Harbor Freight Tools 65162 Owner's Manual

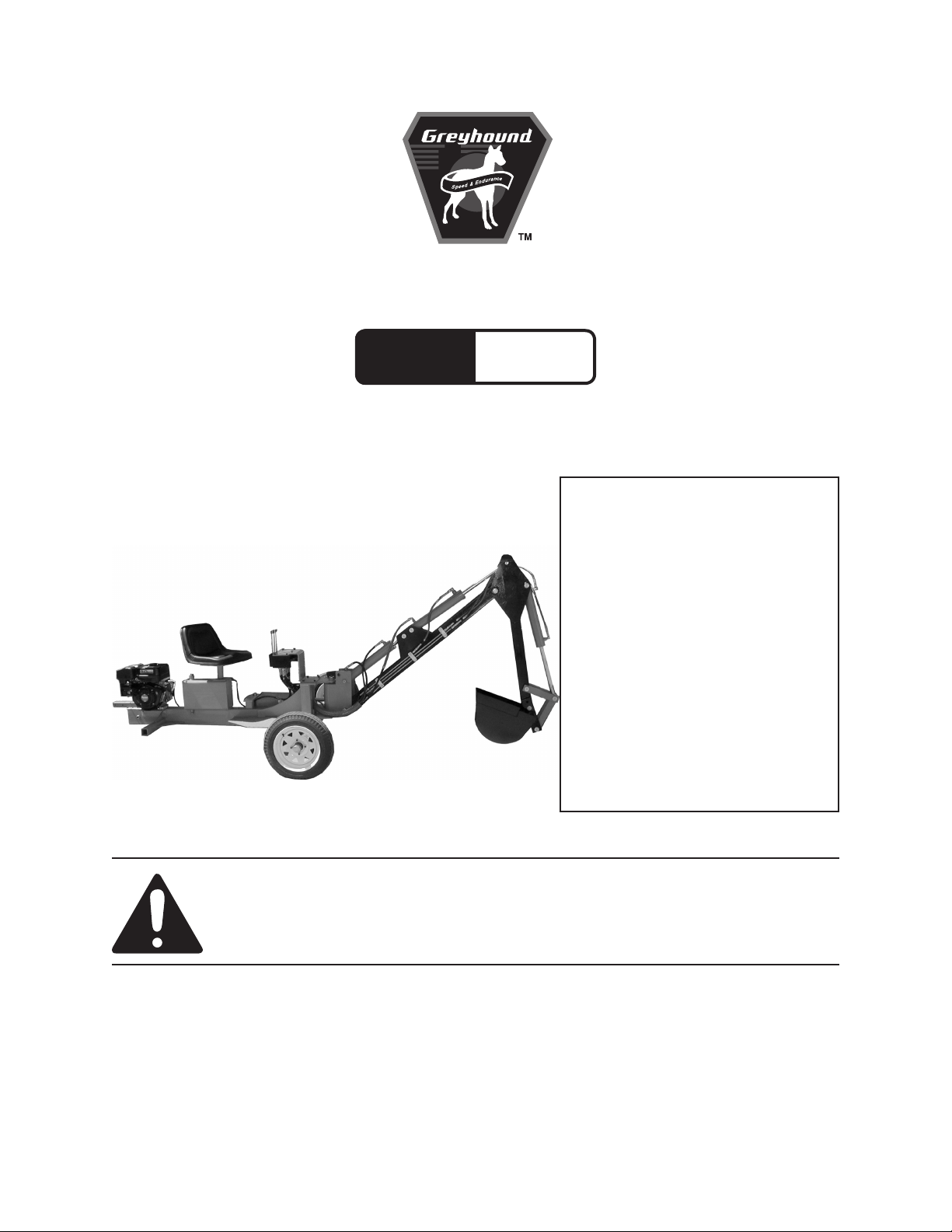

9 HP RIDE-ON TRENCHER

Model

65162

SET UP, OPERATING, AND SERVICING

INSTRUCTIONS

WARNING!

IMPORTANT INFORMATION

The Hitch Coupler MUST be properly

secured to the hitch ball of the towing vehicle.

After assembly and attachment, pull up and

down on the Hitch Coupler to make sure the

hitch ball is tting snugly in the Hitch Coupler.

There must be no play between the hitch

ball and Hitch Coupler. If there is play, tighten

the Adjustment Nut until no play is present. If

the Adjustment Nut is too tight, the Handle

will not lock. Carefully read and follow

the complete instructions in this manual

BEFORE setup or use.

If the Coupler is not secured

properly, the ball could come loose

while the Log Splitter is in motion,

possibly causing property damage,

SERIOUS PERSONAL INJURY, or

DEATH.

Revised 11a

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2008 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools. Diagrams within this

manual may not be drawn proportionally. Due to continuing improvements, actual

product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

CONTENTS

IMPORTANT SAFETY

INFORMATION ............................ 4

SET UP PRECAUTIONS .................... 4

OPERATING PRECAUTIONS ............ 5

SERVICE PRECAUTIONS ............. 6

REFUELING: .................................7

TRENCHER PRECAUTIONS ........ 7

BASIC SPECIFICATIONS ............. 8

CLEANING, MAINTENANCE, AND

LUBRICATION SCHEDULE .......... 21

AFTER 20 OPERATION HOUR

BREAK-IN PERIOD: ................21

AFTER EVERY 25 OPERATION

HOURS: ....................................21

AFTER EVERY 50 OPERATION

HOURS: ....................................21

AFTER EVERY 100

OPERATION HOURS: ..............21

AFTER EVERY 300

OPERATION HOURS: ..............21

PERIODICALLY: .........................21

UNPACKING .................................. 8

SET UP INSTRUCTIONS ............... 8

ASSEMBLY.........................................8

ATTACHING THE LEG ASSEMBLY 10

PURGING THE CYLINDER ..............12

OPERATING INSTRUCTIONS .... 12

STARTING THE ENGINE .................12

CHECKING ENGINE OIL LEVEL 12

ENGINE DIAGRAM ...................... 13

CHECKING FUEL LEVEL ........... 14

BREAK-IN PERIOD ....................14

EQUIPMENT OPERATION ...............15

MOVING THE TRENCHER ......... 16

TRANSPORTING THE

TRENCHER ..............................17

TECHNICAL SPECIFICATIONS .. 19

SERVICING .................................. 19

MAINTENANCE PROCEDURES .....19

ENGINE OIL CHANGE ...............19

AIR FILTER ELEMENT

MAINTENANCE .......................19

SPARK PLUG MAINTENANCE .. 20

FUEL FILTER REPLACEMENT

(IF EQUIPPED) .........................20

STORAGE ........................................21

LUBRICATION POINTS ...................22

TROUBLESHOOTING ...................... 23

PARTS LIST ................................. 25

GENERAL ASSEMBLY

DIAGRAM .................................. 26

CYLINDER HEAD PARTS LIST

& DIAGRAM .............................. 27

CRANK CASE PARTS LIST &

DIAGRAM .................................. 28

CRANK CASE COVER PARTS

LIST AND DIAGRAM ................. 29

CRANKSHAFT/PISTON PARTS

LIST & DIAGRAM ...................... 30

GAS DISTRIBUTION

ADJUSTMENT SYSTEM

PARTS LIST & DIAGRAM ......... 31

STARTER SUBASSEMBLY

PARTS LIST & DIAGRAM ......... 32

DIVERSION ASSEMBLY PARTS

LIST & DIAGRAM ...................... 33

Page 2SKU 65162 For technical questions, please call 1-800-444-3353.

CARBURETOR PARTS LIST &

DIAGRAM .................................. 34

FLYWHEEL/COIL ASSEMBLY

PARTS LIST & DIAGRAM ......... 35

CONTROL SYSTEM PARTS

LIST & DIAGRAM ...................... 36

AIR CLEANER PARTS LIST &

DIAGRAM .................................. 37

MUFFLER PARTS LIST &

DIAGRAM .................................. 38

FUEL TANK PARTS LIST &

DIAGRAM .................................. 39

LIMITED 1 YEAR / 90 DAY

WARRANTY .............................. 40

EMISSION CONTROL SYSTEM

WARRANTY .............................. 40

Page 3SKU 65162 For technical questions, please call 1-800-444-3353.

SAVE THIS MANUAL

Keep thi s man ual for th e safety

warnings and prec autions , asse mbly,

operating, inspection, maintenance and

cleaning procedures. Write the product’s

serial number in the back of the manual near

the assembly diagram (or month and year of

purchase if product has no number). Keep

this manual and the receipt in a safe and dry

place for future reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information

provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

DANGER indicates

DANGER

situation which, if not

avoided, will result in death or

serious injury.

WARNING

WARNING

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

CAUTION

alert symbol, indicates a

hazardous situation which, if

not avoided, could result in

minor or moderate injury.

a hazardous

indicates a

with the safety

Notice

CAUTION

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

WARNING! Read all instructions.

Failure to follow all instructions

listed below may result in re,

serious injury and/or DEATH.

The warnings and precautions

discussed in this manual cannot

cover all possible conditions and

situations that may occur. It must

be understood by the operator that

common sense and caution are

factors which cannot be built into

this product, but must be supplied

by the operator.

SAVE THESE INSTRUCTIONS

SET UP PRECAUTIONS

Gasoline fuel and fumes are 1.

ammable, and potentially explosive.

Use proper fuel storage and handling

procedures. Do not store fuel or

other ammable materials nearby.

Have multiple ABC class re 2.

extinguishers nearby.

This equipment has a spark 3.

arresting mufer included. A spark

arresting mufer is required by law

in California, on some US Forest

Service land, and possibly in other

areas or situations.

Set up and use only on a at, level, 4.

well-ventilated surface.

Page 4SKU 65162 For technical questions, please call 1-800-444-3353.

Wear ANSI-approved safety goggles, 5.

heavy-duty work gloves, and dust

mask/respirator during set up and

use.

Use only oil and fuel recommended 6.

in the “Specications” section of this

manual.

OPERATING PRECAUTIONS

1. CARBON MONOXIDE

HAZARD

Using an engine indoors

CAN KILL YOU IN

MINUTES.

Engine exhaust contains carbon

monoxide. This is a poison you

cannot see or smell.

NEVER use inside a home or garage,

EVEN IF doors and windows are

open.

Only use OUTSIDE and far away

from windows, doors, and vents.

Keep children and observers 20 feet 2.

away from the equipment while it is

operating.

Tools for your model. Accessories

that may be suitable for one piece of

equipment may become hazardous

when used on another piece of

equipment.

Stay alert, watch what you are 7.

doing and use common sense when

operating a piece of equipment. Do

not use a piece of equipment while

tired or under the inuence of drugs,

alcohol or medication.

Do not overreach. Keep proper 8.

balance at all times. This enables

better control of the equipment in

unexpected situations.

Dress properly. Do not wear loose 9.

clothing or jewelry. Keep hair,

clothing and gloves away from

moving parts. Loose clothes, jewelry

or long hair can be caught in moving

parts.

Parts of the equipment, especially 10.

exhaust system components, get

very hot during use. Stay clear of hot

parts.

Do not leave the equipment 3.

unattended when it is running. Turn

off the equipment (and remove safety

keys, if available) before leaving the

work area.

Wear ANSI-approved safety goggles 4.

and hearing protection during use.

People with pacemakers should 5.

consult their physician(s) before

use. Electromagnetic elds in close

proximity to a heart pacemaker could

cause pacemaker interference

or pacemaker failure. Caution is

necessary when near the engine’s

magneto or recoil starter.

Use only accessories that are 6.

recommended by Harbor Freight

Do not cover the engine or equipment 11.

during operation.

Keep the equipment, engine, and 12.

surrounding area clean at all times.

Use the equipment, accessories, etc., 13.

in accordance with these instructions

and in the manner intended for the

particular type of equipment, taking

into account the working conditions

and the work to be performed. Use

of the equipment for operations

different from those intended could

result in a hazardous situation.

Do not operate the equipment with 14.

known leaks in the engine’s fuel system.

Page 5SKU 65162 For technical questions, please call 1-800-444-3353.

This product contains or, when 15.

used, produces a chemical known

to the State of California to cause

cancer and birth defects or other

reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

When spills of fuel or oil occur, they 16.

must be cleaned up immediately.

Dispose of uids and cleaning

materials as per any local, state,

or federal codes and regulations.

Store oil rags in a bottom-ventilated,

covered, metal container.

Keep hands and feet away from 17.

moving parts. Do not reach over or

across equipment while operating.

Before use, check for misalignment 18.

or binding of moving parts, breakage

of parts, and any other condition

that may affect the equipment’s

operation. If damaged, have the

equipment serviced before use.

Many accidents are caused by poorly

maintained equipment.

Use the correct equipment for the 19.

application. Do not modify the

equipment and do not use the

equipment for a purpose for which it

is not intended.

SERVICE PRECAUTIONS

Before service, maintenance, or 1.

cleaning:

Turn the engine switch to its a.

“OFF” position.

Allow the engine to completely cool.b.

Then, remove the spark plug c.

wire(s) from the spark plug(s).

guards include mufer, air cleaner,

mechanical guards, and heat shields,

among other guards.

Do not alter or adjust any part of 3.

the equipment or its engine that

is sealed by the manufacturer

or distributor. Only a qualied

service technician may adjust

parts that may increase or

decrease governed engine speed.

Wear ANSI-approved safety goggles, 4.

heavy-duty work gloves, steel toe

work boots, dust mask/respirator and

hard hat during use and service.

Do not allow the hydraulic hose to 5.

come in contact with any hot part

of the unit. The hose might be

damaged, possibly causing it to burst

or leak under high pressure.

Maintain labels and nameplates 6.

on the equipment. These carry

important information. If unreadable

or missing, contact Harbor Freight

Tools for a replacement.

Have the equipment serviced by a 7.

qualied repair person using only

identical replacement parts. This

will ensure that the safety of the

equipment is maintained. Do not

attempt any service or maintenance

procedures not explained in this

manual or any procedures that you

are uncertain about your ability to

perform safely or correctly.

Store equipment out of the reach of 8.

children.

Follow scheduled engine and 9.

equipment maintenance.

Keep all safety guards in place and 2.

in proper working order. Safety

Page 6SKU 65162 For technical questions, please call 1-800-444-3353.

Refueling:

Do not smoke, or allow sparks, 1.

ames, or other sources of ignition

around the equipment, especially

when refuelling.

Do not rell the fuel tank while the 2.

engine is running or hot.

do this type of work. To reduce your

exposure to these chemicals: work in

a well ventilated area, and work with

approved safety equipment, such as

those dust masks that are specially

designed to lter out microscopic

particles. (California Health & Safety

Code § 25249.5, et seq.)

Do not ll fuel tank to the top. Leave 3.

a little room for the fuel to expand as

needed.

Refuel in a well-ventilated area only.4.

TRENCHER PRECAUTIONS

Always make sure the hitch coupler 1.

is securely xed to the vehicle before

moving it. If the Coupler is not secured properly, the link could come

loose while the trailer is in motion,

possibly causing property damage,

SERIOUS PERSONAL INJURY, or

DEATH.

Contact local utility companies 2.

before beginning any project. Buried

utility lines may not be marked

and, if struck, can cause SERIOUS

PERSONAL INJURY or DEATH.

Never place your hands or body near 4.

a hydraulic uid leak. High-pressure

uid can be forced under the skin

resulting in serious injury.

Do not exceed 30 MPH when towing 5.

the Trencher.

Do not tow the Trencher on roads or 6.

highways. This product is not D.O.T.

compliant, and is not road legal.

SAVE THESE

INSTRUCTIONS.

WARNING: Some dust created by 3.

power sanding, sawing, grinding,

drilling, and other construction

activities, contains chemicals

known [to the State of California] to

cause cancer, birth defects or other

reproductive harm. Some examples

of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and

cement or other masonry products

• Arsenic and chromium from

chemically treated lumber

Your risk from these exposures

varies, depending on how often you

Page 7SKU 65162 For technical questions, please call 1-800-444-3353.

BASIC SPECIFICATIONS

Fuel

Type

Capacity 1.58 Gallons

Type SAE

Engine Oil

Capacity 1.2 Quarts

Hydraulic Oil 3.5 Gallons

Engine Speed 3,600 RPM

Engine Family 6CGP.2702GA

Tire Ination 65 PSI

Digging Depth 5-1/2 and 7 Feet Deep

Maximum Digging

Reach

Spool Valve Rated 10.6 G.P.M.

Pump Rated 2.7 G.P.M.

Boom Travel 60° Left/Right

Bucket Load Capacity 1.24 Cubic Feet

Hitch Ball size 1-7/8” Diameter

Note: Additional specications found

in the TECHNICAL ENGINE

SPECIFICATIONS chart in this

manual.

The emission control system for this

product’s Engine is warranted for standards

set by the U.S. Environmental Protection

Agency and by the California Air Resources

Board (also known as CARB). For warranty

information, refer to the last pages of this

manual.

At high altitudes, the engine’s carburetor,

governor (if so equipped), and any other

parts that control the fuel-air ratio will need to

be adjusted by a qualied mechanic to allow

efcient high-altitude use and to prevent

damage to the engine and any other devices

used with this product.

86+ octane unleaded

gasoline

10W 30 above 32° F

5W30 at 32° F or below

8 Feet

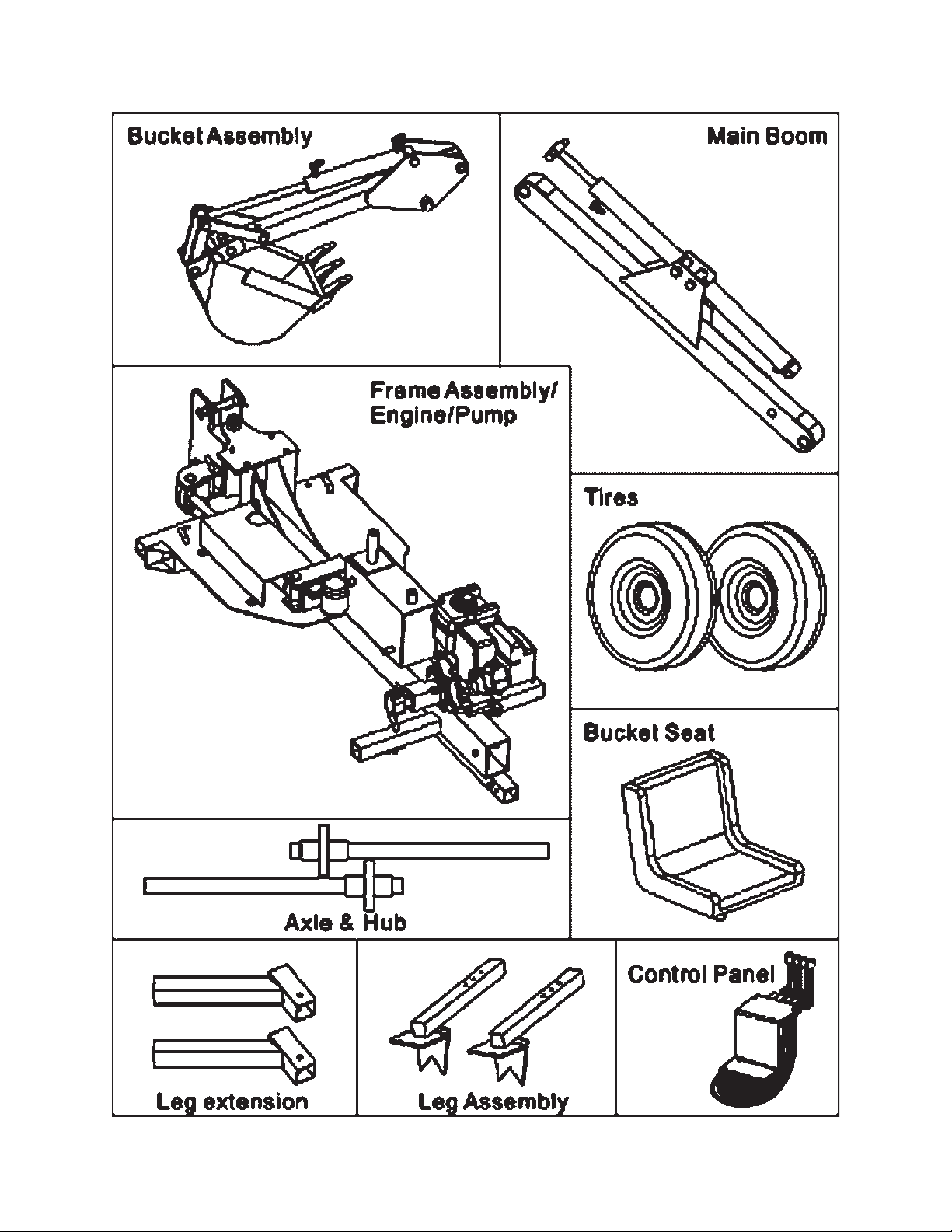

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please call

Harbor Freight Tools at the number shown

on the cover of this manual as soon as

possible.

SET UP INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

WARNING

Note: For additional information regarding

Risk of accidental

starting; resulting

in serious personal injury.

Turn the Power Switch of the

equipment to its “OFF”

position, wait for the engine to

cool, and unplug the spark

plug wire(s) before

assembling or making any

adjustments to the equipment.

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Assembly

This equipment has a spark arresting 1.

mufer. A spark arresting mufer is

required by law in California, on some

US Forest Service land, and possibly

in other areas or situations.

Due to the size of the Trencher and 2.

its components, assistance may be

required during the entire assembly

process.

Use jacks (not included) to evenly 3.

raise the Frame Assembly (90)

& support with jack stands (not

included).

REV 09b, 09i

Page 8SKU 65162 For technical questions, please call 1-800-444-3353.

Page 9SKU 65162 For technical questions, please call 1-800-444-3353.

Mount both Axles (50) near the boom 4.

end of the frame and secure with

Lock Pins (82).

Boom

Pivot (38)

Clevis Pin

No. 1 (29)

Place a Tire (52) over the four studs 5.

on each Hub. Secure the Tires to

the Hubs, using four Lug Nuts (53)

per Tire. The lug nuts must be snug.

Inate the tires to 65 PSI.

Slightly raise the Jacks, remove the 6.

Jack Stands, then lower the Jacks.

Block the tires and tighten the Lug

Nuts to at least 90 Ft-Lbs.

Attach Seat (73) to the Seat Bottom 7.

Plate (10) and secure both Seat and

Plate to the post on top of Hydraulic

Oil Tank.

Attach the Control Support (3) to the 8.

Frame Assembly (90) using four Hex

Bolts (81).

NOTE: The Hydraulics of this unit are

tested before shipment. There

may be hydraulic uid present in

components. Assemble the unit in

an area that will not be damaged

by leaking hydraulic uid. It is

recommended that you wrap

rags securely over the Hydraulic

connectors on all the Cylinders during

assembly. Wear splash-resistant

ANSI approved safety goggles and

other protective gear to prevent injury

from leaking uid.

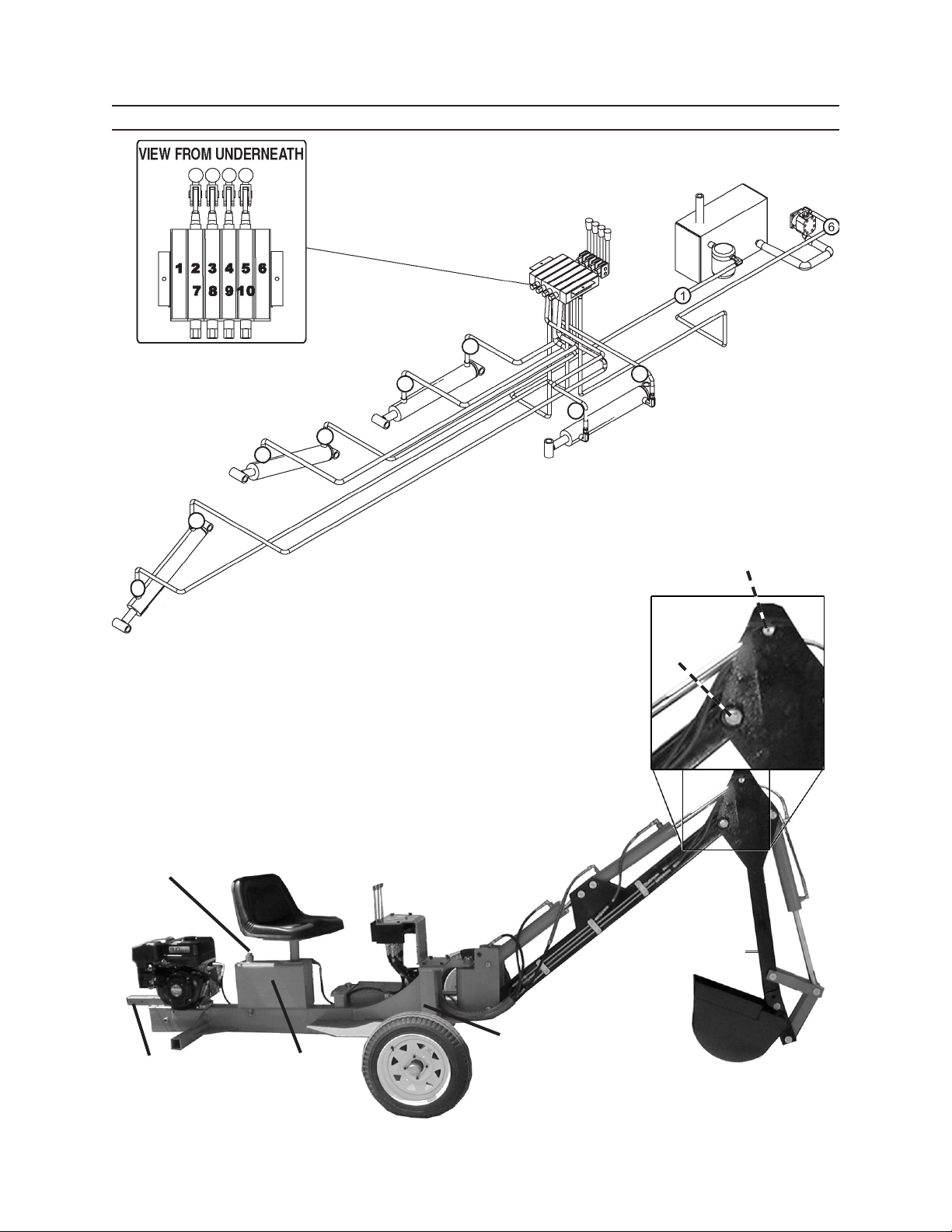

Attach the Main Boom (36) to the 9.

Boom Pivot (38) using the Pin (42)

through the bottom hole and Clevis

Pin No. 1 (29) through the upper

hole. Secure both pins with Hair Pin

Clip (31); Pin (42) requires one Cotter

pin on each end. See photo above

right.

Main

Boom

(36)

Pin

(42)

Mount the Boom Extension (34) to 10.

the Main Boom (36) using the Pin

(42), left, and Clevis Pin No. 1 (29),

top. Secure both pins with Hair Pin

Clip (31).

Attach the Hitch Coupler (58) to 11.

the Frame Assembly (90) under the

Engine (74) using Hex Bolts (75) and

Hex HD. Bolt (72).

Connect, tighten, and check all 12.

hydraulic hose ttings to the proper

connections, as shown in the Hose

Connection Diagram. Hoses and

ttings are numbered. Tighten all

ttings.

Open the Hydraulic Fluid Fill Plug 13.

(11). Top off the Hydraulic Fluid

Reservoir with high quality hydraulic

uid. Check that the Fluid level is

between the lines on the attached

Dipstick. Close the Hydraulic Fluid Fill

Plug securely.

Attaching the Leg Assembly

To use the Trencher, the Leg 1.

Assemblies must be installed next to

the Boom (36), and the Wheels and

Axles (50) moved to the rear.

REV 09i

Page 10SKU 65162 For technical questions, please call 1-800-444-3353.

Hose Connection Diagram

Control Panel / Spool Valve (9)

Hydraulic Fluid

Reservoir

part of Frame (90)

Hydraulic

Pump (65)

Bucket

Control

Cylinder

7

2

Boom

Extension

Cylinder

8

3

Main Boom

Cylinder

9

4

5

10

Boom Swing

Cylinder

Clevis Pin No. 1

(29)

Pin

(42)

Hydraulic Fluid

Fill Plug (11)

Engine (74)

Mount Hitch

Coupler (58)

Here

Seat (73)

Hydraulic

Fluid

Reservoir

Control

Panel

(9)

Boom Extension (34)

Frame Assy. (90)

TOW CONFIGURATION

REV 09b, 11a

Page 11SKU 65162 For technical questions, please call 1-800-444-3353.

Move the Trencher to the work area 2.

(See “Starting The Engine” - page

14).

Start the engine and use the Boom 3.

Controls to curl the bucket toward the

boom without touching the ground.

Moving the Bucket As sembly (32)

down to the ground will raise the

Frame Assembly (90). Lift the Tires

just off the ground and stop.

Ensure the controls will not be 4.

touched or bumped, and that the

Trencher will remain motionless.

Never place any part of your body

under the trencher.

With the Tires (52) off the ground, 5.

remove the Wheel and Axle (50)

to the operator’s left and replace

with the left side Extension Leg (19)

and Leg Assembly (24). Direct the

Extension Leg so it turns toward the

Bucket end of the Trencher. Secure

with Lock Pin No. 2 (82). Repeat

procedure for the right side. Raise

Bucket As sembly again to lower onto

Leg Assembly, and turn Engine off.

Using a jack and jack stands (not 6.

included), raise up the engine end of

the trencher and disconnect from the

towing hitch. Slide the Wheels and

Axles (50) into the engine end of the

Frame (90). Secure each axle with

Lock Pin No. 2 (82).

Press forward on the Main Boom 3.

Lever until the Main Boom is fully

raised. Then, press Forward on the

Boom Extension Lever until the Boom

is fully extended.

Press forward on the Bucket Lever 4.

until the bucket is fully extended. Pull

back on the lever to retract it fully.

Pull back on the Boom Extension 5.

Lever until the Boom is pulled back

all the way. Pull back on the Main

Boom Lever until the Main Boom is

lowered completely.

Adjust the boom back to its rest 6.

position and replace all locking

devices.

Shut off the Engine, check the 7.

Hydraulic Fluid level and rell as

necessary.

Note: The Fill Plug is vented. When 8.

tightening the Fill Plug, tighten it

securely then back it off slightly.

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Starting the Engine

Purging the Cylinder

Remove all Safety Locking Pins (15), 1.

disengage the Safety Latch (41) and

loosen Hydraulic Tank Fill Plug (11).

Press forward on the Boom Swing 2.

Lever (located on Control Panel (9)

until the Boom stops moving, then

pull back on it until it moves in the

other direction. Center the Boom.

Inspect engine and equipment

looking for damaged, loose,

and missing parts before

set up and starting. If any

REV 09i

Page 12SKU 65162 For technical questions, please call 1-800-444-3353.

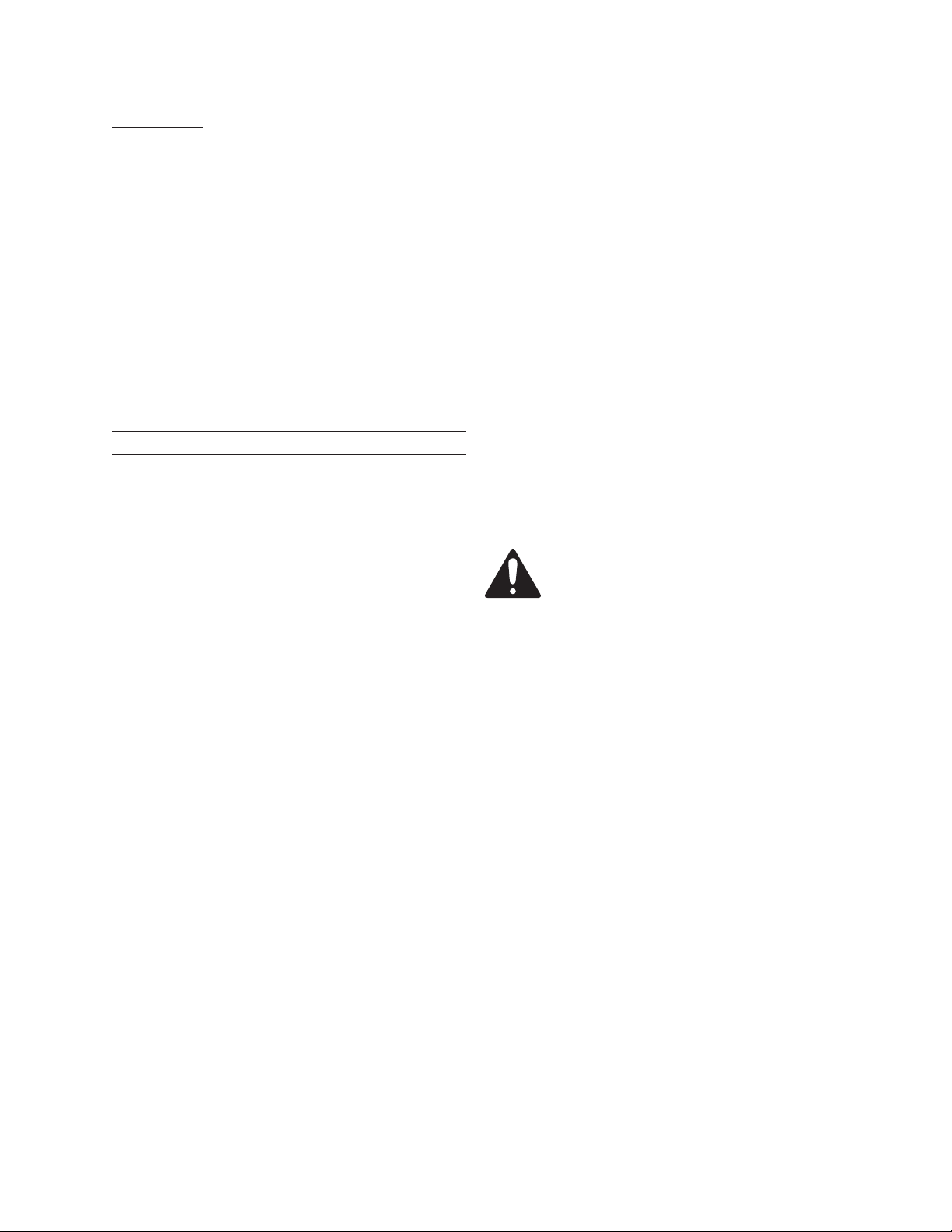

COMPONENTS & CONTROL LOCATIONS

2.

COMPONENTS & CONTROL LOCATIONS

THROTTLE LEVER

MUFFLER

SPARK PLUG

AIR CLEANER

FUEL VALVE LEVER

CHOKE LEVER

RECOIL STARTER

STARTER GRIP

IGNITION SWITCH

FUEL FILLER CAP

FUEL TANK

OIL DRAIN PLUG

OIL FILLER CAP/DIPSTICK

ENGINE DIAGRAM

Page 13SKU 65162 For technical questions, please call 1-800-444-3353.

Loading...

Loading...