outlet.

18. Never use accessories rated for less than 3500 RPM.

WARNING! Avoid serious injury. Never install carbide tipped or steel circular saw

blade for use on this Sander/Polisher. Never install a wood carving blade, carving disc

with saw chain cutters, or a cutting carving disc on this Sander/Polisher. Never install

abrasive cutoff discs and wheels, flap wheels, wire brushes, or wire wheel brushes.

WARNING! People with pacemakers should consult their physician(s) before using

this product. Operation of electrical equipment in close proximity to a heart pacemaker

could cause interference or failure of the pacemaker.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities, contain chemicals known (to the State of California) to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals

are: lead from lead-based paints, crystalline silica from bricks and cement or other masonry products, arsenic and chromium from chemically treated lumber. Your risk from

these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

(California Health & Safety Code 25249.5, et seq.)

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool or

product. Never remove the grounding prong from the plug. Do not use the tool if

the power cord or plug is damaged. If damaged, have it repaired by a service

facility before use. If the plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

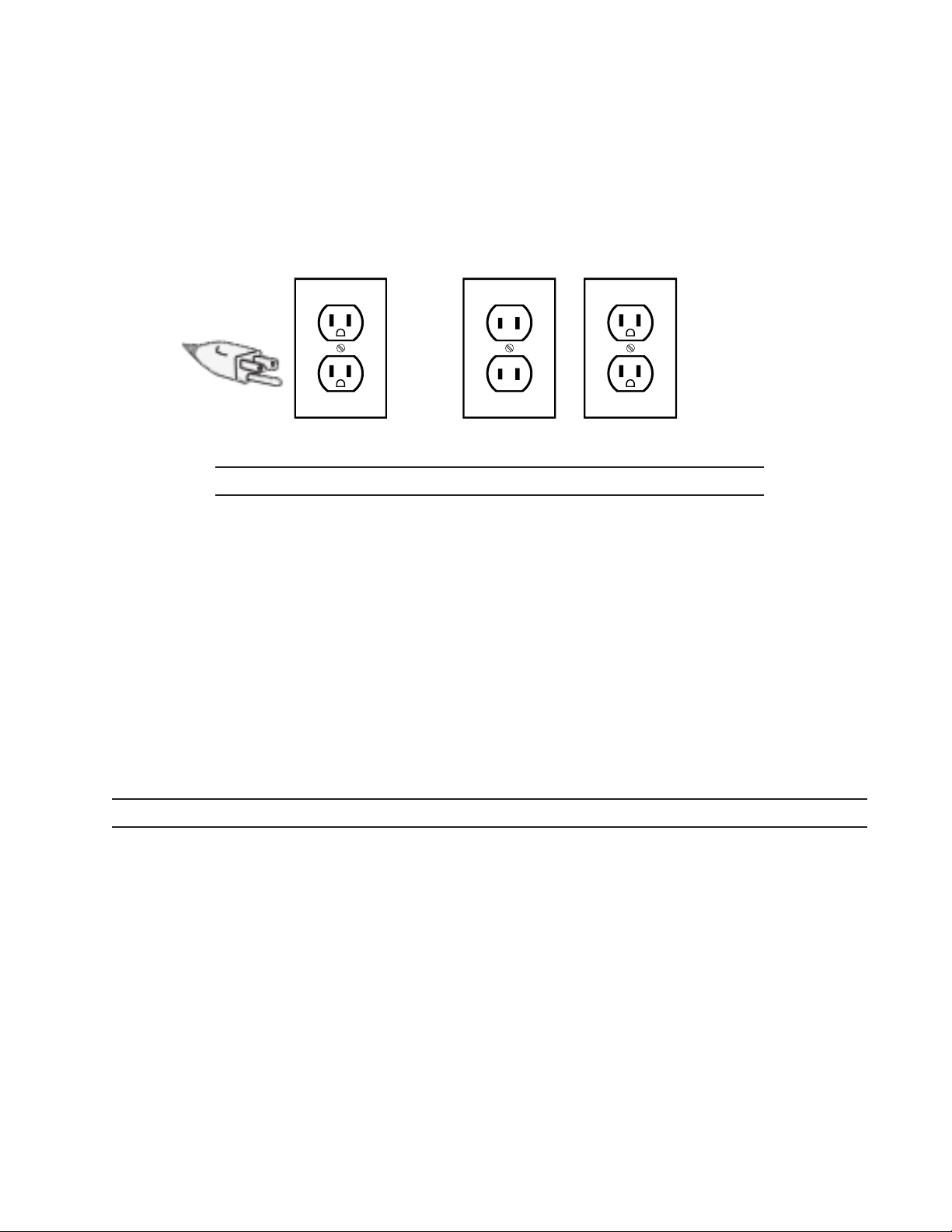

Grounded Tools: Tools with Three Prong Plugs

1. Tools marked with “Grounding Required” have a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If the tool

should electrically malfunction or break down, grounding provides a low resistance path

to carry electricity away from the user, reducing the risk of electric shock. (See Figure A.)

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 6

Page 7

2. The grounding prong in the plug is connected through the green wire inside the cord to

the grounding system in the tool. The green wire in the cord must be the only wire

connected to the tool’s grounding system and must never be attached to an electrically

“live” terminal. (See Figure A.)

3. Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

those in the following illustration. (See Figure A.)

Figure A

Figure B

Double Insulated Tools: Tools with Two Prong Plugs

4. This product has a polarized plug (one blade is wider than the other) as a feature

to reduce the risk of electric shock. This plug will fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician. Never use with an extension cord unless plug can be

fully inserted. Do not alter the plug.

5. Tools marked “Double Insulated” do not require grounding. They have a special double

insulation system which satisfies OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Figure B above.)

6. Double insulated tools may be used in either of the 120 volt outlets shown in the

following illustration. (See Figure B above.)

EXTENSION CORDS

1. Grounded tools require a three wire extension cord. Double Insulated tools can use

either a two or three wire extension cord.

2. As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a serious

drop in voltage, resulting in loss of power and possible tool damage. (See Table A.)

3. The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher current than a 16 gauge cord. (See Table

A.)

4. When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required. (See Table A.)

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 7

Page 8

5. If you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum cord size. (See Table A.)

6. If you are using an extension cord outdoors, make sure it is marked with the suffix “W-

A” (“W” in Canada) to indicate it is acceptable for outdoor use.

7. Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified

electrician before using it.

8. Protect your extension cords from sharp objects, excessive heat, and damp or wet

areas.

Table A

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS*

(120 VOLT)

NAMEPLATE

AMPERES

(At Full Load)

25

Feet

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 16 14 12 10

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - * Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

EXTENSION CORD LENGTH

50

Feet

75

Feet

100

Feet

150

Feet

-

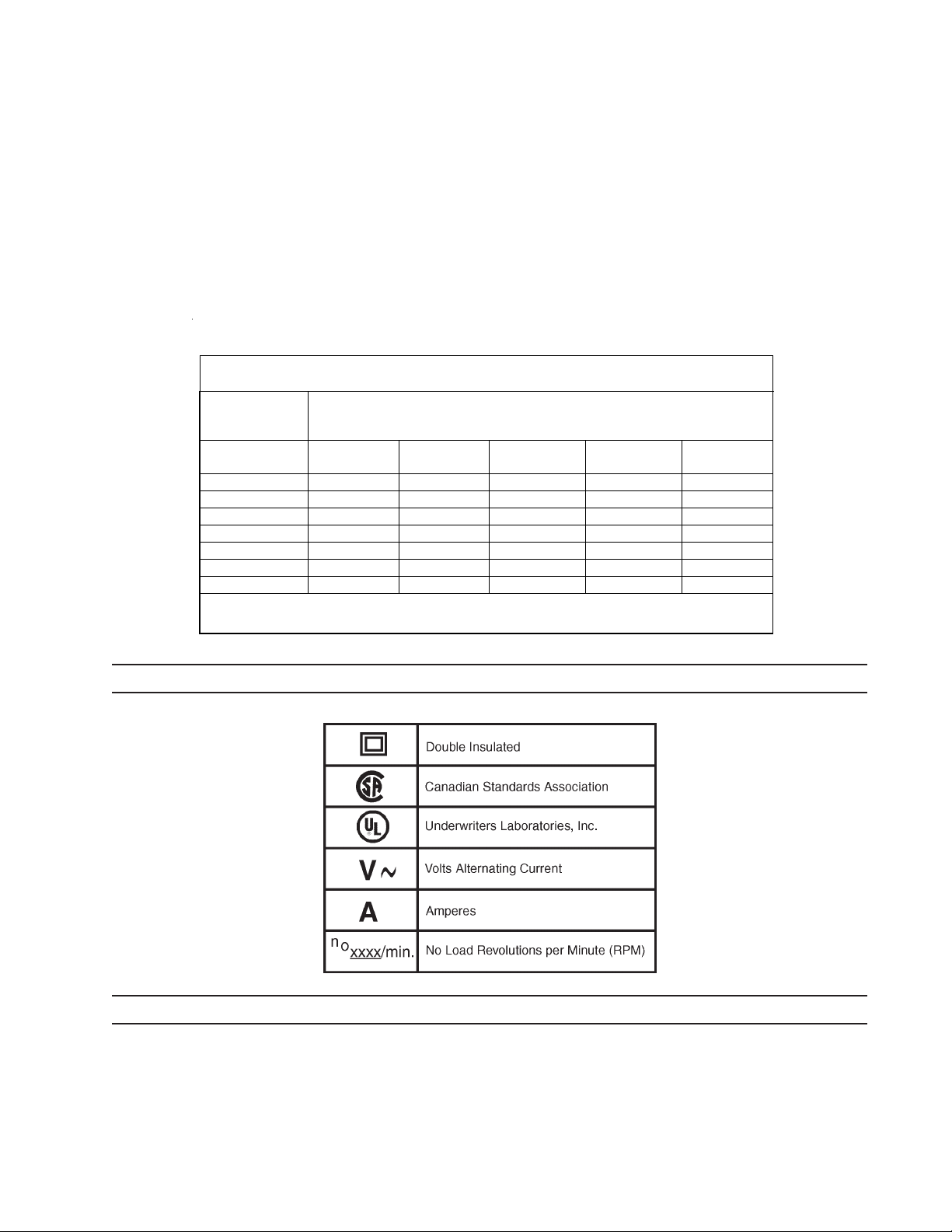

SYMBOLOGY

Table B

UNPACKING

When unpacking, check to make sure that all the parts are included. Refer to the Assembly

section, and the Assembly Drawing and Parts List at the end of this manual.

If any parts are missing or broken, please call Harbor Freight Tools at the number on the

cover of this manual as soon as possible.

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 8

Page 9

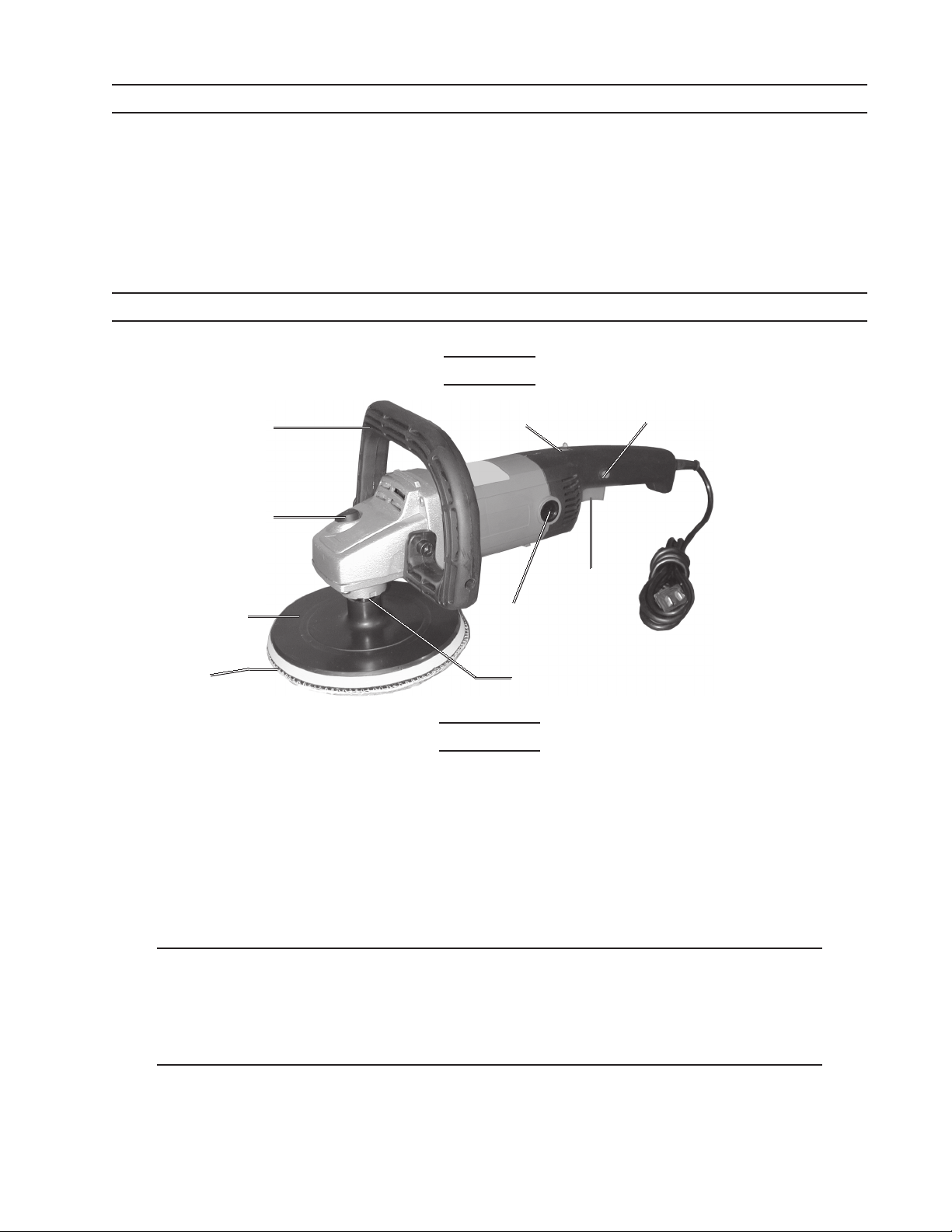

ASSEMBLY INSTRUCTIONS

Caution: Verify that the Power Cord (41) of the Sander/ Polisher is unplugged from its

extension cord or outlet prior to making any adjustments to the tool.

1. Press in the Spindle Lock Cap (17) to keep the Spindle shaft from turning.

2. Screw the Polishing Pad (2) counterclockwise onto the Spindle (3) until it is secure.

Release the Spindle Lock Cap (17).

OPERATING INSTRUCTIONS

Controls

Handle (19)

Spindle Lock Cap (17)

Polishing Pad (2)

Sanding Disk (47 or 48)

Speed Adjustment (37)

Switch (36)

Brush Holder

Cover (30)

Spindle (3)

Lock-on Button

Power Cord (41)

Polishing

1. Place a clean Foam Pad (44) securely onto the Polishing Pad (2).

NOTE: Prior to waxing or polishing a vehicle, make sure it’s surface has been thoroughly

washed, and is free of dust, dirt, oil, grease, etc.

2. Apply about two tablespoons of wax (not included) evenly on the Foam Pad (44).

Do not apply the wax directly to the surface of the vehicle. The amount of wax needed

will vary according to the size of the vehicle being waxed.

IMPORTANT

Carefully inspect the condition of the accessory before use and check the accessory

continually during use. If any damage is noted, stop immediately and replace the accessory

with an undamaged one. Harbor Freight Tools cannot be held responsible for damage

caused by using a damaged accessory on this tool.

NOTE: Avoid using too much wax. For additional applications of wax to the Foam Bonnet,

reduce the amount of wax. The Foam Bonnet will not absorb as much wax in subsequent

applications.

REV 06/05

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 9

Page 10

3. Plug the Power Cord (41) into an electrical extension cord (not included). Then, plug the

extension cord into a grounded, GFCI, 120 volt, electrical outlet.

NOTE: Always start and stop the Polisher while it is held firmly against the surface of the

vehicle. Failure to do so may result in the Bonnet being thrown from the Polishing Pad (2).

4. To start, grip the Polisher firmly with both hands and press in on the Switch (36) trigger.

Press the Lock-on Button to lock the Switch in the On position. Press in on the Switch to

unlock again.

Position the unit on the area to be polished, select the desired speed by rotating the

Speed Adjustment (37) knob, and allow the Polishing Pad (2) to rotate until it has reached

that speed. Keep pressure off of the Polisher/Sander when operating. The Polishing

Bonnet should LIGHTLY contact the polishing surface.

Caution: Only use the lower speeds (1 through 4) for polishing. Otherwise, damage may

occur to the paint being polished. Harbor Freight Tools is not responsible for damage to

the vehicle’s finish due to improper use of this polisher.

5. Begin applying wax to the vehicle.

Apply the wax to all flat surfaces with broad, sweeping strokes in a crisscross pattern.

Apply the wax evenly over the surface of the vehicle, and add additional wax as needed.

6. After the wax has been applied to the vehicle’s surface, release the Switch (36) to its Off

position. Then unplug the Power Cord (41) from the electrical extension cord.

7. Remove the Foam Pad (44) from the Polishing Pad (2) and with your hand and the Foam

Pad (44), apply the wax to all hard to reach areas of the vehicle such as around lights,

door handles, under bumpers, etc.

8. Allow sufficient time for the wax to dry on the vehicle.

9. Place a clean Polishing Bonnet securely onto the Polishing Pad (2). Note: Always tightly

pull the string to secure the Polishing Bonnet. Secure the string and keep it out of the

way by tying several knots.

10. Plug the Power Cord (41) of the Polisher into the electrical extension cord.

NOTE: Always start and stop the Polisher while it is held firmly against the surface of the

vehicle. Failure to do so may result in the Bonnet being thrown from the Polishing Pad (2).

11. To start, grip the Polisher firmly with both hands and press in on the Switch (36) trigger.

Press the Lock-on Button to lock the Switch in the On position. Press in on the Switch to

unlock again.

12. Begin polishing the vehicle by lightly buffing off the wax residue in a circular pattern.

Continue polishing until all the wax residue is removed.

13. When finished, release the Switch (36) to its Off position. Then unplug the Power Cord

(41) from the electrical extension cord. Unplug the extension cord from the electrical

outlet.

14. Remove the Polishing Bonnet from the Polishing Pad (2). With the Polishing Bonnet or

Terry Cloth (46) in your hand, remove the wax from all hard to reach areas of the vehicle.

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 10

Page 11

Sanding

1. Attach the desired grit Sanding Disk (47 or 48) onto the Polishing Pad (2).

2. Plug the Power Cord (41) of the Polisher/Sander into the electrical extension cord. Then,

plug the extension cord into the grounded, GFCI, 120 volt, electrical outlet.

3. Identify the area you wish to sand. Make sure the power cord will reach that far without

stressing any connections. Place the Polisher/Sander onto the sanding area.

4. To start, grip the Polisher/Sander firmly with both hands and press in on the Switch (36)

trigger. Press the Lock-on Button to lock the Switch in the On position. Press in on the

Switch to unlock again.

5. Position the unit on the area to be sanded, select the desired speed by rotating the Speed

Adjustment (37) knob (1 through 6), and allow the Sanding Disk (1) to rotate until it has

reached that speed. Keep heavy pressure off of the Polisher/Sander when operating.

Allow the sanding disk to do the work.

6. Move the Polisher/Sander in a uniform pattern up and down or side to side as you sand

to ensure even sanding.

7. Periodically, stop the Polisher/Sander and check for possible disc wear. Replace used or

worn sanding discs when necessary.

8. When finished, release the Switch (6) to its Off position. Then unplug the Power Cord

(41) from the electrical extension cord. Unplug the extension cord from the electrical

outlet.

INSPECTION, MAINTENANCE, AND CLEANING

WARNING! Make sure the Power Switch of the Polisher/Sander is in its “OFF” posi-

tion and that the tool is unplugged from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

1. Before each use, inspect the general condition of the Polisher/Sander. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, damaged

electrical wiring, and any other condition that may affect its safe operation. If abnormal

noise or vibration occurs, have the problem corrected before further use. Do not use

damaged equipment.

2. Periodically recheck all nuts, bolts, and screws for tightness.

3. Store in a clean and dry location.

4. The most common error when waxing/polishing a vehicle is applying too much wax. If

the Foam Pad (44) becomes saturated with wax, polishing will be more difficult and will

take longer. Applying too much wax may also reduce the life of the Foam Pad. If the

Foam Pad continually comes off the Polishing Pad (2) during use, too much wax may

have been applied.

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 11

Page 12

5. Remove the Foam Pad (44) from the Polishing Pad (2) when the Polisher/Sander is not

in use. This will allow the Polishing Pad to dry and retain its original shape. Wash with

mild soap and water before storing.

6. To prolong Polishing Pad (2) life and shape, store the Polisher Pad face down to keep

the surface flat.

7. The Polishing Bonnet (45) may be machine washed in cold water with mild detergent.

Then hang dry.

8. Use only a clean cloth and mild detergent to clean the body of the Polisher. Do not use

solvents. Do not immerse any part of the tool in liquid.

9. Over time, if the performance of the tool diminishes, or it stops working completely, it may

be necessary to replace the Carbon Brushes (31) by removing the Brush Holder Cover

(30). This procedure should be completed by a qualified technician. If the Carbon Brushes

are not worn down, try cleaning the Carbon Brush tips with an ink eraser.

PARTS LIST

traPnoitpircseDyt'QtraPnoitpircseDyt'Q

1yeKxeH15281#,gniraeB1

2gnihsiloP,daP162dleihSdniW,gniR1

3eldnipS17255x5,paT,wercS2

431x4,elcriCflaH,yeK182rotatS1

561x5,wercS49

6gnirpS,rehsaW403redloHhsurB,revoC2

7tnorF,revoC1130014#,nobraC,hsurB2

8102#,gniraeB1230014#,hsurB,redloH2

92

01egraL,raeG1a43kcaBreppU,revoC1

1121,redneF,gniR15301x3,paT,wercS2

2101x8x21,B511,leetS

3103x5,paT,wercS4a73tnemtsujdAdeepS1

41llehSdaeH1a83kcaBrewoL,revoC1

51kcoL,niP19302x4,wercS4

61kcoL,gnirp

71kcoLeldnipS,paC114rewoP,droC1

8161x8,daeHxeH,wercS224draoBelbaCsserP1

91eldnaH13441x4,paT,wercS2

02101#,gn

12sserPelgnairT,revoC154tennoBgnihsiloP1

224,gnirpS,rehsaW364)nwohston(tennoBhtolCyrreT1

3201x4,wercS374t

42erutamrA184tirG042,ksiDgnidnaS1

,eveelS1a63hctiwS1

S104521#,htaehS1

iraeB144daPmaoF1

3,redneF,gniR133rotoM,gnisuoH1

2011#,gnirpS2

irG06,ksiDgnidnaS1

NOTE: Some parts are listed and shown for illustration purposes only and are not available

SKU 92623

individually as replacement parts.

For technical questions, please call 1-800-444-3353

REV 01/05

English

Page 12

Page 13

ASSEMBLY DIAGRAM

NOTE: Part 46 - Terry Cloth - not shown.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED

TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 92623

For technical questions, please call 1-800-444-3353

REV 01/05

English

Page 13

Page 14

LIMITED 1 YEAR

WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for

the period of one year from the date of purchase. This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, or to lack of

maintenance. We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection verifies the defect, we will either repair or replace the product at our election or we may elect to

refund the purchase price if we cannot readily and quickly provide you with a replacement. We will return

repaired products at our expense, but if we determine there is no defect, or that the defect resulted from

causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-33533491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-33533491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

SKU 92623

For technical questions, please call 1-800-444-3353

English

Page 14

Page 15

POLISSEUR/PONCEUSE DE

VITESSE VARIABLE DE 7 POUCES

92623

MONTAGE ET INSTRUCTIONS FONCTIONNANTES

IMPORTANT!

Cette édition de langue

française est une traduction

du manuel anglais original

accompagnant ce produit. Si

une partie du manuel anglais

original est inconsistante

avec cette traduction, le

manuel anglais original

gouvernera.

3491 BLVD DE CHÊNES DE MISSION, CAMARILLO, CA 93011

VISITEZ NOTRE SITE INTERNET À HTTP://WWW.HARBORFREIGHT.COM

Le Copyright © 2006 par le Harbor Freight Tools ®. Tous droits réservés. Aucune

portion de ce manuel ou de n’importe quel travail d’art contenu ici ne peut être

reproduite dans aucune forme ou forme sans le consentement rapidement écrit

de Harbor Freight Tools.

Pour les questions techniques et les pièces détachées, appelez-vous s’il vous plaît 1-800-444-3353

Page 16

SPÉCIFICATIONS

riovuoPedecnegixEzH06,)egrahcenucua(serèpma5.4,~V021

essetiVelbairaV;nim-rt7733à002

euqsiDedruednarGsecuop

7

uaesuFedruednarG11-8/5edecuoP

engiLednodroCtnaruocedesirpalésiralopatnedxueDal;sdeip6

sdioP.servil6.6

seri

osseccAelbas042te06:seuqsiDsedredoré'dtiaFel-2

essuoMedtenissuoC-1

lewoTegnopéussiT-1

tennoBudegassiloP-1

tenissuoCudegassiloP-1

E194601

SAUVEZ CE MANUEL

Vous aurez besoin du manuel pour les avertissements de sécurité et les précautions, les

instructions de montage, en fonctionnant et les procédures de maintenance, la liste de pièces

et le diagramme. Gardez votre facture avec ce manuel. Écrivez le nombre de facture sur

l’intérieur de la couverture première. Gardez le manuel et la facture dans un coffre-fort et un

endroit sec pour la référence future.

RÈGLES RÉPANDUES DE SÉCURITÉ

AVERTISSEMENT!

LISEZ ET COMPRENEZ TOUTES LES INSTRUCTIONS. L’échec de suivre toutes

les instructions énumérées peut ci-dessous s’ensuivre dans le décharge

électrique, le feu, et-ou la blessure sérieuse.

SAUVEZ CEUX-CI L’INSTRUCTION

Région de Travail

1. Garder votre région de travail propre et bien allumé. Les bancs encombrés et les

régions sombres invitent des accidents.

2. Ne faire pas marcher d’instruments de pouvoir dans les atmosphères explosives,

comme en présence des liquides inflammables, les gaz, ou la poussière. Les

instruments de pouvoir créent des étincelles qui peuvent enflammer la poussière ou les

exhalaisons.

3. Garder des spectateurs, des enfants et des visiteurs loin en faisant marcher un

instrument de pouvoir.

Les distractions peuvent vous faire perdre le contrôle. Protégez d’autres dans la région

de travail des débris comme les frites et les étincelles. Fournissez des barrières ou des

protecteurs comme nécessaire.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 2

Page 17

Sécurité Électrique

4. Éviter le contact de corps avec les surfaces mises à la terre comme les tuyaux, les

radiateurs, les variétés et les réfrigérateurs. Il y a un risque augmenté de décharge

électrique si votre corps est mis à la terre.

5. Ne découvrir pas d’instruments de pouvoir pour pleuvoir ou les conditions

mouillées. L’eau entrant dans un instrument de pouvoir augmentera le risque de décharge

électrique.

6. Les instruments mis à la terre doivent être branchés à une prise de courant murale

correctement installée et mise à la terre conformément à tous les codes et aux

ordonnances. N’enlevez jamais la dent d’installer à la terre ou modifiez la prise de

courant de toute façon. N’utilisez pas de prises de courant d’adaptateur. Vérifiez

avec un électricien qualifié si vous êtes douteux quant à si la prise de courant

murale est correctement mise à la terre. Si les instruments devraient électriquement

mal fonctionner ou se décomposer, installer à la terre fournit un sentier de résistance

faible pour emporter l’électricité de l’utilisateur.

7. Les instruments isolés doubles sont équipés avec une prise de courant polarisée

(une lame est plus large que l’autre). Cette prise de courant correspondra dans

une prise de courant murale polarisée seulement à une voie. Si la prise de courant

ne va pas complètement dans la prise de courant murale, inverse la prise de

courant. S’il ne va pas toujours, contactez un électricien qualifié pour installer une

prise de courant murale polarisée. Ne changez pas la prise de courant de toute

façon. L’isolation double élimine le besoin pour le trois fil a mis le cordon de pouvoir à la

terre et a mis le système d’alimentation électrique à la terre.

8. N’abuser pas du Cordon de Pouvoir. N’utilisez jamais le Cordon de Pouvoir pour

porter les instruments ou tirer la Prise de courant d’une prise de courant murale.

Tenez le Cordon de Pouvoir à distance de la chaleur, les bords de pétrole, pointus,

ou les pièces bougeantes. Remplacez des Cordons de Pouvoir faits tort

immédiatement. Les Cordons de Pouvoir Faits tort augmentent le risque de décharge

électrique.

9. En faisant marcher un instrument de pouvoir à l’extérieur, utilisez “W-A” marqué

d’un cordon d’extension en plein air ou “W”. Ces cordons d’extension sont estimés

pour l’utilisation en plein air et réduisent le risque de décharge électrique.

Sécurité Personnalisée

10. Séjour vigilant. La surveillance que vous faites et utilisez le sens commun en faisant

marcher un instrument de pouvoir. N’utilisez pas d’instrument de pouvoir pendant

que fatigué ou sous l’influence de drogues, alcool, ou médication. Un moment

d’inattention en faisant marcher des instruments de pouvoir peut s’ensuivre dans la

blessure personnalisée sérieuse.

11. Robe correctement. N’usez pas de vêtements desserrés ou de bijouterie. Contenez

de longs cheveux. Gardez vos cheveux, vêtements et gants loin de déplacer des

pièces. Les vêtements desserrés, la bijouterie, ou les longs cheveux peuvent être attrapés

dans les pièces bougeantes.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 3

Page 18

12. Éviter le commencement accidentel. Soyez sûrs que l’Interrupteur de Pouvoir est

éteient avant le fait de brancher. Le fait de porter des instruments de pouvoir avec

votre doigt sur l’Interrupteur de Pouvoir, ou en branchant des instruments de pouvoir

avec l’Interrupteur de Pouvoir sur, invite des accidents.

13. Enlever des clés s’adaptant ou des tourne-à-gauche avant le fait d’allumer

l’instrument de pouvoir. Un tourne-à-gauche ou une clé qui est laissée attachée à une

pièce tournante de l’instrument de pouvoir peuvent s’ensuivre dans la blessure

personnalisée.

14. Ne dépaser pas. Gardez la position nécessaire et l’équilibre à tous moments. La

position nécessaire et l’équilibre permettent le meilleur contrôle de l’instrument de pouvoir

dans les situations inattendues.

15. Utiliser l’équipement de sécurité. Usez toujours la protection d’oeil. Le masque de

filtre, les chaussures de sécurité antidérapantes, le chapeau dur, ou l’audition de la

protection doivent être utilisés pour les conditions appropriées.

Utilisation d’Instrument et Soin

16. Utiliser des attaches (non inclus) ou d’autres façons pratiques de stabiliser et

soutenir la pièce de fabrication à une plate-forme ferme. La possession du travail à

la main ou contre votre corps est instable et peut causer la perte de contrôle.

17. Ne forcer pas l’instrument. Utilisez l’instrument correct de votre application.

L’instrument correct fera le travail mieux et plus sûr au taux auquel il est conçu.

18. N’utiliser pas l’instrument de pouvoir si l’Interrupteur de Pouvoir ne l’allume pas

ou éteie. N’importe quel instrument qui ne peut pas être contrôlé avec l’Interrupteur de

Pouvoir est dangereux et doit être remplacé.

19. Débrancher la Prise de courant de Cordon de Pouvoir de la source de pouvoir

avant le fait de faire n’importe quels ajustages, accessoires changeants, ou le fait

de conserver l’instrument. De telles mesures de sécurité préventives réduisent le risque

de commencer l’instrument par hasard.

20. Le magasin les instruments à l’arrêt hors de portée des enfants et d’autres

personnes sans formation. Les instruments sont dangereux dans les mains

d’utilisateurs sans formation.

21. Maintenir des instruments avec le soin. Continuez à couper des instruments pointus

et propres. Les instruments correctement maintenus avec un tranchant pointu se lieront

moins probablement et sont plus faciles de contrôler. N’utilisez pas d’instrument fait tort.

L’étiquette a fait tort aux instruments “n’utilisent pas” jusqu’à ne réparé.

22. Vérifier pour le défaut d’alignement ou le fait d’attacher de pièces bougeantes, la

fracture de pièces et d’autre condition qui peut affecter l’opération de l’instrument.

Si fait tort, faites assurer l’entretien de l’instrument avant l’utilisation. Beaucoup

d’accidents sont causés par les instruments pauvrement maintenus.

23. Utiliser seulement des accessoires qui sont recommandés par le fabricant pour

votre modèle. Les accessoires qui peuvent être convenables pour un instrument peuvent

devenir les hasardeux quand utilisé sur un autre instrument.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 4

Page 19

Entretien

24. L’entretien d’instrument doit être exécuté seulement par le personnel de réparation

qualifié. L’entretien ou la maintenance exécutée par le personnel disqualifié pourraient

s’ensuivre dans un risque de blessure.

25. En assurant l’entretien d’un instrument, utilisez des pièces détachées seulement

identiques. Suivez des instructions dans

section

Nettoyante

de ce manuel. L’utilisation de pièces faites sans autorisation ou

la “Inspection, la Maintenance Et la “

d’échec de suivre les instructions de maintenance peut créer un risque de décharge

électrique ou de blessure.

LES RÈGLES DE SÉCURITÉ SPÉCIFIQUES POUR LE POLISSEUR/PONCEUSE

1. Les accessoires doivent être estimés pour au moins la vitesse recommandée sur

l’instrument conseillant l’étiquette. Les roues et d’autres accessoires débordant la

vitesse évaluée peuvent voler à part et causer la blessure.

2. Tenez l’instrument par les surfaces de captage isolées en exécutant une opération

où l’instrument coupant peut contacter des circuits électriques cachés ou son

propre cordon. Contact avec un fil “électriquement stimulé” fera des pièces en métal

découvertes de l’instrument devient “électriquement stimulés” et choquent l’opérateur.

3. Maintenir des étiquettes et des plaques sur le Polisseur / Ponceuse. Ceux-ci portent

des renseignements importants. Si illisible ou l’absence, contactez le Harbor Freight

Tools pour un remplacement.

4. Usez toujours des lunettes de protection d’oeil d’impact de sécurité approuvées

d’ANSI et des gants de travail très résistants en utilisant le Polisseur / Ponceuse.

L’utilisation les artifices de sécurité personnalisés réduit le risque pour la blessure. Les

lunettes de protection d’oeil d’impact de sécurité et les gants de travail très résistants

sont en vente du Harbor Freight Tools.

5. Maintenir un cadre de travail sûr. Gardez la région de travail bien éclairée. Assurez-

vous qu’il y a le cadre de travail environnant adéquat. Gardez toujours la région de travail

sans obstructions, graisse, pétrole, déchets et d’autres débris. N’utilisez pas d’instrument

de pouvoir dans les régions près des produits chimiques inflammables, les poussières

et les vapeurs. N’utilisez pas ce produit dans un endroit humide ou mouillé.

6. Assurer pour lire et comprendre toutes les instructions et les précautions de

sécurité comme exposé dans le manuel du fabricant pour le véhicule que vous cirerez/

polirez.

(1)

7. En utilisant un instrument de pouvoir à main, maintenez toujours une prise ferme

sur l’instrument avec les deux mains pour résister au moment de torsion de départ.

8. Tenez toujours le cordon d’extension à distance de déplacer des pièces sur

l’instrument. Éloignez-le de la terre et loin de l’eau.

9. Éviter le commencement inconscient. Assurez-vous que vous êtes disposés à

commencer le travail avant le fait d’allumer le Polisseur / Ponceuse.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 5

Page 20

10. Ne forcer pas le Polisseur/Ponceuse. Cet instrument fera le travail mieux et plus sûr à

la vitesse et à la capacité à laquelle il a été conçu. Ne forcez pas les coussinets contre le

véhicule étant ciré/poli. Appliquez la pression modérée, en permettant au Bonnet de

tourner librement sans être forcé.

11. En cirant/polissant un véhicule, ne faites pas marcher le moteur du véhicule dans

une région fermée. L’oxyde de carbone est un incolore, sans odeur, du gaz émis

du moteur de fait de faire marcher d’un véhicule qui peut causer la blessure sévère

ou la mort si inhalé.

12. Ne posez jamais le Polisseur/Ponceuse avant que le Coussinet de Polissage (2) ne

soit venu à un arrêt complet. Le Coussinet Soutenant peut saisir la surface et tirer

l’instrument de votre contrôle.

13. Assurer que le véhicule étant ciré/poli est libre des tesson en métaux et d’autre

matière étrangère qui pourrait faire tort à l’instrument.

14. Ne laissez jamais le Polisseur / Ponceuse sans surveillance quand il est branché à

une prise de courant murale électrique. Éteignez l’instrument et débranchez-le de sa

prise de courant murale électrique avant le départ.

15. Débranchez toujours le Polisseur / Ponceuse de sa prise de courant murale

électrique avant le fait d’exécuter n’importe quelle inspection, maintenance, ou le fait

de nettoyer des procédures.

16. Quand le fait d’éroder, utilisez seulement 7” coussinets de fait d’éroder avec un

crochet et une boucle en arrière qui fait partie solidement du Coussinet Soutenant.

17. Relier à un GFCI. Reliez toujours le Cordon de Ligne à une prise de courant murale

électrique protégée par un Interrupteur de Circuit de Faute de Terre (GFCI).

18. N’utilisez jamais des accessoires estimés de moins de 3500 tr-min.

AVERTISSEMENT! Évitez la blessure sérieuse. N’installez jamais la lame de scier

circulaire inclinée de carbure ou d’acier pour l’utilisation sur ce Ponceuse/Polisseur.

N’installez jamais une lame de gravure sur bois, en sculptant le disque avec les coupeurs

de chaîne de scier, ou une coupure sculptant le disque sur ce Ponceuse/Polisseur.

N’installez jamais des disques de coupe abrasifs et des roues, des roues de battement,

des balais métalliques, ou des balais de roue métalliques.

AVERTISSEMENT! Les gens avec les stimulateurs cardiaques devraient consulter leur

docteur (s) avant le fait d’utiliser ce produit. L’opération d’équipement électrique dans la

proche proximité à un stimulateur cardiaque du cœur pourrait causer l’interférence ou

l’échec du stimulateur cardiaque.

AVERTISSEMENT! Un peu de poussière créée par le fait d’éroder de pouvoir, le sciage,

le grincement, le forage et d’autres activités de construction, contient des produits

chimiques connus (à l’État de Californie) pour causer le cancer, les anomalies

congénitales ou d’autre mal reproducteur. Quelques exemples de ces produits

chimiques sont : le plomb des peintures à base de plomb, la silice cristalline des briques

et le ciment ou d’autres produits de maçonnerie, l’arsenic et le chrome du bois de

construction chimiquement traité. Votre risque de ces expositions varie, selon combien

de fois vous faites ce type de travail. Réduire votre exposition à ces produits chimiques

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 6

Page 21

: le travail dans une région bien aérée et un travail avec l’équipement de sécurité approuvé,

comme ces masques de filtre qui sont spécialement conçus pour éliminer des particules

microscopiques. (Le Code § 25249.5 de Sécurité et de Santé de Californie,

et seq.

)

INSTALLER À LA TERRE

AVERTISSEMENT!

Improprement le branchement du fil d’installer à la terre peut s’ensuivre dans le

risque de décharge électrique. Vérifiez avec un électricien qualifié si vous êtes

douteux quant à si la prise de courant murale est correctement mise à la terre. Ne

modifiez pas la prise de courant de cordon de pouvoir fournie avec l’instrument

ou le produit. N’enlevez jamais la dent d’installer à la terre de la prise de courant.

N’utilisez pas l’instrument si le cordon de pouvoir ou la prise de courant sont

faits tort. Si fait tort, faites-le réparer par un établissement d’entretien avant

l’utilisation. Si la prise de courant ne correspondra pas à la prise de courant murale,

faites installer une prise de courant murale nécessaire par un électricien qualifié.

Instruments Mis à la terre: Instruments avec Trois Prises de

courant de Dent

1. Les instruments marqués avec “Installer à la terre de Voulu” ont un trois cordon métallique

et trois dent mettant la prise de courant à la terre. La prise de courant doit être reliée à

une prise de courant murale correctement mise à la terre. Si l’instrument devrait

électriquement mal fonctionner ou se décomposer, installer à la terre fournit un sentier

de résistance faible pour emporter l’électricité de l’utilisateur, en réduisant le risque de

décharge électrique. (Voir l’Image A.)

2. La dent d’installer à la terre dans la prise de courant est reliée par le fil vert à l’intérieur

du cordon au système d’installer à la terre dans l’instrument. Le fil vert dans le cordon

doit être le seul fil relié au système d’installer à la terre de l’instrument et ne doit jamais

être attaché à un terminus électriquement “de force”. (Voir l’Image A.)

3. Votre instrument doit être branché à une prise de courant murale appropriée, a

correctement installé et a mis à la terre conformément à tous les codes et aux

ordonnances. La prise de courant et la prise de courant murale devraient ressembler à

ceux en illustration suivante. (Voir l’Image A.)

Image A

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Image B

Français

Page 7

Page 22

Instruments Isolés Doubles : Instruments avec les Prises de courant de Deux dents

4. Ce produit a une prise de courant polarisée (une lame est plus large que l’autre)

comme une caractéristique pour réduire le risque de décharge électrique. Cette

prise de courant correspondra dans une prise de courant murale polarisée seulement à

une voie. Si la prise de courant ne va pas complètement dans la prise de courant murale,

inverse la prise de courant. S’il ne va pas toujours, contactez un électricien qualifié.

N’utilisez jamais avec un cordon d’extension à moins que la prise de courant ne puisse

être complètement insérée. Ne changez pas la prise de courant.

5. Les instruments marqués “Double Isolé” n’exigent pas installer à la terre. Ils ont un système

d’isolation double spécial qui satisfait des exigences OSHA et se plie aux normes

applicables d’Underwriters Laboratories, Inc., l’Association Standard canadienne et le

Code Électrique national. (Voir l’Image B.)

6. Les instruments isolés doubles peuvent être utilisés dans n’importe laquelle des prises

de courant murale de 120 volts montrées en illustration suivante.

(Voir l’Image B.)

CORDONS D’EXTENSION

1. Les instruments mis à la terre exigent un trois cordon d’extension métallique. Les

instruments Isolés doubles peuvent utiliser deux ou trois cordon d’extension métallique.

2. Comme la distance des augmentations de prise de courant murale d’alimentation, vous

devez utiliser un plus lourd cordon d’extension de calibre. L’utilisation des cordons

d’extension avec le fil insuffisamment de grandeur cause une baisse sérieuse dans le

voltage, en s’ensuivant dans la perte de pouvoir et de dommage d’instrument possible.

(Voir le Tableau A.)

3. Plus petit le nombre de calibre du fil, plus grand la capacité du cordon. Par exemple, un

14 cordon de calibre peut porter un plus haut courant qu’un 16 cordon de calibre.

(Voir le Tableau A.)

4. En utilisant plus qu’un cordon d’extension pour créer la longueur totale, assurez-vous

que chaque cordon contient au moins la grandeur métallique minimale exigée.

(Voir le Tableau A.)

5. Si vous utilisez un cordon d’extension de plus qu’un instrument, ajoutez les ampères de

plaque et utilisez la somme pour déterminer la grandeur de cordon minimale voulue.

(Voir le Tableau A.)

6. Si vous utilisez un cordon d’extension dehors, assurez-vous qu’il est marqué avec le

suffixe “W-A” (“W” au Canada) pour indiquer que c’est acceptable pour l’utilisation en

plein air.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 8

Page 23

7. Assurer que votre cordon d’extension est correctement télégraphié et dans la bonne

condition électrique. Remplacez toujours un cordon d’extension fait tort ou faites-le

réparer par un électricien qualifié avant le fait de l’utiliser.

8. Protéger vos cordons d’extension des objets pointus, la chaleur excessive et les régions

humides ou mouillées.

Tableau A

LE CALIBRE MÉTALLIQUE MINIMAL RECOMMANDÉ POUR L'EXTENSION CORDS*

LES AMPÈRES

DE PLAQUE

(à la Pleine

charge)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 16 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

* Basé sur le fait de limiter le voltage de ligne tombe à cinq volts à 150 % des ampères évalués.

25

Pieds

(120 volts)

LONGUEUR DE CORDON D'EXTENSION

50

Pieds

75

Pieds

100

Pieds

150

Pieds

SYMBOLOGY

Tableau B

Double Isolé

Ass ociation de Normes

Canadienne

Underwriters Laboratories,

Inc.

V ~

A

no

xxxx/min.

Courant alternatif de Volts

Ampères

Aucune Révolut ion de Charge

par Minute (TR-MIN)

DÉFAISANT

En défaisant, vérifiez pour vous assurer que toutes les pièces sont incluses. Faites allusion à

la section de Montage et le Dessin de montage et la Liste de Pièces à l’extrémité de ce manuel.

Si des pièces manquent ou cassées, appelez s’il vous plaît le Harbor Freight Tools au nombre

sur la couverture de ce manuel aussitôt que possible.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 9

Page 24

INSTRUCTIONS DE MONTAGE

Prudence : Vérifiez que le Cordon de Pouvoir (41) de Ponceuse / le Polisseur est non

branché de son cordon d’extension ou prise de courant murale avant de faire n’importe

quels ajustages à l’instrument.

1. Appuyer dans la Capsule de Serrure de Fuseau (17) pour empêcher l’arbre de Fuseau

de tourner.

2. Visser le Coussinet de Polissage (2) en sens inverse des aiguilles d’une montre sur le

Fuseau (3) jusqu’à ce que ce soit stable. Lâchez la Capsule de Serrure de Fuseau (17).

LE FAIT DE FAIRE MARCHER DES INSTRUCTIONS

Commandes

Poignée (19)

Capsule de Serrure

de Fuseau (17)

Polissage de

Coussinet (2)

Disque de Fait d'érode

(47 ou 48)

Ajustage de Vitesse (37)

Interrupteur

(36)

Balai de carbone

la Couverture de

Support (30)

Fuseau (3)

La serrure - sur le Bouton

Cordon de

Pouvoir (41)

Polissage

1. Placer un Coussinet de Mousse propre (44) solidement sur le Coussinet de Polissage

(2).

NOTEZ : Avant de cirer ou polir un véhicule, assurez-vous que c’est la surface a été tout à fait

lavé et est sans poussière, crasse, pétrole, graisse, etc.

2. Appliquer environ deux cuillères à soupe de cire (non inclus) uniformément sur le

Coussinet de Mousse (44).

N’appliquer pas la cire directement à la surface du véhicule. La quantité de cire nécessaire

variera selon la grandeur du véhicule étant ciré.

IMPORTANT

Inspectez soigneusement la condition de l’annexe avant l’utilisation et vérifiez l’annexe

constamment pendant l’utilisation. Si un dommage est noté, arrêtez-vous immédiatement et

remplacez l’annexe avec un non endommagé. Le Harbor Freight Tools ne peut pas être

tenu responsable du dommage causé en utilisant une annexe faite tort sur cet instrument.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 10

Page 25

NOTEZ : Évitez d’utiliser trop de cire. Pour les applications supplémentaires de cire au Bonnet

de Mousse, réduisez la quantité de cire. Le Bonnet de Mousse n’absorbera pas si beaucoup

de cire dans les applications ultérieures.

3. Brancher le Cordon de Pouvoir (41) à un cordon d’extension électrique (non inclus).

Alors, branchez le cordon d’extension à un mis à la terre, GFCI-protégé, 120 volts, une

prise de courant murale électrique.

NOTEZ: Commencez Toujours et arrêtez le Polisseur pendant qu’il est tenu fermement contre

la surface du véhicule. L’échec de faire ainsi peut s’ensuivre dans le Bonnet étant lancé du

Coussinet de Polissage (2).

4. Commencer, serrer le Polisseur fermement avec les deux mains et presse dans sur

l’Interrupteur (36) la manette. Appuyez sur la Serrure - sur le Bouton pour enfermer

l’Interrupteur le Sur la position. Appuyez dans sur l’Interrupteur pour ouvrir de nouveau.

Placer l’unité sur la région à être polie, choisir le désiré passent à toute vitesse en faisant

tourner l’Ajustage de Vitesse (37) le bouton et permettent au Coussinet de Polissage (2)

de tourner jusqu’à ce qu’il ait atteint cette vitesse. Éloignez la pression du Polisseur/

Ponceuse en faisant marcher. Le Bonnet de Polissage devrait LÉGÈREMENT contacter

la surface de polissage.

Prudence: Utilisez Seulement les vitesses plus faibles (1 à 4) du polissage. Autrement,

le dommage peut se produire à la peinture étant polie. Le Harbor Freight Tools n’est pas

responsable du dommage à la fin du véhicule en raison de l’utilisation impropre de ce

polisseur.

5. Commencer à appliquer la cire au véhicule.

Appliquer la cire à toutes les surfaces plates avec les balayures, les larges coups dans

un mouvement sillonne. Appliquez la cire uniformément sur la surface du véhicule et

ajoutez la cire supplémentaire comme nécessaire.

6. Après que la cire a été appliquée à la surface du véhicule, lâchez l’Interrupteur (36) à

son Éteier la position. Débranchez alors le Cordon de Pouvoir (41) du cordon d’extension

électrique.

7. Enlever le Coussinet de Mousse (44) du Coussinet de Polissage (2) et avec votre main

et le Coussinet de Mousse (44), appliquez la cire à tous durement pour atteindre des

régions du véhicule comme environ les lumières, les pognées, sous les pare-chocs, etc.

8. Permettre au temps suffisant pour la cire de vous sécher sur le véhicule.

9. Placer un Bonnet de Polissage propre solidement sur le Coussinet de Polissage (2).

Notez: Tirez Toujours fermement la ficelle pour stabiliser le Bonnet de Polissage.

Stabilisez la ficelle et gardez-le de la voie en attachant plusieurs nœuds.

10. Brancher le Cordon de Pouvoir (de 41) du Polisseur dans le cordon d’extension électrique.

NOTEZ: Commencez Toujours et arrêtez le Polisseur pendant qu’il est tenu fermement contre

la surface du véhicule. L’échec de faire ainsi peut s’ensuivre dans le Bonnet étant lancé du

Coussinet de Polissage (2).

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 11

Page 26

11. Commencer, serrer le Polisseur fermement avec les deux mains et presse dans sur

l’Interrupteur (36) la manette. Appuyez sur la Serrure - sur le Bouton pour enfermer

l’Interrupteur le Sur la position. Appuyez dans sur l’Interrupteur pour ouvrir de nouveau.

12. Commencer à polir le véhicule en en polissant légèrement du résidu de cire dans un

mouvement circulaire. Continuez à polir jusqu’à ce que tout le résidu de cire ne soit

enlevé.

13. Quand fini, lâchez l’Interrupteur (36) à son “éteier” la position. Débranchez alors le Cordon

de Pouvoir (41) du cordon d’extension électrique. Débranchez le cordon d’extension de

la prise de courant murale électrique.

14. Enlever le Bonnet de Polissage du Coussinet de Polissage (2). Avec le Bonnet de

Polissage ou Tissu éponge Cloth (46) dans votre main, enlevez la cire de toutes les

régions dures-à-portée du véhicule.

Fait d’éroder

1. Attacher le sable désiré Érodant le Disque (47 ou 48) sur le Coussinet de Polissage (2).

2. Brancher le Cordon de Pouvoir (de 41) du Polisseur/Ponceuse dans le cordon d’extension

électrique. Alors, branchez le cordon d’extension au mis à la terre, GFCI, 120 volts, la

prise de courant murale électrique.

3. Identifier la région que vous voulez éroder. Assurez-vous que le cordon de pouvoir

l’atteindra loin sans insister sur n’importe quelles connexions. Placez le Polisseur/

Ponceuse sur la région de fait d’éroder.

4. Commencer, serrer le Polisseur/Ponceuse fermement avec les deux mains et presse

dans sur l’Interrupteur (36) la manette. Appuyez sur la Serrure - sur le Bouton pour enfermer

l’Interrupteur le Sur la position. Appuyez dans sur l’Interrupteur pour ouvrir de nouveau.

5. Placer l’unité sur la région à être érodée, choisir le désiré passent à toute vitesse en

faisant tourner l’Ajustage de Vitesse (37) le bouton (1 à 6) et permettent au Disque de

Fait d’éroder (1) de tourner jusqu’à ce qu’il ait atteint cette vitesse. Éloignez la lourde

pression du Polisseur/Ponceuse en faisant marcher. Permettez au disque de fait d’éroder

de faire le travail.

6. Déplacer le Polisseur/Ponceuse dans un dessin uniforme en haut et en bas ou un côté

au côté comme vous érodez pour garantir même le fait d’éroder.

7. Périodiquement, arrêtez le Polisseur/Ponceuse et vérifiez pour l’usure de disque possible.

Remplacez des disques de fait d’éroder utilisés ou usés si nécessaire.

8. Quand fini, lâchez l’Interrupteur (6) à son “Éteier” la position. Débranchez alors le Cordon

de Pouvoir (41) du cordon d’extension électrique. Débranchez le cordon d’extension de

la prise de courant murale électrique.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 12

Page 27

L’INSPECTION, LA MAINTENANCE ET LE NETTOYAGE

AVERTISSEMENT! Assurez-vous que l’Interrupteur de Pouvoir du Polisseur/Ponceuse

est dans son “ÉTEIER” la position et que l’instrument est non branché de sa prise de

courant murale électrique avant le fait d’exécuter n’importe quelle inspection,

maintenance, ou le fait de nettoyer des procédures.

1. Avant chaque utilisation, inspectez la condition répandue du Polisseur/Ponceuse.

Vérifiez pour les vis desserrées, le défaut d’alignement ou le fait d’attacher de pièces

bougeantes, pièces craquées ou cassées, a fait tort aux circuits électriques et à autre

condition qui peut affecter son opération sûre. Si le bruit anormal ou la vibration se

produisent, faites corriger le problème avant l’utilisation de plus. N’utilisez pas

d’équipement fait tort.

2. Revérifiez périodiquement tous les écrous, les boulons et les vis pour l’étroitesse.

3. Magasin dans un endroit propre et sec.

4. L’erreur la plus commune en cirant/polissant un véhicule applique trop de cire. Si le

Coussinet de Mousse (44) devient saturé avec la cire, le polissage sera plus difficile et

prendra plus de temps. L’application de trop de cire peut aussi réduire la durée du

Coussinet de Mousse. Si le Coussinet de Mousse s’enlève constamment le Coussinet

de Polissage (2) pendant l’utilisation, trop de cire peut avoir été appliquée.

5. Enlever le Coussinet de Mousse (44) du Coussinet de Polissage (2) quand le Polisseur/

Ponceuse n’est pas dans l’utilisation. Cela permettra au Coussinet de Polissage de sécher

et retenir sa forme originale. Lavez-le avec le savon léger et l’eau avant le fait de

conserver.

6. Pour prolonger le Coussinet de Polissage (2) la durée et la forme, conservez le visage

en bas de Coussinet de Polisseur pour garder l’appartement de surface.

7. Le Bonnet de Polissage (45) peut être lavé de machine dans l’eau froide avec le détersif

léger. Suspendez-le alors sec.

8. Utiliser seulement du tissu propre et du détersif léger pour nettoyer le corps du Polisseur.

N’utilisez pas de solvants. Ne plongez pas de pièce de l’instrument dans le liquide.

9. Au cours du temps, si la performance de l’instrument diminue, ou il arrête de travailler

complètement, il peut être nécessaire de remplacer les Balais de carbone (31) en enlevant

la Couverture de Support de Balai de carbone (30). Cette procédure devrait être accomplie

par un technicien qualifié. Si les Balais de carbone ne sont pas usés, essayez de nettoyer

les bouts de Balai de carbone avec une gomme d’encre.

LISEZ S’IL VOUS PLAÎT LE SUIVANT SOIGNEUSEMENT

LE FABRICANT ET-OU LE DISTRIBUTEUR A FOURNI LA LISTE DE PIÈCES ET LE DIAGRAMME DE MONTAGE

DANS CE MANUEL COMME UN INSTRUMENT DE RÉFÉRENCE SEULEMENT. AUCUN LE FABRICANT OU

LE DISTRIBUTEUR FONT N’IMPORTE QUELLE REPRÉSENTATION OU GARANTIE DE N’IMPORTE QUELLE

SORTE À L’ACHETEUR QU’IL OU ELLE EST AUTORISÉ POUR FAIRE N’IMPORTE QUELLES RÉPARATIONS

AU PRODUIT, OU QU’IL OU ELLE EST AUTORISÉ POUR REMPLACER N’IMPORTE QUELLES PIÈCES DU

PRODUIT. EN FAIT, LE FABRICANT ET-OU LE DISTRIBUTEUR DÉCLARE EXPRESSÉMENT QUE TOUTES

LES RÉPARATIONS ET LES REMPLACEMENTS DE PIÈCES DEVRAIENT ÊTRE ENTREPRIS PAR LES

TECHNICIENS DIPLÔMÉS ET AGRÉÉS ET PAS PAR L’ACHETEUR. L’ACHETEUR SUPPOSE TOUT LE RISQUE

ET LA RESPONSABILITÉ SURVENANT DU FAIT DE SES RÉPARATIONS AU PRODUIT ORIGINAL OU AUX

PIÈCES DÉTACHÉES Y, OU SURVENANT DU FAIT DE SON INSTALLATION DE PIÈCES DÉTACHÉES Y.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 13

Page 28

LISTE DE PIÈCES

ecèiPnoitpircseDétitnauQecèiPnoitpircseDétitnauQ

1enogaxeH'délC15281#reilaP1

2tenissuoCedegassiloP162tnevedruetcetorpeduaennA1

3uaesuF17255x5teniboRedsiV2

431x4elcrec-im

561x5siV492011#spmetnirP2

6erèinatnirPellednoR403troppuSederutrevuoCalenobracedialaB2

7erèimerPerutre

8102#reilaP1230014#troppuSenobracedialaB2

923euob-edraGeduaennA133elibomotuAnoitatibaH1

01e

1121euob-edraGeduaennA15301x3teniboRedsiV2

2101x8x21,B511reica'Det

3103x5teniboRedsiV4a73essetiVedegatsujA1

41etêtedllehS1a83erutrevuoCelbiaf-sulp-erèirrA1

51er

61erurreSedspmetnirP104521#uaerruoF1

71uaesuFederurreSedeluspaC114riovuoPednodroC1

8161x8enog

91eéngioP13441x4teniboRedsiV2

02101#reilaP144essuoMedtenissuoC1

12elgnairT

224erèinatnirPellednoR364)értnomnon(htolCegnopéussitedtennoBeL1

3201x4s

42erutamrA184elbaS042,redoré'dtiaFedeuqsiD1

eDedélC182rotatS1

vuoC1130014#enobracedialaB2

ganergnEdnarG1a43erutrevuoCerueirépus-erèirrA1

tehcoPaL1a63ruetpurretnI1

urreSedelgnipÉ19302x4siV4

axeH'detêTedsiV224eélbâCehcnalPalruszeyuppA1

edesserPederutrevuoC154tennoBudegassiloP1

iV374elbaS06,redoré'dtiaFedeuqsiD1

LIMITÉ GARANTIE

DE 1 ANNÉE

Harbor Freight Tools Co fait tout le possible pour assurer que ses produits rencontrent la haute qualité et les

normes de durabilité et les mandats à l’acheteur original que ce produit est libre des défauts dans les matériaux et

le travail professionnel pour la période d’un an de la date de l’achat. Cette garantie ne fait pas une demande au

dommage dû directement ou indirectement, au mauvais usage, l’abus, la négligence ou les accidents, les réparations

ou les modifications à l’extérieur de notre équipement, ou au manque de maintenance. Nous ne serons en aucun

cas responsables pour la mort, les blessures aux personnes ou à la propriété, ou pour les dommages accessoires,

contingents, spéciaux ou importants émanant de l’utilisation de notre produit. Quelques états fédéraux ne permettent

pas l’exclusion ou la restriction de dommages accessoires ou importants, donc la susdite restriction d’exclusion

peut ne pas s’appliquer à vous. CETTE GARANTIE EST EXPRESSÉMENT AU LIEU DE TOUTES LES AUTRES

GARANTIES, L’EXPRESS OU IMPLIQUÉE, EN INCLUANT LES GARANTIES DE VALEUR MARCHANDE ET DE

CONFORMITÉ.

Pour profiter de cette garantie, le produit ou la pièce doivent nous être rendus avec les charges de transport

payées d’avance. La preuve de date d’achat et d’une explication de la plainte dans l’anglais doit accompagner les

marchandises. Si notre inspection vérifie le défaut, nous ou réparerons ou remplacerons le produit à notre élection

ou nous pouvons choisir de rembourser le prix d’achat si nous ne pouvons pas sans hésiter et vite vous fournir un

remplacement. Nous rendrons des produits réparés à nos frais, mais si nous déterminons qu’il n’y a aucun défaut,

ou que le défaut est provenu des causes pas dans les limites de notre garantie, alors vous devez porter le prix de

rendre le produit.

Cette garantie vous donne des droits juridiques spécifiques et vous pouvez aussi avoir d’autres droits qui varient

d’état fédéral à l’état fédéral.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-33533491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-33533491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 14

Page 29

DIAGRAMME DE MONTAGE

NOTEZ : La pièce 46 - Tissu éponge Cloth - non montré.

NOTEZ: Quelques pièces sont énumérées et montrées pour les buts d’illustration seulement et ne sont pas en

vente individuellement comme les pièces détachées.

MODÈLE Pour les questions techniques, appelez-vous s’il vous plaît 1-800-444-3353.

92623

Français

Page 15

Loading...

Loading...