Page 1

®

12 VOLT IMPACT WRENCH

Model 92349

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2004 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

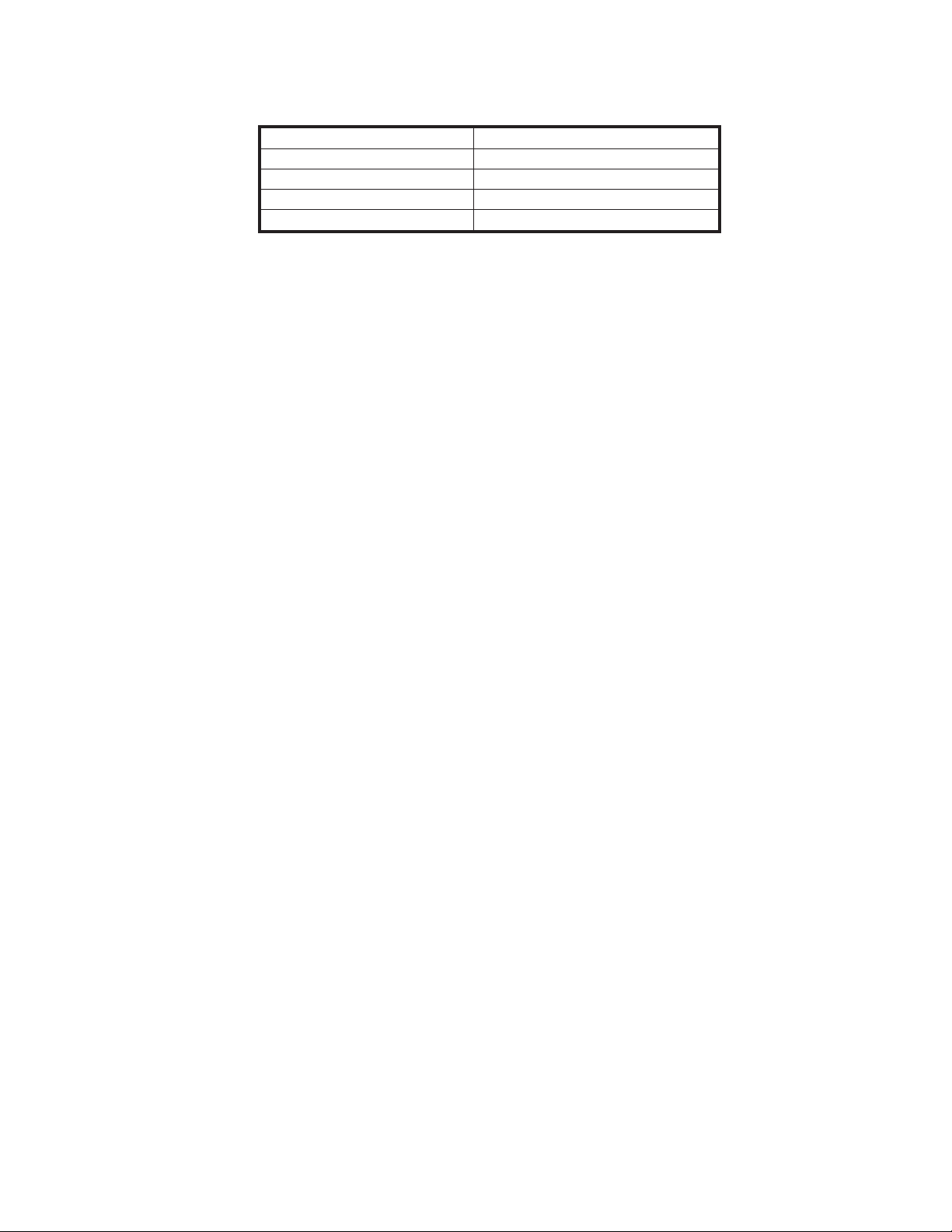

Specifications

Maximum Torque 150 Ft. Lbs.

Drive Size

Blows Per Minute 30 to 40

Power Cord (12 Volt Plug In) 18 AWG X 2C SPT - 2, 11’ Long

Accessories 7/8”, 13/16”, 3/4”, & 11/16” Sock ets

1

/2” Square

NOTE: Unlike air-operated or 120V A C impact wrenches, this Wrenc h will build up inertia

before striking a blow. This is normal, and DOES NOT INDICATE A PROBLEM.

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this tool

was designed. It will do the job better and more safely at the rate for which it was

intended. Do not modify this tool and do not use this tool for a purpose for which it

was not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically nonconductive clothes and nonskid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

7. Use eye protection. Always wear ANSI approved impact safety goggles.

8. Do not overreach. Keep proper footing and balance at all times.

Page 2SKU 92349 For technical questions, please call 1-800-444-3353

Page 3

9. Maintain tools with care. Keep tools clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords periodically

and, if damaged, have them repaired by an authorized technician. The handle must

be kept clean, dry, and free from oil and grease at all times.

10. Disconnect power. Unplug tool when not in use.

11. Avoid unintentional starting. Be sure the Trigger is in the Off position when not in

use and before plugging in. Do not carry any tool with your finger on the trigger,

whether it is plugged in or not.

12. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

13. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be proper ly repaired or replaced by a qualified

technician. Do not use the tool if any Trigger does not operate properly.

14. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures. Use caution near batteries and

starters.

15. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor

Freight Tools.

16. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

17. Maintenance. For your safety, service and maintenance should be performed

regularly by a qualified technician.

18. People with pacemakers should consult their physician(s) before using this

product. Electromagnetic fields in close proximity to a heart pacemaker could cause

interference to or failure of the pacemaker.

19. Use this tool with both hands. This tool requires the use of both hands when

operating. This helps maintain tool stability and keeps hands away from the working

area of the tool.

20. This unit should only be powered b y 12 Volt DC systems.

Note: Performance of this tool may vary depending on variations in battery power.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator .

Page 3SKU 92349 For technical questions, please call 1-800-444-3353

Page 4

Unpacking

When unpacking, check to make sure the parts listed on page 7 are included. If any parts

are missing or broken, please call Harbor Freight Tools at the number on the cover of this

manual as soon as possible.

Operation

WARNING! Running engines produce carbon monoxide, an odorless, colorless gas that is

extremely to xic. Exposure to carbon monoxide can result in headaches, dizziness, v omiting,

and even death. The engine must only be run in an open, well-ventilated place.

1. Prior to use, be sure that your vehicle or other work object is safely secured in preparation

for maintenance.

2. This tool operates on 12 Volts DC. Do not attempt to use this tool with any other v oltage .

3. You may connect to the 12 Volt power source by directly plugging in the 12 Volt Plug-In

(24) to the vehicle’s receptacle, or, you may use the Battery Adapter Cable. To use the

Battery Adapter Cable, simply insert the 12 V olt Plug-In into the Adapter . When it is saf e

to do so, connect the RED clamp to the POSITIVE terminal of a 12 volt battery. Connect

the BLACK clamp to a clean grounded part of the vehicle such as the engine block or

frame member . NEVER leave either c lamp attached to the vehicle while the impact

wrench is not being used; disconnect clamps

finished. Also, make certain that neither clamp can come into contact with any

other wire or metal portion of the vehicle’s engine. See FIGURE 1.

immediately as soon as work is

NOTE: If the engine is left running while performing this operation, be sure to avoid placing

any cables or clamps, or your hands, clothes, hair or any other appendage in close proximity

to the moving parts of the engine.

FIGURE 1

Clamp

Anvil (4)

Adapter (40)

12 Volt

Plug-In (24)

FIGURE 2

Trigger (26)

12 V olt

Plug-In (24)

Page 4SKU 92349 For technical questions, please call 1-800-444-3353

Page 5

Operation (continued)

WARNING: Working around vehicle engines whether running or not is inherently dangerous,

and extraordinary precautions outside the scope of this booklet are required. Refer to the

owner’s manual of your vehicle for more information.

4. NOTE: Unlike air-operated or 120V AC impact wrenches, this wrenc h will build up

inertia before striking a blow . This is normal, and DOES NO T INDICA TE A PROBLEM.

5. Make sure the vehicle is parked safely away from all other moving traffic. Be sure the

vehicle is parked on a flat, dry, level surface. Be sure the vehicle’s emergency brake is

set, and the tires have wheel blocks prev enting movement.

6. Select the appropriate size socket to fit the wheel lug nut. Attach the sock et to the Impact

Wrench by pressing them on to the Anvil (4). Only use impact soc kets and attachments.

7. Position an appropriate lift (not included) under the lift point for each wheel to be removed. (Follow the vehicle and lift manufacturer’s instructions for doing so.) Lift the

vehicle until the wheel is off the ground, and support the vehicle securely on jack stands

(not included).

8. The Impact Wrench is rev ersible. To operate the Impact Wrench in a f orward (tightening)

direction, set the Directional Lever toward the “R” symbol - see FIGURE 3. To operate

the Impact Wrench in reverse direction, set the Directional Lever toward the “L” symbol.

If the Directional Lev er is set in the middle, the unit will not turn in either direction. Using

the Impact Wrench in re verse, remo ve the wheel lug nuts according to the manuf acturer’s

recommendations. (In most cases, the manufacturer will recommend that you remove

the lugs in an alternate pattern, moving around the wheel.)

FIGURE 3

Note: For night use, this Impact

Wrench has a LED (27)

light. See FIGURE 4.

Directional

Lever

Trigger (26)

LED (27)

FIGURE 4

Page 5SKU 92349 For technical questions, please call 1-800-444-3353

Page 6

Operation (continued)

9. Occasionally, you will have to manually break a nut loose bef ore y ou can remo v e it with

the Impact Wrench. To do so, use a Breaker Bar (not included) and Socket to break the

nut loose. Then, proceed as discussed in number 8 on page 5.

10. Replace the wheel on the vehicle hub , aligning the wheel studs with the bolt holes in the

wheel.

11. Install the wheel lug nuts, following the vehicle manufacturer’s recommendations. To

avoid cross-threading the lug nuts, thread the nuts on by hand first, before using the

Impact Wrench.

CA UTION

Do not use the Impact Wrench to tighten the lug nuts.

The torque may e xceed the vehicle specifications and damage may result.

12. When the wheel is securely refastened, use a torque wrench (not included) to check the

torque on all bolts and ensure that the tightness meets the manufacturer’s recommendations. Check under the vehicle and remove any tools. Lower the vehicle, disconnect

the tool and replace the lift and the Impact Wrench to their storage places.

Maintenance

1. When not in use, store your Impact Wrench and its accessories in its case, in a secure, dry place. Protect it from water, moisture, oil, fuel, grease or other foreign

materials which may damage the case, moving parts, or electrical components.

2. This tool should only be repaired by a qualified technician.

3. The 12 Volt Plug-In (24) assembly has a fuse that will eventually need replacing.

Remove the Cap at the end of the Plug-In and replace the fuse making sure to replace the pieces below, in the exact same order as shown. Only replace the fuse

with another 12A-250V fuse of the same style.

12 V olt

Plug-In (24)

Fuse

Cap

Page 6SKU 92349 For technical questions, please call 1-800-444-3353

Page 7

Parts List

Part No. Description Part No. Description

1 Bearing 21 Bolt

2 Anvil Bearing 22 Cable Block

3 Radial Bearing 23 Cable Bushing

4 Anvil 24 12V Plug-In

5 Oil Bearing 25 Left Housing

6 Rachet Wheel Base 26 Trigger

7 Wheel 27 LED

8 Wheel Tray 28 Bolt

9 Pull Spring 29 Wheel

10 Wheel Brace 30 Pull Spring

11 Rachet Wheel Bearing 31 Bolt

12 Pedestal Bearing 32 Bolt

13 Gear 33 Pawl

14 Gear Shaft 34 Rod

15 Drive Wheel 35 7/8” Socket

16 Motor Gear Wheel 36 13/16” Socket

17 Gear Box Lid 37 3/4” Socket

18 Bolt 38 11/16” Socket

19 Right Housing 39 Bolt

20 Motor 40 Battery Adapt. Cable

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTA TION OR W ARRANTY OF ANY KIND TO THE BUYER THA T HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY ST A TES THA T ALL REPAIRS AND P ARTS REPLA CEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NO T BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS T O THE ORIGINAL PRODUCT OR REPLACEMENT P AR TS THERET O , OR ARISING

OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

Page 7SKU 92349 For technical questions, please call 1-800-444-3353

Page 8

19

Assembly Drawing

23

24

18

17

16

14

13

12

11

9

10

7

8

6

5

4

32

15

29

30

31

20

28

38

22

21

25

26

27

37

33

3

2

1

35

Note: The Battery Adapter Cable (40) is not shown.

34

36

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

39

Page 8SKU 92349 For technical questions, please call 1-800-444-3353

Loading...

Loading...