Page 1

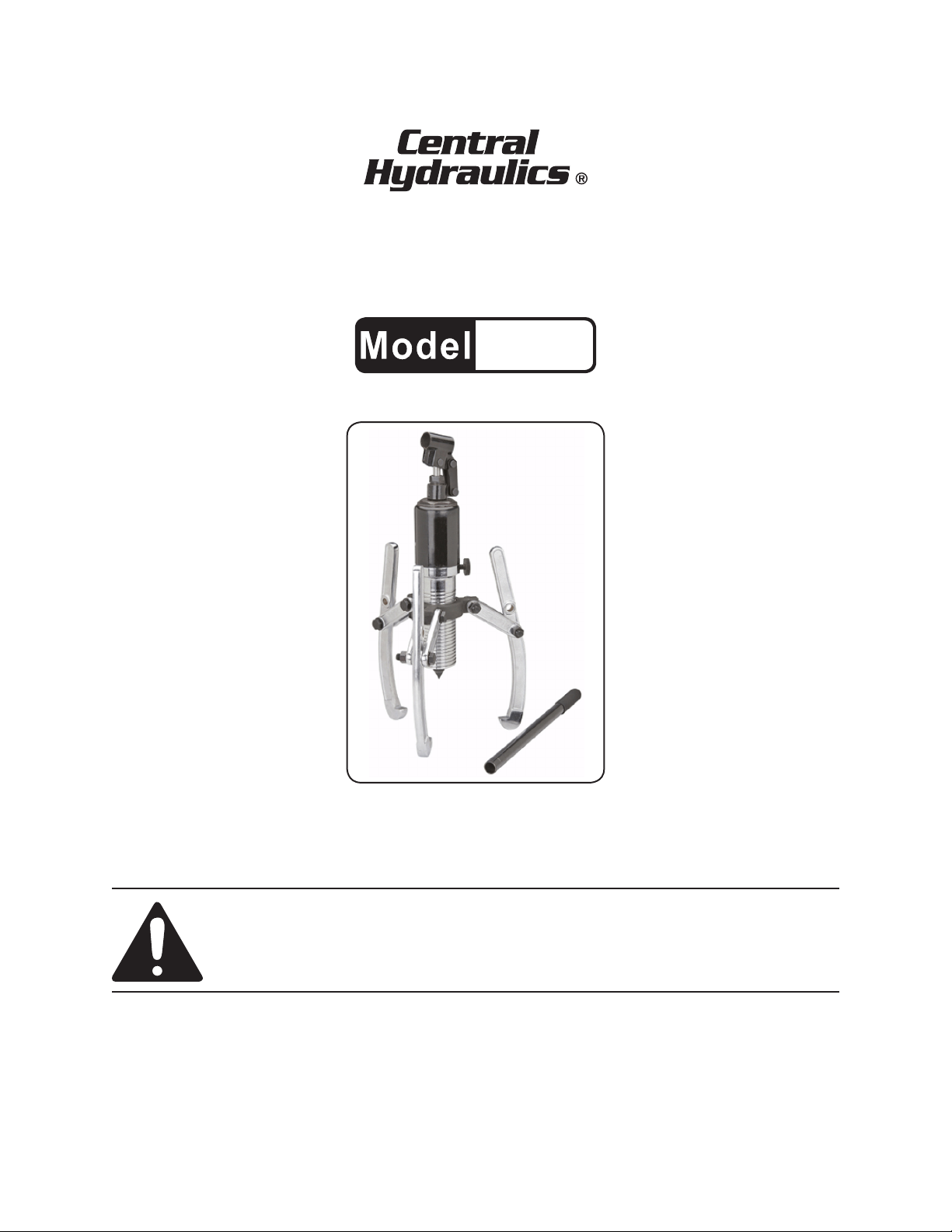

12 TON HYDRAULIC GEAR

PULLER KIT

66657

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial

number in the back of the manual near the

assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and

dry place for future reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information provided with this product:

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

General Tool Safety Warnings

WARNING Read all safety

warnings and instructions.

Failure to follow the warnings and

instructions may result in serious

injury.

Save all warnings and

instructions for future reference.

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

Work area safety1.

Keep work area clean and well lit. a.

Cluttered or dark areas invite accidents.

Keep children and bystanders b.

away while operating the Gear

Puller. Distractions can cause you to

lose control.

Personal safety2.

Stay alert, watch what you are do-a.

ing and use common sense when

operating the Gear Puller. Do not

use while you are tired or under

the inuence of drugs, alcohol or

medication. A moment of inattention

while operating the tool may result in

serious personal injury.

Use personal protective equip-b.

ment. Always wear eye protection.

Do not overreach. Keep proper c.

footing and balance at all times.

This enables better control of the tool

in unexpected situations.

SKU 66657 For technical questions, please call 1-800-444-3353. Page 2

Page 3

Dress properly. Do not wear loose d.

clothing or jewelry. Keep your

hair, clothing and gloves away

from moving parts. Loose clothes,

jewelry or long hair can be caught in

moving parts.

Only use safety equipment that e.

has been approved by an appropriate standards agency. Unapproved

safety equipment may not provide

adequate protection. Eye protection

must be ANSI-approved and breathing protection must be NIOSH-ap-

proved for the specic hazards in the

work area.

Gear Puller use and care3.

Do not force the Gear Puller. Use a.

the correct tool for your application. The correct tool will do the job

better and safer at the rate for which

it was designed.

Store idle tools out of the reach of b.

children and do not allow persons

unfamiliar with the Gear Puller or

these instructions to operate the

tool. Tools are dangerous in the

hands of untrained users.

Maintain the Gear Puller. Check c.

for misalignment or binding of

moving parts, breakage of parts

and any other condition that may

affect the tool’s operation. If damaged, have the tool repaired before

use. Many accidents are caused by

poorly maintained tools.

Use the Gear Puller and any acces-d.

sories in accordance with these instructions, taking into account the

working conditions and the work

to be performed. Use of this tool

for operations different from those

intended could result in a hazardous

situation.

Service4.

Have your Gear Puller serviced a.

by a qualied repair person using

only identical replacement parts.

This will ensure that the safety of the

tool is maintained.

Hydraulic Gear Puller Safety

Warnings

Do not exceed 12 ton (24,000 lbs.) 1.

Gear Puller capacity.

Read and understand instruction 2.

manual.

Always wear ANSI-approved safety 3.

goggles.

Maintain labels and nameplates on 4.

the tool. These carry important safety

information. If unreadable or missing, contact Harbor Freight Tools for a

replacement.

This product is not a toy. Keep it out 5.

of reach of children.

The warnings, precautions, and in-6.

structions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

SAVE THESE

INSTRUCTIONS.

SKU 66657 For technical questions, please call 1-800-444-3353. Page 3

Page 4

SPECIFICATIONS

Assembly

Pressure Capacity 12 ton (24,000 lbs.)

Type

Size Capacity 9 ¾” max. diameter

3 jaw puller with

hydraulic cylinder

UNPACKING

Puller Unit

Puller

Sleeve (6)

Handle (11)

When unpacking, make sure that the

above parts are included and that they are

undamaged. If any parts are missing or

broken, please call Harbor Freight Tools

at the number shown on the cover of this

manual as soon as possible.

Bolt, Washer,

Nut sets (19)

Connector

Plates (5)

Jaws (1)

Thread the Puller Sleeve (6) onto 1.

the Puller Unit about half way up the

threaded section of the Puller Unit.

Determine if the best grip on the part 2.

to be pulled is from the outside or the

inside. The hooks on the Jaws (1)

face inward when gripping the part

from the outside. They face outward

when gripping the part from the inside.

Determine whether to use the upper 3.

or lower holes in the Jaws. The upper

holes (nearest the end of the Jaw),

are for larger items, approximately

6” - 9” in diameter. The lower holes

(closest to the center of the Jaw), are

for items smaller than 6”.

Pump Handle Socket (12)

Puller

Sleeve (6)

Connector

Plates (5)

Bolt/Washer/Nut Sets (19)

Handle (11)

INSTRUCTIONS FOR

PUTTING INTO USE

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

4. Assemble each of the three Jaws

onto the Puller Sleeve (6) using two

Connector Plates (5) and two Bolt

Sets (19) as shown in the photo

above.

Insert the Handle (11) into the Pump 5.

Handle Socket (12)

SKU 66657 For technical questions, please call 1-800-444-3353. Page 4

Jaw (1)

Page 5

Functions

The tool is designed to pull items

such as bearings, pulleys, and chucks

from shafts. The Jaws (1) grip the item

from the inside or outside, whichever offers a better grip. The Piston (8) will push

on the central shaft while the Jaws pull

away. This will remove the item from the

shaft by pulling it straight out evenly, without hammering or binding from pulling at

an angle.

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

CAUTION! This tool will deliver up to

12 tons (24,000 lbs.) of pulling

force. DO NOT use this tool on

any work piece which cannot

withstand this amount of

pressure.

Work Piece and Work Area Set Up

Designate a work area that is clean 1.

and well-lit. To prevent injury and/or

distraction, the work area must not

allow access by children or pets.

overtighten, as this will damage the

seal.

Place the Jaws (1) around (or in) the 2.

item to be pulled. Be sure they will

have a rm grip.

While holding the Jaws in place, 3.

rotate the Puller Unit in the Puller

Sleeve (6), until the end of the Piston

(8) contacts the work piece.

Pump the Handle (11) up and down 4.

to force the Piston down, causing the

Jaws to pull upward.

Continue pumping the Handle, be-5.

ing sure the Jaws stay in place on

the object and the object is not being

damaged.

In most cases, a certain amount of 6.

pressure will build up, and the Gear

Puller will suddenly loosen and release. Be sure the Gear Puller does

not fall when loosened.

When nished, open the Return Valve 7.

(7) by turning it 1 turn counter clockwise (do not remove), and remove

the Gear Puller form the work piece.

To prevent accidents, clean, then 8.

store the Gear Puller in it’s case,

indoors out of children’s reach.

There must not be hazardous ob-2.

jects, such as utility lines or foreign

objects, nearby that will present a

hazard while working.

General Operating Instructions

Close the Return Valve (7) by turning 1.

it clockwise until hand tight. Do not

SKU 66657 For technical questions, please call 1-800-444-3353. Page 5

Page 6

MAINTENANCE AND

SERVICING

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

SERIOUS INJURY

FROM TOOL FAILURE:

Do not use damaged

equipment. If abnormal noise

or vibration occurs, have the

problem corrected before

further use.

Cleaning, Maintenance, and

Lubrication

BEFORE EACH USE,1. inspect the

general condition of the Gear Puller.

Check for loose screws, misalignment

or binding of moving parts, cracked or

broken parts, and any other condition

which may affect its safe operation.

Note: This step should ONLY be per-

formed by a qualied technician.

Remove the Pump Handle Socket a.

(12) and Pump Axle (10).

Using an oil gun, pour oil slowly into b.

the pump housing to overowing.

Reassemble, and wipe excess oil c.

from the tool.

AFTER USE,2. clean external surfaces

with clean cloth.

Lightly oil the threads and pivoting 3.

joints periodically to keep them operating smoothly.

Keep Piston (8) in the fully retracted 4.

position while in storage to prevent

rust or damage.

If rust appears on any part of the tool, 5.

remove it with a penetrating oil.

If the tool fails to perform adequately, 6.

the oil level in the system should be

checked and air purged from the

system.

SKU 66657 For technical questions, please call 1-800-444-3353. Page 6

Page 7

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 66657 For technical questions, please call 1-800-444-3353. Page 7

Page 8

PARTS LIST

PARTS LIST

Part Description Qty.

1 Jaw 3

2 Piston 1

3 Spring 1

4 Oil Cylinder 1

5 Connector Plate 6

6 Puller Sleeve 1

7 Return Valve 1

8 Piston 1

9 Outer Sleeve 1

10 Pump Axle 1

ASSEMBLY DIAGRAM

Part Description Qty.

11 Handle 1

12 Pump Handle Socket 1

13 Connecting Rod 2

14 Hanger Foot 1

15 Pump Core 1

16 Oil Reservoir 1

17 Oil Seal 1

18 Screw 1

19 Bolt/Washer/Nut Set 6

19

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

SKU 66657 For technical questions, please call 1-800-444-3353. Page 8

Loading...

Loading...