Page 1

DUAL SIDE GATE OPENER

®

47821

ASSEMBLY AND OPERATING INSTRUCTIONS

Gate and Fence not supplied;

only Gate Opener components are included.

3491 MISSION OAKS BLVD., CAMARILLO, CA 93011

VISIT OUR WEB SITE AT HTTP://WWW.HARBORFREIGHT.COM

Copyright © 2005 by Harbor Freight Tools®. All rights reserved. No portion of

this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

Contents

UNPACKING .................................................................................................... 2

SPECIFICATIONS ............................................................................................ 3

SAVE THIS MANUAL ....................................................................................... 3

GENERAL SAFETY RULES ............................................................................ 4

INSTALLATION INSTRUCTIONS .................................................................... 7

Preparation ................................................................................................. 7

Providing a Power Source ......................................................................... 8

Mounting Actuator Arms ........................................................................... 8

Mounting the Control Box ....................................................................... 11

Placement of Accessories ...................................................................... 11

Wire Connections to the Control Box .................................................... 11

Emergency Battery .................................................................................. 13

Transformer Connection ......................................................................... 13

GATE SETTINGS ........................................................................................... 14

Adjusting Motor Thrust ........................................................................... 14

Automatic Gate Wing Closing ................................................................. 14

PROGRAMMING ........................................................................................... 15

Programming the T1 Button - Remote Control ...................................... 15

Programming the T1 Button - Control Panel ......................................... 15

Programming the T2 Button - Remote Control ...................................... 16

Programming the T2 Button - Control Panel ......................................... 16

OPERATING INSTRUCTIONS ....................................................................... 17

“Manual” Mode ......................................................................................... 17

“Automatic” Mode .................................................................................... 17

INSPECTION, MAINTENANCE, AND CLEANING ........................................ 17

TROUBLESHOOTING ................................................................................... 18

SCHEMATIC DIAGRAM ................................................................................ 19

PARTS LIST ................................................................................................... 19

ASSEMBLY PARTS ....................................................................................... 20

UNPACKING

When unpacking, check to make sure that all the parts are included. Refer to the Assembly

section, and the Assembly Drawing and Parts List at the end of this manual. If any parts are

missing or broken, please call Harbor Freight Tools at the number on the cover of this manual

as soon as possible.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 2

Page 3

SPECIFICATIONS

Gate Size 8.2 feet (maximum) for each gate wing

Gate Weight 550 lb. (maximum) for each gate wing

Input Voltage/ Power Consumption

(AC/ DC Transformer)

Operating Power/ Circuit Protection

(Circuit Board)

Actuators 2 - 12 VDC; 16 inch stroke

Motor 12 VDC, 34 inch cable

Arm Dimensions 30” (L) x 4” (W) x 6.25” (H)

Warning Light 12 V, 10 W Bulb

Weight 26.8 lb.

Operating Modes “Manual Mode” Push button (remote), or key open, stop and

Features 1 - Programmable Controller (Printed Circuit Board, CTR42s) with

Optional Accessories

(Not Included)

110 VAC, 60 Hz, 75 Watts/ 1.6 Amps Fused

12 VDC/ 10A Fused

1.

close.

“Automatic Mode” Push button (remote) or key open with adjustable

2.

automatic time delayed close.

control box. Controller has two adjustable dials (pot switches/

“Ampere 1, 2”) for motor’s open/closing strength. One adjustable

dial for (pot switch/ “Time”) setting the automatic time delayed

closing feature.

2 - Two channel transmitters (require one 12V (23A) battery each,

included)

1 - Key switch, to open gate wings without the Remote Control

Transmitters.

1 - Blinking yellow warning light; Quick flashes (blinking) indicate the

gates are opening, slow flashes indicate the gates are closing.

1 - Motor Unlock Key (triangular shaped), disengages the motors to

open gates manually in case of emergency, or power failure.

- Single wing gate operation (T2), or dual wing gate operation (T1).

Photocells (1 pair).

This feature provides additional safety for use around small children or

disabled persons. This accessory transmits an invisible infrared beam

across the gates threshold, and when the beam is interrupted the gates

will automatically stop closing.

SAVE THIS MANUAL

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 3

Page 4

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow all instructions

listed below may result in electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control. Protect others in the work area from debris

such as chips and sparks. Provide barriers or shields as needed.

Electrical Safety

4. Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of electric shock if your body is grounded.

5. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

6. Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the

tools should electrically malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

7. Double insulated tools are equipped with a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in any way. Double

insulation eliminates the need for the three wire grounded power cord and grounded

power supply system.

8. Do not abuse the Power Cord. Never use the Power Cord to carry the tools or pull

the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp edges,

or moving parts. Replace damaged Power Cords immediately. Damaged Power

Cords increase the risk of electric shock.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 4

Page 5

9. When operating a power tool outside, use an outdoor extension cord marked “W-

A” or “W”. These extension cords are rated for outdoor use, and reduce the risk of

electric shock.

Personal Safety

10. Stay alert. Watch what you are doing, and use common sense when operating a

power tool. Do not use a power tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may result

in serious personal injury.

11. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

12. Avoid accidental starting. Be sure the Power Switch is off before plugging in.

Carrying power tools with your finger on the Power Switch, or plugging in power tools

with the Power Switch on, invites accidents.

13. Remove adjusting keys or wrenches before turning the power tool on. A wrench

or a key that is left attached to a rotating part of the power tool may result in personal

injury.

14. Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control in unexpected situations.

Tool Use and Care

15. Use clamps (not included) or other practical ways to secure and support the

workpiece to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

16. Do not force the tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed.

17. Do not use the power tool if the Power Switch does not turn it on or off. Any tool

that cannot be controlled with the Power Switch is dangerous and must be replaced.

18. Disconnect the Power Cord Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

19. Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

20. Maintain with care. Keep cutting tools sharp and clean. Properly maintained tools

with a sharp cutting edge are less likely to bind and are easier to control. Do not use a

damaged tool. Tag damaged tools “Do not use” until repaired.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 5

Page 6

21. Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools.

22. Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

Service

23. Gate Opener service must be performed only by qualified repair personnel. Service

or maintenance performed by unqualified personnel could result in a risk of injury.

24. When servicing the Gate Opener, use only identical replacement parts. Follow

instructions in the “Inspection, Maintenance, And Cleaning” section of this manual.

Use of unauthorized parts or failure to follow maintenance instructions may create a risk

of electric shock or injury.

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on the Gate Opener. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a replacement.

2. Always wear ANSI-approved safety impact eye goggles and heavy work gloves

when using tools to install the Gate Opener. Using personal safety devices reduce

the risk for injury.

3. Maintain a safe working environment. Keep the work area well lit. Make sure there

is adequate surrounding workspace. Always keep the work area free of obstructions,

grease, oil, trash, and other debris. Do not use power tools in areas near flammable

chemicals, dusts, and vapors. Do not use power tools in a damp or wet location.

4. Avoid electrical shocks. Always turn off the circuit breaker to the Gate Opener

Control Box before performing any inspection, maintenance, or cleaning procedures

of the Gate Opener.

5. Periodically check all nuts, bolts, and screws on the Gate Opener for tightness.

Vibration during gate movement may cause these to loosen.

6. Install this product on a proper surface. Locate the Gate Opener Arms on a flat,

vertical, and solid surface of the fence gate column that is capable of supporting the

weight of the gate being pulled open.

7. Install and use this product with care. Harbor Freight Tools is not responsible for any

damage or personal injury due to the incorrect installation or improper operation of this

product.

8. Avoid vehicle damage. Any vehicle parked within striking range of the gate wings under

movement could be damaged.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 6

Page 7

INSTALLATION INSTRUCTIONS

Warning: Installation of the Gate Opener requires knowledge of mechanical and electrical

concepts and experience. If you do not have these, you should contract a qualified technician

to do the installation. Electrical supply wiring must be done by a licensed electrician.

Preparation

1. Verify that the gate wings swing open easily, and without obstructions such as scraping

the ground. See illustration below.

2. Verify that each gate wing does not weigh over 550 pounds.

3. Determine a location for the Control Box within two feet of either Actuator Arm (A).

It may be mounted to the pillar or post supporting the gate. It should also be on the gate

side with electrical access.

4. Determine the 110 VAC, 20A, circuit source to power the Gate Opener.

The connection can be completed with conduit (or other approved means) going directly

to the Control Box (B).

5. Select a location to mount the Warning Light (E).

6. Determine the conduit route from the far Actuator Arm (A), across the drive way, to the

Control Box (B).

7. Purchase hardware to secure the Brackets (F and G) to the gate post and gate wings,

and to mount the Control Box (B). See illustrations on page 8.

In some cases, it may be necessary to weld the Pivot T-brackets (G) to the gate.

8. Purchase conduit and two-pair cable (18-20 gauge AWG solid) for the Warning Light (E),

Key Switch (D), and far Actuator Arm (A). The conduit for the far actuator arm will have

weight pass over it and must be designed to withstand the stresses created by heavy

loads passing overhead.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 7

Page 8

Providing a Power Source

1. Find a 110 VAC, fused, electrical box nearest the placement of the Control Box (B).

If none exists, a licensed electrician will have to run new cable (14 AWG) and conduit

from the electrical distribution box to the Control Box (B).

2. If an outdoor electrical outlet is near enough to use as a power source, a licensed

electrician will have to run new cable and conduit from this outlet to the Control Box.

Mounting Actuator Arms

The placement of the Arm Mounting Brackets (F) on the gate support post or pillar will affect

the amount of gate opening, its speed, and force. Other factors include the weight and length

of the gate wing. The control board has two POT Switches MOT1, MOT2 (Ampere 1, 2 on

the circuit board) that allow the user to adjust the opening and closing force of motor 1 and 2

respectively. This feature will work in conjunction with the adjustable “K” plate.

The following steps describe, generally, the installation of the Arm Mounting Brackets (F),

The Actuator Arms (A), and the Pivot T-brackets (G). Each installation is different so some

modification to these steps may be necessary. Refer to the illustrations below.

1. Assemble the Arm Mounting Brackets (F) using the supplied hardware (F and H) as

shown below-left.

2. Place a Pivot Pin (H) through the rear bracket of the Actuator Arm (A) and the Arm

Mounting Brackets (F). Secure with the Pivot Pin (H), Washer, and Snap Lock from

beneath.

3. Place the Motor Disengage Key (I) (see page 19 assembly parts list) into the triangle

hole in the Actuator Arm (A) motor housing and turn it counterclockwise. This disengages

the motor so the Actuator Arm piston can be pulled out or pushed in.

4. Attach the Actuator Arm (A) piston to the Pivot T-bracket (G) using a Pivot Pin (H), Washer,

and Snap Lock from below. See illustration below-right.

5. Push the Actuator Arm (A) piston all the way in. See illustration below-right.

6. Open one Gate Wing to the desired opening (usually 90° as shown below, mid-page).

7. With the help of another person, hold up the Actuator Arm (A) with Arm Mounting brackets

(F) against the mounting post, and Pivot T-bracket (G) against the Gate Wing.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 8

Page 9

The Actuator Arm (A) must be parallel to the Gate Wing and to the ground. The placement

of the Pivot T-bracket (G) should be on a Gate Wing cross member (if there is one), about

1/3 to 1/2 the distance from the ground.

8. Using a pencil, mark the outline of the Arm Mounting Bracket (F) on the Mounting

Post.

9. Mark the outline of the Pivot T-bracket (G) on the Gate Wing cross member.

10. Close the Gate Wing completely. See illustration below.

11. Pull out the Actuator Arm (A) piston.

12. Place the Arm Mounting Bracket (F) over the marked outline on the Mounting Post, and

the Pivot T-bracket over marked outline on the Gate Wing cross member.

13. If both mounting brackets easily cover the marked outline, then mark through the bracket

mounting holes in preparation for drilling and installation.

If the Pivot T-bracket (G) cannot reach the marked outline, make a new marked outline

where is does reach.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 9

Page 10

14. Close the Gate Wing again, push in the Actuator Arm (A) piston, and hold up the Actuator

Arm against the new marked outline on the Wing Gate and the marked outline on the

Mounting Post. See the illustration under step 9, page 9.

It may be necessary to move the Arm Mounting Bracket (F) farther or closer to the

centerline of the Gate Wing hinge (dimension “X”). See illustration below. There is a

relationship between the “X” and “Y” dimensions, where “X” is the width dimension from

the Gate Wing hinge centerline and the Pivot Pin (H) centerline; And “Y” is the depth

dimension from the Pivot Pin (H) centerline and the Gate Wing hinge centerline.

Guidelines:

Gate Wings under 5’ (W), X = 4”, Y = 4”

Gate Wings over 5’ (W), X = 5.5”, Y = 4.8”

15.

When the locations of the Arm Mounting Bracket (F) and the Pivot T-bracket (G) have

been determined, mount the brackets with hardware (not supplied).

Minor adjustments to the opening and closing of the Gate Wing can be made by moving

the Pivot Pin (H) to a different hole in the Arm Mounting Bracket (F). Refer to the illustration

at the bottom-left on page 8.

16. Repeat these steps for the opposite Gate Wing. The Actuator Arm (A) should, however,

be mounted in the same location on the opposite Mounting Post or Pillar.

17. Test the Gate Wings. Both should move in and out freely. Close Gate Wings and Engage

Motors. (To engage Motors, do the reverse as described in step 3, page 8.)

SKU 47821 For technical questions, please call 1-800-444-3353 Page 10

Page 11

Mounting the Control Box

1. Find a secure location for the Control Box (B) within two feet of the Actuator Arm (A).

It has to be close because one of the Actuator Arm cables goes directly into the Control

Box (B). See the illustration on page 9.

2. Open the Control Box and find the four mounting screw holes. Being careful not to touch

the circuit board inside the box, hold the box against the surface where it will be mounted

and make a drill mark on the mounting surface.

3. Drill out five cable holes at the bottom of the Control Box. The Cable Inlet Nuts and Bolts

(L) must be mounted in these holes before any cables are inserted. See photo at the

middle of page 12. Use conduit connectors (not supplied) if conduit is routed directly to

the Control Box.

4. Drill four holes in the mounting surface and secure the Control Box with hardware not

supplied.

Placement of Accessories

1. Mount the Warning Light (E) in a location where it can be easily seen from both sides

of the gate. When flashing, it indicates that the gate wings are opening or closing — stay

clear. Mount the Warning Light with hardware, not supplied. Connect two-pair cable (not

supplied) to the Warning Light (E) and route to the bottom of the Control Box (B). If cable

needs to be buried, conduit must be used. The Warning Light bulb uses 12 volts at 10

watts.

2. Mount the Key Switch (D) in a location where it can be reached from outside of the

gate wings (mounting hardware not supplied). Try to hide it from public view. When a key

is placed in it and turned, the gate wings will open. The two-pair cable (not supplied),

once connected within the Key Switch box, should be routed through a wall or conduit

to prevent tampering from outside. Route cable to the bottom of the Control Box (B).

3. Mount the Antenna (N) as high as possible, and within its cable length from the Control

Box (B). Mounting hardware not supplied. Route the cable to the bottom of the Control

Box (B).

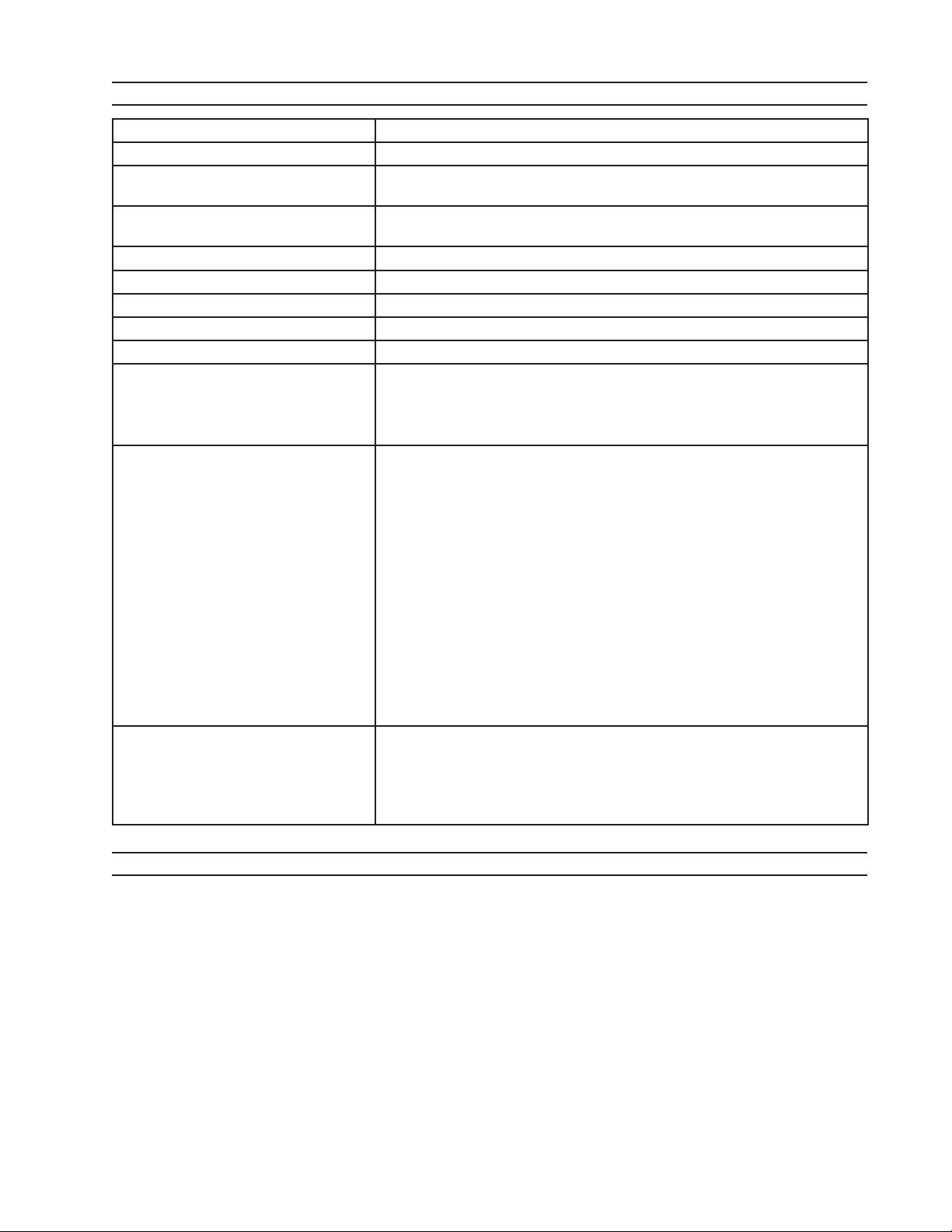

Wire Connections to the Control Box

1. Push each cable up and through the Inlet Nuts and Bolts (L) at the bottom of the Control

Box (B). See photo at the middle of page 12.

2. Strip 3/8 inch insulation off each wire. If the wire is stranded, twist the lead tightly.

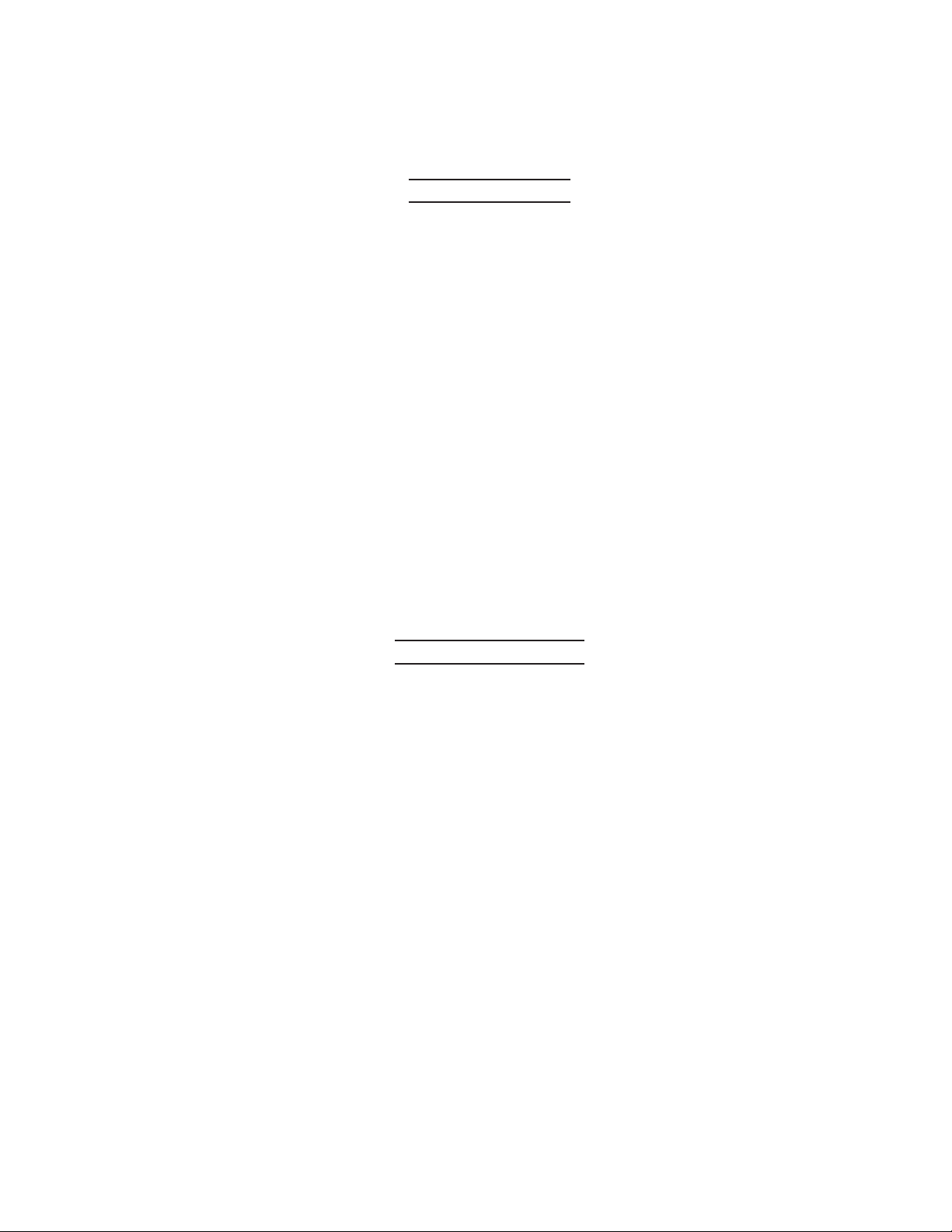

3. Connect each cable wire as shown in the circuit board photo on page 12.

Loosen lug screws 1, 2, 3, 5, and 12-17 on the terminal strip. Insert the wire in the hole

from above. When the wire is completely pushed in (no wire showing), tighten the lug

screw again. Pull on the wire gently to test that it is secure.

Terminals 4, 5, 10 and 11 are only used when installing photocells (Not Included).

The jumper wire between terminals 4 and 5 will need to be removed when installing

photocells.

Terminals 6, 7, 8, 9, 18, 19, 20 and 21 are not used.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 11

Page 12

Note: The far Actuator Arm (A) will need an extension cable splice to the Motor 34 inch cable of

the same size and type (14 AWG stranded) to reach the Control Box (B). Route through

conduit above or below the Gate Wings.

4. Turn off the circuit breaker that provides the power, check to ensure it is disconnected,

and connect the 110 VAC wires last. See photo at the top of page 13.

5. When all the connections are made to the terminal strip, verify that each wire goes to

the correct terminal number.

6. When the Gate Opener operates properly, seal each cable inlet hole with silicone sealer

(not supplied) to prevent moisture from entering. Use cable clamps (not supplied) to

secure cables.

Note: One Gate Wing is normally delayed in its opening or closing. This accommodates any

center gate hardware that must be opened or closed first. Connect the gate that needs

to open first to terminals 16 & 17.

Actuator

Arm M1

Antenna

Key

Switch

Photocell

Receiver*

Actuator

Arm M2

MOT1MOT1TIME

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Photocell

Transmitter*

Warning

Light

110

VAC

Key

Switch

Blue

Blue

Brown

Warning

Light

FUSE 10A

BATT

Brown

Antenna

Cable

V12 V0

BATT

Blue

Brown

M1 M2

*Not included.

Brown

Blue

REV 04/06

SKU 47821 For technical questions, please call 1-800-444-3353 Page 12

Page 13

For instructions below, refer to illustration on page 12.

Emergency Battery

A 12 VDC, 6.3 Ah, rechargeable battery (not supplied)

can be installed to enable the Gate Opener when facility power is out. The switch-over to battery power is

automatic. The Gate Opener will operate approximately

30 times on battery power. The battery is automatically

recharged when facility power is restored. The Battery

is connected to BATT pins + and –. See illustration on

page 12.

14 Gauge Wire Input14 Gauge Wire Input

Transformer Connection

Connect the plug from the transformer to terminals V0 and V12 on the circuit board. The plug

is designed to only fit one way. If it goes on with difficulty or if the prongs bend during installation, it is likely being installed wrong.

REV 04/06

SKU 47821 For technical questions, please call 1-800-444-3353 Page 13

Page 14

GATE SETTINGS

Adjusting Motor Thrust

If high winds or heavy Gate Wings keep the Gate Opener from working efficiently, the motor

thrust strength can be adjusted. For safety, and to reduce needless wear on the product,

adjust only to minimum thrust required.

1. Make certain that the gates are closed before changing the settings. Use a small

slotted screwdriver (not included) to gently operate the controls.

2. Turn the TIME, MOT1, and MOT2 controls counterclockwise completely.

3. a. Press the T1 button on the remote control or turn the key switch to open the gates.

Take note of the speed that the gates open and also the noise that the motors make

(if any).

b. If the gates open in a fluid motion and the motors do not sound strained, the gates

are at the correct setting.

c. If not, close the gates, turn the MOT1 and MOT2 controls clockwise slightly, and

repeat steps 3a - 3c.

4. Once the controls are properly adjusted, the gates will be in “Manual” mode. To set

the gates to “Automatic” mode or for an explanation of the modes, refer to the following

Automatic Gate Wing Closing directions.

Automatic Gate Wing Closing

The Gate Opener can be programmed to close automatically after predetermined time.

1. Make certain that the gates are closed before changing the settings. Use a small

slotted screwdriver (not included) to gently turn the control.

2. To set the gates to “Manual” mode:

Turn the TIME control counterclockwise all the way. Do not force the control. In “Manual”

mode the gates remain open until the remote controller or the key switch is operated.

Note: If the control is even slightly turned clockwise, the unit will be in “Automatic”

mode.

3. To set the gates to “Automatic” mode:

Turn the TIME control clockwise to the desired setting. To keep the gates open about one

minute, turn the control clockwise until it stops. The control can be adjusted in between

the minimum and maximum for settings less than a minute.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 14

Page 15

PROGRAMMING

ExamplE

The Remote Control (C) transmitter comes pre-programmed from the factory. Changing the transmitting codes should only be done if absolutely

necessary.

The Remote Control Transmitter has two buttons.

The T1 button is used to open and close both of the Gate Wings.

The T2 button can be programmed and used to open one Gate Wing.

Both buttons are used to program the Remote Control transmitter.

Example Code Chart

1 2 3 4 5 6 7 8 9 10 11 12

ON (T2)

OFF (T1)

X X X X X X

X X X X X X

T1

T1

(Off)

(Off)

T2

T2

(On)

(On)

Programming the T1 Button - Remote Control

1. Using the T1 chart to the right, mark one

1 2 3 4 5 6 7 8 9 10 11 12

block either (On) or (Off) in all twelve

columns – see also Example Chart.

This will be the new twelve-button code

ON (T2)

ON (T2)

OFF (T1)

OFF (T1)

1 2 3 4 5 6 7 8 9 10 11 12

sequence that is assigned to the T1

button on the controllers.

2. Next press and hold both buttons (T1 & T2) until the LED stops flashing, turns off and

turns back on. Now the remote is in Programming Mode. Note: The remote will remain

in Programming Mode until a twelve button code sequence is entered; i.e. the twelvebutton code sequence from the chart above.

3. Press and hold the T1 button until the LED turns on. The T1 button is now ready to be

reprogrammed. (If you release the button before the LED turns on, repeat this step.)

T1 Code Chart

T1 Code Chart

4. Next, press the first button in the T1 twelve-button code sequence from the chart above

(using T2 for ON and T1 for OFF). Be sure to hold down the button until the LED turns

on. Continue to enter the rest of the sequence in this manner until all twelve have been

entered. Once the twelve-button code has been entered successfully, the remote will

automatically return to its normal operating mode, indicated by the LED blinking while

either button is pressed.

NOTE: If you make a mistake while entering the coded sequence, continue entering the original

code until all twelve are entered, signified by the LED blinking while button is pressed.

Then repeat steps 2- 4 to restart the reprogramming process.

Programming the T1 Button - Control Panel

The following steps program the control panel to open both gates when the T1 button (programmed above) is pressed.

1. Before any new codes can be programmed the old ones have to be cleared. To clear

SKU 47821 For technical questions, please call 1-800-444-3353 Page 15

Page 16

the old codes: press and hold the P1 button on the Control Board for ten seconds until

the red LED light begins to flash. (When the P1 button is released the red LED light will

turn off.)

2. Then press the P1 button one more time; the red LED will turn on and remain lit.

3. Next press and hold the T1 button on the remote transmitter until the red LED light blinks

once and the gates begin to open. Now the Control board is re-programmed to open

both gate wings (M1, M2) by pressing the T1 button.

Programming the T2 Button - Remote Control

This function, after being programmed, causes the T2 button on the remote will open one gate

wing (M1) only.

1. Using the T2 chart to the right, mark one

block either (On) or (Off) in all twelve

columns. This will be the new twelvebutton code sequence that is assigned

ON (T2)

ON (T2)

OFF (T1)

OFF (T1)

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

T2 Code Chart

T2 Code Chart

to the T2 button on the controllers.

2. Next press and hold both buttons (T1 & T2) until the LED stops flashing, turns off and

turns back on. Now the remote is in “Programming Mode”. Note: The remote will remain

in “Programming Mode” until a twelve button code sequence is entered; i.e. the twelvebutton code sequence from the chart above.

3. Press and hold the T2 button until the LED turns on. The T2 button is now ready to be

programmed. (If you release the button before the LED turns on, repeat this step.)

4. Next, press the first button in the T2 twelve-button code sequence from the chart above

(using T2 for ON and T1 for OFF). Be sure to hold down the button until the LED turns

on. Continue to enter the rest of the sequence in this manner until all twelve have been

entered. Once the twelve-button code has been entered successfully, the remote will

automatically return to its normal operating mode, indicated by the LED blinking while

either button is pressed.

NOTE: If you make a mistake while entering the coded sequence, continue entering the original

code until all twelve are entered, signified by the LED blinking while button is pressed.

Then repeat steps 2- 4 to restart the reprogramming process.

Programming the T2 Button - Control Panel

1. The codes were cleared in step 1 of Programming the T1 Button - Control Panel, do not

clear the codes again or else the first code will be lost.

2. Press the P1 button on the control board (once) the red LED light will turn on and remain

lit.

3. Then press the P1 button again (once) the red LED light will blink and remain lit.

4. Next press and hold the T2 button on the remote transmitter until the red LED light blinks

once and one gate wing (M1) begins to open. Now the Control Board is programmed.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 16

Page 17

OPERATING INSTRUCTIONS

Note: During operation, keep all persons and vehicles away from gate wing movement.

“Manual” Mode

1. To open both Gate Wings, press T1 on the Remote Control. The warning light will flash

rapidly and the gates will open.

2. To close the gate wings, press T1 again. The warning light will flash slowly and the gates

will close.

3. To stop the Gate Wings at any time, press T1 once.

“Automatic” Mode

1. To open both Gate Wings, press T1 on the Remote Control. The warning light will flash

rapidly and the gates will open.

2. The gates will automatically close after the time period set by the controls (see Automatic

Gate Wing Closing section for details).

3. To stop the Gate Wings while the gates are closing, press T1 once. The gates will not

stop while opening or opened in this mode.

INSPECTION, MAINTENANCE, AND CLEANING

WARNING! Make sure the Circuit Breaker for the Gate Opener is in its “OFF” position

and that the fuse is pulled from within the Gate Opener Control Box before performing

any inspection, maintenance, or cleaning procedures.

1. Before each use, inspect the general condition of the Gate Opener hardware. Check

for loose screws, misalignment or binding of moving parts, cracked or broken parts,

damaged electrical wiring, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use. Do

not use damaged equipment.

2. Periodically recheck all nuts, bolts, and screws for tightness.

3. Periodically wash the Actuator Arm (A) stainless steel pistons with mild soap and water.

Do not oil the pistons.

4. Replace the Remote Control Battery every year as follows: Remove the two screws from

the back cover. Carefully open the cover. Remove the current battery. While following the

polarity markings on the plastic housing and the circuit board, install a new battery of the

same kind (“23A”). Carefully close the remote and secure. If the battery replacement is

done in a timely manner, the remote will store its codes in its memory. If not, reprogram

the remote according to the directions earlier in the manual.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 17

Page 18

Symptom Possible Cause Remedy

Gate does not open when

Remote Control T1 is

pressed.

One Actuator Arm opens,

while the other closes.

Gates do not close after

opening.

Warning Light does not

function.

Actuator Arm motor works

slowly after years of use.

0.8 amp fuse burned out.

10 amp fuse burned out.

Control Box green LED off.

TROUBLESHOOTING

Remote Control battery dead.

1.

No power to Control Box.

2.

Remote Control program wrong.

3.

Incorrect wire connections to M1 and

M2 on the circuit board.

Blown Fuse inside Control Box.

1.

Control Board in “Manual” Mode.

2.

Light bulb burned out.

1.

Fuse blown.

2.

Motor brushes are worn.

Control Box Transformer burned.

1.

Shor t c i r c u i t i n m o t or supply

2.

voltage.

Optional battery fault.

1.

Warning Light short circuit.

2.

No 110 VAC power.

1.

0.8 amp fuse blown.

2.

Replace battery.

1.

Check power source and all fuses.

2.

Reprogram Remote Control.

3.

Check Actuator Arm connections as

shown on page 12.

Replace 10A fuse in Control Box.

1.

Use Remote or Key Switch to close

2.

gates. See Automatic Gate Wing

Closing section for mode-setting

instructions.

Replace light bulb (12V, 10W)

1.

Replace 10A fuse in Control Box.

2.

Have motor brushes replaced by a

qualified technician.

Replace Transformer.

1.

Check Actuator Arm cables for short

2.

circuits.

Replace optional battery.

1.

Check light bulb and wiring.

2.

Check power supply.

1.

Check circuit breakers and internal

2.

fuses.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER

NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND

TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE

PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF

HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 18

Page 19

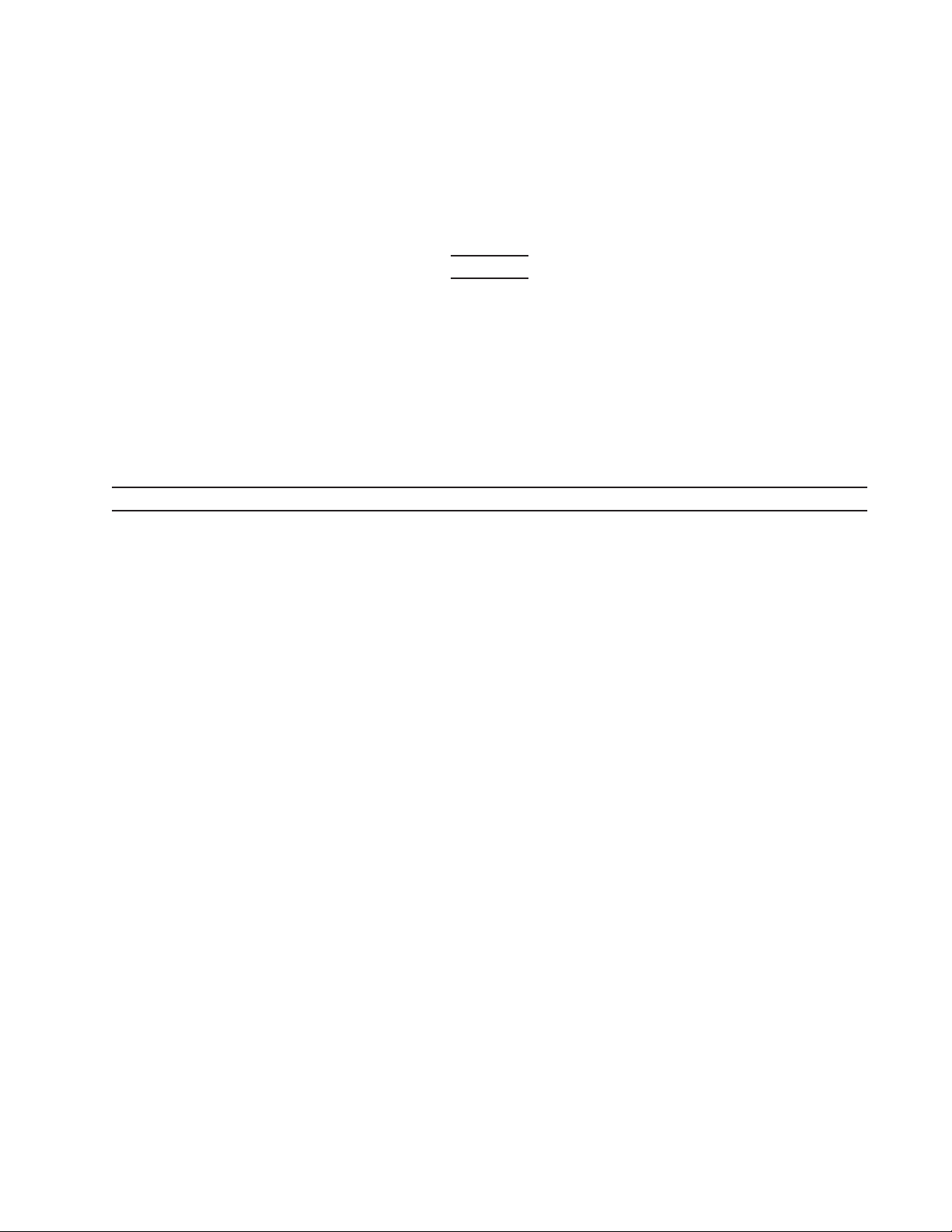

SCHEMATIC DIAGRAM

Antenna

Key

Switch

Blue

Brown

FUSE 10A

Blue

Brown

MOT1MOT1TIME

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Photocell

Receiver*

Warning

Light

Photocell

Transmitter*

Blue

Brown

M1 M2

V12 V0

BATT

BATT

Brown

Blue

*Not included.

PARTS LIST

Part Description Q’ty

A Arms, Actuators, 12V, 16” 2

B Control Board, 7853 / CTR42/s 1

C Remote Control Unit 2

D Switch, Key 1

E Light, Warning 1

F Brackets, Arm Mounting 1

G Brackets, Pivot, “T” 2

H Pins, Pivot 4

I Key, Motor Disengage 1

L Cable Inlet Nuts and Bolts 4

M Photocells (Not included) 0

N Antenna 1

O Control Box Shell (2 pieces) 1

P Transformer 1

NOTE: Some parts are listed and shown for illustration purposes only and are

not available individually as replacement parts.

REV 04/06

SKU 47821 For technical questions, please call 1-800-444-3353 Page 19

Page 20

ASSEMBLY PARTS

Parts B, M, O, and P not shown.

SKU 47821 For technical questions, please call 1-800-444-3353 Page 20

Loading...

Loading...