Page 1

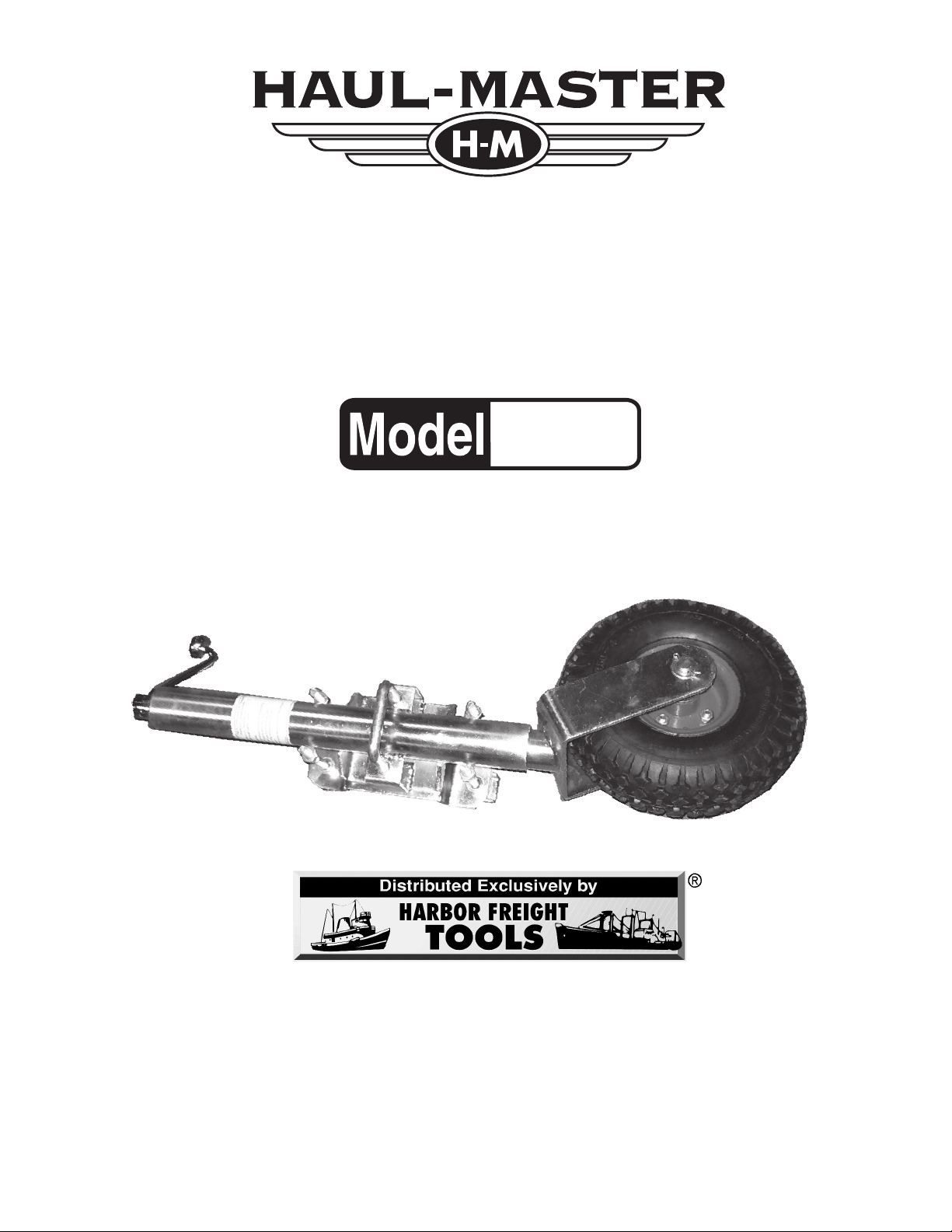

500 LB. SWING BACK

TRAILER JACK

WITH 10” TIRE

92372

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright© 2004 by Harbor F reight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

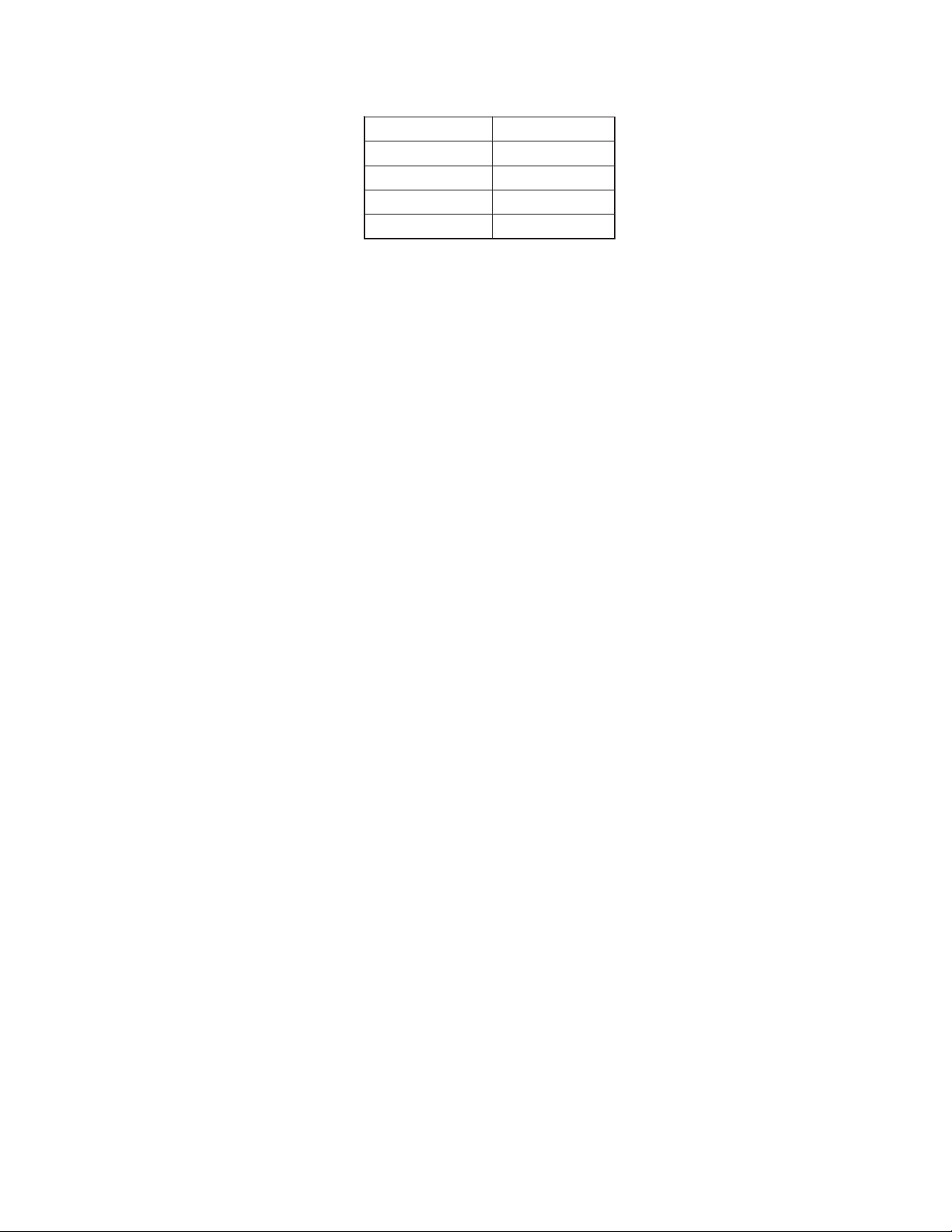

Specifications

yticapaCthgieW.sbL005

eziSeriT)citamuenP(”01

erusserPeriTISP03

3

thgieHmuminiM-82

thgieHmumixaM”93

/4”

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dr y place for future reference.

Safety Warnings and Precautions

WARNING: When using this product, basic safety precautions should always be followed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this product!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Keep work area well lit.

3. Keep children away . Children must ne ver be allow ed in the work area. Do not let them

handle the Jack.

4. Store idle equipment. When not in use , Jacks must be stored in a dry location to inhibit

rust. Always lock up Jacks and keep out of reach of children.

5. Use the right product for the job. Do not attempt to f orce a small product or attachment

to do the work of a larger industrial product. There are certain applications for which this

product was designed. It will do the job better and more safely at the rate f or which it was

intended. Do not modify this product and do not use this product for a purpose for which

it was not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. W ork boots, work gloves and work pants are necessary when working. Protectiv e,

electrically nonconductive clothes and nonskid footwear are recommended when w orking.

Wear restrictive hair covering to contain long hair.

7. Use eye protection. Always wear ANSI approved impact safety goggles.

8. Do not overreach. Keep proper footing and balance at all times.

9. Maintain products with care. Keep the Jack clean for better and safer performance.

The handle must be kept clean, dry, and free from oil and grease at all times.

10. Stay alert. Watch what you are doing, use common sense. Do not operate any product

when you are tired.

11. Never work alone. Always have an assistant nearby to help if unexpected problems

arise during use. An assistant can also get help if you are injured.

12. Check for damaged parts. Before using any product, any part that appears damaged

Page 2SKU 92372 For technical questions, please call 1-800-444-3353.

Page 3

should be carefully checked to determine that it will operate properly and perform its

intended function. Check f or alignment and binding of moving parts; an y broken parts or

mounting fixtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician.

13. Replacement parts and accessories. When having serviced, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this product. Approved accessories are av ailable from Harbor F reight

Tools.

14. Do not operate product if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgment or reflexes are impaired

while taking drugs. If there is any doubt, do not operate the product.

15. Maintenance. For your saf ety, service and maintenance should be performed regularly

by a qualified technician.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator.

Specific T railer Jack Safety Warnings

1. Roll away. A v oid situations which allo w the trailer to roll a w a y on the caster wheel and

trailer wheels. If using the trailer jack on an incline, be sure to chock the wheels. Never

leave the trailer unattended while on the jack if the wheels are not chocked.

2. Swivel failure. The swivel is very strong and exceeds the stated capacity of the jack.

Howe v er ab use , corrosion or damage ma y cause the s wiv el to break. Regularly inspect

the swivel for damage, and discontinue use if the swivel is damaged.

3. Loose mounting plates or hardware. Never operate this Trailer Jack if the mounting

hardware is not secure on the tongue of the trailer. Regularly inspect the hardware for

proper assembly.

4. Overloading. Never attempt to lift or support loads in excess of the rated strength of

this Trailer Jack. Sudden failure of the Jack may result in serious personal or property

injury.

BE AWARE OF D YNAMIC LOADING!

Suddenly dropping a load on the trailer that the jac k is attached to may create,

for a brief instant, an excess load, which may result in damage to the pr oduct and/

or personal injury.

5. Swing up before driving. Always check to be sure that the Jack is properly swung up

into its raised position before driving. Driving with the Jack lowered can cause serious

damage to property . This Trailer Jack is not designed for highway use.

6. Dollying on uneven surfaces. The Tire on this Jack makes moving your tr ailer without

a vehicle convenient. However, moving the trailer on uneven or inclined surfaces can

cause personal injury or potential damage to the Jack or other property.

7. Not to be used for aircraft purposes.

Page 3SKU 92372 For technical questions, please call 1-800-444-3353.

Page 4

Unpacking

When unpacking, check to make sure the parts listed on page 7 are included. If any parts

are missing or broken, please call Harbor Freight Tools at the number on the cover of this

manual as soon as possible.

Assembly / Installation

WARNING: The trailer tongue must be square or rectangular in profile for this Jack to

mount properly. A rounded tongue will allow the Jack to rotate to the side

causing the trailer to fall suddenly, causing potentially serious personal or

property injury.

NOTE: Do not drill holes or otherwise damage the trailer tongue when installing this

Jack. Failure of the trailer tongue may result.

NOTE: Installing this Jack is most easily done with the Trailer mounted on the towing

vehicle hitch.

FIGURE 1

Handle (1)

FIGURE 2

Hardware Set (19)

(1 of 4)

Tire (18)

See detail inset in FIGURE 2.

Mounting Bar (20)

(1 of 2)

Swivel Plate (6)

Outer Tube (7)

Inner Tube (8)

Page 4SKU 92372 For technical questions, please call 1-800-444-3353.

Page 5

Assembly / Installation (continued)

Refer to FIGURES 1 and 2 on page 4, and the Assembly Drawing on page 8.

1. Slide the Handle (1) over the Shaft and secure it with the set Screw (2).

2. T o mount the Tire (18): Slide the Axle (10) through a Washer (9), the Inner Tube (8) Left

Bracket, a Spacer (11), the Wheel, the other Spacer (11), the Inner Tube (8) Right

Bracket, and the other Washer (9). Inser t a Cotter Pin (12) through the axle on each

side, and bend both over completely to secure.

3. Measure the trailer tongue for the best location to mount the Jack. Remember that,

while in its storage position, the Jack m ust not interf ere with the V ehicle or trailer when

turning or passing over speed bumps, boat ramps, etc.

4. Pull on the Swivel Handle (15) to adjust the Swivel Plate (6), so the Jack is in the

lowered position.

5. Hold the Jack against the trailer tongue while using the Jack Handle (1) to lower the

Tire (18) to the ground.

6. Using the four Hardware Sets (19) and two Mounting Bars (20), attach the Jack to the

trailer tongue. The Mounting Bars m ust run across (perpendicular) to the trailer tongue .

NOTE: You may wish to use some remo v a b le thread loc king compound (not included)

on the bolt threads to help secure them.

7. Test the operation of the Trailer Jack. Make adjustments if necessary.

8. Tighten the Hardware Sets (19) firmly and evenly.

Operation

Dismounting The T railer from The T owing V ehicle.

WARNING:Before dismounting, make sure the trailer wheels are properly chocked to

prevent the trailer from rolling. This procedure requires at least 2 people to

be present.

1. With the trailer on the hitch, pull the Swivel Handle (15), and rotate the Ja ck downwards.

WARNING: Keep your fingers away from the Swivel Plate area (See FIGURE 2),

and do not allow the Tire (18) to strike your foot as the Jack rotates downward.

2. Assure that the Swivel Handle pins are in place, locking the Jack into the lowered

position.

3. Rotate the Handle (1) counterclockwise to lower the Tire (18) to the ground. Continue

to crank just enough for the Trailer Jack to take the weight of the trailer. This will make

it easier to disengage the trailer hitch.

4. Disengage the trailer hitch. Remember to disengage any safety chains, electrical

connections and other connections between the vehicle and the trailer.

5. You may need to extend the Jack further to clear the trailer hitch. When the vehicle is

completely clear, and it is safe to do so, drive the vehicle away from the trailer.

WARNING: Be sure to have 2 spotter s watch this operation to be sure the trailer is clear

of the vehicle, and that the trailer does not roll away.

Page 5SKU 92372 For technical questions, please call 1-800-444-3353.

Page 6

Operation (continued)

Using the Jack to Mount The Trailer to the Towing Vehicle.

WARNING: Do not attempt to lift the trailer tongue if it is too heavy for you. You may

need assistance for some parts of this operation. This procedure requires at

least 2 people to be present.

1. If the trailer tongue is resting on the ground, pull the Swivel Handle (15) allowing the

Trailer Jack to rotate downward.

2. If you are able, lift the tr ailer tongue, while the J ack rotates into the lo wered position. If

the Tongue is too heavy get assistance.

3. Pull the Swivel Handle (15) out, then reengage the pins, locking the Jack into the

lowered position.

4. Rotate the Handle (1) clockwise to raise the trailer to just abo v e the le v el of the to wing

vehicle’s hitch.

5. Have an assistant spot for you as you move the vehicle close to the trailer. Or, if on

smooth ground, roll the trailer to the vehicle.

6. Mount the trailer onto the towing vehicle’s hitch.

Keep your fingers clear.

7. T urn the Handle (1) counterclockwise to raise the Jac k slightly off the ground, transferring

the trailer weight onto the towing vehicle.

8. Pull out the Swivel Handle (15), and rotate the Jack into its upr ight position. Be sure

that the Swivel Handle locking pins are fully engaged and the wheel choc ks are removed

before driving away.

Maintenance

If you discov er any damage , hav e all damaged parts repaired or replaced before using

your Trailer Jack.

1. Regularly inspect the Springs (17) and Swivel Handle (15) locking pins to be sure they

will properly engage and lock the Jack in both the up and do wn positions. Check all of

the Hardware Sets (19) regularly to ensure that they are tight and the Jack is firmly

attached to the trailer tongue.

2. Keep the Swivel Plate (6) lubricated with light grease. Inspect it regularly for damage.

3. Keep the crank mechanism (inside the Outer Tube (7)) and the top shaft of the Inner

Tube (8) lightly greased. Ensure that this mechanism functions smoothly.

4. Inspect the Tire (18) regularly for damage. Keep the tire filled to a cold pressure of 30

PSI. Keep the axle lightly lubricated.

5. Inspect the entire unit for corrosion which ma y be caused b y exposure to salt water or

weather . Rinse thoroughly and re-lubricate promptly after being immersed in salt water .

6. Keep all moving parts lightly lubricated to prevent corrosion. If corrosion develops , you

may paint exterior parts of the Jack to help arrest and prevent further damage.

Page 6SKU 92372 For technical questions, please call 1-800-444-3353.

Page 7

Parts List

Part No. Description Qty.

1 Handle 1

2 Screw M8x10 1

3 Bearing 1

4 Screw Rod 1

5 Nut 1

6 Swivel Plate 1

7 Outer Tube 1

8 Inner Tube 1

9 Washer 2

10 Axle 1

11 Spacer 2

12 Cotter Pin 2

13 Washer 1

14 Nut M16 1

15 Swivel Handle 1

16 Bushing 2

17 Spring 2

18 Tire 1

19 Hardware Set 4

20 Mounting Bar 2

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PAR TS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THA T HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY ST A TES T HA T ALL REP AIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NO T BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PR ODUCT OR REPLACEMENT PARTS THERETO, OR ARISING

OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

NOTE: Some par ts are listed and shown for illustration pur poses only and are not available

individually as replacement parts.

Page 7SKU 92372 For technical questions, please call 1-800-444-3353.

Page 8

Assembly Drawing

Page 8SKU 92372 For technical questions, please call 1-800-444-3353.

Loading...

Loading...