Page 1

MOTOR - 1/4 HPMOTOR - 1/4 HP

MOTOR - 1/4 HP

MOTOR - 1/4 HPMOTOR - 1/4 HP

MOTOR - 1/3 HPMOTOR - 1/3 HP

MOTOR - 1/3 HP

MOTOR - 1/3 HPMOTOR - 1/3 HP

92103

MOTOR - 1/2 HPMOTOR - 1/2 HP

MOTOR - 1/2 HP

MOTOR - 1/2 HPMOTOR - 1/2 HP

92104

92105

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 MISSION OAKS BLVD., CAMARILLO, CA 93011

VISIT OUR WEB SITE AT HTTP://WWW.HARBORFREIGHT.COM

Copyright © 2004 by Harbor Freight Tools®. All r ights reserved. No portion of

this manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

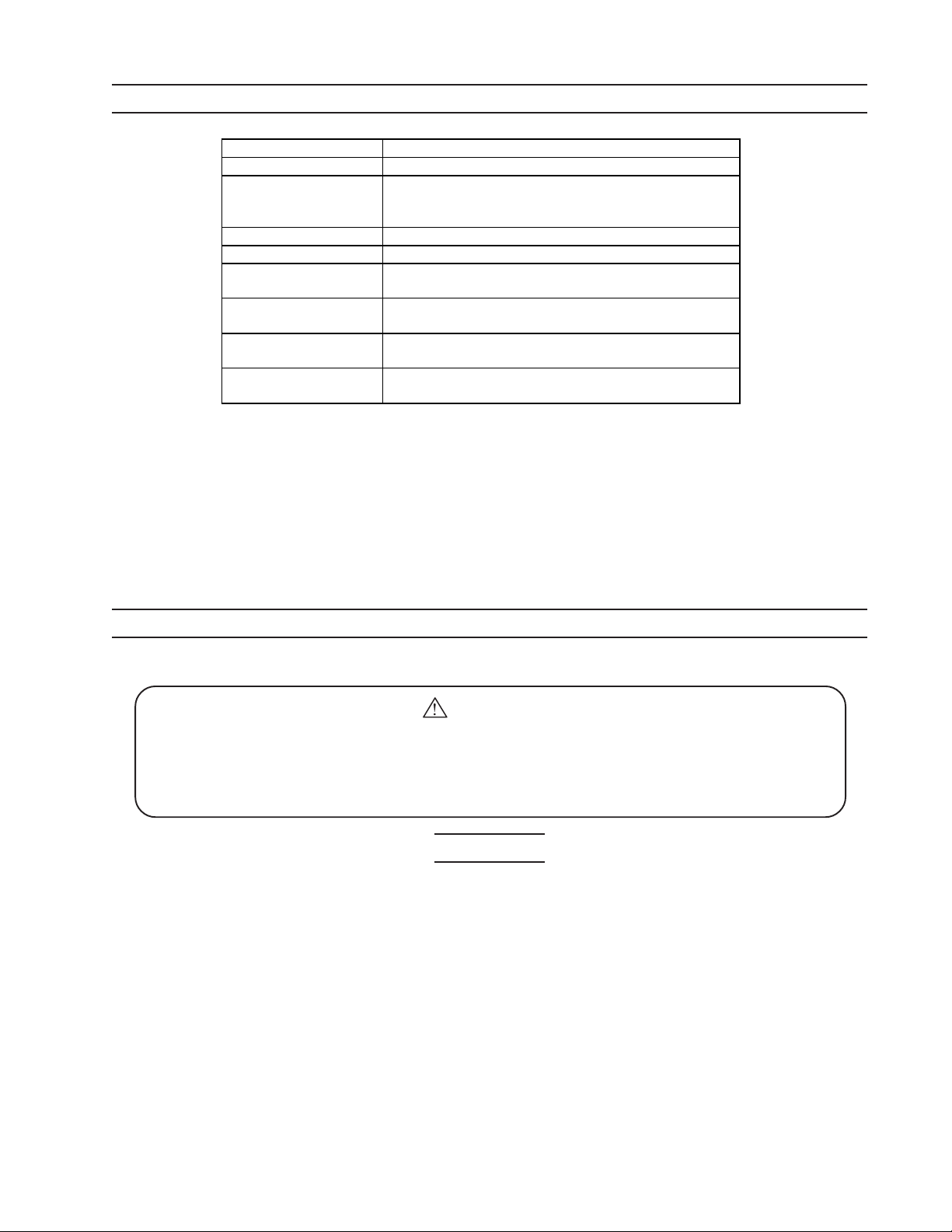

SPECIFICATIONS

Item Description

Power Requirement 115 VAC, 60 Hz, single phase

Current Draw

Output Power 92103: ¼ HP; 92104: 1/3 H P; 9210 5 : ½ H P

Shaft Diameter 92103: 9/16”; 92104: 9/16”; 92105: 5/8”

Rotatio n Facing S haft: Co untercloc k wise (rev ersible);

Frame Type 92103: NEMA 4 4; 92103: N EMA 44;

Features Four poles; Fan cooled; Centrifugal switch;

Overall Dimensions 92103/104: 11.5 (L) x 8.2 (W) x 8.2 (H) inches

92103: 4.37 amps (no load), 12.18 amps (peak)

92104: 5.17 amps (no load), 14 amps (peak)

92105: 5 amps (no load), 7.54 amps (peak)

1725 RPM (max.)

92105: NEMA 4 8

90105: Capacitor start

92105: 12.5 (L) x 8.2 (W) x 8.2 (H) inches

SAVE THIS MANUAL

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERST AND ALL INSTRUCTIONS. Failure to follow all instructions

listed below may result in electric shoc k, fire, and/or serious injury .

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. P ow er tools create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control. Protect others in the work area from debris

such as chips and sparks. Provide barriers or shields as needed.

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 2

Page 3

Electrical Safety

4. Av oid bod y contact with gr ounded surfaces suc h as pipes, radiator s, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

5. Do not expose power tools to rain or wet conditions. W ater entering a pow er tool

will increase the risk of electric shock.

6. Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any wa y. Do not use an y adapter plugs. Check with

a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

7. Double insulated tools are equipped with a polarized plug (one blade is wider

than the other). This plug will fit in a polarized outlet only one wa y . If the plug

does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change the plug in any

way. Double insulation

cord and grounded power supply system.

8. Do not abuse the P ower Cord. Never use the Power Cord to carry the tools or

pull the Plug from an outlet. Keep the Power Cord awa y from heat, oil, sharp

edges, or mo ving parts. Replace damaged P o wer Cords immediatel y. Damaged

Power Cords increase the risk of electric shock.

9. When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These extension cords are rated for outdoor use, and reduce the risk of

electric shock.

eliminates the need for the three wire grounded pow er

Personal Safety

10. Stay alert. Watch what you are doing, and use common sense when operating a

power tool. Do not use a power tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may

result in serious personal injury.

11. Dress properly. Do not wear loose clothing or je welry. Contain long hair. K eep

your hair, clothing, and glo ves a wa y from mo ving parts. Loose clothes, jew elry, or

long hair can be caught in moving parts.

12. Av oid accidental starting. Be sure the Po wer Switch is off before plug ging in.

Carrying power tools with your finger on the Power Switch, or plugging in power tools

with the Power Switch on, invites accidents.

13. Remove adjusting keys or wrenches before turning the power tool on. A wrench

or a key that is left attached to a rotating part of the power tool may result in personal

injury.

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 3

Page 4

14. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

15. Use safety equipment. Always wear eye protection. Dust mask, nonskid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

16. Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

17. Do not force the tool. Use the correct tool for y our application. The correct tool

will do the job better and safer at the rate for which it is designed.

18. Do not use the power tool if the Power Switch does not turn it on or off . An y tool

that cannot be controlled with the Power Switch is dangerous and must be replaced.

19. Disconnect the Power Cor d Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

20. Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

21. Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with a sharp cutting edge are less likely to bind and are easier to control. Do not

use a damaged tool. Tag damaged tools “Do not use” until repaired.

22. Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’ s operation. If damaged, ha ve the tool

serviced before using. Many accidents are caused by poorly maintained tools.

23. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous when

used on another tool.

Service

24. Motor service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

25. When servicing a tool, use only identical replacement parts. Follow instructions

in the

unauthorized parts or failure to follow maintenance instructions may create a risk of

electric shock or injury .

“Inspection, Maintenance, And Cleaning”

section of this manual. Use of

SPECIFIC SAFETY RULES FOR THIS PRODUCT

1. Maintain labels and nameplates on the Motor . These carry important information. If

unreadable or missing, contact Harbor F reight Tools for a replacement.

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 4

Page 5

2. Always wear ANSI approved safety impact eye goggles and heavy work gloves

when setting up and using the Motor . Using personal safety devices reduce the risk

for injury. Safety impact eye goggles and heavy work gloves are available from Harbor

Freight Tools.

3. Maintain a safe working en vir onment. K eep the work area well lit. Make sure there

is adequate surrounding workspace. Always keep the work area free of obstructions,

grease, oil, trash, and other debris. Do not use install the motor in areas near

flammable chemicals, dusts, and vapors. Do not use this product in a damp or wet

location.

4. Av oid unintentional starting. Mak e sure y ou are prepared to begin work before

turning on the Motor.

5. Do not force the Motor. This tool will do the work better and safer at the speed and

capacity for which it was designed.

6. Always unplug the Motor from its electrical outlet (or turn off the circuit breaker

and tag) before performing any inspection, maintenance, or cleaning

procedures.

7. When installing motor , observe all national and local codes. Mak e sure to install,

protect, and fuse according to the latest issue of the National Electric Code, NEMA

Standard Publication No . MG2, and local codes. Ground frames in accordance with

NEC Article 430. For general grounding information, refer to NEC Article 250.

8. Install guards when appropriate. Make sure all mo ving parts, including the shaft

and any attached accessories, are permanently guarded to prevent clothing and body

parts from being caught.

9. Disconnect power before working on motor driven equipment.

10. Before each use, check all nuts, bolts, and screws for tightness. Vibration during

operation may cause these to loosen.

11. Keep extension cord off the ground and away from w ater.

12. Alwa ys connect the Line Cord to a Ground F ault Circuit Interrupter (GFCI) protected

electrical outlet.

13. Do not allow children to play with, or touch this product.

(1)

14. Keep the motor dry; ne ver submerge in w ater. K eep the motor a saf e distance from all

flammable objects.

WARNING! P eople with pacemakers should consult their ph ysician(s) before using

this product. Operation of electrical equipment in close proximity to a heart pacemaker

could cause interference or failure of the pacemaker .

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 5

Page 6

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool or

product. Never remove the grounding prong from the plug. Do not use the tool if

the power cord or plug is damaged. If damaged, have it repaired by a service

facility before use. If the plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

Grounded Tools: Tools with Three Prong Plugs

1. Tools marked with “Grounding Required” ha ve a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If the tool

should electrically malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user , reducing the risk of electric shock. (See

Figure A.)

2. The grounding prong in the plug is connected through the green wire inside the cord to

the grounding system in the tool. The green wire in the cord must be the only wire

connected to the tool’ s grounding system and must never be attached to an electrically

“live” terminal. (See Figure A.)

3. Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

those in the following illustration. (See Figure A.)

Figure A

Figure B

Double Insulated Tools: Tools with Two Prong Plugs

4. Tools marked “Double Insulated” do not require grounding. They have a special double

insulation system which satisfies OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Figure B.)

5. Double insulated tools may be used in either of the 120 volt outlets shown in the

following illustration. (See Figure B.)

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 6

Page 7

EXTENSION CORDS

1. Grounded tools require a three wire extension cord. Double Insulated tools can use

either a two or three wire extension cord.

2. As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a serious

drop in voltage, resulting in loss of power and possible tool damage. (See Table A.)

3. The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher current than a 16 gauge cord. (See Table

A.)

4. When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required. (See Table A.)

5. If you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum cord size. (See Table A.)

6. If y ou are using an e xtension cord outdoors , mak e sure it is marked with the suffix “WA” (“W” in Canada) to indicate it is acceptable for outdoor use.

7. Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified

electrician before using it.

8. Protect your extension cords from sharp objects, excessive heat, and damp or wet

areas.

Table A

RECOMMENDED MINIMUM WIRE GAUG E FOR EXTENSION CORDS*

(120 VOLT)

NAMEPLATE

AMPERES

(At Full Load)

25

Feet

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 16 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - * Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

EXTENSION CORD LENGTH

50

Feet

75

Feet

100

Feet

150

Feet

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 7

Page 8

SYMBOLOGY

Table B

UNPACKING

When unpacking, check to mak e sure that all the parts are included. If any parts are missing or broken, please call Harbor F reight Tools at the number on the cover of this manual as

soon as possible.

INSTALLATION

WARNING: Electrical shoc k hazard. The wiring of the motor to the facility power circuit

must be done by a qualified electrician.

General

1. The ambient air temper ature where the motor is to be installed cannot e xceed 104° F.

If it does, cooling must be provided to ensure the temperature stays below the limit.

2. Do not block motor air vents.

3. This motor should be installed indoors in a clean, dry, and noncorrosive environment

where no flammable liquids or gases are present.

4. When mounting the motor for use, make sure all mounting hardware is securely

fastened. Make sure all hardware (not supplied) is securely fastened.

5. When mounting a pulley (not included) to the drive shaft, make sure it is properly

aligned or motor life will be significantly shortened.

6. Never operate motor without installing a safety guard (not supplied), with at least a two

inch clearance, around all pulleys and belts driven by this motor.

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 8

Page 9

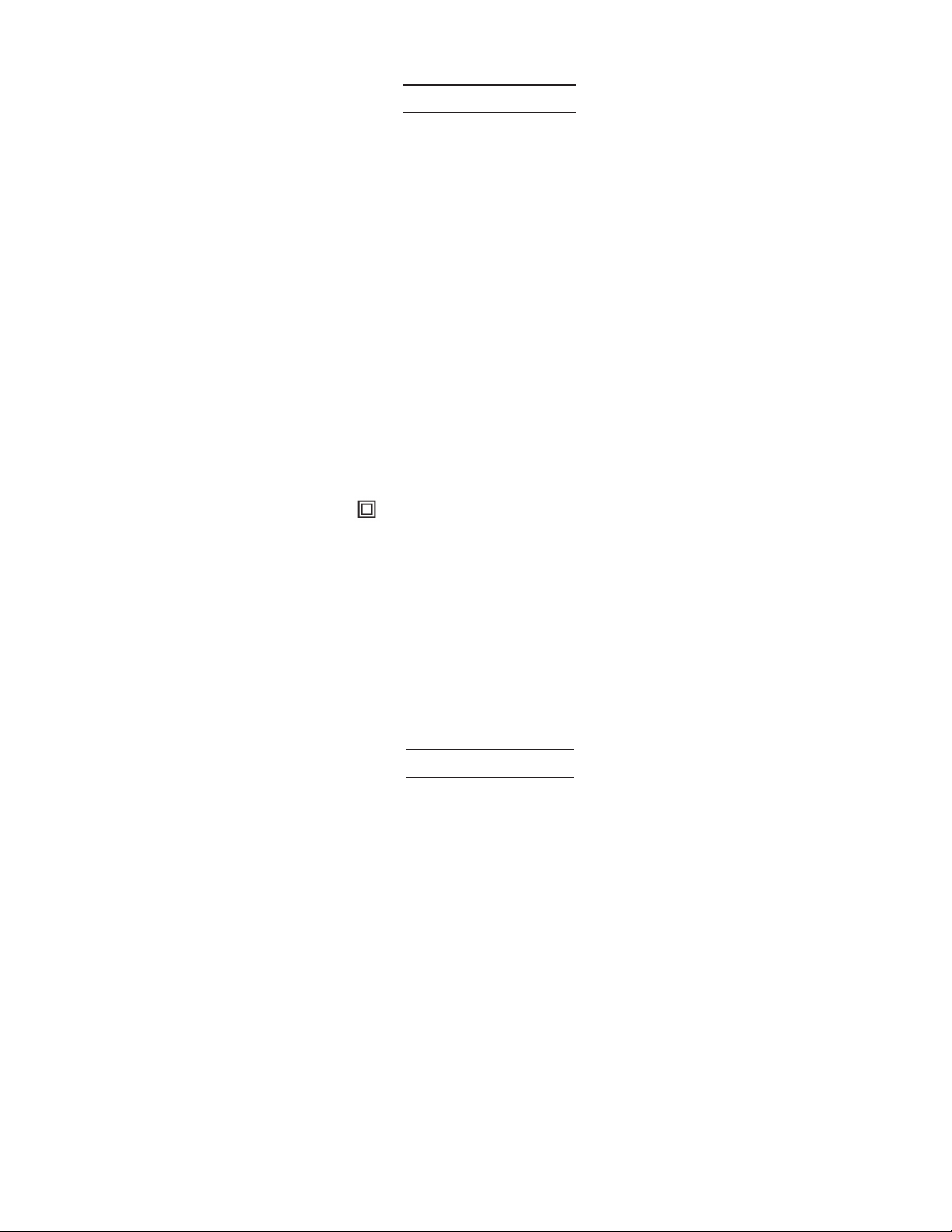

Motor Wire Connections

The table below, and the photo on the next page, indicate the proper wiring connections for

the motor internal wires and the external power connections (neutral power wire is usually

white; hot po w er wire is usually black, ground wire (green) is for earth ground).

1. Remove Connection Cover to expose the terminal strip (see photo below).

2. Verify that there is no power to the circuit to be connected. Chec k fuse bo x and turn off

circuit breaker .

3. Using approved National Electrical Code electrical standards, make the connections

as described in the table below for 115 VAC operation only.

Reverse the blue and black leads for clockwise rotation. Note: As there are tap

connections under the electrical block, do not reverse the line conductors. The facility

power circuit, and connecting wires, must be rated at least 20 amps of current. Use

wire lugs (not included) to connect the wires to the Motor terminal strip. The motor can

be connected by an appropriate size line cord (not included) or hard wired through

conduit.

4. Replace motor Connection Cover.

Caution: Always connect the green grounding wire to the green motor chassis screw.

Failure to connect this wire properly can create a severe safety hazard.

Counterclockwise Clockwise

Wired from factory

for counterclockwise

rotation

Line In (Hot)

Line In (Neutral)

(1)

Connection

Cover

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Ground Wire (green)

Page 9

Page 10

OPERATING INSTRUCTIONS

Before initial operation, verify that:

1. The Motor is dry.

2. The voltage and frequency stamped on motor and control nameplates correspond with

that of the input power line.

3. All connections to the motor are correct.

4. The rotor turns freely when disconnected from the load.

5. The motor is detached from the load f or the initial start. Operate the motor without a

load for about one hour to test for any localized heating in bearings and windings.

6. The voltage is correct and balanced at the motor terminals, and no-load current draw

(in amps) is correct.

7. The motor comes up to its operational speed and is not being overloaded.

INSPECTION, MAINTENANCE, AND CLEANING

WARNING! Make sure the Po wer Switch of the Motor is in its “OFF” position and that

the tool is unplugged or disconnected from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

1. Before each use, inspect the general condition of the Motor . Check f or loose scre ws,

misalignment or binding of moving parts, cracked or broken parts, damaged electrical

wiring, and any other condition that may affect its safe operation. If abnormal noise or

vibration occurs, hav e the problem corrected before further use. Do not use damaged

equipment.

2. Maintenance and repairs should only be done by a qualified technician.

3. Periodically recheck all nuts, bolts, and screws for tightness.

4. Store in a clean and dry location.

Lubrication

Note: If lubrication instructions are shown on motor, they will supersede this general

instruction. Lubrication should be completed by a qualified technician.

1. The Motor is properly lubricated at the time of manufacture. It is not necessary to

lubricate at time of installation unless the motor has been in storage for a period of 12

months or longer .

2. Re-oil sleeve bearings with drops of 5W20 viscosity motor oil every 2000 hours of

normal service. Direct drive operation (no pulleys) requires lubrication every 3000

hours of normal service.

3. Sealed ball bearings require no attention during the life of the bearing.

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

Page 10

Page 11

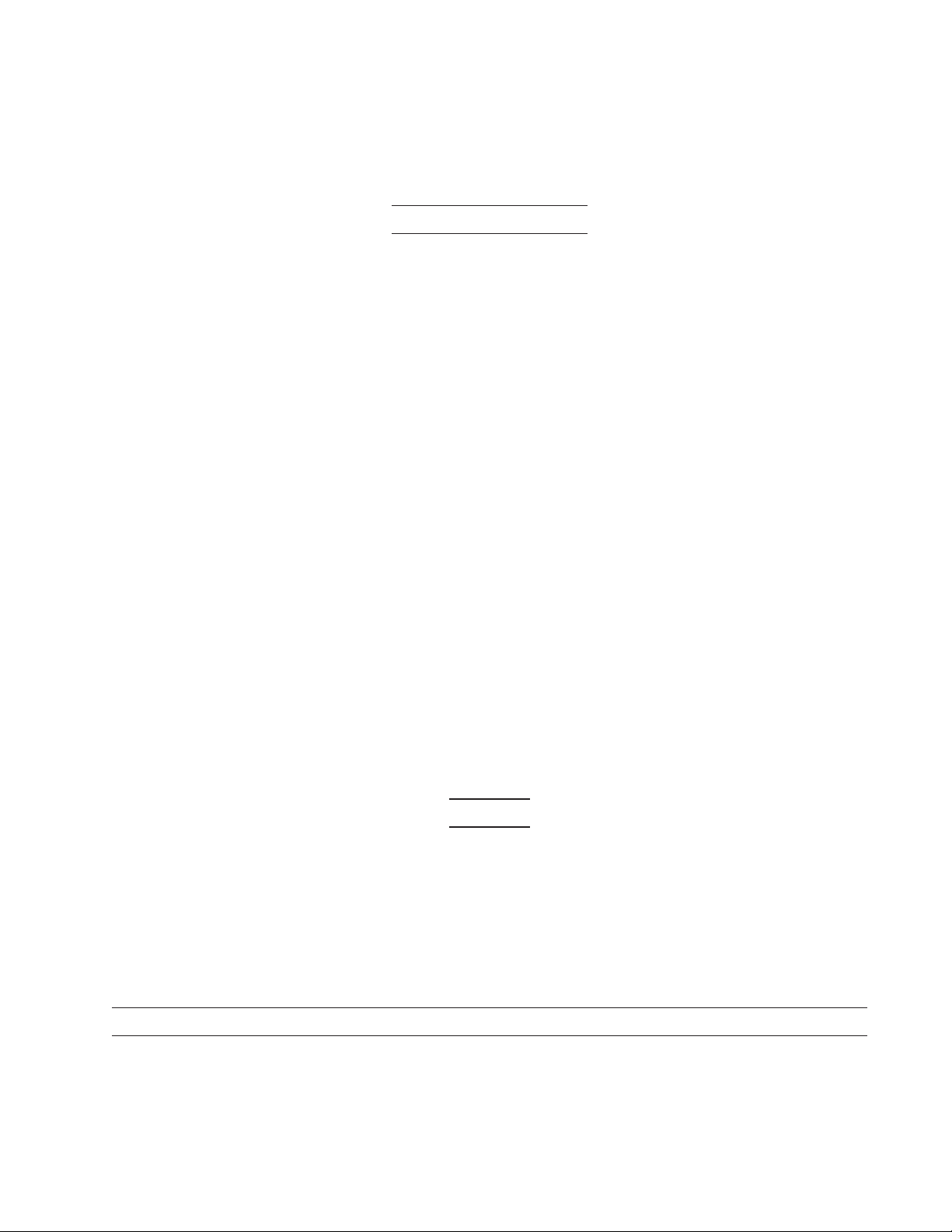

WIRING DIAGRAMS

92103/92104

92105

SKU 92103/104/105 For technical questions, please call 1-800-444-3353

REV 03/05

Page 11

Loading...

Loading...