Page 1

1 HP CAST IRON

SEWAGE PUMP

66351

SET UP, OPERATING, AND MAINTENANCE

INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Revised Manual 09i

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial

number in the back of the manual near the

assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and

dry place for future reference.

IMPORTANT SAFETY

INSTRUCTIONS

In this manual, on the labeling,

and all other information

provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

When using

electric products,

basic safety precautions

should always be followed to

reduce the risk of re, electric

shock, and personal injury,

including the following:

READ ALL INSTRUCTIONS

POWER CORD SAFETY

DO NOT use this Sewage Pump with 1.

an extension cord.

Ground Fault Circuit Interrupter 2.

(GFCI) protection should be provided

on the circuit(s) or outlet(s) to be

used for the Sewage Pump. Receptacles are available having built-in

GFCI protection and may be used for

this measure of safety.

Do not Abuse Cord - Do not carry 3.

by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil,

and sharp edges.

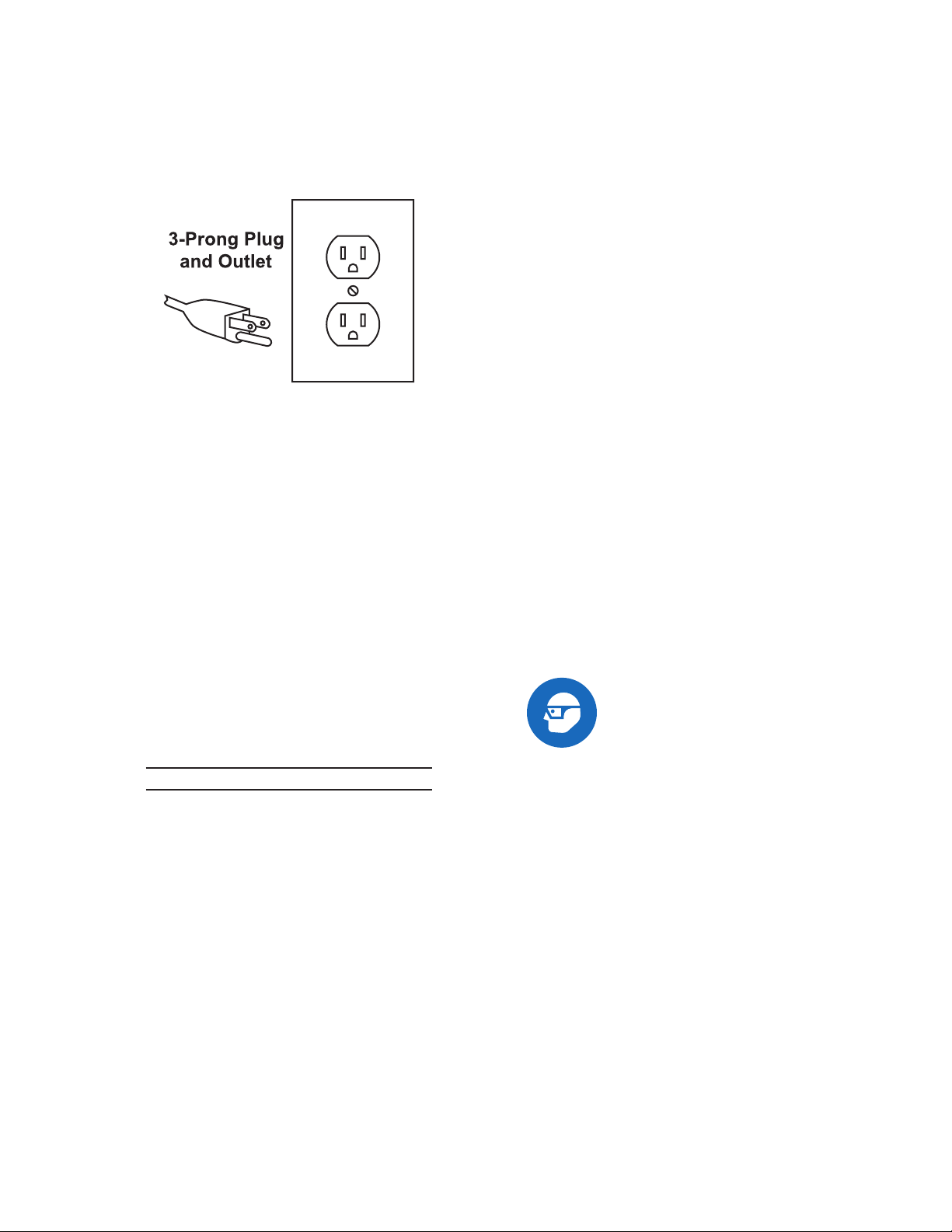

This 1 HP Cast Iron Sewage Pump 4.

should be grounded while in use to

reduce the risk of electric shock to

the operator. The Sewage Pump is

equipped with a 3-conductor cord

and 3-prong grounding plug to t

the proper grounding receptacle.

The green or green and yellow con-

SKU 66351 For technical questions, please call 1-800-444-3353. Page 2

Page 3

ductor in the cord is the grounding

wire. Do not connect the green or

green and yellow wire to a live terminal.

Your unit has a plug as illustrated

above. The outlet used should look

like the outlet illustrated above. Do

not remove the grounding prong

from the plug. If the plug will not

t the outlet, have a proper outlet

installed by a qualied electrician.

WARNING: Handling the cord on 5.

this product will expose you to lead,

a chemical known to the State of

California to cause cancer, and birth

defects or other reproductive harm.

Wash hands after handling. (California Health & Safety Code § 25249.5,

et seq.)

General and Specic Safety

DO NOT operate this Sewage d.

Pump if either the Power Cord (1),

Power Plug (29), Housing (10), or

Base (27), appear cracked or damaged in any way.

WARNING! DO NOT repair a dam-e.

aged power cord. Always replace

the cord before further use of this

Sewage Pump.

DO NOT place this Sewage Pump f.

in water with bare hands. Always

wear heavy-duty, insulated rubber

gloves.

DO NOT attach the power plug to g.

electrical outlet until the Sewage

Pump is placed where it will remain during operation.

Always unplug the Sewage Pump h.

before touching, moving, inspecting, or servicing.

Keep Children Away when assem-2.

bling, setting up, inspecting and/or

servicing this Sewage Pump.

3. Wear ANSI-approved safety

goggles, heavy-duty insulated rubber work gloves

and rubber boots while working with

or around this Sewage Pump.

WARNING: To prevent serious per-1.

sonal injury and/or death to yourself and/or others:

DO NOT use this Sewage Pump to a.

pump any ammable, or explosive

uids, such as gasoline, fuel oil,

kerosene, etc.

DO NOT use in ammable, and/or b.

explosive atmosphere.

Use this Sewage Pump only with c.

liquids compatible with pump

component materials.

SKU 66351 For technical questions, please call 1-800-444-3353. Page 3

Do not Overreach - Keep proper foot-4.

ing and balance at all times.

Stay Alert - Watch what you are do-5.

ing. Use common sense.

Page 4

OUTLET

DEVICE

CORD

Drip Loop

product, but must be supplied by the

operator.

SAVE THESE

INSTRUCTIONS.

SPECIFICATIONS

6. Use Drip-Loop to prevent water from

accidentally entering the electrical

power outlet. Use only with a GFCI

outlet. See second paragraph in

“Power Cord Safety” section of

this manual.

Use and Care

When servicing use only identical 1.

replacement parts.

Do not use this Sewage Pump for 2.

any job except that for which it is

intended.

Disconnect the Sewage Pump from 3.

the power supply when not in use,

or before inspection and/or service/storage.

Store Idle Sewage Pump Indoors 4.

when not in use out of reach of children.

Maintain labels and nameplates on 5.

the appliance. These carry important

safety information. If unreadable or

missing, contact Harbor Freight Tools

for a replacement.

The warnings, precautions, and in-6.

structions discussed in this instruction

manual cannot cover all possible conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

Electrical Information 120 V, 60 Hz, 10.5 AMPS

Gallons Per Minute 110

Pump Motor 1 HP, 3450 RPM

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

SET UP INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INSTRUCTIONS

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

TO

PREVENT

SERIOUS

INJURY FROM ACCIDENTAL

OPERATION:

Unplug the Sewage Pump

from its electrical outlet

before assembling,

inspecting, making any

adjustments, or servicing.

Note: For additional information regarding

the parts listed in the following pages,

SKU 66351 For technical questions, please call 1-800-444-3353. Page 4

Page 5

refer to the Assembly Diagram near

the end of this manual.

ASSEMBLY

Thread a discharge hose, or pipe 1.

(not supplied) to the orice on side of

Base (27).

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section

at the beginning of this manual

including all text under

subheadings therein before set

up or use of this product.

If you use a check-valve (not sup-2.

plied), mount the check valve horizonally or at 45°. The valve pivot

should be on top. NOTE: If the

check valve should be mounted in a

vertical position, solid waste will tend

to lodge on top of the valve apper

preventing it from opening.

If using a check-valve, drill a 1/16” 3.

hole in the discharge hose, or pipe 1”

to 2” above the Base (27). The hole

will prevent an air lock in the Motor (18) both at start up and/or if the

Sewage Pump should lose its prime.

After the check-valve, a (full-port) 4.

gate-valve (not supplied), which will

pass 2” solid waste should be installed in the system. The gate-valve

allows removal of the Sewage Pump

for cleaning and service.

NOTE: If you do not feel qualied to

completely (and safely) install this

Sewage Pump, it is recommended

that you have it installed by a

qualied plumber, or service technician.

Before operating the Sewage Pump, 1.

put on ANSI-approved safety goggles and other safety gear including

heavy-duty, insulated rubber gloves.

Safety goggles and other safety gear

are sold separately.

Install the Sewage Pump rmly on it’s 2.

Legs and supported by rigid hose, or

pipe discharge xtures to eliminate

twisting and damage from motor

torque during operation.

After installation, allow the Sew-3.

age Pump to ood with water before

plugging Power Cord (1) into outlet.

This will help prevent over heating

from running the Motor (18) with no

water resistance moving through the

Sewage Pump. Once this Sewage

Pump is plugged into a 120 Volt GFCI

outlet, the Motor (18) will start automatically.

This Sewage Pump is designed to 4.

transfer waste water in cycles.

Rev 09i

SKU 66351 For technical questions, please call 1-800-444-3353. Page 5

Page 6

MAINTENANCE AND

SERVICING

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION OR ELECTRIC

SHOCK:

Unplug the Sewage Pump

from its electrical outlet

before performing any

accessory change, inspection,

maintenance, and/or cleaning

procedures.

TO PREVENT SERIOUS

INJURY FROM TOOL

FAILURE:

Do not use damaged

equipment. If abnormal noise

or vibration occurs, have the

problem corrected before

further use.

Cleaning, Maintenance, and

Lubrication

WARNING: This Sewage Pump contains

dielectric motor oil for both lubrication and heat transfer. It may be

under pressure because of heat

collection. Let the Sewage Pump

cool for at least 2 hours before

inspecting, or servicing. This oil

may be dangerous to the environment. Always dispose of used oil

in compliance with all local, State

and Federal rules and regulations.

Unclogging the Impeller (24).

Unplug the Sewage Pump, put on 1.

heavy-duty insulated rubber gloves

and ANSI-approved safety goggles.

Remove the discharge hose, or pipe.2.

Lift Sewage Pump out of water using 3.

the Handle (5).

To unclog the Impeller (24), remove 4.

5 Screws (28) on the Sewage Pump

bottom and remove Base (27).

Flush the Impeller (24) with clean, 5.

lukewarm water.

Reinstall the Impeller (24) and re-6.

place the Base (27) using the 5

Screws (28).

BEFORE USE and PERIODICALLY 1.

THEREAFTER, inspect the gen-

eral condition of the Sewage Pump.

Check for loose screws, misalignment

or binding of moving parts, cracked or

broken parts, damaged electrical wiring, and any other condition that may

affect its safe operation.

2. WARNING! If the supply cord of

this appliance is damaged, it must

be replaced only by a qualied

service technician.

SKU 66351 For technical questions, please call 1-800-444-3353. Page 6

Using the Handle (5), replace the 7.

Sewage Pump into water in original

position.

Re-thread the discharge pipe, or 8.

hose.

Plug the Sewage Pump back into the 9.

120 Volt, GFCI power outlet.

The Sewage Pump will start auto-10.

matically.

Page 7

Troubleshooting

Problem Possible Causes Likely Solutions

Sewage Pump will not

start.

Low ow from

discharge outlets.

Sewage Pump starts

and stops too often.

Sewage Pump

operates but delivers

little or no water.

No power at outlet.1.

Circuit breaker tripped.2.

Cord not connected.3.

Water level too low. 4.

Possible excess solid debris lodged 1.

in Impeller.

Possible back ow from discharge 1.

pipe and/or hoses.

Check-valve either not installed, or if 2.

installed, it is leaking.

Low line voltage. 1.

Debris caught in Impeller or 2.

discharge hoses or pipes.

Check-valve stuck closed or 3.

installed backwards.

Check power at outlet.1.

Check circuit breaker for outlet.2.

Check that cord is plugged in.3.

Check water level.4.

Check and clean debris from 1.

Impeller per instructions on Page 6.

Install a check-valve. 1.

Remove and examine check-valve 2.

for proper installation and operation.

Replace if necessary.

If voltage is under recommended 1.

minimum, check wiring size from the

main switch on property. If not OK,

contact local power company.

Remove and check Impeller and 2.

discharge hoses or pipes. Clean if

needed.

Remove and examine check-valve 3.

and reinstall correctly or replace.

Follow all safety precautions whenever diagnosing or servicing the

appliance. Disconnect power supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.

REV 09i

SKU 66351 For technical questions, please call 1-800-444-3353. Page 7

Page 8

PARTS LIST

PARTS LIST

Part Description Q’ty

1 Power Cord 1

2 Screw 3/16 - 24 X 1/4 2

3 Cord Cover (Protector) 1

4 Screw 1/4 - 20 X 1/4 2

5 Handle 1

6 Washer 3/16 1

7 Strain Relief 1

8 Screw 3/16 24 X 308 1

9 1/4” NPT Oil Plug 1

10 Pump Motor Housing 1

11 Washer 3/16 X 1/4 2

12 Capacitor 40uf/350 V Vac 1

13 Screw M4 X 130 4

14 Rear Cover 1

15 Washer 2

16 Washer 608zz 1

ASSEMBLY DIAGRAM

Part Description Q’ty

17 Motor Shaft 1

18 Motor 1

19 Washer 6202zz - 12.7 1

20 Mechanic Seal Typ 21 1

21 O-Ring 1

22 Motor Seat 1

23 V-Seal 1

24 Impeller 1

25 Flat Screw 3/16 - 24 X 5/8 6

26 Packing Gasket 1

27 Base 1

28 Screw 1/4 - 20 X 3/4 5

29 Power Plug 1

SKU 66351 For technical questions, please call 1-800-444-3353. Page 8

Page 9

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from

the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from the use of our product. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection veries the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect

resulted from causes not within the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

SKU 66351 For technical questions, please call 1-800-444-3353. Page 9

Loading...

Loading...