Page 1

MICRO MILL/DRILL MACHINE

®

Model 47158

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

Copyright© by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

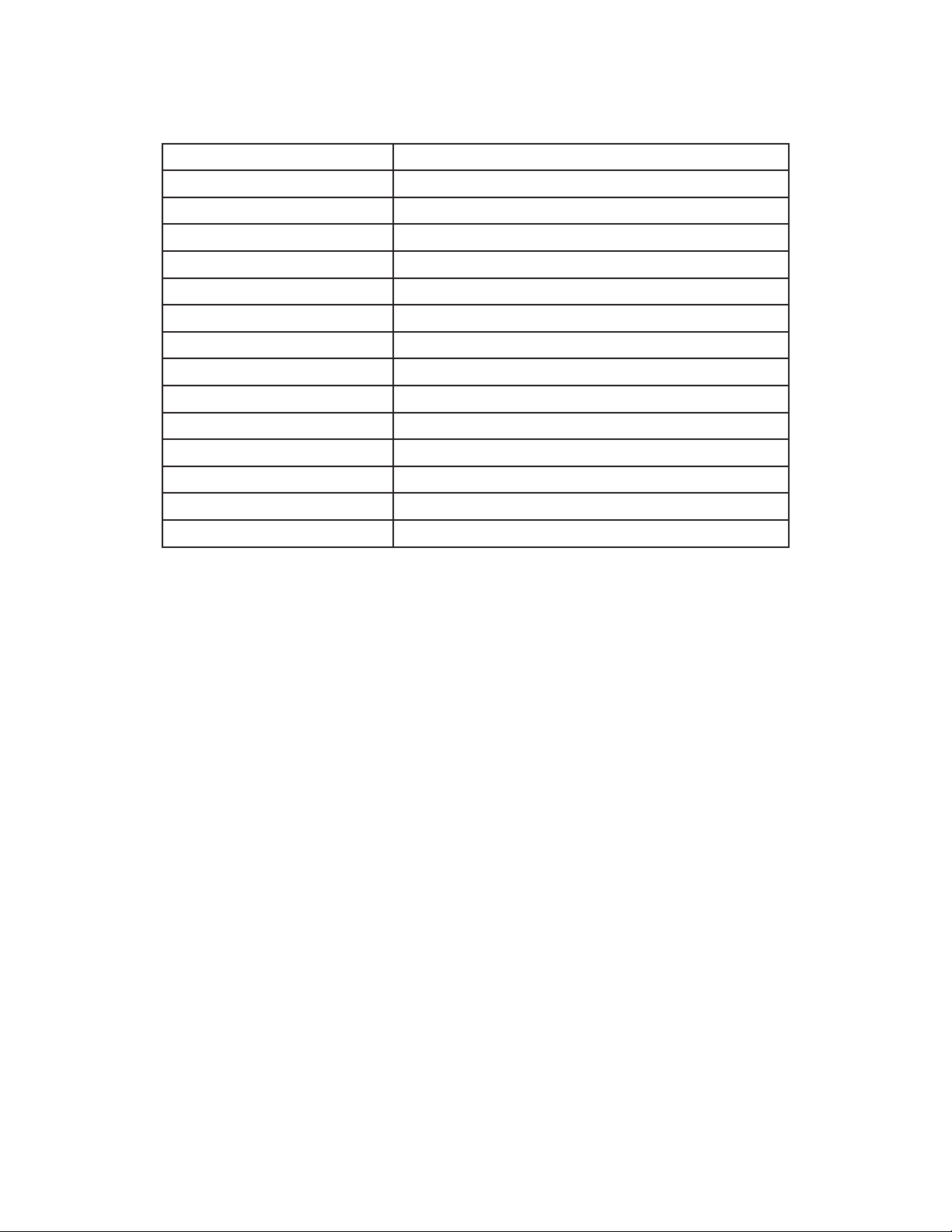

SPECIFICATIONS TABLE

Electrical Requirements 120 V / 6 0 Hz / 1/5 HP

2 Speed Ranges High: 100-2,000 RPM / Low: 100-1,000 RPM

Maximum Chuck Capacity 25/64” Drill Bit / 25/64” End Mill / 3/4” Face Mill

Maximum X Travel 9”

Maximum Y Travel 4”

Maximum Z Travel 8-1/2”

X, Y, Z Graduations .001” / Line

Table Size 9-3/8” x 5-3/8”

Table Slot 5/16” x 5/8”

Throat Depth 5-1/2”

Swing Diameter 11”

Base Size 10-1/8” x 9-3/8”

Spindle Stroke 1-3/16”

Spindle Taper MT2

Weight 103 Pounds

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and

assembly diagram. Keep your invoice with this manual. Write the invoice

number on the inside of the front cover. Keep this manual and invoice in a safe

and dry place for future reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp, or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be

stored in a dry location to inhibit rust. Always lock up tools and equipment, and

keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgement or

reflexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this product.

For technical questions, please call 1-800-444-3353.

Page 2SKU 47158

Page 3

5. USE EYE AND BREATHING PROTECTION. Wear ANSI approved safety impact

eyeglasses when using this product. Also, use an ANSI approved dust mask if

the operation produces excessive dust. ANSI approved safety impact

eyeglasses and dust masks are available from Harbor Freight Tools.

6. DRESS SAFELY. Do not wear loose clothing or jewelry, as they can become

caught in moving parts. Wear a protective hair covering to prevent long hair from

becoming caught in moving parts. If wearing a long-sleeve shirt, roll sleeves up

above elbows.

7. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENT.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do

not use this product when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product. Replace or repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES: When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this product clean, dry, and keep

all cutting bits sharp for better and safer performance.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualified technician.

14. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. It will do the job better and more

safely at the rate for which it was intended. Do not modify this tool, and do not

use this tool for a purpose for which it was not intended.

15. WARNING: The warnings, precautions, and instructions discussed in this manual

cannot cover all possible conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied by the operator.

For technical questions, please call 1-800-444-3353.

Page 3SKU 47158

Page 4

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. MAINTAIN A SAFE WORKING ENVIRONMENT. Keep the work area well lit.

Make sure there is adequate surrounding workspace. Always keep the work area

free of obstructions, grease, oil, trash, and other debris. Do not use the Micro

Mill/Drill Machine in areas near flammable chemicals, dusts, and vapors. Do not

use the Micro Mill/Drill Machine in a damp or wet location.

2. GROUND THIS PRODUCT. The electrical Power Cord/Plug (part #128) for this

product is equipped with a grounded, 3-prong Plug. Never remove the grounding

prong or modify the Plug in any way. Do not use adapter plugs with this product.

To comply with the National Electric Code, and to provide additional protection

from the risk of electrical shock, this product should only be connected to a 120

Volt, 3-hole electrical outlet that is protected by a Ground Fault Circuit Interrupter

(GFCI). (See Assy. Diagram.)

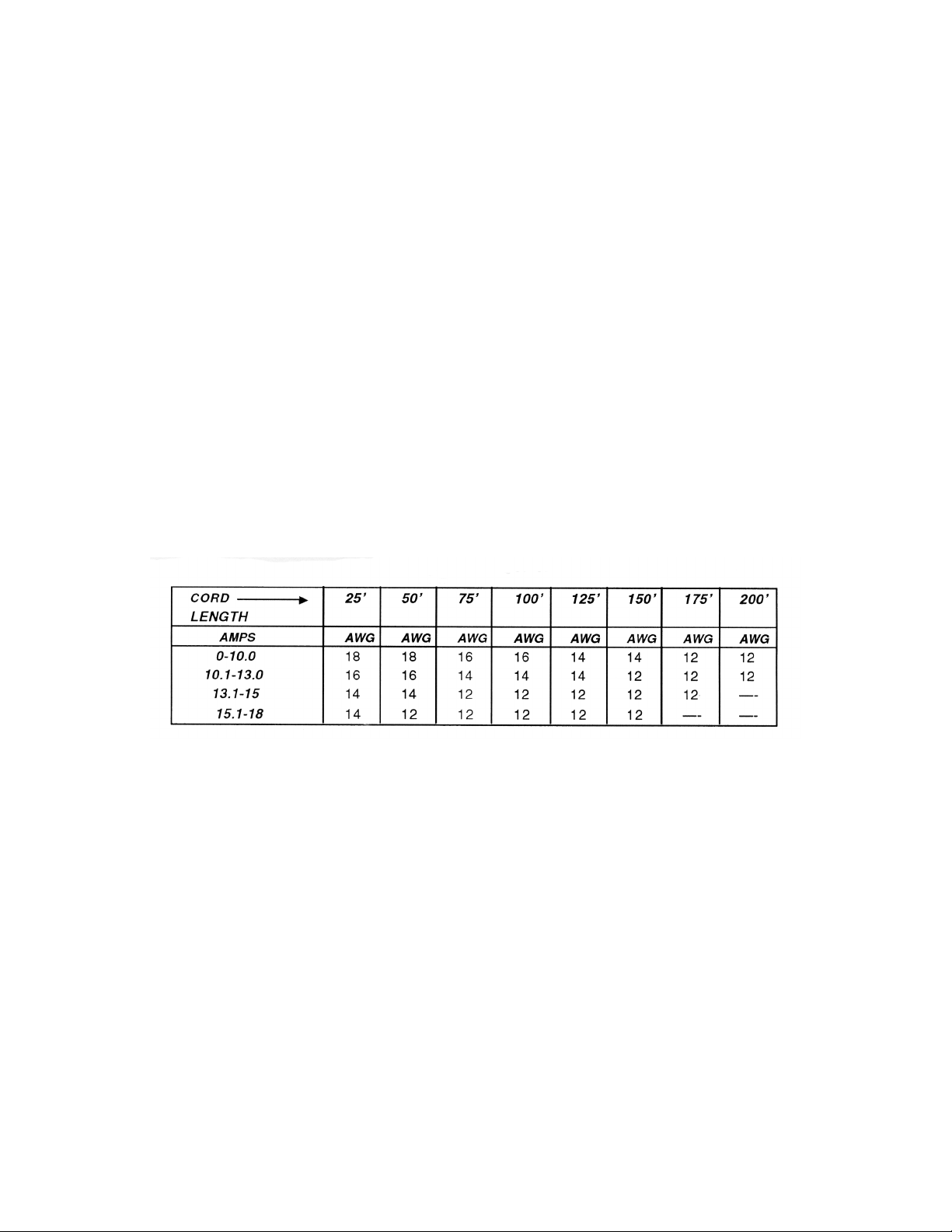

3. IF AN EXTENSION CORD (not provided) IS USED, MAKE SURE TO USE

ONLY UL APPROVED CORDS HAVING THE CORRECT GAUGE AND

LENGTH. (See Figure A.)

AWG RATING CHART - 120 VOLT

FIGURE A

4. KEEP ALL SAFETY GUARDS IN PLACE, IN PROPER ADJUSTMENT, AND IN

PROPER ALIGNMENT.

5. REDUCE THE RISK OF ACCIDENTAL STARTING. Make sure the Forward/Re-

verse Switch (part #125) is in the “OFF” position before plugging the Power Cord/

Plug (part #128) into a grounded, 3-hole, 120 Volt, electrical outlet.

(See Figure B, and Assy. Diagram.)

6. PRIOR TO STARTING THE MICRO MILL/DRILL MACHINE, MAKE SURE ALL

ADJUSTING KEYS AND WRENCHES ARE REMOVED FROM THE TOOL.

7. DO NOT USE ROTARY PLANERS, WIRE WHEELS, OR ROUTER BITS ON

THIS MICRO MILL/DRILL MACHINE.

For technical questions, please call 1-800-444-3353.

Page 4SKU 47158

Page 5

8. BEFORE DRILLING OR CUTTING, TURN ON THE MICRO MILL/DRILL

MACHINE AND CHECK FOR BIT WOBBLE OR MACHINE VIBRATION. If this is

found, turn off the tool and correct the problem before using.

9. SECURE THE WORKPIECE. Whenever possible, secure the workpiece to the

Worktable (part #105) with a vise or clamps. If the workpiece begins to spin, do

not attempt to stop it with your hands. Turn the Micro Mill/Drill Machine OFF, and

wait until the workpiece stops spinning before attempting to remove it.

(See Figure B, and Assy. Diagram.)

10. ALWAYS FEED THE WORKPIECE INTO AND AGAINST THE ROTATIONAL

DIRECTION OF A BIT OR CUTTER.

11. WHEN DRILLING OR CUTTING SOFTER MATERIALS OR SMALL HOLES,

USE THE HIGHER SPEEDS. WHEN DRILLING OR CUTTING HARDER

MATERIALS OR LARGER HOLES, USE THE SLOWER SPEEDS.

12. NEVER LEAVE THE MICRO MILL/DRILL MACHINE UNATTENDED WHEN IT

IS RUNNING. Turn off the tool, and wait until it has completely stopped before

leaving.

13. ALWAYS UNPLUG THE MICRO MILL/DRILL MACHINE FROM ITS

ELECTRICAL SUPPLY SOURCE BEFORE PERFORMING ANY INSPECTION,

MAINTENANCE, OR CLEANING PROCEDURES.

14. WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contain chemicals known (to the State of California)

to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are: lead from lead-based paints, crystalline silica from bricks

and cement or other masonry products, arsenic and chromium from chemically

treated lumber. Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

(California Health & Safety Code 25249.5, et seq.)

15. WARNING: People with pacemakers should consult their physician(s) before

using this product. Operation of electrical equipment in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker.

For technical questions, please call 1-800-444-3353.

Page 5SKU 47158

Page 6

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts Lists on pages 12

and 13 are included. If any parts are missing or broken, please call Harbor Freight Tools

at the number shown on the cover of this manual as soon as possible.

CLEANING, ASSEMBLY, AND MOUNTING INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 14.

To Clean The Micro Mill/Drill Machine:

1. When manufactured, the Micro Mill/Drill Machine has a special rust-proof coating applied to its outer parts and should be removed prior to use. To remove the

coating, use a clean cloth and a mild solvent. Then, lubricate all moving parts

with a premium quality, lightweight machine oil.

To Assemble The Micro Mill/Drill Machine:

1. The Lifting Hand Wheel, Longitudinal Feed Hand Wheel, Cross Feed Hand

Wheel, and Fine Feeding Hand Wheel (parts #97) must be assembled prior to

using the Micro Mill/Drill Machine. The four Wheels are each identical in size and

shape, and must be properly attached to the Worm Shaft (part #61), the Lifting

Screw (part #95), and the two Lengthways Screws (part #111).

(See Figure B, and Assy. Diagram.)

2. To attach the four Wheels (parts #97) to the Micro Mill/Drill Machine, insert one

wheel each onto the end of the Worm Shaft (part #61), the Lifting Screw (part

#95), and the two Lengthways Screws (part #111). Then firmly secure each

Wheel, using one Washer (part #67), and one Top Nut (part #68).

(See Figure B, next page, and Assy. Diagram.)

To Mount The Micro Mill/Drill Machine On A Workbench:

1. CAUTION: Make sure the Micro Mill/Drill Machine is mounted on a flat, level,

sturdy, workbench surface capable of supporting the weight of the Micro Mill/Drill

Machine, additional tools, accessories, and the workpiece.

For technical questions, please call 1-800-444-3353.

Page 6SKU 47158

Page 7

2. NOTE: When mounting the Micro Mill/Drill Machine on a workbench, you will

need four 3/8” diameter bolts of appropriate length, four lock washers, and four

nuts (not provided).

LIFTING HAND WHEEL

(#97)

SPINDLE

BOX

(#24)

FORWARD

OFF

REVERSE

SWITCH

(#125)

VARIABLE

SPEED

KNOB (#122)

WORK

TABLE

(#105)

HIGH/LOW SPEED KNOB

CLUTCH

LEVER (#65)

HAND WHEEL (#97)

(#124)

CLUTCH LEVER

FINE FEEDING

FINE FEEDING

HAND WHEEL

HANDLE SHAFT

(#87)

CHUCK (#132)

LONGITUDINAL FEED

HAND WHEEL

(#97)

LIFTING HAND WHEEL

(#97)

HANDLE

SHAFT

(#87)

(#65)

SPINDLE

BOX

(#24)

(#97)

CHUCK

(#132)

WORK

TABLE

(#105)

CROSS FEED

HAND WHEEL (#97)

LONGITUDINAL FEED

HAND WHEEL (#97)

FIGURE B

3. With assistance, position the Micro Mill/Drill Machine in the desired location on

the top of the workbench. Use the four mounting holes in the Base (part #74) of

the Micro Mill/Drill Machine as a template, and trace with a pencil on the top of

the workbench four 3/8” diameter mounting holes . Then, temporarily remove the

Micro Mill/Drill Machine from the workbench. (See Assy. Diagram.)

4. Where the four pencil marks are located, drill four 3/8” diameter holes completely

through the top of the workbench.

For technical questions, please call 1-800-444-3353.

Page 7SKU 47158

Page 8

5. Then, secure the Micro Mill/Drill Machine to the workbench, using the four 3/8”

diameter bolts of appropriate length, four lock washers, and four nuts as

mentioned in Step #2.

MACHINE ADJUSTMENT INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 14.

To Use The Adjustment Controls:

1. CAUTION: ALWAYS TURN OFF THE MICRO MILL/DRILL MACHINE, UNPLUG

ITS ELECTRICAL POWER CORD/PLUG (part #128), AND WAIT UNTIL IT

COMPLETELY STOPS RUNNING BEFORE MAKING ANY ADJUSTMENTS.

2. To adjust the height of the Spindle Box (part #24) to accommodate the work-

piece being milled/drilled; turn the Lifting Hand Wheel (part #97) clockwise to

raise the Spindle Box, and turn the Lifting Hand Wheel counterclockwise to lower

the Spindle Box. (See Figure B, and Assy. Diagram.)

3. To lower and raise the Chuck (part #132); pull the Handle Shaft (part #87)

down to lower the Chuck. Pull the Handle Shaft up to raise the Chuck.

(See Figure B, and Assy. Diagram.)

4. To adjust the fine feeding mechanism; push in on the Clutch Lever (part #65)

which is located on the Fine Feeding Hand Wheel (part #97). Turn the Fine

Feeding Hand Wheel clockwise to bring the tip of the Chuck (part #132) up. Turn

the Fine Feeding Hand Wheel counterclockwise to bring the tip of the Chuck

down. The Fine Feeding Hand Wheel may be adjusted from 0” to 1-1/4” up or

down. NOTE: For normal, manual feeding, make sure the Clutch Lever is pulled

out. (See Figure B, and Assy. Diagram.)

5. To move the Worktable (part #105)to the front and to the back; turn the

Longitudinal Feed Hand Wheel (part #97) clockwise to position the Worktable

toward the front of the machine. Turn the Longitudinal Feed Hand Wheel

counterclockwise to position the Worktable toward the back of the machine. (See

Figure B, and Assy. Diagram.)

6. To move the Worktable (part #105) to the right and to the left; turn the Cross

Feed Hand Wheel (part #97) clockwise to position the Worktable to the right.

Turn the Cross Feed Hand Wheel counterclockwise to position the Worktable to

the left. (See Figure B, and Assy. Diagram.)

For technical questions, please call 1-800-444-3353.

Page 8SKU 47158

Page 9

7. To turn the machine on/off, and adjust the rotational direction of the Chuck

(part #132); turn the Switch (part #125) from its “OFF” position to its “FORWARD”

position to turn on the machine and for a clockwise rotation of the Chuck. Turn

the Switch from its “OFF” position to its “REVERSE” position to turn on the ma-

chine and for a counterclockwise rotation of the Chuck. To turn off the

machine, turn the Switch to its “OFF” position.

(See Figure B, and Assy. Diagram.)

8. To adjust the speed at which the Chuck (part #132) rotates; First set the

High/Low Knob (part #124) until the letter “L” appears on its dial so that the Mirco

Mill/Drill Machine begins running at its low speed range (100-1,000 RPM). Turn

the Machine on. Note: Adjusting the High/Low Know (part #124) until the letter

“H” appears on its dial, will run the machine at its high speed range (100-2,000

RPM). Once the HIGH or LOW speed range has been set, use the Variable

Speed Knob (part #122) to fine-adjust the RPM at which the Chuck rotates.

NOTE: It is recommended to use a higher speed for softer materials or small

holes. Use a lower speed for harder materials and larger holes. (See Figure B,

and Assy. Diagram.)

OPERATING INSTRUCTIONS

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 14.

1. CAUTION: Make sure the Switch (part #125) on the Micro Mill/Drill Machine is in

its “OFF” position. Then, plug the Power Cord/Plug (part #128) into the nearest

120 volt, grounded, 3-prong electrical outlet. (See Figure B, and Assy. Dia-

gram.)

2. Check to make sure the Handle Shaft (part #87) is in its full “UP” position.

(See Figure B, and Assy. Diagram.)

3. Place the workpiece on the Worktable (part #105) and, if possible, firmly secure the

workpiece to the Worktable with clamps (not provided).

(See Figure B, and Assy. Diagram.)

4. Insert the shank of the drill bit/cutting tool (not provided) all the way up into the

Chuck (part #132). Then, use the Chuck Key to tighten the Chuck onto the drill

bit/cutting tool. NOTE: There are three tightening/loosening holes in the Chuck.

Make sure to use the Chuck Key in all three holes.

(See Figures B, and C.)

For technical questions, please call 1-800-444-3353.

REV 08/03

Page 9SKU 47158

Page 10

(CLOCKWISE TO TIGHTEN. COUNTERCLOCKWISE TO LOOSEN.)

CHUCK (#132)

CHUCK KEY

FIGURE C

5. If necessary, use the Lifting Hand Wheel, Longitudinal Feed Hand Wheel, Cross

Feed Hand Wheel, and Fine Feeding Hand Wheel (parts #97) to adjust the Micro

Mill/Drill Machine for the work to be done. NOTE: Do not attempt to make any

further adjustments while the machine is running.

(See Figure B, and Assy. Diagram.)

6. Set the High/Low Speed Knob (part #124) to the speed range required.

NOTE: Do not attempt to make any further adjustments while the machine is run-

ning. (See Figure B, and Assy. Diagram.)

7. Set the Variable Speed Knob (part #122) to fine-adjust the speed range.

NOTE: Do not attempt to make any further adjustments while the machine is run-

ning. (See Figure B, and Assy. Diagram.)

8. Turn the Switch (part #125) from its “OFF” position to either its “FORWARD” position or its “REVERSE” position, depending on the work to be done. NOTE: Do

not attempt to turn the Switch directly from its “FORWARD” position to its “REVERSE” position, or its “REVERSE” position to its “FORWARD” position, while

the machine is running. To change the rotational direction, turn the Switch to its

“OFF” position. Wait until the machine completely stops. Then, change the rotational direction. (See Figure B, and Assy. Diagram.)

9. After testing the machine in Forward and Reverse position, evaluate the machine’s operation; check for loose or damaged parts, wobbling of the chuck or

any other unusual situation. If the machine appears to be operating normally, the

Micro Mill/Drill Machine is ready to use.

10. Once the work is completed, make sure to turn the Switch (part #125) to its “OFF”

position. Wait until the machine has completely stopped. Unplug the Micro Mill/Drill

Machine from its electrical power source. Remove the workpiece. And re m o v e

the drill bit/cutting tool.

For technical questions, please call 1-800-444-3353.

Page 10SKU 47158

Page 11

INSPECTION, MAINTENANCE, AND CLEANING

NOTE: For additional references to the parts listed below, refer to the Assembly

Diagram on page 14.

1. CAUTION: Always unplug the Power Cord/Plug (part #128) from its 120 volt electrical outlet before performing any inspection, maintenance, or cleaning.

2. BEFORE EACH USE, inspect the general condition of the Micro Mill/Drill Machine. Check for loose screws, misalignment or binding of moving parts, cracked

or broken parts, damaged electrical wiring, and any other condition that may

affect its safe operation. If abnormal noise or vibration occurs, have the problem

corrected before further use. Do not use damaged equipment.

3. DAILY: With a soft brush, cloth, or vacuum, remove all debris from the Micro Mill/

Drill Machine. Then, use a premium quality, lightweight machine oil to lubricate all

moving parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND

ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE

MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY

OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS

TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF

THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF

HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

For technical questions, please call 1-800-444-3353.

Page 11SKU 47158

Page 12

PARTS LIST

Clutch

For technical questions, please call 1-800-444-3353.

Page 12SKU 47158

Page 13

PARTS LIST

Variable Speed

High/Low Speed

Power Cord/

Lengthways

For technical questions, please call 1-800-444-3353.

Page 13SKU 47158

Page 14

ASSEMBLY DIAGRAM

NOTE: Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

For technical questions, please call 1-800-444-3353.

Page 14SKU 47158

Page 15

Green Lamp

SCHEMATIC DIAGRAM

Yellow Lamp

(fault)

Fuse

110V/60Hz

Forward/Off/Reverse

Switch

Potentiometer

Motor

For technical questions, please call 1-800-444-3353.

REV 08/04

Page 15SKU 47158

Page 16

WIRING DIAGRAM

1 2 3 4

A

B

C

D

4321

D

C

B

A

A

B

C

BR

KBL406

D1

FR207

B

D7

IN4007

D6

IN4007

D8

IN4007

D9

IN4007

C1

47uF/25V

C5

47uF/25V

JK2A

JK1A

JK3A

Vin

GND

+12V

7812

C12

100uF/50V

C11

100uF/50V

-12V

+12V

R2

10K

R3

220K

U4

TIL113

D3

IN4007

R8

68K

D4

DW18V

C4

47uF/25V

R42

470

D2

IN4007

C2

473/250V

R5

100K

R4

100

-

+

U5B

LM324

-

+

U5A

LM324

JK3B

DEG-12VDC

C6

220uF/25V

D10

IN4007

D11

IN4007

R49

220K

R50

24K

R45

12KVR1

3296-503

VR2

3296-503

C15

105

R46

33K

R47

47K

R1

0.33

+12V

-12V

-12V

+12V

VR

10D681

R2-2

12K

R9

1.8K

JK2B

+12V

Vin

GND

-12V

7912

P1 P4

AC3 AC4

5

6

7

Q1

MTW-20N50E

470

FT2813-220-15DP

L

DEG-12VDC

DEG-12VDC

DC2

U3

TIL113

DC1

JK1B

D5

IN4007

KG

For technical questions, please call 1-800-444-3353.

REV 07/06

Page 16SKU 47158

Loading...

Loading...