Page 1

LOG SPLITTER

WARNING!

IMPORTANT INFORMATION

This trailer’s Hitch Coupler MUST be

properly secured to the hitch ball of the towing

vehicle. After assembly and attachment, pull

up and down on the Hitch Coupler to make

sure the hitch ball is fitting snugly in the Hitch

Coupler. There must be no play between the

hitch ball and Hitch Coupler. If there is play,

tighten the Adjustment Nut until no play is

present. If the Adjustment Nut is too tight, the

Handle will not lock. Carefully read and follow

the complete instructions in this manual

BEFORE setup or use.

If the Coupler is not secured

properly, the ball could come loose

while the trailer is in motion, possibly

causing property damage, SERIOUS

PERSONAL INJURY, or DEATH.

®

WITH ROBIN

MODELS 91839, 91840 & 92199

ASSEMBLY AND OPERATING INSTRUCTIONS

ENGINE

Copyright© 2004 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Visit our Web site at http://www.harborfreight.com

3491 Mission Oaks Blvd., Camarillo, CA 93011

REV 11/04; REV 02/06

Page 2

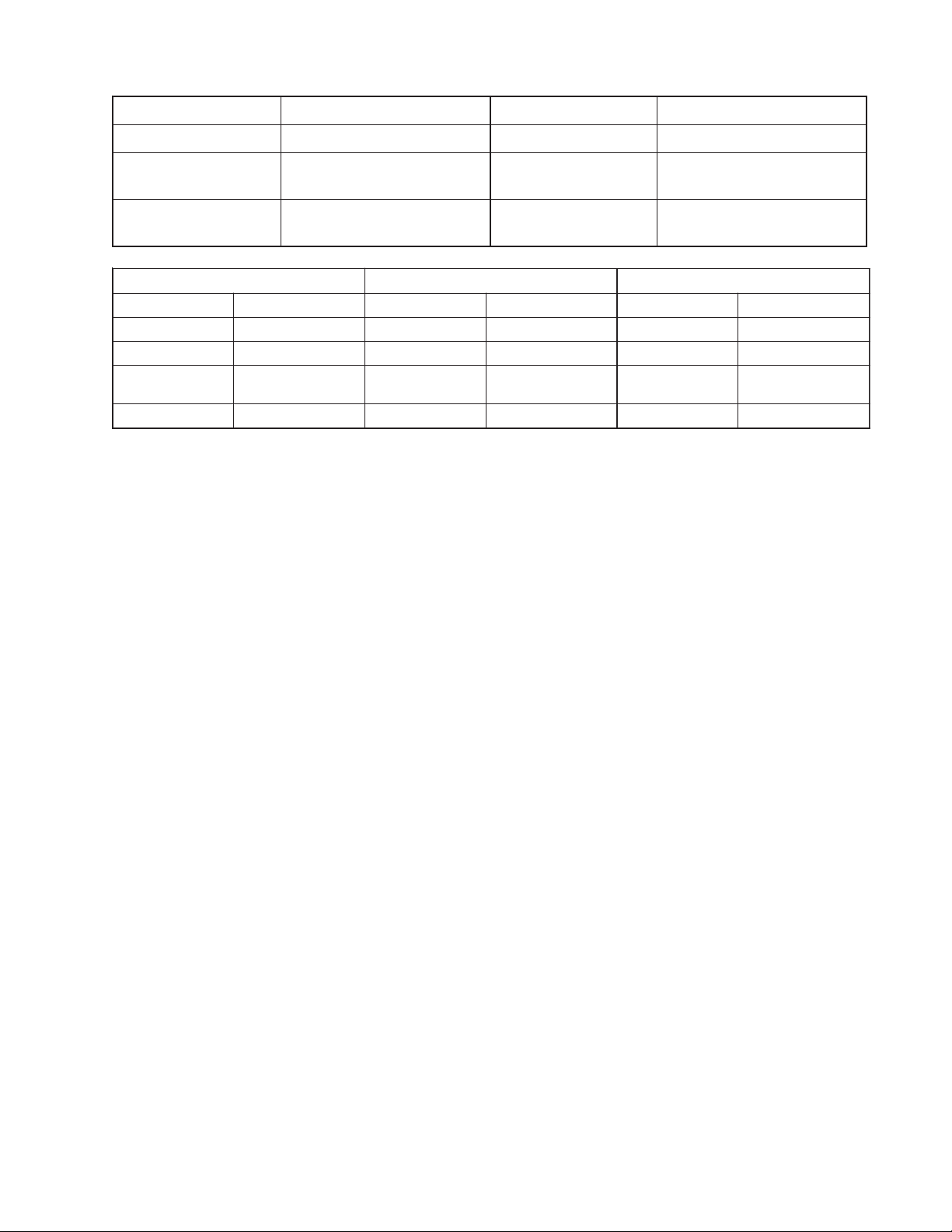

Specifications

yticapaCgoLretemaiD”8,gnoL”52erusserPriAeriTISP06dloC

snoisnemiDllarevO”4/1-73x”2/1-24x”4/1-97eziSegdeWllaT”8

diulFciluardyH

snollaG5.2ssenkcihTetalPeoT”8/5-1

/1-7

yticapaC

eziSleehW.T.O.D,retemaiD”8

retemaiDmaRl

larevO”4/3-1

devorppA

93819UKS04819UKS99129UKS

enignEniboR72-XEPH9

retemaiDrednilyC”2/1-4retemaiDrednilyC”5retemaiDrednilyC”5.4

ecroFfosnoT42ecroFfosnoT03ecroFfosnoT22

pmuPxedlaH

thgieW.sbL894thgieW.sbL046thgieW.sbL294

®

®

-2,MPG11

raeGegatS

enignEniboR72-XEPH9

pmuPxedlaH

®

®

-2,MPG61

raeGegatS

enignEniboRPH6

pmuPxedlaH

®

®

raeGegatS

This product requires engine oil, hydraulic oil, and fuel to be added before starting.

Attempting to start the engine without oil will ruin the engine and void the warranty.

Before starting the engine, refer to the engine owners manual for additional engine

maintenance information.

-2,MPG11

Note: 8” maximum diameter applies to most soft to medium types of woods. Maximum

diameter of hardwoods may vary depending on density of the wood.

Note: Read and follow the instructions and safety warnings in the manual that accompanies the Robin® engine. Engine specifications are listed in the engine manual.

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted.

3. Keep children away; this unit may produce hazardous flying debris. Children must

never be allowed in the work area. Do not let them handle machines or tools.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

RAV 01/07

Page 2For replacement parts, please call 1-800-444-3353.

SKUs

91839, 91840

& 92199

Page 3

5. Use the right tool for the job. Do not attempt to force a small tool or attachment to do the

work of a larger industrial tool. There are certain applications for which this tool was

designed. It will do the job better and more safely at the rate for which it was intended.

Do not modify this tool and do not use this tool for a purpose for which it was not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically nonconductive clothes and nonskid, steel toe footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

7. Use eye protection. Always wear ANSI approved impact safety glasses underneath a

full face shield. Wear an ANSI approved dust mask or respirator when working around

wood dust.

8. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across the Log Splitter.

9. Maintain tools with care. Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect tool hoses periodically, and if damaged, have them repaired by an authorized technician. The handle must

be kept clean, dry, and free from oil and grease at all times.

10. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches are

removed from the tool or machine work surface before plugging it in.

11. Never leave the Log Splitter unattended while in operation.

12. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

13. Never attempt to split two logs on top of each other.

14. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts or

mounting fixtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician. Do

not use the tool if any switch does not turn On and Off properly.

15. Always operate the Log Splitter on a dry, flat, level surface with the wheels blocked.

16. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

17. Do not operate tool if under the influence of alcohol or drugs. Read warning labels

if taking prescription medicine to determine if your judgment or reflexes are impaired

while taking drugs. If there is any doubt, do not operate the tool.

18. Maintenance. For your safety, service and repairs should be performed regularly by a

qualified technician. Maintenance should be performed regularly.

19. Never place your hands or body near a hydraulic fluid leak. Never check for a leak

with your hands or other body parts. High-pressure fluid can be forced under your skin

resulting in serious injury.

20. Never place hands or feet between the log and splitter wedge, or between the log

and the ram during the forward or reverse stroke.

SKUs

91839, 91840

& 92199

Page 3For replacement parts, please call 1-800-444-3353.

Page 4

21. This equipment must never be used in any sealed structure. Carbon mon-

oxide is produced during operation and is DEADLY in a closed environment.

Early signs of carbon Monoxide poisoning resemble the flu, with headaches,

dizziness, or nausea. If you have these signs, the tool may not be working properly or is improperly vented, get fresh air immediately.

22. Never split a log that contains any foreign materials.

23. WARNING: The brass components in this product contain lead, which is a chemical

known to the State of California to cause cancer and birth defects or other reproductive

harm. (California Health & Safety Code § 25249.5,

et seq.

)

24. People with pacemakers should consult their physician(s) before using this prod-

uct. Electromagnetic fields in close proximity to a heart pacemaker could cause

interference to or failure of the pacemaker.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator.

Unpacking

When unpacking, check to make sure the parts listed on page 9 are included. If any

parts are missing or broken, please call Harbor Freight Tools at the number on the cover of

this manual as soon as possible.

Assembly

Note: Because of the weight and size of the Log Splitter, assembly should be done with the

help of another person.

Attaching the Tires

Refer to the Assembly Drawing on page 9 and FIGURE 1 on page 5.

1. Position the Tires (48) next to each of the Axles located on the bottom of the Oil Tank

Assembly (10). The Tires (48) come completely assembled.

2. Make certain to pack the bearings as explained in the included insert.

3. Put a Seal (59) and Bearing (49) on the Axle and then put the Tire (48) on the Axle.

4. Follow the

manual. With each Tire (48) in place, add a Washer (50) and a Spindle Nut (51) onto

the ends of the Axles. Tighten the Spindle Nuts (51) to 20-25 ft. pounds, and turn each

tire several times to seat the bearing. Back off the Spindle Nut (51) one half turn. Insert

a Cotter Pin (25) through both the Axle and the Spindle Nut (51) and bend the end of

the Pin back to hold it in place. Lastly, tap on a Wheel Cap (61).

Bearing Packing Instructions

as explained on the last page of this

The Tire (48) assembly is now complete. Note: It may be necessary to reset the wheel

bearings after the Log Splitter has been towed.

The wheel manufacturer states the maximum speed is not to exceed 40 MPH. The tires

are DOT approved for public roads; however, this item is not for use on public roads or

highways.

SKUs

91839, 91840

& 92199

REV 11/04

Page 4For replacement parts, please call 1-800-444-3353.

Page 5

Assembly (continued)

Connecting the Rail Assembly (2) to the Oil Tank Assembly (10B)

1. Insert the Front Leg Assembly (11) into the bracket on the Oil Tank Assembly (10B).

Insert the remaining Hex Head Bolt (16) through the hole in the middle of the bracket of

the Oil Tank Assembly (10B). Secure it with a Hex Head Nut (17). Refer to the Hex

Head Nut (17) attached to the Hex Head Bolt (16) at the top of the Front Leg Assembly

(11) in FIGURE 1 below. Note: When travelling, remove the Push Pin (26) and Hair

Pin Clip (29) and lift the Front Leg Assembly up so that it is parallel to the Rail Assem-

bly (2). Then, replace the Push Pin (26) and Hair Pin Clip (29) into the Horizontal

Transport Hole shown just above the Oil Plug (37), in FIGURES 1 and 2.

2. To connect the Rail Assembly (2) to the Oil Tank Assembly (10B), insert a Hex Head

Bolt (16) into the middle hole of the “L” shaped bracket on the Oil Tank Assembly

(10B). Secure it with a Hex Head Nut (17). Refer to the Hex Head Nut (17) attached to

the Hex Head Bolt (16) just above the tire in FIGURE 1 below. Insert the Push Pin (26)

through the hole, as shown in FIGURE 3.

3. In FIGURES 1 and 2, the Rail Assembly (2) is shown in Horizontal mode for operation

and travel (as mentioned above, the Front Leg Assembly (11) must be secured up in

the horizontal position when travelling). For vertical operation see page 6.

FIGURE 1

Safety Chain

with Hook (4)

Hitch Coupler (9)

Front Leg Assembly (11)

FIGURE 2

Cylinder (1)

Hex Head Nut (17) is attached to Hex Head Bolt (16)

Horizontal transport hole

Push Pin (26) and

Hair Pin Clip (29

Oil Tank (10B)

Horizontal transport hole

)

Slide Assembly (3)

Oil Plug (37)

with air inlet hole

Oil Removal Plug

Wheel Cap (61)

FIGURE 3

Second Push Pin (26) secures

Rail Assembly (2), and is removed

for vertical log splitting.

Push Pin (26)

Air Inlet Hole

Base

Place Log Here

Rail Assembly (2)

Vertical Position Hole

Hex Head Nut (17) is attached

to Hex Head Bolt (16)

Vertical position

locking hole

Push Pin (26)

Close-up of Push Pin (26) securing the

Front Leg Assembly (11) to the bracket

on the Oil Tank Assembly (10B).

SKUs

91839, 91840

& 92199

Oil Plug (37)

with air inlet ho

le

Page 5For replacement parts, please call 1-800-444-3353.

Page 6

Transportation

CAUTION

Care must be taken when backing up

the Trailer; only back up the trailer on a

straight path. If the Trailer is allowed to turn

off the straight path while backing up, the Trailer

could jackknife, causing severe damage to the

trailer and to the towing vehicle.

When transporting the Log Splitter, make sure

your hitch (not included) is compatible with the

Hitch Coupler (9). Follow all of the safety warnings for towing in your vehicle’s manual. Always

use the Safety Chain with Hook (4) when towing

a vehicle. Do not tow the Log Splitter at speeds

above 45 MPH. As mentioned in number 2 on page 5, always travel with the Front Leg

Assembly (11) in the horizontal position. The Rail Assembly (2) must always be secured

in the horizontal position for travelling. Note: Make sure the air inlet hole on the Oil Plug

(37) is covered when transporting. See FIGURE 3 on page 5, and refer to number 2 in

Operation below.

Pull up and down on the Hitch Coupler to make sure the hitch ball is fitting snugly in the

Hitch Coupler. There should be no play between the hitch ball and Hitch Coupler. If there

is play, tighten the Adjustment Nut until no play is present. If the Adjustment Nut is too

tight, the Handle will not lock.

Note: The hitch will accept 2 inch hitch balls.

FIGURE 4

Operation

Warning!! Always block the wheels before changing the

position (vertical/horizontal) of the unit.

In FIGURE 1, the Rail Assembly (2) is shown in Horizontal mode for operation and travel. In FIGURE 4 the unit is

shown in the vertical position. To change positions, remove the Hair Pin Clip (29) and the Push Pin (26). A

close-up of this Push Pin (26) is shown in FIGURE 3 on

page 5. Tilt the unit to the vertical position as shown in

FIGURE 4, and replace both the Push Pin (26)

and the Hair Pin Clip (29) into the vertical posi-

Base

Place

Log

Here

tion hole (See FIGURE 1). Reverse the process

to return to the horizontal position.

1. Remove the Oil Plug (37) and fill the tank with Hydraulic oil (not included). To check the

oil level remove the Dipstick (62), check the level then replace it. The oill should be at

the upper notch of the Dipstick. Be sure that a constant oil level of 2.5 gallons is maintained. See FIGURE 3 on page 5, Parts List page9, and Assembly Diagram page 10.

2. The hydraulic system must be vented during operation or it may become vacuum locked

and stop working properly. To vent the system, open the air inlet hole (See FIGURE 3)

by loosening the Oil Plug. You may have to move the o-ring to expose the air inlet vent.

When the Log Splitter is not in operation or being transported, close the air inlet hole by

tightening the Oil Plug (37).

Vertical Position

3. Make certain that the maximum length of each log does not exceed 25 inches with a

SKUs

diameter of 8 inches.

91839, 91840

& 92199

07e

Page 6For replacement parts, please call 1-800-444-3353.

Page 7

Operation (continued)

4. Place the log on the Splitter Base as shown in FIGURES 1 and 4. Make sure the

wedge on the Slide Assembly (3) is facing the log. (See FIGURE 1).

5. After reading and following all of the setup, safety, and operation warnings in the Robin

Operating Manual, turn on the engine. See FIGURE 5. Set the engine’s throttle all the

way to the fast setting (represented by the rabbit, left in the picture below).

FIGURE 5

(9 HP Engine Shown)

Throttle

Choke

Starter Cord

®

WARNING!! Stand clear of the splitting area. No spectators should be within

twenty feet of the log splitting area. Wood projectiles can fly in any direction.

FIGURE 6

6. Grip the Directional Valve (58) and move

it into the lower position to move the

Slide Assembly (3) toward the log to split it.

7. Once the log is split, remove the split pieces.

To back the wedge off the log, move the

Directional Valve (58) away from the log

Directional Handle (58)

you just split.

To stop movement of the Log Splitter at any time, move the Directional Valve

(58) into the midpoint. Do not ever go near the splitting area if the Slide

Assembly (3) is moving.

8. Continue repeating the above steps until all of the logs are split.

SKUs

91839, 91840

& 92199

Page 7For replacement parts, please call 1-800-444-3353.

Page 8

Maintenance

The engine must be off when performing any maintenance. If the unit was

recently used, make sure that the engine has cooled to avoid burns.

1. After every use, wipe down the Log Splitter to remove any tree sap or dirt. This will extend the

life of the unit. Always keep the wedge and base clean.

2. When storing, make sure the Log Splitter is locked in a location where children cannot reach it.

3. Read the maintenance section of the engine manual and follow all of the procedures.

Note: The recommended interval for changing the hydraulic oil and filter is approximately every 3

months.

4. BEFORE TRANSPORTING, inspect the general condition of the Trailer. Check for loose Bolts

and Nuts, misalignment or binding of moving parts, cracked, bent, or broken parts, excessively worn Safety Chain , damaged Tail Lights/Side Running Lights/Wiring Harness, loose Lug

Nuts, loose Hitch connection, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use.

use damaged equipment.

5. BEFORE TRANSPORTING, check the Tires for wear and proper inflation (60 PSI).

6. BEFORE TRANSPORTING AND AT 500 MILE INTERVALS DURING EVERY TRIP, check

and tighten the Tire Lug Nuts. Torque from 85 to 90 Ft.-Lbs.

Do not

7. EVERY 2,000 TO 3,000 MILES OF TRAVEL, lubricate the Hub Assemblies with a heavy weight

bearing grease. Follow the

this manual. After each Hub Assembly is reassembled, tighten the Castle Nut until the wheel

starts spinning with slight resistance. Loosen the Castle Nut about 1/2 turn from this point.

Insert a new Cotter Pin through the Castle Nut and the hole in the axle. Bend the Pin back,

locking it and the Nut in place.

Bleeding the Hydraulic System

If the Log Splitter begins to lose power or splitting efficiency, it may be a result of air becoming trapped

in the hydraulic system. Follow the steps below to bleed air from the system.

1. Loosen the Oil Plug (37) and make sure the o-ring is out of the way to expose the air hole in the

Oil Plug (37).

2. Remove the spark plug from the engine (see engine manual) to keep the engine from starting

during this process.

3. Push the Directional Valve (58) forward, toward the front of the Cylinder (1) (see FIGURE 1).

4. Pull the engine starter cord 10-15 times until the hydraulic cylinder piston moves forward.

CAUTION: Keep everything away from the splitting edge during this process.

5. Tighten the Oil Plug (37).

Bearing Packing Instructions

as explained on the last page of

6. Replace the spark plug.

7. Test the Log Splitter to make sure it is operating properly. If not, repeat the above process.

Warning! Only a qualified technician should repair or service the inter-

nal hydraulic system of this unit.

SKUs

91839, 91840

& 92199

Page 8For replacement parts, please call 1-800-444-3353.

Page 9

Parts List

When ordering parts, be certain to note which Sku number they are for.

traPnoitpircseD.ytQtraPnoitpircseD.ytQ

1rednilyC123esoHerusserPhgiH1

2ylbmessAliaR133esoHnruteR1

3ylbmessAedilS143esoHtelnI1

4kooHhtiWniahCytefaS153pmalCesoH4

5ediuGedilS263rotcennoCelaM1

6reniateRedilS273gulPliO1

7''2/1-2*''2/1tloB683gnittiFerusse

8''2/1tuNxeH7932#gnittiFwoblE°092

9relpuoChctiH1043#gnittiFwoblE°092

B01ylbmessAknaTliO114''4/3*''8/3tloBdaeHxe

11ylbmessAgeLtnorF124''1*''61/5tloBdaeHxeH4

21''4/3-1*''2/1tloBdaeHxeH234retliFliO1

31''2/1tuNxeH244tekcarBgnitnuoMp

41''8/3tuNdaeHxeH354pmuP1

51''2/1rehsaW264''1*''61/5tloBdaeHxeH4

61''4/1-1*''61/9tloBdaeHxeH274''4/1-3*''8/3tloBda

71''61/9tuNxeH284eriT2

81rehsaW194E50203gniraeB4

91''4/3-2*''61/5tloBdaeHxeH105''4/3rehsaW2

02''8/3tuNdaeHxeH115tuNeld

12laeSgniRO125ediSpmuP-gnilpuoC1

22''4/3-1*''2/1tloBdaeHxeH435ediSenignE-gnilpuoC1

32''61/5tuNxeH445''8/1yeKpmuP1

4

2''61/5rehsaWgnirpS855yeKenignE1

52niPrettoC265wercSxeH2

62niPhsuP275enignE * 1

72niPsivelC185evlaVlanoitceriD1

82pilCniPriaH295la

92''5.2pilCniPriaH206''2/1-3*''8/3tloBdaeHxeH1

03redloHedilS116paCleehW2

13gnibuTciluardyH126kcitspiD1

rPhgiH1

H1

muP1

eHxeH2

nipS2

eS2

SKUs

*The parts list for the Engine (57) is in the separate Robin® Engine Manual.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT

BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR

HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

91839, 91840

07e

& 92199

Page 9For replacement parts, please call 1-800-444-3353.

Page 10

Assembly Drawing

SKUs

61

91839, 91840

& 92199

07e

Page 10For replacement parts, please call 1-800-444-3353.

Page 11

Hydraulic Ram Seals

stiKlaeS

ledoMukStraP

93819

17662

99129

0481927882

Warning! Only a qualified technician should repair or service the internal

hydraulic system of this unit.

SKUs

91839, 91840

& 92199

REV 10/05

Page 11For replacement parts, please call 1-800-444-3353.

Page 12

Hydraulics Drawing

Bearing Packing Instructions

Important

Read and adhere to the following instructions; failure to read and obey all of the

following instructions COMPLETELY will void the warranty and can result in damage to

the trailer, property damage, or SERIOUS PERSONAL INJURY.

Whenever a hub is disassembled (if a hub on a new unit requires assembly or a hub is

disassembled for maintenance), the following procedure MUST be followed.

1. Using a suitable solvent, thoroughly clean the bearings and the rest of the parts in the Hub

assembly of all grease, dirt, metal shavings, or any other foreign object. The parts must be

cleaned even if they are new or

2. Allow all pieces to dry completely.

3. Make sure that your hands are thoroughly clean and the bearing packer (not included) is also

thoroughly clean.

4. Place fresh, clean bearing grease in the packer.

5. With the grease-filled bearing packer in one hand and the bearing in the other, press the bearing into the grease, forcing the grease inside the slots in the bearing, continue doing this until

every slot in the bearing is completely full of grease.

6. Finish assembling the hub/wheel assembly as explained in this manual, being careful not to

get any dirt or debris on any part of the assembly.

appear

clean.

SKUs

91839, 91840

& 92199

Page 12For replacement parts, please call 1-800-444-3353.

Loading...

Loading...