Harbor Freight Tools 66784 Product manual

12V Diesel Transfer Pump

Item 66784

Read this material before using this

product. Failure to do so can result in

serious injury. SAVE THIS MANUAL.

When unpacking, make sure that the product is intact and undamaged.

If any parts are missing or broken, please call 1-800-444-3353 as soon as possible.

Visit our website at: http://www.harborfreight.com

Copyright© 2009 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for assembly and service may not be included.

Manual Revised 11h

Save This Manual

Keep this manual for the safety warnings and

precautions, assembly, operating, inspection,

maintenance and cleaning procedures. Write the

product’s serial number in the back of the manual near

the assembly diagram (or month and year of purchase

if product has no number). Keep this manual and the

receipt in a safe and dry place for future reference.

Safety Alert Symbol

and Signal Words

In this manual, on the labeling, and all other

information provided with this product:

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

Work Area

a. Keep the work area clean and well lighted.

Cluttered or dark areas increase the risks of

electric shock, re, and injury to persons.

b. Do not operate pumps in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Pumps create

sparks which may ignite the dust or fumes.

c. Keep bystanders, children, and visitors away

while operating the pump. Distractions are able

to result in the loss of control of the pump.

Electrical Safety

a. Do not expose pumps to rain or wet

conditions. Water entering a pump will

increase the risk of electric shock.

b. Do not abuse the Power Cables. Never use

the cables for carrying or pulling the pump.

Keep cables away from heat, oil, sharp edges

or moving parts. Damaged or entangled

cables increase the risk of electric shock.

Personal Safety

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices

not related to personal injury.

CAUTION, without the safety alert symbol, is used

to address practices not related to personal injury.

IMPORTANT SAFETY

INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS

WARNING – When using pumps, basic precautions

should always be followed, including the following:

a. Stay alert, watch what you are doing and

use common sense when operating a pump.

Do not use a pump while you are tired or under

the inuence of drugs, alcohol or medication.

A moment of inattention while operating pumps

may result in serious personal injury.

b. Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to the power supply.

c. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables better

control of the pump in unexpected situations.

d. Use safety equipment. A dust mask,

non-skid safety shoes and a hard hat must

be used for the applicable conditions.

e. Wear ANSI-approved safety goggles

during setup and use.

f. Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry

or long hair can be caught in moving parts.

Pump Use and Care

a. Do not force the pump. Use the correct pump for

your application. The correct pump will do the job

better and safer at the rate for which it was designed.

Page 2 For technical questions, please call 1-800-444-3353. SKU 66784

b. Do not use the pump if the switch does not turn

it on and off. Any pump that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the Cables from the power

supply before making any adjustments,

changing accessories, or storing pumps.

Such preventive safety measures reduce the

risk of starting the pump accidentally.

d. Store idle pumps out of the reach of children and

do not allow persons unfamiliar with the pump or

these instructions to operate the pump. Pumps

are dangerous in the hands of untrained users.

e. Maintain pumps. Check for misalignment or

binding of moving parts, breakage of parts

and any other condition that may affect

the pump’s operation. If damaged, have the

pump repaired before use. Many accidents

are caused by poorly maintained pumps.

4. Do not use for uid transfer into or from aircraft.

5. This product is not designed for use with medical

products, water, or uids for human consumption.

6. Anchor the barrel or tank (not included)

to prevent tipping.

7. Do not use while on a motorized vehicle

while the engine is running.

8. Avoid unintentional starting. Prepare to

begin work before turning on the Pump.

9. When using a handheld pump, maintain

a rm grip on the pump with both

hands to resist starting torque.

10. Do not leave the Pump unattended

when it is connected to a power supply.

Turn off the pump, and disconnect it from

its power supply before leaving.

f. Use the pump, accessories and pump bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of

the pump for operations different from those

intended could result in a hazardous situation.

Battery Precautions

a. Under abusive conditions, liquid may be

ejected from the battery. Avoid contact.

If contact accidentally occurs, ush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

Service

a. Pump service must be performed only

by qualied repair personnel, using

only identical replacement parts.

Specic Safety Instructions

1. This Pump is designed for use with diesel fuel or

kerosene only. Not for use with uids that have a

ash point below 100° F (i.e., gasoline, alcohol).

2. Maintain labels and nameplates on

the Pump. These carry important safety

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

11. This product is not a toy. Keep

it out of reach of children.

12. People with pacemakers should consult their

physician(s) before use. Electromagnetic elds

in close proximity to heart pacemaker could

cause pacemaker interference or pacemaker

failure. In addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with power switch locked on.

• Properly maintain and inspect

to avoid electrical shock.

13. WARNING: Handling the cord on this product will

expose you to lead, a chemical known to the State of

California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5, et seq.)

The brass components of this product contain lead,

a chemical known to the State of California to cause

birth defects.

(California Health & Safety Code § 25249.5, et seq.)

14. The warnings, precautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product,

but must be supplied by the operator.

SAVE THESE

3. Never smoke near the Pump or use

the Pump near an open ame.

INSTRUCTIONS.

Page 3For technical questions, please call 1-800-444-3353.SKU 66784

Functional Description

Specications

Only use with diesel fuel or

kerosene.

Product

Applications

Electrical Input 12VDC / 13.5A

Fuse 25A (included)

Motor

Pump

Operating Conditions

Hose Size

Thermal Overload

Protection

Do not use with gasoline,

alcohol, water, corrosive

chemicals, solvents, or

liquids that have a ash

point below 100° F.

30 Minute Duty Cycle*

2800 RPM

Self-Priming, Volumetric,

Rotating Vane,

with Bypass Valve

Inlet/Outlet: 3/4″ Female NPT

Lift: 6.6 Feet

Flow Rate: 10 GPM

-4° – 140° F

up to 90% Relative Humidity

0.75 IN. I.D., 1.125 IN. O.D.,

13 FT. Long

Yes

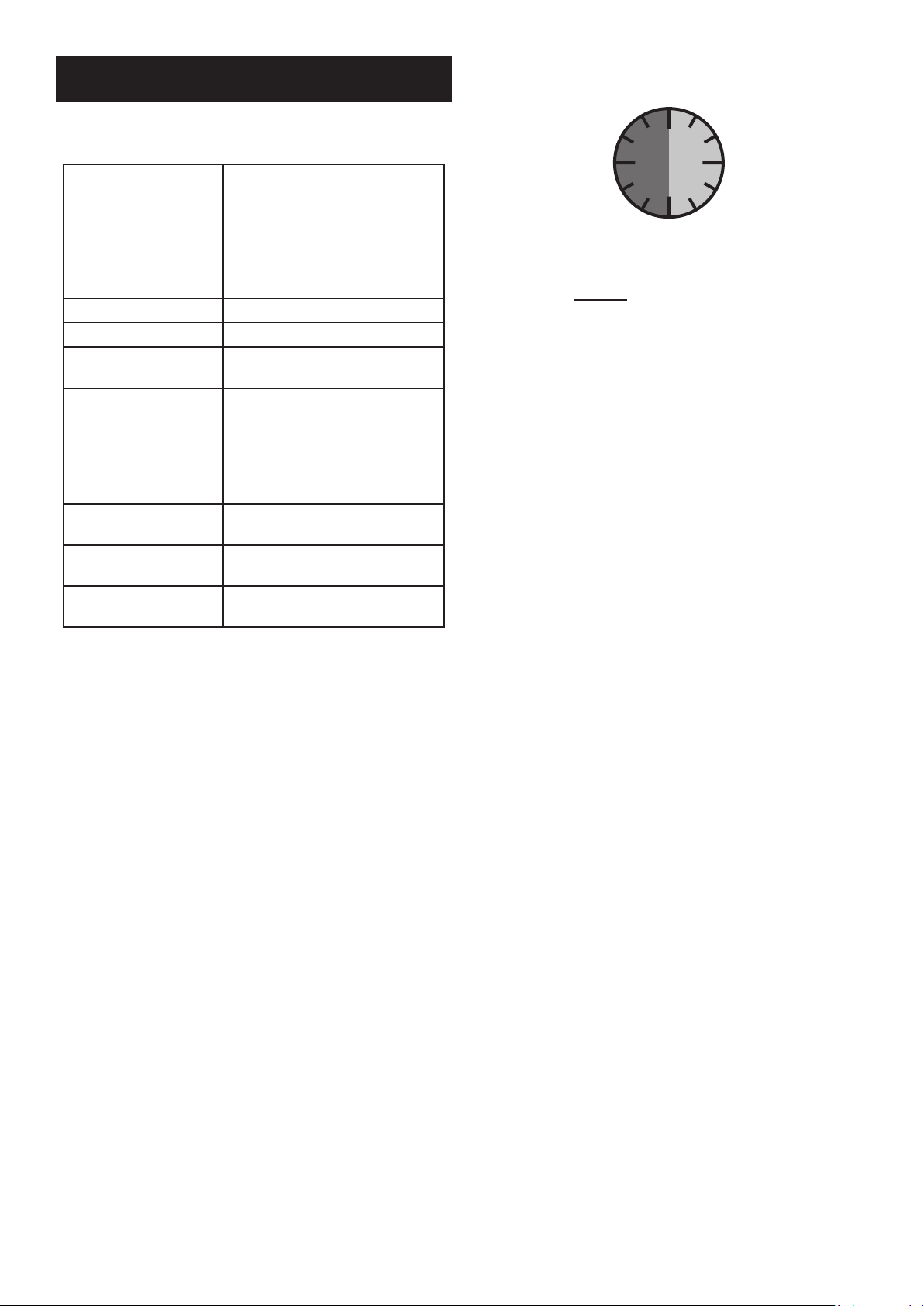

*Duty Cycle (Duration of Use)

30 Minute Duty Cycle

30 minutes welding

followed by

at least 30 minutes of rest

Avoid damage to the Pump by not pumping for

more than the prescribed duty cycle time. The Duty

Cycle denes the number of minutes, within a one hour

period, during which a given pump can pump without

overheating. For example, this Pump with a 30 minute

duty cycle must be allowed to rest for at least 30 minutes

after every 30 minutes of use. Failure to carefully

observe duty cycle limitations can easily over-stress

a pump contributing to premature pump failure.

This pump has an internal thermal protection system

to help prevent this sort of over-stress. When the

unit overheats, it automatically shuts down, then it

automatically begins pumping again after cooling off.

When the pump can be used again, use shorter pumping

periods and longer rest periods to prevent needless wear.

Page 4 For technical questions, please call 1-800-444-3353. SKU 66784

Loading...

Loading...