Harbor Freight Tools 61476 Product manual

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INFORMATION

1. Study, understand, and follow all instructions

before operating this device.

2. Do not exceed rated capacity.

3. Use only on hard, level surfaces.

4. Lifting device only. Immediately after lifting,

support the vehicle with appropriate means.

5. Do not move or dolly the vehicle while on the jack.

6. Failure to heed these markings may result in

personal injury and/or property damage.

7. Lift only areas of the vehicle as specified

by the vehicle manufacturer.

8. No alterations shall be made to this product.

9. Never work on, under or around a load

supported only by this device.

10. Do not adjust safety valve.

11. Wear ANSI-approved safety goggles and

heavy-duty work gloves during use.

12. Keep clear of load while lifting and lowering.

13. Lower load slowly.

14. Apply parking brake and chock

tires before lifting vehicle.

15. Lift vehicle only at manufacturer

recommended locations.

16. Inspect before every use; do not use

if parts are loose or damaged.

17. Do not use for aircraft purposes.

18. The warnings, precautions, and instructions

discussed in this manual cannot cover all

possible conditions and situations that may occur.

The operator must understand that common sense

and caution are factors, which cannot be built into

this product, but must be supplied by the operator.

19. The brass components of this product contain lead,

a chemical known to the State of California to cause

cancer, birth defects (or other reproductive harm).

(California Health & Safety Code § 25249.5, et seq.)

IMPORTANT! Before first use:

Check hydraulic oil level and fill to 1/4″ below

the fill port as needed as stated on page 5.

Thoroughly test the Jack for proper operation.

If it does not work properly, bleed air from its

hydraulic system as stated on page 5.

Page 2 For technical questions, please call 1-800-444-3353. Item 61476

Air Source

a. Never connect to an air source that

is capable of exceeding 200 psi.

Over pressurizing the tool may cause

bursting, abnormal operation, breakage

of the tool or serious injury to persons.

Use only clean, dry, regulated compressed air at the

rated pressure or within the rated pressure range as

marked on the tool. Always verify prior to using the

tool that the air source has been adjusted to the rated

air pressure or within the rated air-pressure range.

Symbol Definitions

Symbol Property or statement

PSI

CFM

SCFM

NPT

Pounds per square inch of pressure

Cubic Feet per Minute flow

Cubic Feet per Minute flow

at standard conditions

National pipe thread, tapered

Chart continued in next column.

b. Never use oxygen, carbon dioxide, combustible

gases or any bottled gas as an air source

for the tool. Such gases are capable of

explosion and serious injury to persons.

Symbol Property or statement

WARNING marking

concerning Risk of Eye Injury.

Wear ANSI-approved eye protection.

WARNING marking concerning Risk of

Hearing Loss. Wear hearing protection.

WARNING marking concerning

Risk of Respiratory Injury. Wear

NIOSH-approved dust mask/respirator.

WARNING marking concerning

Risk of Explosion.

SAVE THESE INSTRUCTIONS.

Page 3For technical questions, please call 1-800-444-3353.Item 61476

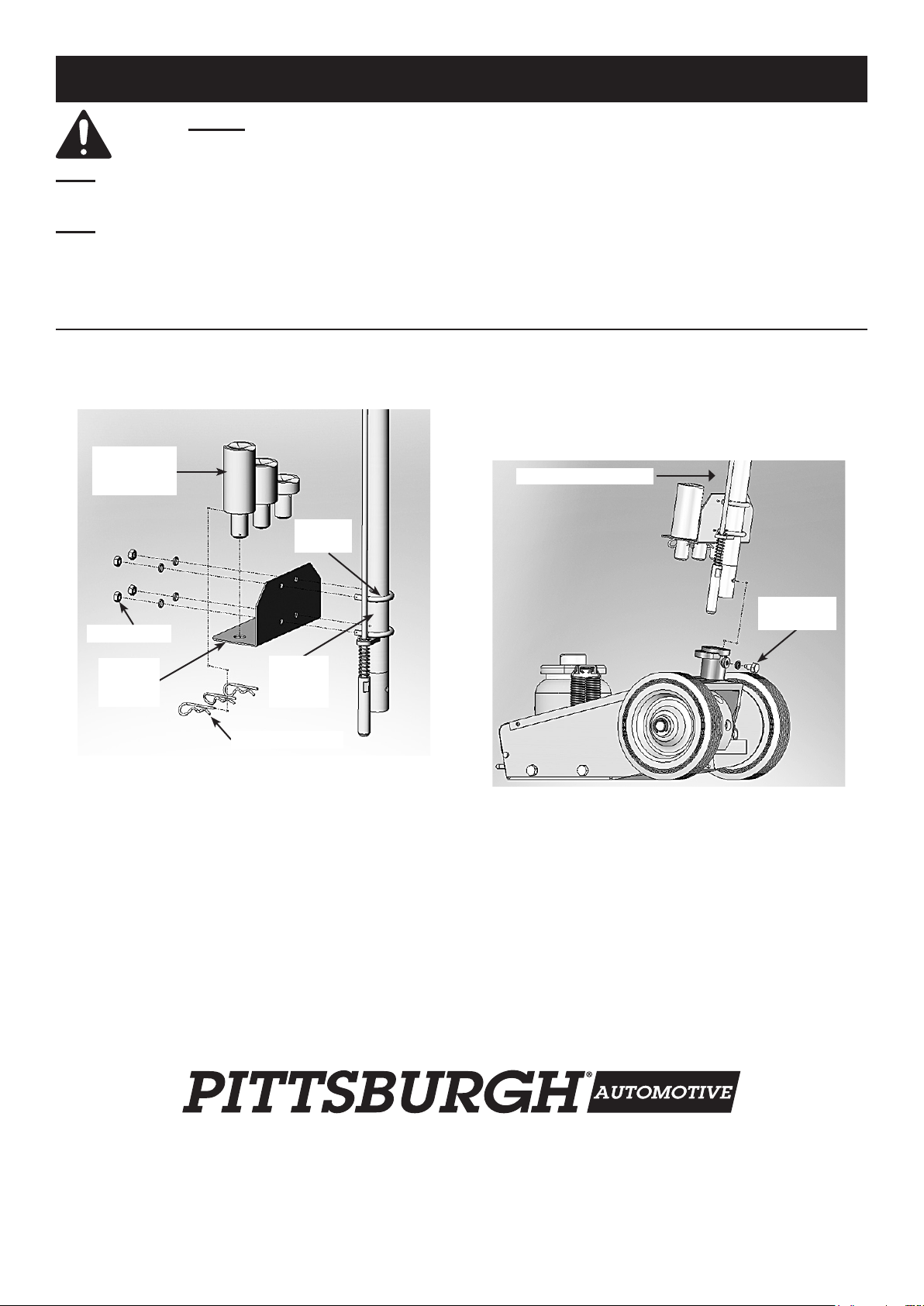

Assembly Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this document

including all text under subheadings therein before set up or use of this product.

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

Note: This air tool may be shipped with a protective plug covering the air inlet. Remove this plug before set up.

Assembly

1. Attach Adapter Holder (66) to the Lower Handle (18)

with two U-Bolts (65) and Nuts (23).

See Figure A, below.

Saddle

Adapters

(67-69)

U-Bolts

(65)

Nuts (23)

Adapter

Holder

(66)

Figure A

2. Tighten Nuts to secure Adapter Holder to Handle.

Lower

Handle

(18)

Cotter Pin (71)

3. Put height adjustment Adapters into

the Adapter Holder and lock each with

a Cotter Pin (71). See Figure A.

5. Put the Handle Assembly into Handle Socket and

secure with Set Screw. See Figure B, below.

Completed Handle

Set

Screw (6)

Figure B

Page 4 For technical questions, please call 1-800-444-3353. Item 61476

Loading...

Loading...