Page 1

SPECIFICATIONS

Weight Capacity 150 lb.

For LED / LCD / Plasma TVs 37” to 61” wide

FLAT PANEL TV

WALL MOUNT

Model

INSTRUCTIONS AND PRECAUTIONS

Visit our website at: http://www.harborfreight.com

SAVE THESE

INSTRUCTIONS.

READ ALL

PRECAUTIONS AND

INSTRUCTIONS.

Copyright© 2010 by Harbor Freight Tools®. All rights

reserved. No portion of this document or any artwork

contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight

Tools. Diagrams within this document may not be drawn

proportionally. Due to continuing improvements, actual

product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

For technical questions or replacement parts,

please call 1-800-444-3353.

67781

UNPACKING

When unpacking, make sure that the item is

intact and undamaged. If any parts are missing or

broken, please call Harbor Freight Tools at

1-800-444-3353 as soon as possible.

IMPORTANT SAFETY INFORMATION

Do not exceed 150 lb. max. weight capacity of 1.

TV Bracket. Sudden load movement may briey

create excess load causing product failure.

Do not mount TV Bracket to hollow wall, gypsum 2.

board, or similar material that will not support the

weight of the TV. Mount only to 2” x 4” wood stud

or concrete/brick walls that can safely support

combined weight of Bracket, TV and all attached

hardware and components.

If you are unsure wall is strong enough to 3.

support weight of TV and TV Bracket, contact a

professional installer to reinforce wall.

Do not mount overhead.4.

Assemble and install only according to these 5.

instructions. Improper assembly and installation

can create hazards and lead to personal injury

and property damage.

Verify that mounting surface has no hidden utility 6.

lines before drilling or driving screws.

Wear ANSI-approved safety goggles and heavy-7.

duty work gloves during installation.

Inspect before installing; do not mount to wall if 8.

parts are missing, loose or damaged.

Use as intended only. Do not use TV Bracket for 9.

any purpose for which it was not designed.

Keep installation area clean and well lit.10.

Do not assemble or install when tired or when 11.

under the inuence of drugs or medication.

This product is not a toy. Do not allow children to 12.

play with or near this item.

Maintain product labels and nameplates. These 13.

carry important safety information. If unreadable

or missing, contact Harbor Freight Tools for a

replacement.

Page 2

ASSEMBLY AND MOUNTING

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning

of this document including all text under

subheadings therein before set up or use

of this product.

NOTE: The following tools (none supplied)

are required for mounting and installation:

Stud Finder, 11/16” socket, ratchet handle,

#2 Phillips screwdriver, 1/4” drill bit (for

drilling into wood stud), 1/2” masonry drill bit

(for drilling into brick or concrete wall), and

minimum 6” level, 5mm hex wrench, and

10mm combination wrench.

Before Installing

Use the 5mm hex wrench to double-check that 1.

all four socket screws of the Wall Bracket (1) are

tight. Tighten any connection, if needed.

Set Wall Bracket against the wall at the desired 2.

height. Place a level over the upper or lower

cross bar and adjust Bracket until level. Use a

marker to indicate locations of mounting holes.

Attaching to Wood Studs

First, verify woods studs are at least 16” apart. 1.

Use a Stud Finder (not included) to nd two

adjacent studs 16” apart. Use a marker to

indicate locations of the studs.

Drill four 1/4” holes at least 3-1/2” deep into the 2.

studs at the marked spots.

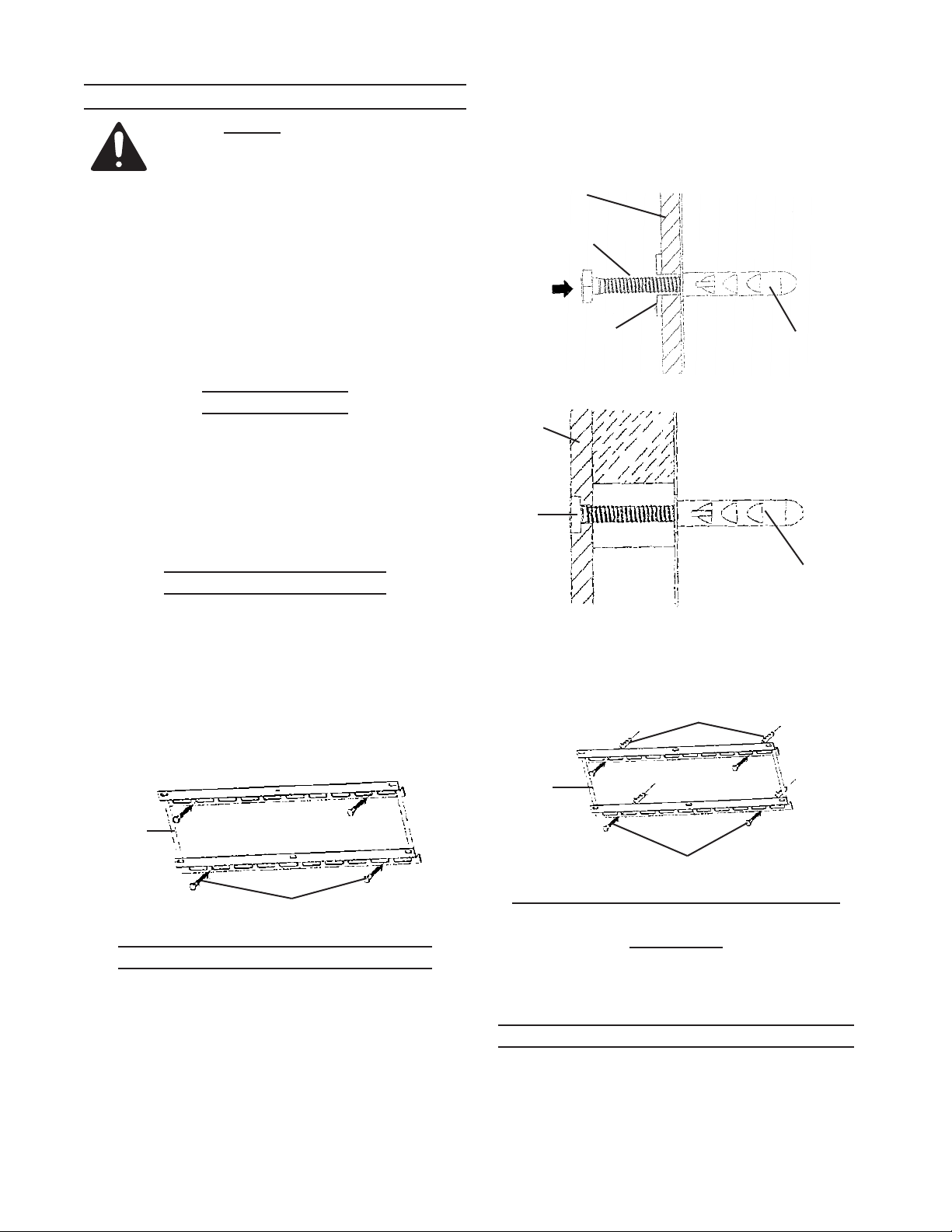

Use Lag Bolts (10) and Washers (9) to mount 3.

Wall Bracket to wall. See Figure 1, below.

Wall

Bracket

(1)

Attaching to Brick or Concrete Wall

NOTE: 1. Verify at least 6” of space are between

any two holes. Use 1/2” carbide tip masonry drill

bit and drill four 3-3/8” deep holes.

Insert the Wall Anchors (11) into the holes, 2.

making sure they are ush with the wall surface.

WARNING! 3. Wall Anchors must be set rmly

against concrete or masonry. If mounting to

Lag Bolt (10) and Washer (9)

Figure 1

a masonry wall covered with drywall/plaster,

counter bore a hole through drywall/plaster

around mounting holes’ locations. This will allow

Wall Anchors to be set directly against concrete

or masonry. See Figures 2a and 2b, below.

Wall Bracket (1)

Bolt (10)

Lag

Concrete

Washer

(9)

Wall

Anchor (11)

Wall

Bracket

(1)

Figure 2a

Concrete

Lag

Bolt

(10)

Plaster/

Drywall

Wall

Anchor (11)

Figure 2b

Once Wall Anchors are securely set into 4.

concrete, use Lag Bolts and Washers to install

Wall Bracket to wall. See Figure 3, below.

Wall Anchor (12)

Wall

Bracket

(1)

Lag Bolt (11) and Washer (10)

Figure 3

Attaching to Metal Studs or Concrete

Block Wall

NOTE: 1. If mounting to steel stud wall or cinder

block wall, alternative mounting hardware is

required.

Installing Support Arms to Flat Panel TV

WARNING! 1. Verify TV is unplugged before

threading any Screw into the TV’s back panel.

Page 2For technical questions, please call 1-800-444-3353.SKU 67781

Page 3

WARNING!2. Do no lay at panel TV face down;

cover its surface with a towel or other soft

material and tilt it against the wall or another solid

surface.

WARNING!3. Some Flat Panel TVs are heavy; two

people may be needed to lift and support the TV

while it is being attached to the TV Bracket.

Locate the mounting holes on back of TV and 4.

select mounting Screws (3-6) that t properly.

NOTE: If you do not nd the appropriate-sized

Screws, refer to TV owners manual or contact TV

manufacturer. Thread the Screws (3, 4, 5 or 6)

through the Square Pads (8), the Support Arms

(2), Spacers (7) and into the mounting holes in

the back of TV panel. See Figure 4, below.

Screws (3-6)

Square Pad (8)

Spacer (7)

Support

Arms (2)

Figure 4

TV Panel

NOTE: 5. The wide part of the Spacers rest against

the Support Arms.

Carry TV to mounted Bracket and lower onto 6.

Cross Bars, making sure the four tabs of the

mounts are hooked onto the top of Cross Bars

and that TV is centered. See Figure 5.

Cross Bars

Figure 5

Tighten the two clamping screws leaving about 7.

an eight of an inch space. See Figure 6.

Clamping

Screw

Figure 6

To adjust the TV angle, back off the two nuts at 8.

the Support Arm hinges by one turn. Back off

the two angle-adjusting screws located at the

sides of the Support Arms until end of the screw

threads are almost ush with the other side of the

Support Arms. See Figure 7.

Angle Adjusting

Screw

Angle Adjusting

Screw

Figure 7

CAUTION: 9. Make sure that the end of the screws

does not come out of the Support Arms.

Tilt the TV to the desired angle (four approximate 10.

adjustment positions = 0°, 3°, 7° and 12°).

Tighten the Angle-adjusting screws all the way to

lock the angle position.

Page 3For technical questions, please call 1-800-444-3353.SKU 67781

Page 4

PARTS LIST & ASSEMBLY DIAGRAM

Part Description Qty.

1 Wall Bracket 1

2 Support Arm 2

3 Screw (M4 x .7 x 35mm) 4

4 Screw (M5 x .8 x 35mm) 4

5 Screw (M6 x 1.0 x 35mm) 4

6 Screw (M6 x 1.25 x 35mm) 4

7 Spacer 4

8 Square Pad 4

9 Washer 4

10 Lag Bolt 4

11 Wall Anchor 4

2

1

3

7

8

4

9

5

10

6

11

Record Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available individually as

replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS DOCUMENT AS

A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY

OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS,

AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT

PARTS THERETO.

Page 4For technical questions, please call 1-800-444-3353.SKU 67781

Loading...

Loading...