Page 1

SHALLOW WELL PUMP

®

3/4 Horsepower, PVC Housing

Model 47907

ASSEMBLY and OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2002 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools .

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

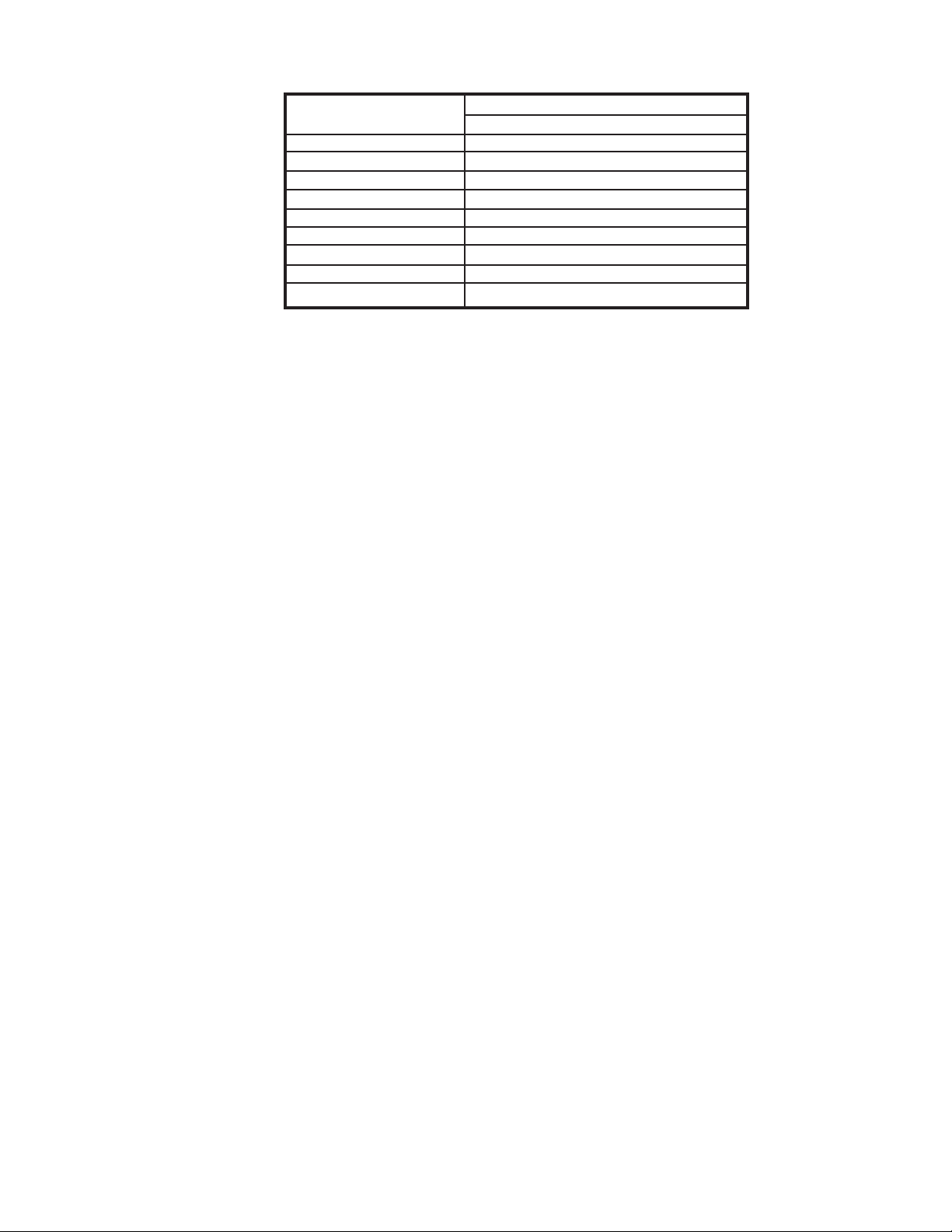

Specifications

Motor 120 Volt, 60 Hz, 4 Amps (start-up)

Single Phase, 3400 RPM

Discharge Size 1” Diameter

Maximum Flow 898 GPH

Maximum Suction Depth 26 Feet

Maximum Lift 140 Feet

Overall Dimensions 19” H x 10-5/8” W x 17-1/2” Long

Pressure Tank Capacity 5 Gallons

Maximum Pressure 75 PSI

Tank Hose Length 10 Inch

Weight 28-3/4 Lbs.

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not expose this pump to rain or direct immersion.

Don’t expose to rain. Keep work area well lighted. Do not use electrically powered

tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle Pump.

4. Use the right pump for the job. Do not attempt to force a small Pump to do the work

of a larger industrial Pump. There are certain applications for which this Pump was

designed. It will do the job better and more safely at the rate for which it was intended.

Do not modify this Pump and do not use this Pump for a purpose for which it was not

intended.

5. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair.

6. Use eye and ear protection. Always wear ANSI approved impact safety goggles and

ear protection.

7. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

8. Maintain Pump with care. Keep Pump clean for better and safer performance.

Inspect tool cords periodically; If damaged, have them repaired by a qualified

technician.

Page 2SKU 47907 For technical questions, please call 1-800-444-3353.

Page 3

9. Disconnect power. Unplug Pump when not in use.

10. Stay alert. Watch what you are doing, use common sense. Do not install Pump when

you are tired.

11. Check for damaged parts. Before using Pump, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician.

12. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

13. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

14. Do not install Pump if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not install the Pump.

15. Use proper size and type extension cord. If an extension cord is required, it must be

of the proper size and type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or cause electrical damage to

the tool. This tool requires use of an extension cord of 0 to 10 amps capability (up to

50 feet), with wire size rated at 18 AWG. Longer extension cords require larger size

wire. If you are using the tool outdoors, use an extension cord rated for outdoor use

(signified by “WA” on the jacket).

16. Maintenance. For your safety, maintenance should be performed regularly by a

qualified technician.

Warning: People with pacemakers should consult with their physician(s) before

using this product; operation of equipment in close proximity to a heart pacemaker

could cause interference or failure of the pacemaker.

Warning! Never operate this pump if the power cord or electrical components are

damaged or the seals are compromised. Never plug in the power cord when wet or

standing on damp or wet ground. Exercise extreme caution when working with electrical

equipment in the presence of water to maintain your personal insulation to avoid shock.

Do not allow others in the work area when working with electrical equipment. Use GFCI

outlets when using this pump.

Note: Performance of this tool (if powered by line voltage) may vary depending on variations

in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood

by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

Page 3SKU 47907 For technical questions, please call 1-800-444-3353.

Page 4

Unpacking

When unpacking, check to make sure the parts listed on pages 7 and 8 are included. If any

parts are missing or broken, please call Harbor Freight Tools at the number on the cover of

this manual as soon as possible.

Installation

Note: For intake and discharge hose locations, see FIGURE 1 on page 5.

Note: If power cords must be extended, only use no less than UL approved, 18 Gauge wire.

Do not extend the wires more than 50 feet.

1. Install the pump on a rigid, level platform above the water level. This platform must provide

a solid, level surface that is capable of supporting the weight of the pump, and attached

piping filled with water. Never allow the pump to become immersed in water.

2. The level of the intake port should not be more than 12-15 feet above the water. Pumping

efficiency falls off as the height above the water level increases.

3. Keep the vertical lift that the pump must move water before discharge at a minimum. Vertical

delivery above a few feet will degrade pump efficiency.

4. The intake port must have a screen

(not included) attached to prevent

introduction of debris into the pump. At

the end of the discharge pipe, either

purchase a pre-made screen to fit, or

wrap loose screen and secure with

wire.

5. Lay out the intake and discharge pipes

with as few turns as possible to prevent air pockets within the lines. Air

pockets interfere with pressure switch

performance.

6. Intake and discharge pipes must have

a minimum of 1” to 1-1/4” diameter. Systems with larger vertical components should have

larger diameter piping. Keep in mind that the maximum vertical lift (total vertical distance

from the inlet screen to the discharge outlet) is 140 feet.

7. For your protection, the power outlet used should have a Ground Fault Circuit Interrupter

(GFCI). Have it installed by a qualified electrician. Keep the power line safely away from

water.

Typical Installation

Discharge

Pump

Intake

8. The inlet and discharge lines should not be wedged or stressed in a way that puts strain

on the pump. Do not support the pump with the inlet and discharge lines.

9. This is a self starting pump that uses a pressure switch. Once the power cord is connected,

the pump can start at any time. Do not handle or perform maintenance on the pump if

the power cord is plugged in.

Page 4SKU 47907 For technical questions, please call 1-800-444-3353.

Page 5

Priming Valve Inlet

Intake

FIGURE 1

Discharge

Shaft

Air Valve

(not visible)

Note: Compression Tank (#1A) has a

Rubber Bladder (51) inside. This Bladder

Pressure Meter

must be pumped up with between 18 and

19 PSI of air at all times. On the end of

the Compression Tank opposite the side

with the Pressure Meter, is an air valve

located under a cover. Remove the cover

over the air valve and periodically monitor this air valve with an air pressure gauge

to ensure that the Rubber Bladder (51)

maintains the required 18 to 19 PSI.

Operation

Warning! Never pump liquids containing abrasive materials such as sand. Never pump

flammable, corrosive, or volatile liquids.

Warning! Never plug in the power cord when wet or standing on damp or wet ground. Do not

plug in the power cord until step number 3 below.

1. Make sure the intake pipe is fully submerged before operating the pump.

2. Gently insert a screwdriver into the motor shaft and make sure the shaft turns freely.

(See Figure 1)

3. Important Note: Before starting the pump for the first time, prime it by pouring clean

water into the Priming Valve Inlet (see Figure 1). If water leaks from the drain valve

underneath the pump, securely close it and refill the unit.

4. To begin pumping, plug in the power cord.

REV 06i, REV 07g

Page 5SKU 47907 For technical questions, please call 1-800-444-3353.

Page 6

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED

TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY

PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES

THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Troubleshooting

Problem Cause Solution

The pump won’t start No power Check connections

Blocked Impeller Free the motor shaft

Pressure switch disconnected Check gauge

Thermal Protection cut out Allow pump to cool

The pump operates but it Inlet tube not submerged Submerge the inlet

won’t discharge water Air in suction pipe Check pipe and seals

Inlet screen clogged Clean screen

Lifting height exceeded Reduce lifting height

Pump has low capacity Inlet pipe is too small Increase pipe diameter

Liquid is too dirty Clean screen frequently

Lift height exceeded Reduce lift height

Tank’s rubber bladder under- Inflate to 18-19 PSI

inflated.

Never disassemble the pump or motor as this will damage the water seals. All repairs

should be performed by a qualified technician.

Maintenance

Always disconnect pump from power source before attempting any maintenance.

1. Clean the inlet screen regularly to remove accumulated debris.

2. Use pressure gauge to test pressure in Tank’s Rubber Bladder (51). Pressure should

range between 18 and 19 PSI.

3. Wipe the pump clean with a soft, damp cloth with soapy water. Do not use solvents. Do

not get the electrical components wet.

4. If storing the pump for a long time, store it in a dry location, and apply a light layer of oil to

the metal parts prior to storage, to inhibit rust.

5. To drain the pump, disconnect the water lines and turn it upside down.

REV 06i, REV 07g

Page 6SKU 47907 For technical questions, please call 1-800-444-3353.

Page 7

Parts List

traPnoitpircseD.ytQtraPnoitpircseD.ytQ

121x8MwercS412roticapaC1

2gnisuoHrotoM122revoCediS1

3edalBnaF132etalPlaeShctiwS1

4revoC

5rehsaWgnirpS15202x5.3wercS3

6521x5MtloBrotoM46202x8MtuNxeH4

7rotatS172revoCtnorF1

8gniraeB182gniRrebbu

9rotoR192gnir-01

01gniraeB103egnalF1

11htaehSrebbuR113gniRelibommI1

2151x2.4wercS223gniRrotoM1

31kcolBelbaC133rellepmI1

41eveelSelb

51elbaCnoitcennoC153gnir-01

6151x9.2wercS463.yssAediuGwolF1

71revoCfoorpretaW173gnir-01

81revoCrebbuR183lle

91gnir-0193revoCevlaV.gL2

02revoCroticapaC104gnir-02

raeR142hctiwSfoorpretaW1

R1

aC143etalPediuGwolF1

hSpmuP1

Assembly Drawing

NOTE: Some parts are listed and

shown for illustration purposes

only and are not available individually as replacement parts.

Page 7SKU 47907 For technical questions, please call 1-800-444-3353.

Page 8

ASSEMBLY DRAWING

Note: When ordering a part from this drawing, you must include the suffix “A” with

the number.

REV 08/05

Page 8SKU 47907 For technical questions, please call 1-800-444-3353.

Loading...

Loading...