Page 1

PRESSURE WASHER WITH CART

®

1300 PSI

Model 47761

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY,

READ AND UNDERSTAND ALL WARNINGS

AND INSTRUCTIONS BEFORE USE.

Copyright© 2005 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual revised 07/05

Page 2

Contents

Unpacking ................................................................................ 2

Specifications .......................................................................... 3

Safety ....................................................................................... 3

General Safety Rules ........................................................................3

Specific Safety Rules ........................................................................6

Grounding...........................................................................................8

Assembly ................................................................................ 10

Controls and Setup ................................................................ 11

Controls and Features ..................................................................... 11

Setup .................................................................................................. 13

Operation ................................................................................ 14

Operating Tips ........................................................................ 15

Become Familiar With Your Machine ..............................................15

Use Proper Pressure Washer Operation Techniques ..................15

Cleaning Recommendations ..........................................................16

Inspection, Maintenance, and Cleaning ............................... 17

Parts Lists and Diagrams ...................................................... 18

Main Parts List................................................................................... 18

Main Parts Diagram ..........................................................................19

Parts List and Diagram A ................................................................. 20

Assembly Parts List and Diagram ..................................................21

Troubleshooting ..................................................................... 22

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts Lists on

pages 18-21 are included. If any parts are missing or broken, please call Harbor Freight

Tools at the number shown on the cover of this manual as soon as possible.

SKU 47761 PAGE 2

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 3

stnemeriuqeRlacirtcelEzH06/sPMA0.31/V021

epyT/htgneLdroCrewoPC2XGWA61/'13

sserPmumixaMISP0031

eru

yticapaCmumixaMMPG6.1

SPECIFICATIONS

gulPICFGgnorPowT/esahPelgniS

E193752

deriuqeRylppuSretaW

htgneLecnaL"4/3-51

htgneLecnaLnuG"4

htgneLesoHerusserPhgiH.tF91

seirosseccAelttoBtnegreteD.zo01

thgieW.sdnuoP1.52

MPG4-3muminim

/1-31

ylbmessAtraC/renaelCpiT

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and diagram. Keep

your invoice with this manual. Write the invoice number on the inside of the front cover.

Keep this manual and invoice in a safe and dry place for future reference.

SAFETY

GENERAL SAFETY RULES

IMPORTANT SAFETY INSTRUCTIONS!

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered and dark work areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite

the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

SKU 47761 PAGE 3

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 4

ELECTRICAL SAFETY

1. Grounded tools must be plugged into an outlet properly installed and grounded

in accordance with all codes and ordinances. Never remove the grounding

prong or modify the plug in any way. Do not use any adapter plugs. Check

with a qualified electrician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

2. Avoid body contact with grounded surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk of electric shock if your body is

grounded.

3. Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

4. Do not abuse the Power Cord. Never use the Power Cord to carry the tools or

pull the Plug from an outlet. Keep the Power Cord away from heat, oil, sharp

edges, or moving parts. Replace damaged Power Cords immediately. Damaged

Power Cords increase the risk of electric shock.

5. When operating a power tool outside, use an outdoor extension cord marked

“W-A” or “W”. These extension cords are rated for outdoor use, and reduce the risk

of electric shock.

PERSONAL SAFETY

1. Stay alert. Watch what you are doing, and use common sense when operating

a power tool. Do not use a power tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention while operating power

tools may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

3. Avoid accidental starting. Be sure the Power Switch is off before plugging in.

Carrying power tools with your finger on the Power Switch, or plugging in power

tools with the Power Switch on, invites accidents.

4. Remove adjusting keys or wrenches before turning the power tool on. A wrench

or a key that is left attached to a rotating part of the power tool may result in personal

injury.

5. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the power tool in unexpected situations.

SKU 47761 PAGE 4

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 5

6. Use safety equipment. Always wear eye protection. Nonskid safety shoes, hard

hat, or hearing protection must be used for appropriate conditions. Always wear

ANSI approved safety impact goggles and thick rubber boots during use and

maintenance.

TOOL USE AND CARE

1. Use clamps (not included) or other practical ways to secure and support a

smaller workpiece to a stable platform. Holding the work by hand or against your

body is unstable and may lead to loss of control.

2. Do not force the tool. Use the correct tool for your application. The correct tool

will do the job better and safer at the rate for which it is designed.

3. Do not use the power tool if the Power Switch does not turn it on or off. Any

tool that cannot be controlled with the Power Switch is dangerous and must be

replaced.

4. Disconnect the Power Cord Plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

5. Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

6. Maintain tools with care. Keep tools clean. Properly maintained tools are easier

to control. Do not use a damaged tool. Tag damaged tools “Do not use” until repaired.

7. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tool’s operation. If damaged, have the

tool serviced before using. Many accidents are caused by poorly maintained

tools.

8. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for one tool may become hazardous when

used on another tool.

SERVICE

1. Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

2. When servicing a tool, use only identical replacement parts. Follow instructions

in the

unauthorized parts or failure to follow maintenance instructions may create a risk of

electric shock or injury.

“Inspection, Maintenance, and Cleaning”

section of this manual. Use of

SKU 47761 PAGE 5

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 6

SPECIFIC SAFETY RULES

1. Maintain a safe working environment. Keep the work area well lit. Make sure

there is adequate surrounding workspace. Always keep the work area free of

obstructions, grease, oil, trash, and other debris. Do not use the Pressure Washer in

areas near flammable chemicals, dusts, and vapors.

2. Maintain labels and nameplates on the Pressure Washer. These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a replacement.

3.

4. Use the right product for the right job. There are certain applications for which

5. This product must continuously run with cold water only.

6. To avoid electrical shock, never start and run the Pressure Washer in the rain.

7. Do not allow the GFCI Plug (95) to become wet. Always place the GFCI Plug in

8. When using the Pressure Washer, always maintain a firm grip on the Gun

WARNING! Risk of injection or severe injury. Keep clear of Nozzle. Do not

direct discharge stream at people or animals. Keep the work area clear of all

people and animals.

this product was designed. Do not use small equipment, tools, or attachments to do

the work of larger industrial equipment, tools, or attachments. Do not use this product

for a purpose for which it was not intended.

Never use hot water.

Dry running will cause serious damage to the seals. Make sure the water supply

used for the Pressure Washer is not dirty, sandy, and does not contain any corrosive

chemical products.

Never allow water to leak inside the Body of the Pressure Washer. Do not direct

discharge stream at the Pressure Washer itself or at other live electrical equipment.

a dry location and as far away as possible from the object being sprayed.

Keep all electrical connections dry and off the ground.

Assembly (E) with

a kickback force.

both hands. Squeezing the Trigger of the Gun Assembly causes

9. Do not pull or carry the Power Washer by its Power Cord (95), or pull the Cord

around sharp corners or edges. Do not unplug the Power Washer by pulling on

the Cord. Keep the Cord away from heated surfaces.

10. Do not handle the GFCI Plug (95) with wet hands.

11. Avoid unintentional starting. Make sure you are prepared to begin work before

turning on the Pressure Washer.

12. The work area should have adequate drainage to reduce the possibility of a

fall due to slippery surfaces.

13. This Pressure Washer is intended for outdoor residential use only.

SKU 47761 PAGE 6

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 7

14. Some chemicals or detergents may be harmful if inhaled or ingested. Use an

ANSI approved respirator or mask whenever there is a chance that vapors may be

inhaled.

15. Keep the High Pressure Hose connected to the Pressure Washer and Spray

Gun while the system is pressurized. Disconnecting the Pressure Hose while

the unit is pressurized is dangerous, and may cause injury.

16. Prior to starting the Pressure Washer in cold weather, check all of the parts of

the unit to make sure ice has not formed. Do not store the unit anywhere that the

temperature will fall below 32° F (0° C). (See “Inspection, Maintenance, and

Cleaning” section for proper storage procedures.)

17. Do not feed already-pressurized water (such as that from another pressure

washer) into this washer.

18. When dispensing detergent, apply the detergent to the cleaning area at low

pressure only. Then, spray the detergent off the cleaning area by using the

adjustable Nozzle. NOTICE: Detergent dispensing only works when the Spray

Lance is in the low-pressure position.

19. The high pressure water flow can damage the work surface if not used properly.

Always test the spray in an open area first.

20. Never move the Pressure Washer by pulling on the High Pressure Hose. Use

the Handle provided on the top of the unit.

21. Never leave the Pressure Washer unattended when it is plugged into an

electrical outlet. Turn off the Pressure Washer, and unplug it from its electrical

outlet before leaving.

22. If water is leaking out of the Pressure Washer immediately shut off the unit.

Unplug the Pressure Washer, and discharge all pressure before tightening fittings

or having repair work done by a qualified technician.

23.

24.

WARNING! People with pacemakers should consult their physician(s) before

using this product. Operation of electrical equipment in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker.

WARNING! The warnings and precautions discussed in this manual cannot

cover all possible conditions and situations that may occur. It must be understood

by the operator that common sense and caution are factors which cannot be built

into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS.

SKU 47761 PAGE 7

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 8

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with

the tool. Never remove the grounding prong from the plug. Do not use the

tool if the power cord or plug is damaged. If damaged, have it repaired by

a service facility before use. If the plug will not fit the outlet, have a proper

outlet installed by a qualified electrician.

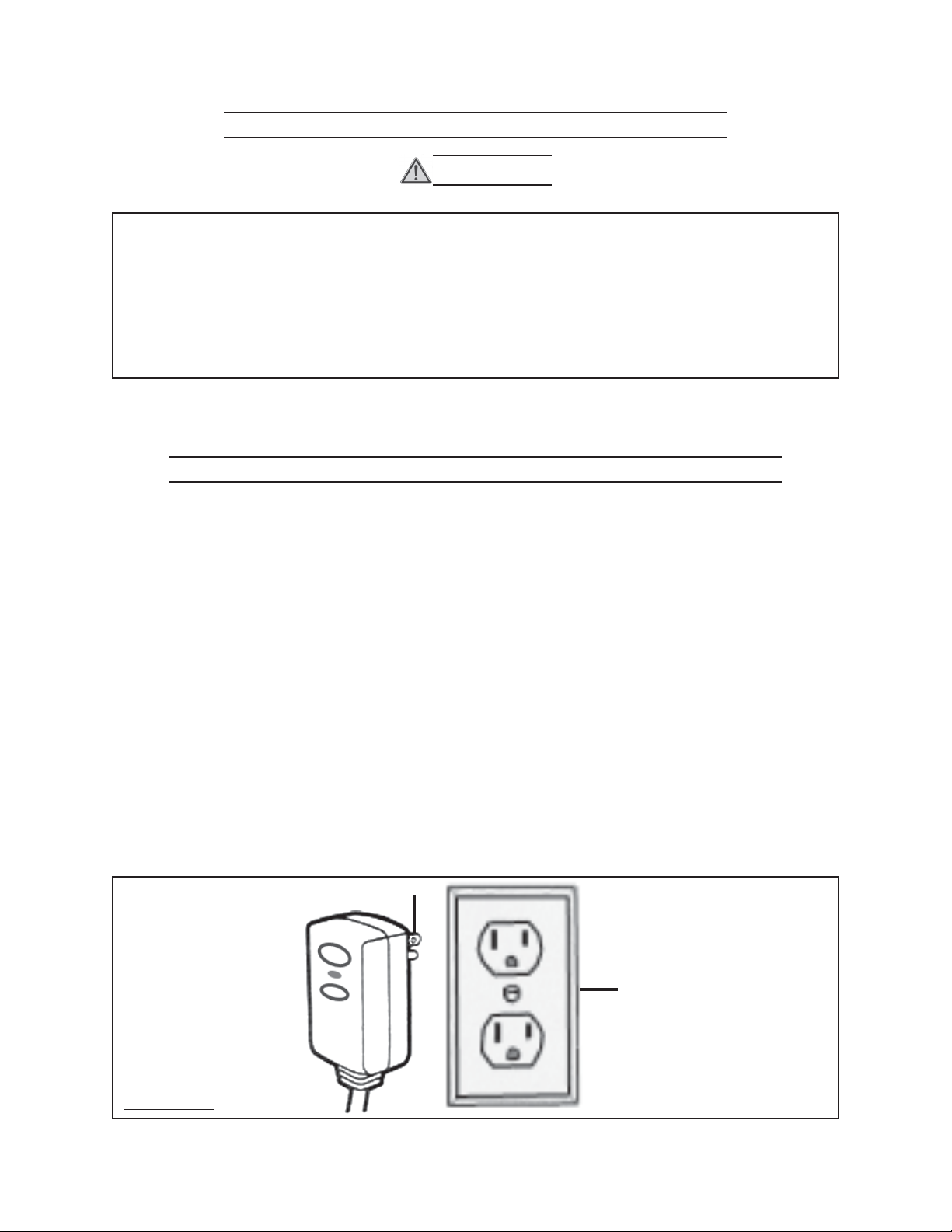

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

1. Tools marked with “Grounding Required” have a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If the

tool should electrically malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user, reducing the risk of electric

shock. (See Figure A,

next page.)

2. The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool. The green wire in the cord must be the only

wire connected to the tool’s grounding system and must never be attached to an

electrically “live” terminal. (See Figure A.)

3. Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

that in the following illustration. (See Figure A.)

3-PRONG PLUG

ELECTRICAL OUTLET

FIGURE A

SKU 47761 PAGE 8

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 9

EXTENSION CORDS

1.

Grounded

tools require a three wire extension cord.

2. As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a serious

drop in voltage, resulting in loss of power and possible tool damage. (See Table A.)

3. The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

WARNING! Do not use 16 or 18 AWG extension cords on this product.

4. When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required. (See Table A.)

5. If you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum cord size.

(See Table A.)

6. If you are using an extension cord outdoors, make sure it is marked with the suffix

“W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

7. Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified

electrician before using it. Protect your extension cords from sharp objects, excessive

heat, and damp or wet areas.

AelbaT

SEREPMAETALPEMAN

)daoLlluFtA(

52

F

tee

0.61-1.214121

0.02-1.612101

tpordegatlovenilehtgnitimilnodesaB*

SYMBOLOGY

Ta bl e B

)V021(*SDROCREWOPROFEGUAGERIWMUMINIMDEDNEMMOCER

HTGNELDROCREWOP

05

teeF

TEEF05REVO

tsumsdroCnoisnetxE

.desuebTON

.serepmadetarehtfo%051tastlovevifo

SKU 47761 PAGE 9

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 10

ASSEMBLY

NOTE: For additional references to the parts listed in the following pages, refer to the

Parts Diagrams on pages 18-21.

1. Slide the Cart Handle (A1) onto the Cart Base (A3), making sure the holes in the

upper

2. Align the mounting holes located at the bottom of the Handle (A1) with the mounting

holes located at the top of the Cart Base (A3). Then insert a Bolt (A4) into the

aligned holes, and secure the Handle to the Base with the Wing Nuts (A5).

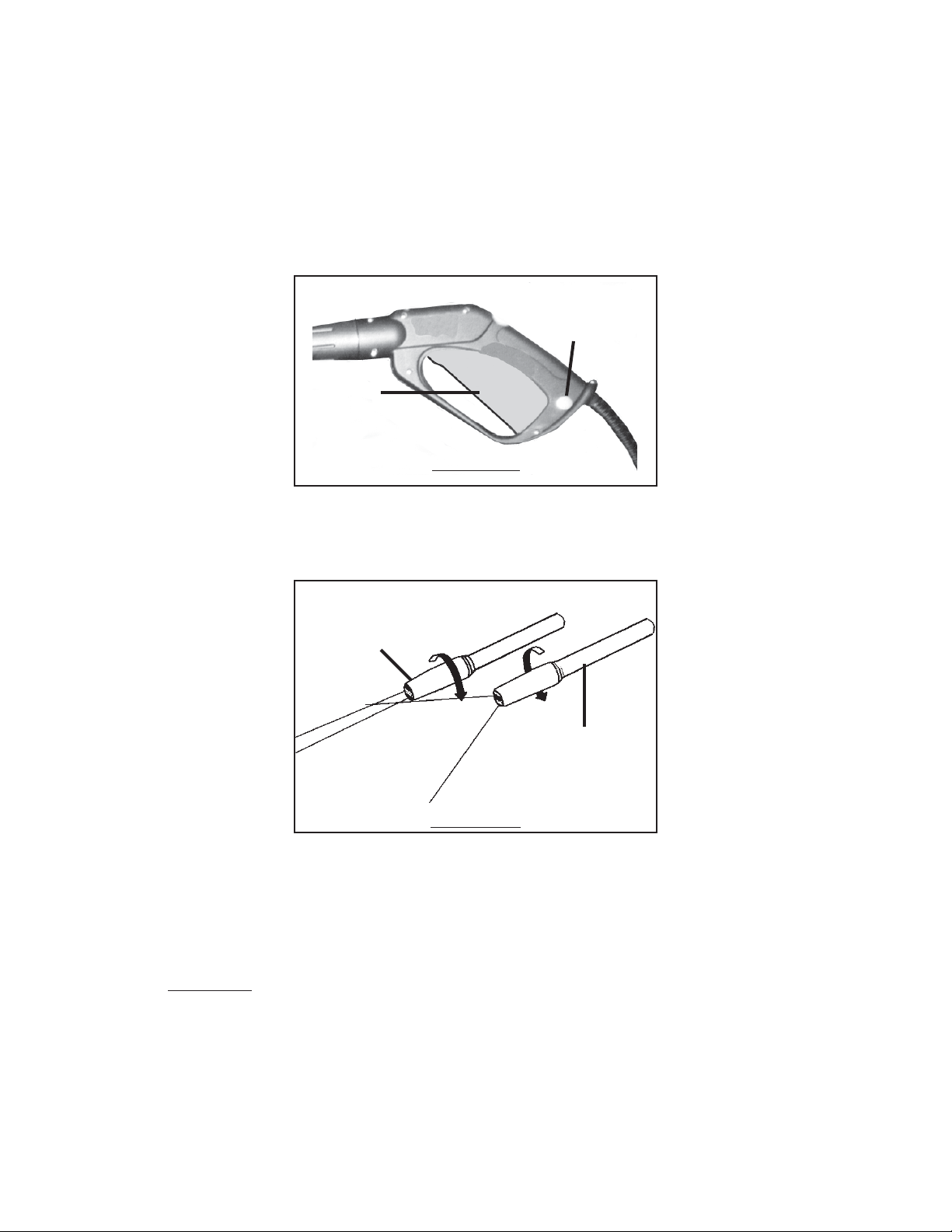

3. Attach the Accessory Holder (B) to the Cart Handle (A1) by inserting the prongs of

the Accessory Holder into the holes located in the upper/rear portion of the Cart

Handle. Then slide the Accessory Holder Bands (A2) down over the Accessory

Holder rack to secure the

Accessory Holder to the Cart

Handle.

4. Place the Pressure Washer unit

evenly onto the Cart Base (A3).

portion of the Handle face toward the rear of the Cart. (See Figure B.)

ACCESSORY

HOLDER

(B)

ACCESSORY

HOLDER

BAND (A2)

BOLTS

(A4)

5. Insert the Pressure Washer

accessories into the Accessory

WING

NUTS (A5)

Holder (B).

6. Attach the Spray Wand

Extension (J) to the Gun

HANDLE

(A1)

BASE

(A3)

Assembly (E) by inserting the tip

of the Wand into the Gun Collar.

Then push in firmly and rotate

to secure the Wand to the Gun.

Pull on the wand to ensure it is

FIGURE B

properly attached to the gun.

(See Figure C, below.)

7. The Spray Lance (K) and Detergent Bottle (H) can be attached to the Spray Wand

Extension (J) in the same manner, by pushing in the accessory and rotating to secure

the accessory to the Extension. (See Figure C.)

SPRAY LANCE

EXTENSION (J)

GUN

ASSEMBLY

(E)

GUN

COLLAR

SPRAY

LANCE (K)

DETERGENT

BOTTLE (H)

FIGURE C

SKU 47761 PAGE 10

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 11

8. Remove the protective plastic caps

from the unit’s water Inlet Port and

water Outlet Port. (See Figure D.)

9.

Ensure the inlet water strainer is

free of debris. Firmly attach the

Heavy Duty Hose Adapter (G) to the

water Inlet Port.

FIGURE D

HEAVY DUTY

HOSE ADAPTER

(G)

10. Firmly attach the High Pressure Hose

(26A) to the water Outlet Port.

HIGH PRESSURE

HOSE (26A)

INLET

OUTLET

CONTROLS AND SETUP

Note: Familiarize yourself with the location and function of all of the machine’s

controls before proceeding to setup of the machine.

CONTROLS AND FEATURES

1. The Pressure Washer features an automatic On/Off Micro Switch. The Motor (C)

of the Pressure Washer does not run continuously, but only when the Trigger (23A)

is squeezed. When spraying water through the unit stops, the Motor will automatically

shut off. However, the unit will build up heat while idle. If the unit is left to sit, then

the electrical circuit’s beaker will eventually trip. For this reason, if the unit is not to

be used for longer than 2 minutes, shut the Switch to “OFF”.

2. The Pressure Washer features a 3-Prong, Ground Fault Circuit Interrupter

(GFCI) Power Plug (95). The GFCI

Power Plug provides additional

protection from the risk of electrical

shock. Make sure that the Trigger (23A)

is released before plugging in. Plug the

GFCI Power Plug into a grounded, 120

volt, electrical outlet. Press the TEST

RESET

BUTTON

TEST

BUTTON

RED

INDICATOR

button and then the RESET button. The

indicator

appear

on the Power Plug should

red. If the indicator is not red,

have the power plug inspected by a

qualified electrician. Never attempt to

alter or disable the GFCI Power Plug.

Should replacement of the GFCI Power

GFCI POWER PLUG (95)

FIGURE E

SKU 47761 PAGE 11

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 12

Plug become necessary,

only

a qualified technician should perform the service.

(See Figure E.)

3. The Pressure Washer is equipped with a Trigger Safety Lock (25A). When the

Trigger (23A) is not squeezed, the Safety Lock should be pressed all the way in to

help prevent children from using the tool. To disengage the Safety Lock, press the

opposite side. (See Figure F.)

SAFETY

TRIGGER LOCK

(25A)

TRIGGER

(23A)

FIGURE F

4. The Knob (16A) on the Spray Lance (K) can be rotated for a range of spray

patterns, from a full fan spray to a direct stream spray. (See Figure G.)

Pattern Adjustment

KNOB (16A)

SPRAY

LANCE (K)

FIGURE G

5. The Detergent Bottle (H) allows the application of

(not included) onto the work surface. When filling the Detergent Bottle with

pressure washing detergent

, do not exceed 10 ounces of detergent. The Pressure

Washer will automatically mix the detergent and water. Note: Do not add water to

the Detergent Dispenser.

CAUTION! NEVER use any products not designed for pressure washer use, nor

any products with bleach, chlorine, or any other corrosive materials, including liquids

containing solvents, trisodium phosphate products, ammonia, or acid-based

cleaners.

pressure washing detergent

SKU 47761 PAGE 12

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 13

SETUP

1. CHECK THE WATER SUPPLY. Prior to using the Pressure Washer for the first time,

it is ESSENTIAL to verify that the water supply is adequate. The Pressure Washer

needs TWICE the water supply (or volume) than the stated water output (1.6 GPM).

This Pressure Washer will need about 3-4 GPM to operate correctly and efficiently.

If the water is being supplied by a well/pump, make certain that the well/pump

produces enough water to keep up with the Pressure Washer’s water demands.

Water supply hoses should be heavy duty to withstand the forces involved. Water

hoses up to 25’ long must be

not use hoses longer than 50’. The more minerals in the water (the harder the water)

you use, the more often mineral buildup will need to be cleaned out from the nozzle.

Flow rate of the water supply must never be allowed to fall below 3 GPM.

To determine the water supply’s flow rate: Run the water at full for one minute

into a 5 gallon container, and measure the amount of water in the container.

CAUTION! If the Pressure Washer is run with an inadequate water supply, the pump

will cavitate. Cavitation causes the pump to operate loudly and will damage it.

2. ARRANGE FOR A PROPER ELECTRICAL SUPPLY. This unit uses a large amount

of current, especially during start-up. Connect this unit only to a dedicated household

circuit capable of providing ample current to it. A dedicated circuit has no additional

loads (running devices) connected to it; shut off any appliances or lights that dim or

slow down while the washer is running. For best results, connect the plug to that

circuit’s outlet that is nearest to the circuit breaker panel.

5

/8” ID. Water hoses up to 50’ long must be 3/4” ID. Do

3. MAKE SURE THE WASHER IS CLEAN AND READY FOR USE. Ensure the inlet

water strainer, nozzle, and the rest of the Washer are totally free of buildup or debris.

4. PLAN OUT THE JOB: Plan out what areas will be cleaned, how many sessions

will be necessary, and how long the individual sessions of work will need to

be. Plan to clean the higher portions first, because the higher portions will typically

remain cleaner while the other areas are cleaned. Plan a safe direction for runoff to

flow while the job is being performed, and plan on working your way in that direction.

You will have a clearer idea of the time involved to clean the area after doing a test

run, as explained on page 15, #3.

5. PREPARE THE CLEANING AREA. Clear the cleaning area of all objects that are

not being cleaned. If any water prone or delicate items cannot be moved, protect or

move them. If detergent is to be used, cover or remove any plants or animals that

may be damaged by the chemicals in the cleaner.

6. PLACE THE PRESSURE WASHER IN AN APPROPRIATE LOCATION. The

location should be protected from any water from the cleaning area; if possible,

select a location higher than the cleaning area. The pressure washer’s location

should be close enough so that the hose will reach every portion of the job to be

done with some slack for movement. Also, select an area with proper access to a

dedicated circuit that can be reached with as short an extension cord as possible.

SKU 47761 PAGE 13

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 14

OPERATION

1. Make sure the Power Switch is in the “OFF” position. Attach the heavy duty

hose to the Pressure Washer, using the Heavy Duty Hose Adapter (G).

3. Attach the Spray Lance (K) or Detergent Bottle (H) into the Spray Wand Extension

(I), and press and twist the Wand into the Extension until the Wand locks in place.

(See Figure C, page 10.)

NOTE: The Pressure Washer will not pressurize if the Nozzle is not completely

assembled. It will not work properly with only part of the Wand installed.

4. Connect the High Pressure Hose (26A) to the Pressure Washer. (See Figure D.)

Make sure all connections are tight. Then, open the water supply valve fully. If

leaks occur, shut off water and retighten connections.

5. IMPORTANT! Prior to turning on the Pressure Washer, connect the unit to the

water supply. Turn on the water, disengage the safety, and squeeze the Trigger

(23A) until water flows out of the Gun Assembly (E) without sputtering. This

removes air from the system and allows the unit to properly perform.

follow this step can damage the Pump.

6. Test the cleaning capabilities and the run before starting your cleaning project, as

explained on page 16, #1. Turn the Power Switch to the “ON” position. The motor

will briefly run when the switch is first turned on to build up pressure and then

go to standby until the trigger is squeezed. DO NOT ALLOW THE UNIT TO REMAIN

IDLE FOR MORE THAN A MINUTE OR TWO; the unit will build up heat when it

is on standby mode.

Failure to

7. Point the Nozzle in a safe direction. Then, disengage the Safety and squeeze the

Trigger (23A). Switch the unit’s switch to the OFF position whenever the gun is not

in use. Clean the area, following the tips contained in the Operating Tips section.

8. When finished spraying, fully engage the Trigger Safety Lock (25A), turn the Power

Switch to its “OFF” position, and turn off the water supply.

WARNING: Do not disconnect the high-pressure hose or water inlet hose

until all pressure is discharged safely.

9.

10. Store the pressure washer and all accessories in accord with the directions under

IMPORTANT! When turning off the unit after use, high pressure will remain inside

the unit its High Pressure Hose (26A), and the water inlet hose. Point the Gun

Assembly (E) in a safe direction and hold the trigger down for several seconds.

Then, release the Trigger (23A) and remove the Spray Wand Extension (J). Hold the

Trigger until water stops flowing from the gun. The high-pressure hose and water

inlet hose can be disconnected after the pressure is released.

Storage

on page 17.

IF ANY UNEXPECTED PROBLEMS ARISE, PLEASE REFER TO THE

TROUBLESHOOTING SECTION AT THE END OF THIS MANUAL.

SKU 47761 PAGE 14

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 15

IMPORTANT!

NEVER ALLOW THE UNIT TO SIT IDLE WITH THE

SWITCH ON FOR LONGER THAN TWO MINUTES.

OPERATING TIPS

BECOME FAMILIAR WITH YOUR MACHINE

1. Before beginning work, set aside enough time to familiarize yourself with this

machine’s cleaning rate and capacity along with all instructions and precautions

contained in this section, along with the Operating Instruction and Operating Controls

sections.

2. This unit is intended for various light to moderate cleaning applications. If deeper

cleaning is desired, it can be attained at times, however this is done at the expense

of speed. This unit is not intended for paint stripping or deep concrete cleaning

applications.

3. Clean a test area to satisfaction before proceeding with the entire area, as stated in

Cleaning Recommendations on the next page. Use this area to approximate the

amount of time required for the project. Be certain to factor in time for touch-ups and

cleanup after the general cleaning is finished.

4. This unit has several settings and adjustments that effect the speed of cleaning and

the water force applied to cleaning. Good guidelines to keep in mind are:

WIDE STREAM =

QUICKER COVERAGE BUT

LIGHTER CLEANING.

NARROW STREAM =

DEEPER CLEANING BUT

SLOWER COVERAGE.

USE PROPER PRESSURE WASHER OPERATION TECHNIQUES

The machine may suddenly stop and require a rest period from time to time;

this is normal and does not indicate a problem

However, certain use techniques may help reduce or even prevent the need for such rest

periods, increasing efficiency:

a. SHUT OFF THE MACHINE IF THE UNIT IS TO SIT IDLE FOR MORE THAN 2

MINUTES. Heat will build up within the unit as it draws current while

recirculating the water. If left for long enough, it will overload the circuit it is

powered by and trip the circuit breaker.

b. Do not release the trigger between sweeps. Release the trigger as few times

as possible during use. Interrupted or sporadic spraying will cause the unit to

heat up quickly and will increase the need for rest periods.

c. Make sure that all obstacles have been moved and the entire area is ready before

starting.

d. For small jobs, try to finish an entire portion of the job before taking a break.

(see Troubleshooting, page 22).

SKU 47761 PAGE 15

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 16

CLEANING RECOMMENDATIONS

1. Clean an inconspicuous test area to help avoid damaging the surface: Always

begin with the fan spray at a distance of about 3-5 feet from the surface being cleaned

to avoid damaging the surface of the object. Make sure that the test area is clear of

people and water prone/delicate objects. If a pressure washing detergent is to be

used, apply the detergent to this area as well. After cleaning this area, switch off the

pressure washer and inspect the area carefully for any damage or discoloration. If

any damage is noted from the pressure setting, use a lighter setting when cleaning

the rest of the area. If damage or discoloration is noted from the detergent, do not

use it when cleaning.

2. First, pass over the area with a light cleaning, and then more thoroughly clean it.

3a. For a

a. Wash from the top down.

b. If possible, direct the stream in the same direction as the slope towards a draining

3b. For a

a. If a thin layer of water accumulates on the surface, periodically use the stream to

b. After the major cleaning is done, sweep the surface with the stream to help direct

4. If detergent is to be applied: Only use pressure washing detergent; other detergents

might clog or damage the pressure washer. Apply the detergent at low pressure by

using the Detergent Bottle (H). Allow the detergent several minutes to sit and soak

into the work surface; this will improve cleaning efficiency. Make certain to rinse off

all detergent completely.

5. Hold the Gun Assembly at about a 45° angle and steadily sweep the stream back

and forth; if a severe, head-on angle is used, dirt may imbed in the surface being

cleaned. Follow a steady, consistent pace during cleaning; this will help prevent

stripes or discoloration afterwards. If streaking or uneven cleaning is noted at the

end of a project, go over the edges of the streaks with a wide fan pattern to help

blend these lighter areas in.

vertical

area. This will enable better drainage and therefore better cleaning.

flat

direct this water towards the drainage.

loose debris toward the drainage.

or

surface:

sloped

surface:

6. If several different surfaces are to be cleaned, be careful not to damage any of the

less solid surfaces while trying to clean the harder ones. This is especially a concern

when cleaning tile and grout, bricks and mortar, or stones and mortar.

7. If wood is being cleaned, be careful not to damage it. Wood will usually require

resurfacing (sanding) and re-coat with a surface protectant (wood, stain, varnish)

after it has dried again. Try to avoid leaving water on a wooden surface; doing so

can harm the surface.

SKU 47761 PAGE 16

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 17

INSPECTION, MAINTENANCE, AND CLEANING

1. WARNING! Make sure that 1) the Trigger is locked in its off position, 2) the

Power Switch of the Pressure Washer is in its “OFF” position, 3) the plug is unplugged

from its electrical outlet, 4) that the water supply is shut off, and 5) all residual water

pressure is safely expelled before performing any inspection, maintenance, or

cleaning procedures. Point the Gun Assembly (E) in a safe direction and discharge

all remaining pressure. Then, disconnect the Heavy Duty hose from the unit.

2. Before each use, inspect the general condition of the Pressure Washer. Check for

loose screws, misalignment or binding of moving parts, damaged electrical wiring,

damaged High Pressure Hose, damaged accessories, and any other condition that

may affect its safe operation. If abnormal noise or vibration occurs, have the problem

corrected before further use.

Do not use damaged equipment.

3. To clean, remove excess water from the Pump by tipping the unit on both sides to

drain any remaining water from the inlet and outlet fittings. Drain the Detergent

Dispenser and flush with running water. Use only a clean cloth and mild detergent

to clean the body of the Pressure Washer. Do not use solvents. Remove the Inlet

Filter and run water through it backwards to remove any debris.

Do not immerse any part of the tool in liquid. Dry off any remaining water on all

parts and fittings. Then engage the Trigger Safety Lock.

Use the included Wire Tip Cleaner (I) to help remove mineral deposits from the

nozzle. The more minerals that are dissolved in the water (the harder the water) you

use, the more often mineral buildup will need to be cleaned out from inside the

nozzle.

SPRAY LANCE (K)

FIGURE I

KNOB (16A)

TIP CLEANER

(I)

4. STORAGE: When storing, always completely empty the Pressure Washer of water.

Frost will damage the Pressure Washer if the unit contains water. Store the Pressure

Washer indoors in a dry, frost-free room. Minerals in the water can harden inside the

workings. Flush the unit with automotive antifreeze prior to long-term storage. Always

dispose of antifreeze in accord with local ordinances.

SKU 47761 PAGE 17

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 18

PARTS LISTS AND DIAGRAMS

MAIN PARTS LIST

traPnoitpircseDyt'QtraPnoitpircseDyt'QtraPnoitpircseDyt'Q

1eldnaH133)esUlaicepS(sehctiwS156retliFriA

2daeHpmuP

3)puC”Y“notsiP(laeS

4)telnI(evlaVkcehC

5gniR-O

6gnirpS

7notsiP

8revoCevlaV

9)07-6M(wercS

D

01tloB

11)evlaVkcehC(gniR-O

21revoCevlaV

31notsiP

41gnirpS

51)teltuO(evlaVkcehC

61

71)evlaVkcehC(paC

81gniR-O

91)toliP(recapS

02)notsiPliO(laeS

12gniR-O

22gniR-O

32llaBleetS

42gnirpSrepaT

52ssorC

62)notsiP(gnisuoH

72)teltuO(revoC

82draoBdexiF106gniraeB

92wercS116maC

03niP126gniraeB

13reveL136laeS

23elcatneT146sixA

D

D

D

D

D

D

D

143wercS966niP

D

353paC176ydoBpmuP

363laeS186raeG

373elcatpeceRnOpilS796gniraeB

383eveelS807)52x9.3TS(tloB7

393xoBhctiwS117)VH041-4(rehsaW7

304eveelSdroC127)telnI(gnisuoH

414droC137)rebbuR(tnuoM4

124elcatpeceRnOpilS147raeG1

D

334llehSevlaV

D

D

D

D

gniR-O

D

D

D

D

D

D

D

D

D

D

D

344gniR-O

354gnirpSnruteRnotsiP

364gniR-O

D

374eloPevlaV

84gniR-Y

3

)troPerusserPhgiH(

94gniR-O

305revoCevlaV

315gniR-O

325)reniateR(paC

335relliFretaW

345laeSgnisuoH,gniR-O

155nruteRnotsiP,gnirpS

265notsiP378rehsaW1

175gnirpSnotsiP,nruteR

185)gniraeB(rehsaW

1

95

1

D

D

D

D

D

D

D

D

D

D

D

D

gniraeB

)tsurhTeldeeN(

D

D

D

D

D

157)laeSgnisuoH(gniR-O1

167wercS4

D

177rotoM

187)rotoM(revoC1

197retliFriA1

108)laeSgnisuoH(gniR-O1

1

18

1

128)02x9.3TS(wercS4

138feileRniartSrennI2

148tuN1

D

158gniR-O1

D

368wercS1

D

388tuN1

198hctiwSrewoP1

09)hctiwSrekcoR(tooB1

1

19

1

129)teltuO(gnisuoH

139leehW2

149)leehW(revoC2

159gulP/droCrewoPICFG1

D

D

D

D

D

F

C

gnisuoH

)droC&hctiwS(

erusolcnE

)tooBhctiwSrekcoR(

F

1

2

1

1

1

1

1

1

1

1

C

= This part is included in the Motor Assembly (C).

D

= This part is included in the Pump Assembly (D).

F

= This part is included in the Housing (F).

SKU 47761 PAGE 18

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 19

MAIN PARTS DIAGRAM

38

37

88

95

87

86

91

90

89

85

84

82

34

81

94

93

83

69

68

72

F

35

34

73

71

70

42

38

37

40

38

39

37

36

80

67

66

65

64

63

51

50

49

23

48

47

46

45

44

43

41

79

78

37, 38

C

77

62

61

60

52

D

59

58

57

56

55

54

27

26

53

23 24 25

22

13

16

151412

17

11

10

9

74

21

20

19

18

8

7

6

5

4

76

75

3

2

1

92

F

29

28

31

32

33

30

C = This part is included in the Motor Assembly (C).

D = These parts are included in the Pump Assembly (D).

F = These parts are included in the Housing (F).

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

SKU 47761 PAGE 19

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 20

PARTS LIST AND DIAGRAM A

traPnoitpircseDyt'QtraPnoitpircseDyt'Q

A1)thgiR(gnisaC

A2)tfeL(gnisaC

A3gnirpS

A4gniR-O

E

E

A5gniRpUkcaB

A6evlaVnotsiP

A7gniR-O

E

A8gnirpS

A9gniR-O

A01ydoBevlaV

A11noisnetxEdnaWyarpS

A21elkcubnruT

A31dnaWyarpS

A41rosserpmoCedalB

A51gniR-O

A61bonK

A71gniR-O

E

= This part is included in the Trigger and Gun Assembly with High Pressure Hose (E).

J

= This part is also listed on the next page as the Spray Wand Ext. (J).

K

= This part is included in the Adjustable Spray Lance (K).

K

K

K

E

E

1A81gniR-O

1A91elzzoN

1A02allemaL

2A12niP

E

E

2A22niP-U

1A32reggirT

1A42wercSgnippaTfleS

K,E

K,E

E

J

E

K

K

2A52kcoLytefaS

2A62esoHerusserPhgiH

1A72tekcaJ

1A82tekcaJ

1A92rotcennoC

1A03tuN

1A13gnilpuoC

1A23gniR-O

1A33gnilpuoC

1

K

K

K

K

K

E

E

E

E

E

E

E

E

E

E

E

1

1

1

1

1

1

6

1

1

1

1

2

1

1

1

1

21A

20A

16A

18A

19A

17A

14A

22A

15A

KJ

13A

33A

1A

25A

31A

29A

30A

9A

8A

11A

10A

8A

9A

4A

5A

4A

3A

7A

6A

12A

24A

23A

32A

2A

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

E

26A

28A

27A

SKU 47761 PAGE 20

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 21

ASSEMBLY PARTS LIST AND DIAGRAM

ylbmessAnoitpircseDyt'QylbmessAnoitpircseDyt'Q

AylbmessAtraC1

1AeldnaH1

2AdnaBredloHyrosseccA2

3AesaB1

4AtloB2

5AtuNgniW2

E

FgnisuoH

GretpadAesoHytuDyvaeH1

HreyarpStnegreteD1

BkooHyrosseccA1IrenaelCpiT1

CylbmessArotoM

D

ylbmessApmuP

)96-34,72-2straP(

)77traP(

1J .txEdnaWyarpS

1K

slooTthgierFrobraHmorftinUsihtrofseirosseccAlanoitpO

)woleBmargaiDehtninwohStoN,yletarapeSdloS(

41893METIecnaLobruT61893METIhsurBgnitatoR

51893METIhsurBdexiF71893METItiKgninaelCepiP

ylbmessAnuGdnareggirT

esoHerusserPhgiHhtiw

)A33-A32,A21,A01-A1straP(

)29&27straP(

)A11traP(

ecnaLyarpSelbatsujdA

)A22-A31,A9,A8straP(

1

1

1

1

A1

A2

B

A5

A4

A3

A

H

I

G

Assemblies C, D, E, F, J, & K are shown on the parts lists and

diagrams on pages 18-20 instead of here.

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED

AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND

LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT

PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS

THERETO.

SKU 47761 PAGE 21

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

Page 22

TROUBLESHOOTING

IMPORTANT!

Be CERTAIN to shut off the Pressure Washer, release all pressure in a safe manner, and

disconnect it from power and water before adjusting, cleaning, or repairing the unit.

PRESSURE WASHER STOPS SUDDENLY

The thermal safety Switch may be

tripped. Switch the unit off and allow

the unit to rest for 20-30 minutes and

try again.

UNIT OPERATES

NORMALLY AFTER

RESTING

The following points should be

applied to help reduce the

frequency of rest periods:

1. NEVER ALLOW THE UNIT TO SIT IDLE

FOR LONGER THAN 2 MINUTES. Use

proper operating techniques. Review the

Operating Tips section, page 15.

2. Verify that this unit is being supplied

with the correct voltage, see page 13, #2.

Connect the plug to the outlet nearest

the circuit breaker panel and remove any

other loads that may be on the circuit.

3. If possible, reduce the length of or

eliminate any extension cord used, see

page 9.

Check the indicator on the GFCI power

plug (explained under

Features,

INDICATOR

APPEARS RED

Dry self thoroughly

and check the circuit

breaker on your

household panel.

Check for electrical shorts. If no shorts are

found, reset breaker.

If breaker continues to trip, try another circuit

or contact a certified electrician.

UNIT DOES NOT

START AFTER

RESTING

Controls and

#2 on page 11).

INDICATOR NOT

RED

Make sure unit is

totally dry, then

press reset button.

If GFCI continues

to trip, contact a

certified electrician.

BREAKER NOT

TRIPPEDBREAKER TRIPPED

Have the unit inspected

and repaired by a

qualified technician.

WATER LEAKING FROM WITHIN THE HOUSING

Seals or gaskets may be worn or damaged.

Leaking water creates a shock hazard;

PROMPTLY

repaired by a qualified technician.

If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualified technician.

SKU 47761 PAGE 22For technical questions, please call 1-800-444-3353.

have the unit inspected and

Page 23

TROUBLESHOOTING (CONTINUED)

IMPORTANT!

Be CERTAIN to shut off the Pressure Washer, release all pressure in a safe manner, and

disconnect it from power and water before adjusting, cleaning, or repairing the unit.

PRESSURE WASHER WILL NOT START

Dry self thoroughly and check the voltage

at the outlet, and the reset button on the

GFCI power plug (explained under

Controls and Features,

#2 on page 11).

POWER SUPPLY

INADEQUATE

Have a certified

electrician correct

the problem.

PRESSURE WASHER DOES NOT BUILD PRESSURE

HOSE IS KINKED

OR SCREEN IS

CLOGGED

RESET BUTTON NOT

SET CORRECTLY

Setup the GFCI plug

as explained on

page 11.

The Thermal safety Switch

may be tripped. Switch the

unit off and allow the unit to

rest for 20-30 minutes and

try again.

Check that hose is unbent and

Inlet Screen is free from debris

and deposits.

HOSE IS NOT KINKED AND

SCREEN IS CLEAN

POWER SUPPLY ADEQUATE

AND RESET BUTTON SET

PROPERLY

Clean Screen and

straighten hose.

Switch to a shorter

Air may be getting in the

water supply hose, check all

connections.

hose, if possible.

CONNECTIONS

ARE LOOSE

Retighten

connections.

Internal valves, seals, or the

nozzle may be worn, contact

ALL CONNECTIONS

a qualified technician.

If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualified technician.

SKU 47761 PAGE 23For technical questions, please call 1-800-444-3353.

ARE TIGHT

Page 24

TROUBLESHOOTING (CONTINUED)

IMPORTANT!

Be CERTAIN to shut off the Pressure Washer, release all pressure in a safe manner, and

disconnect it from power and water before adjusting, cleaning, or repairing the unit.

PRESSURE CHANGES DURING USE

Air may be getting in the water supply

hose, check all connections.

CONNECTIONS

ARE LOOSE

Retighten

connections.

Clean tip, using the

included Tip Cleaner (I).

ALL CONNECTIONS

ARE TIGHT

Check that tip is free from

debris and deposits.

TIP IS

DIRTY

Internal valves or seals may

be worn or sticking, contact

a qualified technician.

DETERGENT WILL NOT DISPENSE

Verify that proper type of pressure

washer detergent is being used, see

page 12, #5.

TIP IS

CLEAN

NON-PRESSURE

WASHER DETERGENT

USED

Open the Detergent

Bottle (H) and rinse it

out thoroughly. Refill

with correct detergent.

If the steps above do not solve the problem or if the repairs involved are too

Open the Detergent Bottle

(H) and check that the

suction tube is not bent or

pinched.

complex, contact a qualified technician.

CORRECT DETERGENT

SKU 47761 PAGE 24For technical questions, please call 1-800-444-3353.

USED

Loading...

Loading...