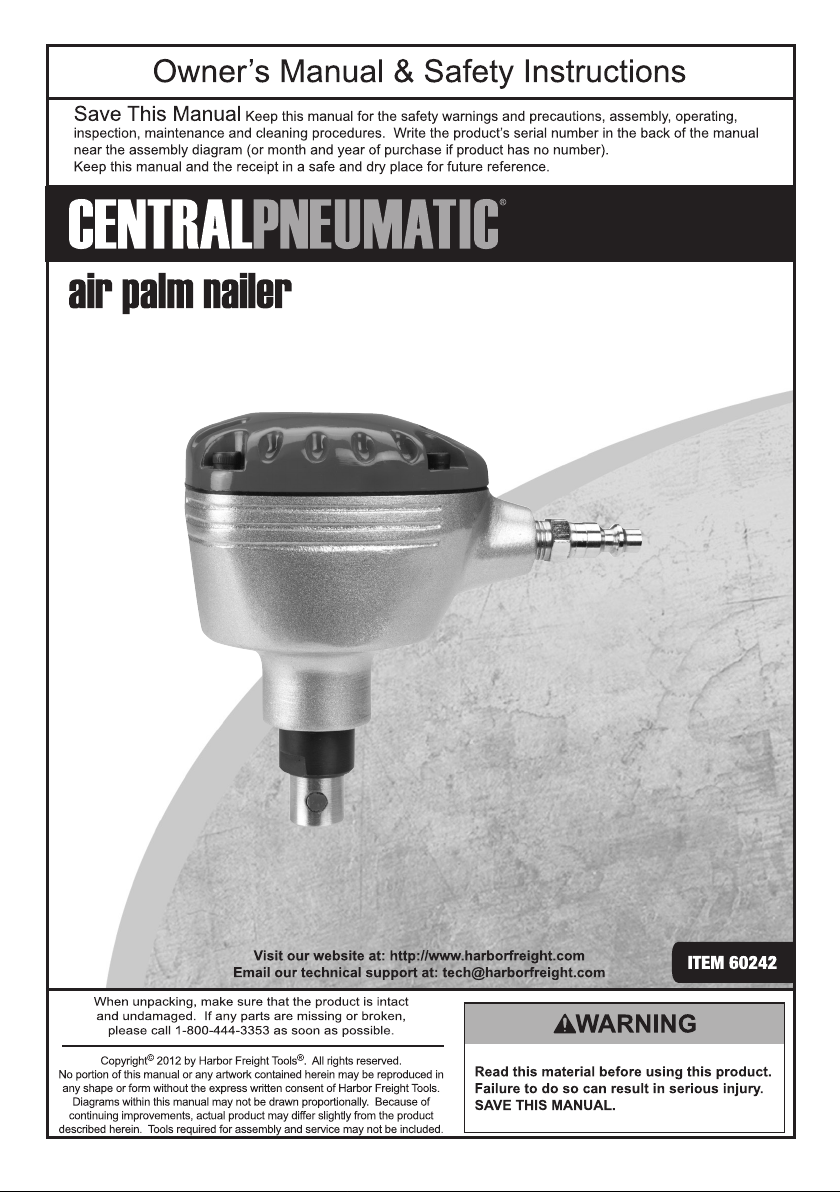

Harbor Freight Tools 60242 Owner's Manual

Table of Contents

Safety ..................................................... 2

SAFETY OPERATION MAINTENANCESETUP

Specifications .........................................7

Setup ...................................................... 7

Operation ............................................... 10

WARNING SYMBOLS AND DEFINITIONS

potential personal injury hazards. Obey all safety messages

Symbol Property or statement

PSI

CFM

SCFM

NPT

NPS

Pounds per square inch of pressure

Cubic Feet per Minute flow

Cubic Feet per Minute flow

at standard conditions

National pipe thread, tapered

National pipe thread, straight

WARNING marking concerning

Risk of Eye Injury.

Wear ANSI-approved safety

goggles with side shields.

Maintenance .......................................... 12

Parts List and Diagram ..........................15

Warranty ................................................16

This is the safety alert symbol. It is used to alert you to

that follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Symbol Property or statement

Warning marking concerning

Risk of Puncture Injury.

Wear heavy-duty work gloves.

Read the manual before

set-up and/or use.

WARNING marking concerning

Risk of Hearing Loss.

Wear hearing protection.

WARNING marking concerning

Risk of Respiratory Injury.

Wear NIOSH-approved

dust mask/respirator.

WARNING marking concerning

Risk of Explosion.

Table A: Symbol Definitions

Page 2 For technical questions, please call 1-800-444-3353. Item 60242

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS

WARNING – When using tools, basic precautions should

always be followed, including the following:

General

To reduce the risks of electric shock, fire, and injury to persons,

read all the instructions before using the tool.

Work area

SAFETYOPERATIONMAINTENANCE SETUP

a. Keep the work area clean and well

lighted. Cluttered benches and dark

areas increase the risks of electric

shock, fire, and injury to persons.

b. Do not operate the tool in explosive

atmospheres, such as in the

presence of flammable liquids,

gases, or dust. The tool is able

to create sparks resulting in the

ignition of the dust or fumes.

Personal safety

a. Stay alert. Watch what you are

doing and use common sense

when operating the tool. Do not

use the tool while tired or under

the influence of drugs, alcohol, or

medication. A moment of inattention

while operating the tool increases

the risk of injury to persons.

b. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep hair, clothing, and gloves

away from moving parts. Loose

clothes, jewelry, or long hair increases

the risk of injury to persons as a result

of being caught in moving parts.

c. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance

enables better control of the tool

in unexpected situations.

c. Keep bystanders, children, and

visitors away while operating the

tool. Distractions are able to result

in the loss of control of the tool.

d. Use safety equipment.

A dust mask, non-skid safety

shoes and a hard hat must be

used for the applicable

conditions. Wear heavy-duty work

gloves during use.

e.

f. Always wear hearing

cause hearing loss.

g. Do not attach the hose or tool

to your body. Attach the hose to

the structure to reduce the risk of

loss of balance if the hose shifts.

Always wear eye protection.

Wear ANSI-approved safety

goggles with side shields.

protection when using the

tool. Prolonged exposure to

high intensity noise is able to

Page 3For technical questions, please call 1-800-444-3353.Item 60242

Tool use and care

a. Use clamps or another practical way

to secure and support the workpiece

SAFETY OPERATION MAINTENANCESETUP

to a stable platform. Holding the

work by hand or against the body is

unstable and can lead to loss of control.

b. Do not force the tool. Use the correct

tool for the application. The correct tool

will do the job better and safer at the

rate for which the tool is designed.

c. Disconnect the tool from the air

source before making adjustments,

doing tool maintenance,

clearing jams, leaving work area,

loading, or unloading the tool.

Such precautionary measures reduce

the risk of injury to persons.

d. Store the tool when it is idle out

of reach of children and other

untrained persons. A tool is dangerous

in the hands of untrained users.

Service

a. Tool service must be performed

only by qualified repair personnel.

b. When servicing a tool, use only

identical replacement parts.

Use only authorized parts.

e. Maintain the tool with care.

A properly maintained tool reduces the

risk of binding and is easier to control.

f. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that affects

the tool’s operation. If damaged,

have the tool serviced before using.

Many accidents are caused by poorly

maintained tools. There is a risk of

bursting if the tool is damaged.

g. Use only accessories that are

identified by the manufacturer for

the specific tool model. Use of an

accessory not intended for use with

the specific tool model, increases

the risk of injury to persons.

h. Use only those fasteners listed in the

Specifications chart of this manual.

Fasteners not identified for use with this

tool by the tool manufacturer are able

to result in a risk of injury to persons or

tool damage when used in this tool.

c. Use only the lubricants supplied

with the tool or specified

by the manufacturer.

Air source

a. Never connect to an air

source that is capable of

exceeding 200 PSI.

Over pressurizing the tool

may cause bursting, abnormal

operation, breakage of the tool or

serious injury to persons. Use only

clean, dry, regulated compressed air at

the rated pressure or within the rated

pressure range as marked on the tool.

Always verify prior to using the tool that

the air source has been adjusted to the

rated air pressure or within the rated

air-pressure range.

b. Never use oxygen, carbon dioxide,

combustible gases or any bottled

gas as an air source for the tool.

Such gases are capable of explosion

and serious injury to persons.

SAVE THESE INSTRUCTIONS.

Page 4 For technical questions, please call 1-800-444-3353. Item 60242

Specific Safety Instructions

1. Operators and others in work area

MUST wear ANSI-approved safety

goggles with side shields during

use. The employer is responsible to

enforce the use of eye protection by the

operator and others in the work area.

2. Do not point the tool toward

yourself or anyone whether it

contains fasteners or not.

3. Respect the tool as a

working implement.

4. No horseplay. This tool is not a toy

and can be dangerous if misused.

5. Disconnect the tool from

the air supply when:

a. Unattended.

b. Performing any

maintenance or repair.

c. Moving the tool to a new location.

6. Do not make any modifications

to this tool.

7. Refer to the tool maintenance

instructions for detailed information on

the proper maintenance of the tool.

8. Fire fasteners into an appropriate

work surface only. Do not attempt to

fire fasteners into surfaces too hard

to penetrate. Do not drive fasteners

on top of other fasteners, or at too

steep of an angle. Fasteners can

ricochet causing personal injury.

9. Do not fire fasteners too close to

the edge of a workpiece. They

may split the workpiece and fly

free, causing personal injury.

10. Keep clear of the workpiece

near the area being fastened.

Fasteners may bend sideways

during firing, causing them to exit

the workpiece at an unexpected

point, causing personal injury.

11. Transport tool safely.

Always disconnect air supply

when moving the tool.

12. Hold tool away from head and body.

During operation the tool may

kick back causing injury.

13. Do not fire fasteners into a workpiece

that has people, utility lines, or

other objects behind or inside it.

14. Keep balance while using this tool.

Keep area below clear if working in

an elevated location, and secure air

hose to prevent falls from bystanders

accidentally pulling on it.

15. Obey the manual for the air

compressor used to power this tool.

16. Install an in-line shutoff valve

to allow immediate control over

the air supply in an emergency,

even if a hose is ruptured.

17. Do not engrave or stamp anything into

the housing to avoid weakening it.

SAFETYOPERATIONMAINTENANCE SETUP

Page 5For technical questions, please call 1-800-444-3353.Item 60242

Loading...

Loading...