Page 1

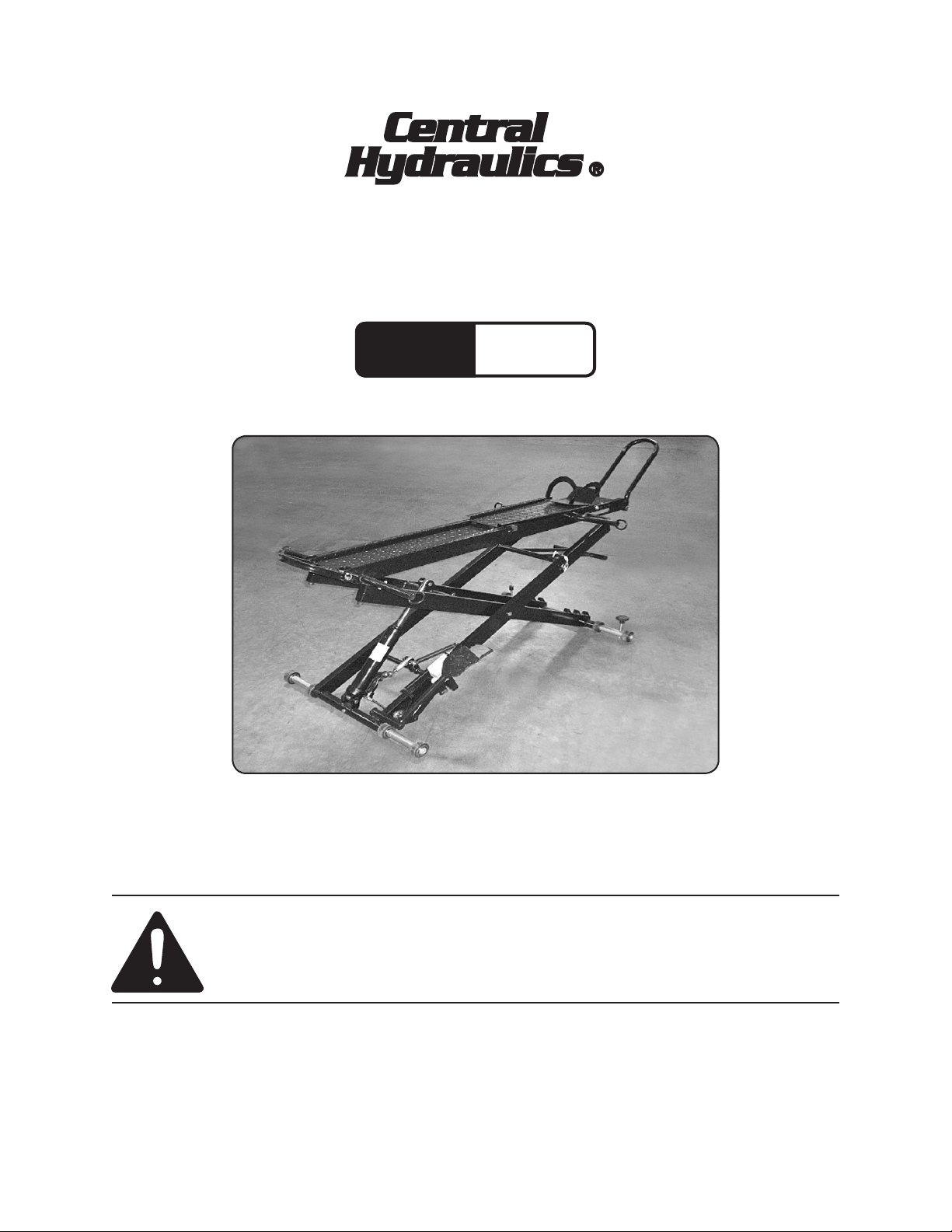

1000 LB. HYDRAULIC

Model

66305

MOTORCYCLE SERVICE LIFT

SET UP AND OPERATING INSTRUCTIONS

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any

artwork contained herein may be reproduced in any shape or form without the express written

consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due

to continuing improvements, actual product may differ slightly from the product described herein.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning

procedures. Write the product’s serial

number in the back of the manual near the

assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and

dry place for future reference.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

IMPORTANT SAFETY

Safety Alert Symbol

and Signal Words

In this manual, on the labeling,

and all other information

provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

INSTRUCTIONS

INSTRUCTIONS PERTAINING

TO A RISK OF FIRE,

ELECTRIC SHOCK, OR

INJURY TO PERSONS

WARNING – When using tools, basic pre-

cautions should always be followed,

including the following:

General

WARNING - To reduce the risks of electric

shock, re, and injury to persons,

read all the instructions before using

the tool.

Work area

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

Keep the work area clean and well a.

lighted. Cluttered benches and dark

areas increase the risks of electric

shock, re, and injury to persons.

Do not operate the tool in explo-b.

sive atmospheres, such as in the

presence of ammable liquids,

gases, or dust. The tool is able to

create sparks resulting in the ignition

of the dust or fumes.

Keep bystanders, children, and c.

visitors away while operating the

Page 2SKU 66305 For technical questions, please call 1-800-444-3353.

Page 3

tool. Distractions are able to result in

the loss of control of the tool.

Personal safety

Stay alert. Watch what you are do-a.

ing and use common sense when

operating the tool. Do not use the

tool while tired or under the inuence of drugs, alcohol, or medication. A moment of inattention while

operating the tool increases the risk

of injury to persons.

Dress properly. Do not wear loose b.

clothing or jewelry. Contain long

hair. Keep hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

increases the risk of injury to persons

as a result of being caught in moving

parts.

Do not overreach. Keep proper c.

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unexpected situations.

d. Use safety equipment. A

dust mask, non-skid safety

shoes and a hard hat must

be used for the applicable

conditions. Wear heavy-duty work

gloves during use.

Risk of Electric Shock. This tool g.

is not provided with an insulated

gripping surface. Contact with a

″live″ wire will also make exposed

metal parts of the tool ″live″ and

shock the operator.

Tool use and care

Use tie downs or another practical a.

way to secure and support the motorcycle on the platform. Holding

the motorcycle by hand or against the

body is unstable and is able to lead to

loss of control.

Do not force the Lift. b. Use the cor-

rect Lift for the application. The cor-

rect tool will do the job better and

safer at the rate for which the tool is

designed.

Do not use the Lift if the controls c.

do not function properly. Any tool

that cannot be controlled is dangerous and must be repaired.

Store the tool when it is idle out of d.

reach of children and other untrained persons. A tool is dangerous

in the hands of untrained users.

Maintain the tool with care. e. A prop-

erly maintained tool reduces the risk

of binding and is easier to control.

e. Always wear eye protec-

tion. Wear ANSI-ap-

proved safety goggles.

f. Always wear hearing

protection when using

the tool. Prolonged expo-

sure to high intensity noise

is liable to cause hearing loss.

Check for misalignment or bind-f.

ing of moving parts, breakage of

parts, and any other condition that

affects the tool’s operation. If dam-

aged, have the tool serviced before

using. Many accidents are caused

by poorly maintained tools. There is a

risk of bursting if the tool is damaged.

Use only accessories that are g.

identied by the manufacturer for

Page 3SKU 66305 For technical questions, please call 1-800-444-3353.

Page 4

the specic tool model. Use of an

accessory not intended for use with

the specic tool model, increases the

risk of injury to persons.

Service

Tool service must be performed a.

only by qualied repair personnel.

When servicing a tool, use only b.

identical replacement parts. Use

only authorized parts.

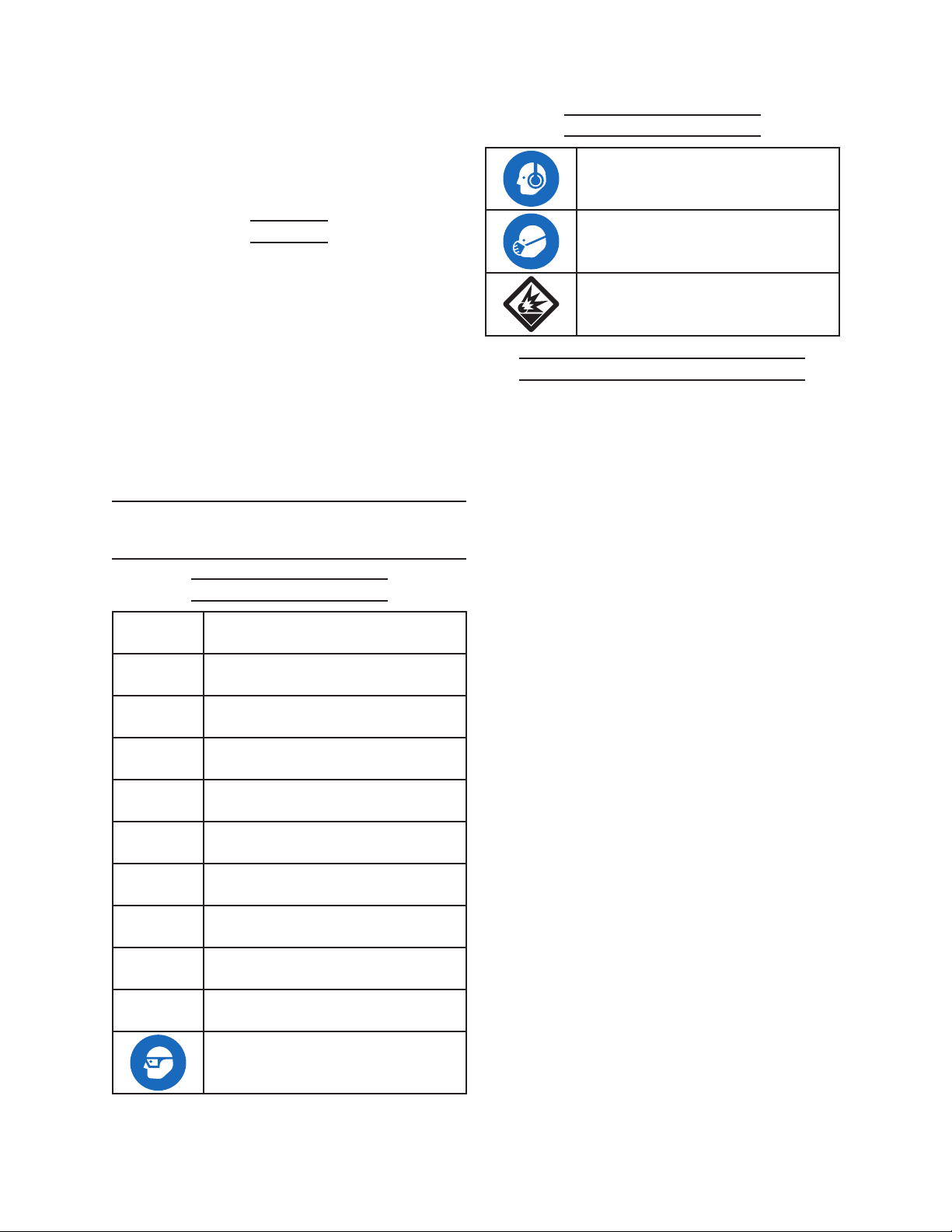

Symbol Denitions

WARNING marking concerning Risk

of Hearing Loss. Wear hearing

protection.

WARNING marking concerning Risk

of Respiratory Injury. Wear NIOSH-

approved dust mask/respirator.

WARNING marking concerning Risk

of Explosion.

Specic Safety Instructions

Use only the lubricants supplied c.

with the tool or specied by the

manufacturer.

SYMBOLS AND SPECIFIC

SAFETY INSTRUCTIONS

Symbol Denitions

Symbol Property or Statement

n

o

.../min

PSI

ft-lb

BPM

CFM

SCFM

NPT

NPS

No-load speed

Revolutions or reciprocation per

minute

Pounds per square inch of pressure

Foot-pounds of torque

Blows per minute

Cubic Feet per Minute ow

Cubic Feet per Minute ow at

standard conditions

National pipe thread, tapered

National pipe thread, straight

Strap Motorcycle to Lift before use.1.

The weight of the motorcycle must be 2.

centered directly over the Deck Plate

(16) during use.

This lift is designed for standard 3.

two-wheel motorcycles only. Do not

attempt to lift a motorcycle with side

car or a three-wheeled vehicle.

Do not exceed the maximum 1000 lb. 4.

weight capacity of this tool. Be aware

of dynamic loading! Dropping or

bouncing load may briey create excess load causing product failure.

Keep all fasteners and pull pins cor-5.

rectly installed and secure when the

Lift is in use.

Always use the Safety Bar (75) as 6.

described in this manual when the

Lift is raised. Never depend on the

Hydraulic Ram (24) alone to keep Lift

elevated.

Do not put Hands, arms, any body 7.

part or object within the interior frame

of the Lift when raising or lowering.

WARNING marking concerning Risk

of Eye Injury. Wear ANSI-approved

eye protection.

Chart continued in next column.

Do not hold onto the Lift as it is raised 8.

or lowered.

Page 4SKU 66305 For technical questions, please call 1-800-444-3353.

Page 5

Do not attempt to manually raise or 9.

lower the Lift. Operate the Lift hydraulically only as described in this

manual only.

Do not leave Lift unattended with a mo-10.

torcycle on it. The Lift is not for long term

storage.

Do not leave any load on the Lift for 11.

an extended period of time. This Lift is

not designed as a storage device. Remove motorcycle from Lift immediately

after completing service operation.

Use only on rm, level unobstructed 12.

surface able to support the weight

of the Lift, the vehicle, and any tools

that will be located in the work area.

Do not use Lift to move the motor-13.

cycle. This Lift is designed to lift the

motorcycle in place only.

Whenever a motorcycle is lifted, the 14.

Safety Bar (75) must be engaged

immediately before any further steps

are taken.

Do not use Lift for any aircraft purpose.15.

For indoor use only.16.

Do not ride on this Lift. Do not ride on 17.

the motorcycle as it is lifted. Riding

on Lift may cause personal injury.

Always control the speed of a loaded 18.

lift. It must raise or lower slowly

when loaded. Never attempt to lower

the Lift when loaded by using the

yellow No Load Pedal (71). The No

Load Pedal is only used to lower the

Lift when it is not loaded.

Do not lower the motorcycle quickly. 19.

Only use the Load Pedal (69) to

slowly lower the Lift when there is a

motorcycle on it. NEVER allow the

vehicle to drop suddenly.

The warnings and precautions dis-20.

cussed in this manual cannot cover

all possible conditions and situations

that may occur. It must be understood by the operator that common

sense and caution are factors which

cannot be built into this product, but

must be supplied by the operator.

Failure to comply with these warn-

ings may result in injury or damage to

property.

SAVE THESE

INSTRUCTIONS.

ASSEMBLY INSTRUCTIONS

The Lift comes completely assembled,

except for the following items: (Refer to

the exploded drawing).

Tie Down Rings: 1. The two front tie

downs are longer than the rear pair.

Slide the front tie downs (13) onto the

rods welded at either side of the front

end of the platform, and secure them

with bolts (14) and nuts (15). Attach

the shorter rear tie-downs (31) to the

rear rods and secure with bolts (14)

and nuts (15).

Wheel Chock: 2. Place the wheel

chock (17) on to the front end of the

platform and align it with a suitable

pair of holes. Slide the long bolt (19)

through a hole in the side of the

platform and through the sleeves

welded to the back of the chock and

out the other side of the platform.

Secure with nut (18).

Front Wheel Attachment. 3. Drop the

ends of the ‘U’ shaped front wheel

Page 5SKU 66305 For technical questions, please call 1-800-444-3353.

Page 6

attachment (21) into the sleeves

welded to the front end of the

platform and secure with a pull pin (7)

and a R-Pin (20) on either side.

Support Leg and Wheel 4.

Assemblies: Identify the two support

leg/wheel assemblies. The front

assembly (74) has a threaded hole

between each pair of wheels. Insert

the front assembly through the

support arm tube at the lower, front

end of the scissor frame. Rotate the

assembly within the tube until the

hole in the centre aligns with the hole

in the tube. Secure with a bolt (26).

Now attach wheels (28), washers (29)

and retaining rings (30) in the order

shown in the diagram below. Identify

the two lock bolts (41) with hand

wheels attached and screw them into

the holes between the wheels on

either side. Insert the rear assembly

(27) through the support arm tube

at the lower, back end of the scissor

frame. Rotate the assembly within the

tube until the hole in the centre aligns

with the hole in the tube. Secure with

a bolt (26). Now attach wheels (28),

washers (29) and retaining rings (30).

How to store the lift vertically.

The lift can be 1.

stored vertically

as shown in

gure below.

WARNING: In

this position the

lift is not free

standing and

must be secured

to a wall with a

heavy duty cable

or chain. Failure

to adequately secure the lift could

result in serious injury or death in

the event the lift tips over.

With the lift in its lowest position 2.

remove the ramp from the end of

the extended platform. Whilst the

platform is still extended remove the

pins from the ‘U’ shaped support on

the end of the extension and fold it

over. Use the two pins to lock it in

this position. Remove the two pins

from the other end of the extension

and push the extension back onto

the main platform until it lines up

with another pair of holes in the rails.

Insert the two pins through the rails to

lock the extension piece in position.

With the help of a second person, 3.

push the rear end of the Motorcycle

Lift against the wall where it will be

secured. Together lift the front end

into a vertical position. As it reaches

the vertical position the weight of the

lift will shift from the wheels to the ‘U’

shaped support leaving the wheels

slightly off the ground. Two people

should continue to support the lift

whilst it is manoeuvred up against the

wall. Whilst one person continues to

support the lift the other will secure

it in position with a heavy cable or

chains and a suitable lock.

Putting the lift back down for 4.

use. When returning the lift to the

horizontal position, equal care is

required to avoid injury to persons.

Reverse the lifting up steps. When

nally lowering the lift to the ground

take hold of the outer part of the

cable tie down bars at the chock

end of the lift to avoid ngers being

trapped under the wheel bars.

Page 6SKU 66305 For technical questions, please call 1-800-444-3353.

Page 7

SPECIFICATIONS

Before Initial Use

Maximum Lifting Capacity 1000 LBS

Maximum Lifting Height 32” Off Floor

Collapsed Height 7-5/8”

Ramp Dimensions 66-3/16” L x 8-3/8” W

Maximum Ramp Extension 84-5/8” Long

Ramp Inside Width 5-3/4”

Wheel Chock Width 5”

Ram Diameter 1.10”

Ram Travel 10-1/4”

Net Weight 165 Lbs.

INITIAL TOOL SET UP/

ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Inspect tool before use, looking

for damaged, loose, and

missing parts or oil leaks. If

any problems are found, do not

use tool until repaired.

Be sure that the Lift is situated on 1.

a solid level surface that can support the combined the weight of this

Lift and any motorcycle that will be

mounted on it.

Purge the Hydraulic Ram.2.

Purging the Hydraulic Ram

Please refer to Hydraulic Ram Assembly Diagram and Parts List near

the end of this manual when performing the following procedure.

Turn the Release Valve (15a) 1/2 turn 1.

counterclockwise. Remove the Oil

Filler Plug (9a).

Pump the Foot Pedal (56) 12 to15 2.

times, until all air is purged from the

pump.

Unpacking

This item is heavy. Ensure that you 1.

have an assistant to help handle and

set up this item.

When unpacking, check to make sure 2.

that the item is intact and undamaged. If any parts are missing or broken, please call Harbor Freight Tools

at the number shown throughout the

manual as soon as possible.

NOTE: This item is pre-assembled at the

factory.

Turn the Release Valve (15a) clock-3.

wise until nger tight.

Top off the hydraulic Ram (24) with 4.

good quality hydraulic oil (not included) until the oil level is even with the

bottom of the Oil Filler Port. Replace

the Oil Filler Plug (9a).

Test the Lift without a load by rais-5.

ing and lowering it. If the lift operates properly you have completed

this process. If the Lift does not raise

or lower smoothly and controllably,

repeat the purging process.

Page 7SKU 66305 For technical questions, please call 1-800-444-3353.

Page 8

IMPORTANT COMPONENTS OF THE LIFT

Front Wheel

Chock (17)

Rear Tie-Down Bracket (31)

Front Wheel Rest (21)

Front

Tie-Down

Bracket (13)

Safety Bar (75)

Safety Bar

Lock Pin (40)

Hydraulic Ram (24)

No Load Pedal (71)

Locking Bolt

Assembly (41)

Load Pedal (69)

Pump Pedal (56)

Figure 1

Load Pedal (69)

Hydraulic Ram (24)

Pump Pedal (56)

yellow

No Load

Pedal (71)

Figure 2

Page 8SKU 66305 For technical questions, please call 1-800-444-3353.

Page 9

OPERATING INSTRUCTIONS

TO PREVENT

SERIOUS INJURY:

Do not adjust or tamper with

any control or component in a

way not specically explained

within this manual. Improper

adjustment can result in tool

failure or other serious

hazards.

Position the Lift in a safe and suitable 1.

area as discussed above.

Rest (21). The Front Wheel Lock will

rotate with the wheel, supporting it

from the rear.

The Wheel Chock (17) can be ad-7.

justed to t your wheel. Remove the

Nut (18) from one end of the Wheel

Lock Axle (19), and slide the Axle out

of the Deck Plate (16). The Wheel

Lock can be moved as needed and

the Wheel Lock Axle inserted in the

appropriate holes in the Deck Plate.

Reinstall the Nut and tighten. See

Figure 3.

Press the Load Pedal (69) to fully 2.

lower the lift.

Pull out the Ramp (1) and Pull Ramp 3.

(8) as needed to accommodate the

length of the motorcycle.

Be sure the Front Wheel Chock (17) 4.

is rotated toward the rear of the Lift.

Roll the motorcycle up the Ramp (1) 5.

and onto the Deck Plate (16).

Front Wheel Rest (21)

Wheel Chock (17)

With a helper holding the motorcycle 8.

upright, secure the motorcycle to the

Lift using the Tie Down Points (13

and 31).

Before lifting any motorcycle, it must 9.

be securely fastened to the Lift using tie-down straps (not supplied) or

other suitable method. Two Front Tie

Down Brackets (13) and two Rear Tie

Down Brackets (31) are built into the

Lift for this purpose.

Refer to the manufacturer’s motorcy-10.

cle service manual for recommended

attachment points on the vehicle.

There must not be hazardous ob-11.

jects (such as utility lines or foreign

objects) nearby that will present a

hazard while working.

Pull Pin (7)

Wheel Lock Axle (19)

Figure 3

Roll the front wheel over the Front 6.

Wheel Chock (17) and into the Wheel

Before lifting the motorcycle, pull out 12.

the Safety Bar Lock Pin (40) to allow

the Safety Bar (75) to rest on the Inner Scissor Arm (35).

To Lift the motorcycle, pump the 13.

Pump Pedal (56) repeatedly until

the motorcycle is lifted to the desired

height.

Page 9SKU 66305 For technical questions, please call 1-800-444-3353.

Page 10

When the motorcycle is lifted, be sure 14.

that the Safety Bar (75) is slightly

above one of the ramps of the Inner

Scissor Arm (35).

Press the Load Pedal (69) until the 15.

Safety Bar (75) is fully engaged with

the ramp of the Inner Scissor Arm

(35). See Figure 4.

Locking Bolt (41)

Inner

Scissor

Arm (35)

insert the Safety Bar Lock Pin (40)

into the hole in the upper axle of the

Safety Bar. This will lock the Safety

Bar in the upright position. See Fig-

ure 5.

Figure 5

Safety Bar Pin (40)

Safety Bar (75)

Figure 4

Once the motorcycle has been lifted, 16.

do not move the Lift around. This Lift

is not designed to transport any load.

The Lift can be immobilized by turning the two Locking Bolts (41) clock-

wise rmly against the oor.

Do not leave the motorcycle on the lift 17.

unattended. If you plan to leave the

area, lower the lift and remove the

motorcycle before leaving.

Do not use the Lift as a storage de-18.

vice.

Pump the Pump Pedal (56) a few 19.

times to remove weight from the

Safety Bar (75).

Press the Load Pedal (69) to GEN-21.

TLY lower the load. NEVER allow the

load to come down quickly or suddenly.

With the load fully lowered, have a 22.

helper hold the motorcycle. Remove

the tie down straps. Roll the motorcycle off the back of the Lift.

Secure the motorcycle.23.

Loosen the two Locking Bolts (41) by 24.

turning a few turns counterclockwise.

Roll the motorcycle lift to a secure 25.

storage area out of the reach of children.

When work has been completed on 26.

the motorcycle, clear all tools away

from the area.

Disengage the Safety Bar (75) from 20.

the ramp of the Inner Scissor Arm

(35). Swing the Safety Bar up and

Page 10SKU 66305 For technical questions, please call 1-800-444-3353.

Page 11

USER-MAINTENANCE

INSTRUCTIONS

Cleaning Maintenance and

Lubrication

Procedures not specically

explained in this manual

must be performed only by a

qualied technician.

TO PREVENT

FROM TOOL FAILURE:

Do not use damaged

equipment. If abnormal noise,

vibration, or leaking air

occurs, have the problem

corrected before further use.

Motorcycle Lift does

not lift

Note: These procedures are in addition to

the regular checks and maintenance

explained as part of the regular operation of the air-operated tool.

Weekly - Pivot Point Lubrication 1.

SERIOUS INJURY

and Safety Inspection:

Lubricate the pivot points of the tool,

using white lithium grease. Inspect for

loose fasteners or any damage to the

Lift. Repair immediately or mark “Out

of Service” until repairs are made.

If the Hydraulic Ram fades or fails to 2.

lift you may need to add oil or purge

the Ram.

Troubleshooting

Possible Causes Likely Solutions

Steel Ball (13a) in the Discharge 1.

Valve or the single-way valve of

the Hydraulic Cylinder does not

seat or seal well.

Steel Ball (13a) in the Single-way 2.

valve does not seat or seal well.

Hydraulic Ram may require 3.

purging.

Discharge Valve is open.4.

Clean or replace these components. 1.

Clean or replace these components. 2.

Purge Ram. See instructions on page 6.3.

Tighten the discharge valve. 4.

Motorcycle Lift

does not lower

Motorcycle Lift

Fades (slowly

lowers on its own)

Oil leaks from top

rod of Hydraulic

Ram (24).

Oil leaks from the

pump and cylinder

Follow all safety precautions whenever diagnosing or servicing the tool.

Discharge Valve is not open1. Check function of Release Linkage Assembly 1.

Leaking Valves or Seals.1.

Low on oil in system. 2.

Hydraulic Cylinder may require 3.

purging.

Ram O-ring (2a or 6a) is worn 1.

out.

O-ring at pump (18a) or Oil Seal 1.

(3a or 10a) is worn out.

(54).

Take to qualied repair technician for service1.

Check oil level. Rell and purge as necessary. 2.

Follow instructions for purging system.

Purge Hydraulic Ram. See instructions on page 6. 3.

Replace the O-ring.1.

Replace the O-ring or Oil Seal.1.

Page 11SKU 66305 For technical questions, please call 1-800-444-3353.

Page 12

OVERALL ASSEMBLY DIAGRAM

75

Page 12SKU 66305 For technical questions, please call 1-800-444-3353.

Page 13

PARTS LIST FOR OVERALL ASSEMBLY

Item # Description QTY

1 Ramp 1

2 Pull Ramp Stand 1

3 End Cap 4

4 Pump Spring 1

5 Nut 2

6 Bolt 2

7 Pull Pin 6

8 Pull Ramp 1

9 Screw 2

10 Nut 2

11 Pull Ramp Guide 2

12 Rivet 2

13 Front Tie-Down Point 2

14 Bolt 4

15 Nut 4

16 Deck Plate 1

17 Wheel Chock 1

18 Nut 2

19 Wheel Lock Axle 1

20 R-Pin 2

21 Front Wheel Rest 1

22 Retaining Ring 4

23 Pump Base Pin 1

24 Hydraulic Ram 1

25 Pump Rod Pin 1

26 Bolt 1

27 Leg 1

28 Wheel 8

29 Washer 12

30 Retaining Ring 12

31 Rear Tie-Down Point 2

32 Retaining Ring 4

33 Pin 1

34 Rubber Gasket 4

35 Inner Scissor Arm 1

36 Retaining Ring 4

37 Pin 2

38 Outer Scissor Arm 1

Item # Description QTY

39 Pin 2

40 Safety Bar Lock Pin 1

41 Locking Bolt Assembly 2

42 Washer 1

43 Screw 1

44 Lever Linkage Assembly 1

45 Nut 1

46 Connecting Rod 1

47 Pin 1

48 Cotter Pin 3

49 Washer 2

50 Connecting Pin 1

51 Washer 2

52 Bushing 1

53 Screw 2

54 Release Linkage Assembly 1

55 Screw 1

56 Pump Pedal 1

57 Retaining Ring 1

58 Pump Link Plate 1

59 Pin 2

60 Pin 2

61 Spring Link Plate 1

62 Bolt 3

63 Nut 1

64 Release Link Ring 1

65 Release Link Plate 1

66 Release Spring 1

67 Nut 1

68 Bolt 1

69 Load Pedal 1

70 Retaining Ring 1

71 No Load Pedal 1

72 Screw 1

73 Nut 1

74 Leg 1

75 Safety Bar 1

Page 13SKU 66305 For technical questions, please call 1-800-444-3353.

Page 14

ASSEMBLY DIAGRAM FOR HYDRAULIC RAM

Note: All parts for the Hydraulic Ram Assembly have an “a” sufx, such as “19a”. Do

not confuse these part numbers with the part numbers for the Overall Assembly

which are listed on page 13, and have no sufx.

Page 14SKU 66305 For technical questions, please call 1-800-444-3353.

Page 15

PARTS LIST FOR HYDRAULIC RAM

Part Description QTY

1a Ram Cap 1

2a Ram O-Ring 1

3a Top Sealing Gasket 1

4a Ram Assembly 1

5a Ram Gasket 1

6a O-Ring 1

7a Cylinder 1

8a Oil Reservoir 1

9a Oil Filler Plug 1

10a Lower Sealing Gasket 1

11a Washer 1

12a Base 1

Part Description QTY

14a Seal 1

15a Release Valve 1

16a Washer 1

17a Pump Cylinder 1

18a O-Ring 1

19a Seal 1

20a Piston Rod 1

21a Pin 3

22a Split Cotter Pin 3

23a Handle Socket 1

24a Link 1

25a Pin 1

13a Steel Ball 3

Note: This parts list is for the Hydraulic Ram Assembly. Please refer to Assembly dia-

gram on previous page (14). All parts for Hydraulic Ram have an “a” sufx. For

example

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS DOCUMENT AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER

OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER

THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 15SKU 66305 For technical questions, please call 1-800-444-3353.

Page 16

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high

quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from

the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from the use of our product. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection veries the defect, we will either repair or replace the product at our election or we may elect to refund the purchase

price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect

resulted from causes not within the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

Page 16SKU 66305 For technical questions, please call 1-800-444-3353.

Loading...

Loading...