Page 1

TIRE CHANGER

Model

45656

SEMI-AUTOMATIC

OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2001 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Revised cover 07h

Page 2

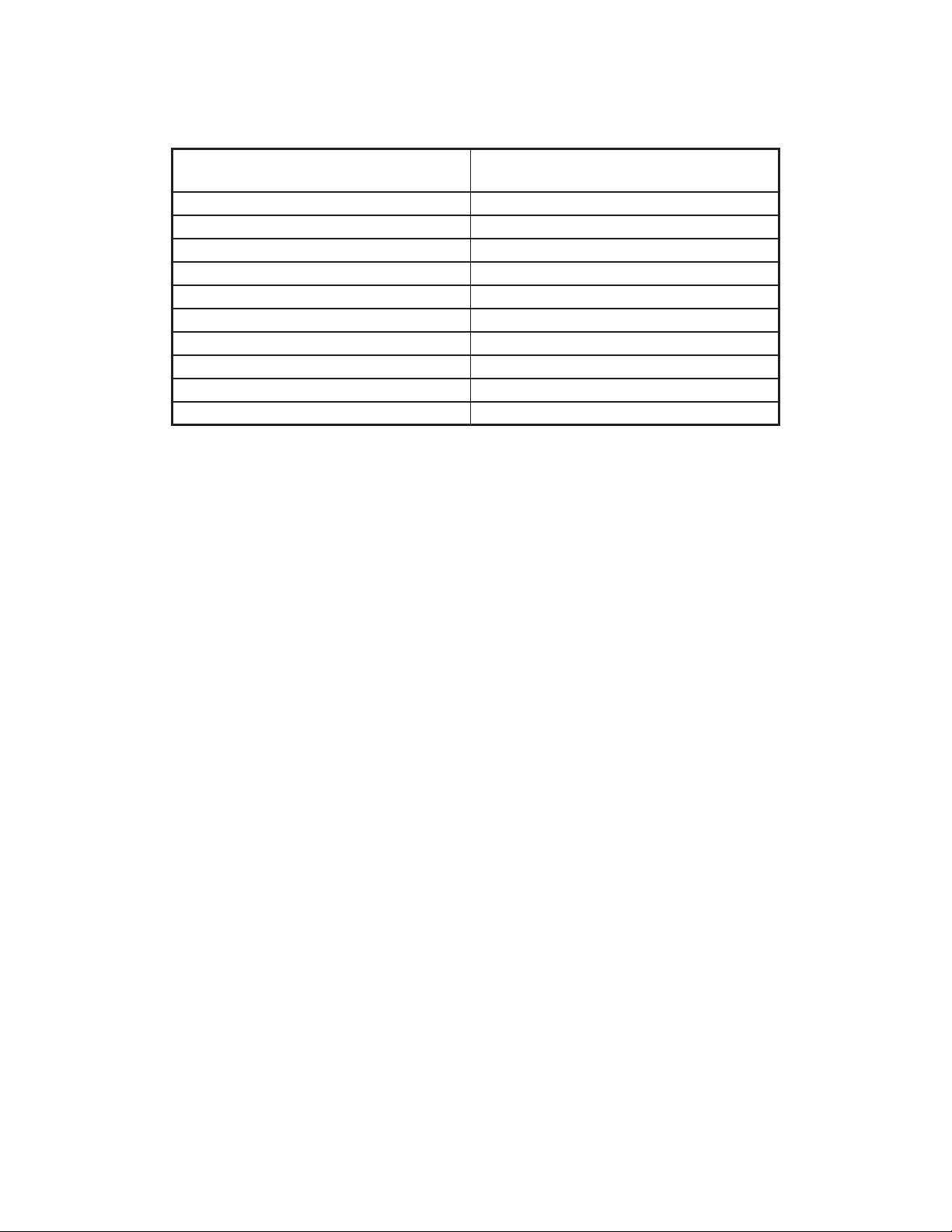

SPECIFICATIONS

Electrical Requirements 220 V~ / 60 Hz / 10.5 A

1 HP Motor / 1740 RPM / 1 Phase

Max. Wheel Diameter 39”

Max. Rim Diameter 10”-20”

Max. Wheel Width 13”

External Locking Rim Dimensions 10”-18”

Internal Locking Rim Dimensions 12”-20”

Max. PSI Working Pressure 110 PSI

Bead Break Force 2500 kg

Max. Rotation Torque (Turntable) 795 ft-lb

Air Inlet Fitting Size 1/4” NPT

Shipping Weight 471 lb.

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly,

operating, maintenance procedures, and parts lists/ assembly diagrams. Keep your

invoice with this manual. Write the invoice number on the inside of the front cover.

Keep this manual and invoice in a safe and dry place for future reference.

SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be

stored in a dry location to inhibit rust. Always lock up tools and equipment and

keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgment or

reexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this tool.

5. USE EYE AND HEARING PROTECTION. Wear ANSI approved safety impact

eye glasses and ANSI approved hearing protection when working with this

Page 2SKU 45656 For technical questions, please call 1-800-444-3353.

Page 3

product. ANSI approved safety impact eye glasses and hearing protectors are

available from Harbor Freight Tools.

6. DRESS SAFELY. Non-skid footwear or safety shoes should be used when

working with this product. Do not wear loose clothing or jewelry as they can

become caught in moving parts. Wear a protective hair covering to prevent long

hair from becoming caught in moving parts.

7. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENTS.

8. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do

not use this tool when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check

that this tool will operate properly and perform its intended function. Check for

damaged parts and any other conditions that may affect the operation of this tool.

Replace or repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this tool clean and dry for better

and safer performance.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualied technician.

14. USE THE RIGHT PRODUCT FOR THE RIGHT JOB. There are certain

applications for which this product was designed. Do not use a small tool or

attachment to do the work of a larger industrial tool or attachment. Do not use

this product for a purpose for which it was not intended.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. ALWAYS DISCONNECT THE TIRE CHANGER FROM ITS AIR SUPPLY

SOURCE. PUMP THE BEAD BREAKER PEDAL (26E) SEVERAL TIMES

TO EVACUATE ALL COMPRESSED AIR FROM THE MACHINE, AND

DISCONNECT THE UNIT FROM ITS ELECTRICAL SUPPLY SOURCE

BEFORE PERFORMING ANY SERVICES OR MAINTENANCE.

Page 3SKU 45656 For technical questions, please call 1-800-444-3353.

Page 4

(SEE FIGURES A, B, E, AND ASSY. DIAGRAM E.)

2. USE CLEAN, DRY, REGULATED COMPRESSED AIR AT UP TO 110 PSI. Do

not exceed the recommended maximum of 110 PSI. Never use oxygen, carbon

dioxide, combustible gases or any other bottled gas as a power source for this

tool.

3. WHEN CONNECTING TO THE AIR SUPPLY:

A. Wrap approximately 4” of Teon tape around the male threads of a Quick

Connector (not provided). Then, wrench tighten the Quick Connector into the

Pressure Regulator (5F). (See Figures A, C, and E.)

B. If an automatic oiler is not used, add two drops of oil into the Quick Connector

of the Pressure Regulator (5F).

Page 4SKU 45656 For technical questions, please call 1-800-444-3353.

Page 5

C. Turn on the compressor and set the regulator to the pressure recommended

for this tool (up to 110 PSI).

4. DO NOT INFLATE A TIRE ABOVE OR BELOW THE AIR PRESSURE

RECOMMENDED BY THE TIRE MANUFACTURER.

5. ALWAYS DISPOSE OF OLD TIRES IN ACCORDANCE WITH LOCAL, STATE,

AND FEDERAL LAWS.

6. IF YOU USE AN EXTENSION CORD, MAKE SURE TO USE ONLY UL

APPROVED CORDS HAVING THE CORRECT GAUGE AND LENGTH.

(SEE FIGURE D.)

Nameplate

Amperes

0 - 5 16 16 16 14 12 12

5.1 - 8 16 16 14 12 10 -

8.1 - 12 14 14 12 10 - -

12.1 - 15 12 12 10 10 - -

15.1 - 20 10 10 10 - - -

7. TO AVOID PERSONAL INJURY AND/OR PRODUCT DAMAGE, ALWAYS

MAKE SURE THE TIRE RIM IS FIRMLY SECURED ON THE TIRE CHANGER

WITH THE JAWS (17C). (SEE FIGURE E AND ASSY. DIAGRAM C.)

8. NEVER PLACE YOUR HANDS BETWEEN THE VEHICLE WHEEL RIM AND

THE JAWS (17C) DURING THE LOCKING/CLAMPING STAGE. (SEE FIGURE

E AND ASSY. DIAGRAM C.)

9. WARNING: This product contains or produces a chemical known to the State of

California to cause cancer and birth defects (or other reproductive harm).

(California Health & Safety Code 25249.5 et seq.)

25’ 50’ 75’ 100’ 150’ 200’

Extension Cord Length

FIGURE D

Page 5SKU 45656 For technical questions, please call 1-800-444-3353.

Page 6

UNPACKING

When unpacking, check to make sure all parts shown on the Parts Lists/Assembly

Diagrams (pages 17 through 22) are included. If any parts are missing or broken,

please call Harbor Freight Tools at the number shown on the cover of this manual as

soon as possible.

PRODUCT DESCRIPTION

Prior to using the Tire Changer, it is recommended that you study and familiarize

yourself with the main components of the unit. (See Figure E.)

Page 6SKU 45656 For technical questions, please call 1-800-444-3353.

Page 7

ASSEMBLY INSTRUCTIONS

NOTE: All parts below refer to the parts listed on pages 17 through 22 of this

manual.

1. Temporarily remove the four mounting Bolts, Washers, and Nuts located at the

top/rear of the Body Assembly. (See Figure F.)

2. Set the column (C) on the body assembly (B) insuring the threaded studs line up

with the mounting holes on the bottom of the column mounting ange. Secure

the column to the body with the nuts and washers (A) provided.

3. Pneumatic Hook Up: Connect the ination gun to its connector. Connect the tire

changer to a compressed air network using the connector which is on the airwater separator (D) located right side of the base assembly.

4. Electric at connection: Before making any electric link up, check to be certain

that the main voltage corresponds to what is stamped on the voltage tag. It is

absolutely essential that the system is equipped with a good grounding circuit.

5. WARNING: The Tire Changer requires the assembly of a UL, CSA, or CE listed,

220 Volt, 3-Prong Electrical Plug (not provided) onto the unit’s electrical power cord.

The National Electric Code requires that the GREEN wire on the unit must be used

as the GROUND wire. The “HOT” wires on the power cord are the BLACK and

WHITE wires. Do not attempt to alter the 220 Volt, 3-Prong Plug or its assembly to

the power cord (as mentioned above) in any way. In addition, it is recommended

that this assembly procedure be carried out by a qualied technician.

Page 7SKU 45656 For technical questions, please call 1-800-444-3353.

Page 8

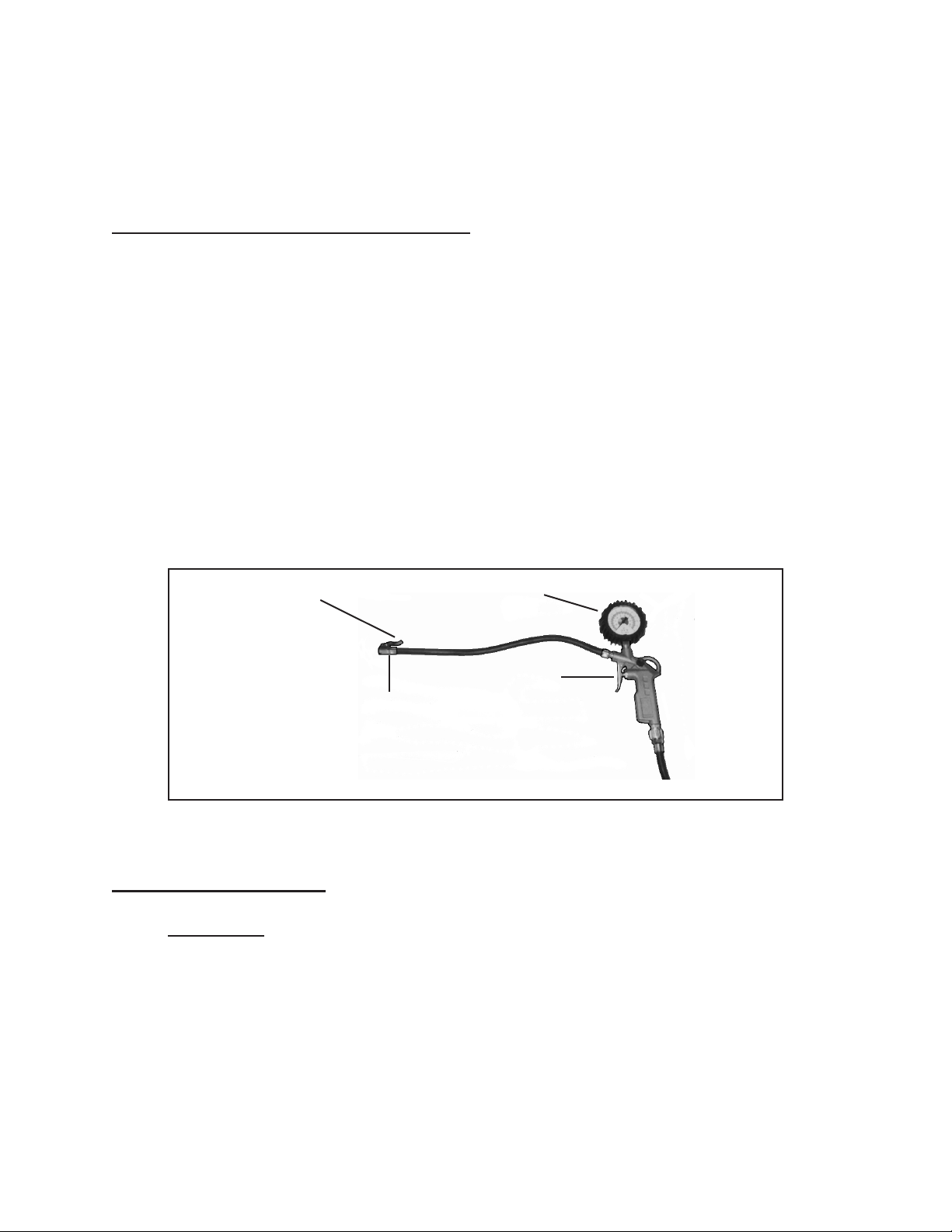

OPERATING INSTRUCTIONS

LOCKING

LEVER

NOZZLE

AIR GAUGE

(#4F)

TRIGGER

FIGURE G

NOTE: All parts below refer to the parts listed on pages 17 through 22 of this

manual.

To Perform Preliminary Operating Tests:

Connect the Tire Changer to its air and electrical supply sources, and allow 1.

adequate time for the compressed air system to reach the recommended 110

PSI. (See Figures A, C, D, and E.)

When the Reverse Pedal (59E) is fully depressed, the Turntable (1C) should turn 2.

in a clockwise direction. (See Figures B and E.)

When the Reverse Pedal (59E) is raised, the Turntable (1C) should turn in a 3.

counterclockwise direction.

Press the Bead Breaker Pedal (26E) to activate the Paddle (7B). When the 4.

Pedal is released, the Paddle should return to its original position.

Press the Jaw Clamp Pedal (26E) once to open the four Jaws (17C). Press the 5.

Pedal again to close the Jaws.

6. Press the Trigger on the Air Gauge (4F) to release air from the Nozzle. (See

Figure G.)

To Break The Tire Bead:

1. WARNING: Before carrying out this procedure, deate the tire fully, and remove

all the wheel weights.

2. Position the wheel against the rubber Buffers (39B) located on the front/left side

of the Tire Changer. (See Figure E and Assy. Diagram B.)

3. Position the Paddle (7B) against the tire bead at a distance of about 1/2” from the

tire rim. (See Figures E and H.)

REV 05/05

Page 8SKU 45656 For technical questions, please call 1-800-444-3353.

Page 9

PADDLE

(#7B)

TIRE BEAD

WHEEL

FIGURE H

4. Depress the Bead Breaker Pedal (26E) fully to activate the Paddle (7B). Release

pressure on the Bead Breaker Pedal when the Blade has reached the end of its

travel and/or when the tire bead is broken.

(See Figures B, E, and H.)

5. Rotate the tire slightly, and repeat the procedure around the entire circumference

of the wheel rim until the bead is completely detached from the rim.

6. Repeat the above Steps for the other side of the wheel/tire.

To Remove The Tire From The Wheel:

1. WARNING: Before carrying out this procedure, deate the tire fully, and remove

all the wheel weights.

2. Spread tire grease (or a similar lubricant) liberally on the complete circumference

of the broken tire bead. NOTE: Failure to lubricate the tire bead may cause

serious damage to the bead.

3. Place the wheel/tire evenly on the Turntable (1C). (See Figure E.)

4. To lock the wheel on the Turntable (1C), proceed as follows according to the

wheel rim size:

Rims from 10” to 18”: Position the four Jaws (17C) according to the reference

mark located on the Turntable (1C) by depressing the Jaw Clamp Pedal (26E)

halfway down. (See Figures B and E.)

Page 9SKU 45656 For technical questions, please call 1-800-444-3353.

Page 10

Place the wheel on the four Jaws (17C) and, while keeping the wheel rim

TOOLS SHAFT

(#13A)

MOUNTING

HEAD (#15A)

LEVER (#1F)

FIGURE I

pressed down, depress the Jaw Clamp Pedal (26E) as far down as it will go.

Check to make sure the wheel is rmly secured by the Jaws (17C).

Rims from 12” to 20”: Position the four Jaws (17C) so that they are completely

closed.

Place the wheel on the four Jaws (17C) and depress the Jaw Clamp Pedal (26E)

to open the Jaws, thereby locking the wheel rim in place.

Check to make sure the wheel is rmly secured by the Jaws (17C).

5.

Lower the Tools Shaft (13A) until the Mounting Head (15A) rests next to the

wheel rim and on top of the tire. Then, lock the Tools Shaft in position, using the

Block Support (7A). (See Figures E and I.)

6. Insert the Lever (1F) between the tire bead and the front section of the Mounting

Head (15A). (See Figures E and I.)

7. Move the tire bead over the Mounting Head (15A) by pulling upward on the

Reverse Pedal (59E). NOTE: To avoid damaging the inner tube (if there is one),

it is recommended to perform this Step with the inner tube valve stem positioned

about 1” to the right of the Mounting Head. (See Figures B and I.)

8. With the Lever (1F) held in position, rotate the Turntable (1C) in a clockwise

direction by fully depressing the Reverse Pedal (59E). Continue until the tire is

completely separated from the wheel rim.

9. Remove the inner tube (if there is one), and repeat the above Steps for the other

side of the wheel/tire.

Page 10SKU 45656 For technical questions, please call 1-800-444-3353.

Page 11

To Mount The Tire Onto The Wheel Rim:

TOOLS SHAFT

(#13A)

MOUNTING

HEAD (#15A)

FIGURE J

1. WARNING: Before carrying out this procedure, deate the tire fully, and remove

all the wheel weights.

2. Spread tire grease (or a similar lubricant) liberally on the complete circumference

of the tire bead to avoid damage to the tire and to facilitate the mounting

procedure.

3. Lock the wheel rim, using the inner part of the Jaws (17C). (See Figure E.)

4. NOTE: When you are working with wheel rims of the same size, it is not always

necessary to lock and unlock the Tools Shaft (13A). Instead, move the Swinging

Arm (5A) sideways with the Tools Shaft locked.

(See Figure E.)

5.

Move the tire so that the bead passes below the front section of the Mounting

Head (15A) and is brought up against the edge of the rear section of the

Mounting Head. (See Figure J.)

6. Keep the tire bead pressed down into the wheel rim channel with your hands.

Then, depress the Reverse Pedal (59E) to rotate the Turntable

(1C) clockwise. Continue this process throughout the entire circumference of the

wheel and tire. (See Figures B and E.)

7. Insert the inner tube (if there is one).

Page 11SKU 45656 For technical questions, please call 1-800-444-3353.

Page 12

8. Repeat the Steps above the mount the other side of the tire.

VALVE

LOCKING LEVER

FIGURE K

AIR GAUGE NOZZLE

(#4F)

To Inate The Tire:

1. WARNING: A burst tire can cause serious injury or even death to the operator.

Always make sure the wheel rim and the tire are of the same size. Check

the condition of the tire, and make sure it has no defects before beginning

the ination process. Keep your hands and body as far away from the tire as

possible. Inate the tire with brief jets of air, checking the air pressure frequently.

Never inate a tire above or below the air pressure recommended by the tire

manufacturer.

2.

To inate the tire, attach the Air Gauge Nozzle (4F) to the tire valve stem with the

Locking Lever in the “UP” position. Check to make sure the Nozzle is pressed

down completely over the threads of the valve stem. (See Figures G and K.)

3. When the Air Gauge Nozzle (4F) is rmly in place, press the Locking Lever down

to lock onto the valve stem.

4. Remember to Inate the tire with brief jets of air, checking the air pressure

frequently. Once the proper air pressure has been reached, disconnect the

Nozzle from the valve stem and screw a valve cap onto the stem.

Page 12SKU 45656 For technical questions, please call 1-800-444-3353.

Page 13

CLEANING AND MAINTENANCE

1. WARNING: Always disconnect the Tire Changer from its air supply source.

Pump the Bead Breaker Pedal (26E) several times to evacuate all compressed

air from the machine, and disconnect the unit from its electrical supply source

before performing any services or maintenance.

(See Figures A, B, and E.)

2. Before each use, inspect the general condition of the Tire Changer. Check for

loose screws, misalignment, binding of moving parts, broken parts, loose or

damaged air supply hose/electric power cord, and any other condition that may

affect its safe operation. If abnormal noise or vibration occurs, disconnect the

Tire Changer from its air and electric supply sources immediately and have the

problem corrected before further use. Do not use damaged equipment. (See

“Troubleshooting” guide.)

3. At least once per week, clean the Turntable (1C) with detergent or a

nonammable solvent. Also, grease the Jaw Guides (17C).

4. At least once per month, check the oil level in the Lubricator Tank. If necessary,

remove the Oil Cap, ll the Tank with SAE 30 oil, and replace the Oil Cap. Also,

make sure that one drop of oil is injected into the Tank every 3-4 times the Bead

Breaker Pedal (26E) is depressed. If necessary, regulate the rate of oil injection

with the Oil Regulator Screw. (See Figures B, E, and L.)

5. After the rst 20 days of use, retighten the Jaws Tightening Screws (14C) and

the Screws (10C) located on the Turntable Slides. (See Figure E, and Assy.

Diagram C.)

Page 13SKU 45656 For technical questions, please call 1-800-444-3353.

Page 14

6. In the event of a loss of power, check to see if the Belt (16D) is tight. To do

so, remove the Side Cover (33B), which is located on the left side of the Body

Assembly, by unscrewing the four Screws. Tighten the Belt, using the Adjusting

Screw located on the Motor Support. (See Figures F, M, and Assy. Diagram D.)

7. In the event the Block Support (7A) doesn’t lock the Tools Shaft (13A) in place, or

the Mounting Head (15A) doesn’t rise at least 1/8” above the wheel rim which is

necessary for working, adjust the Nuts as shown in Figure N.

Page 14SKU 45656 For technical questions, please call 1-800-444-3353.

Page 15

8.

FIGURE O

AIR HOSE (#40E)

CENTER

CHUCK VALVE (#28E)

SILENCER (#36E)

To clean or replace the Center Chuck Valve (28E), remove the Side Cover (33B),

which is located on the left side of the Body Assembly, by unscrewing the four

Screws.

(See Figure E, F, O, and Assy. Diagram B.)

9. Remove the Air Hoses (40E) from the Center Chuck Valve (28E).

10. Clean the Center Chuck Valve (28E), using a jet of compressed air. Or if

necessary, replace the unit.

11. For cleaning or replacing the Bead Breaker Valve (41E), follow Steps #8, 9, and

10 above. (See Figure O, and Assy. Diagram E.)

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER

NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND

TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE

PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF

HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

PLEASE READ THE FOLLOWING CAREFULLY

Page 15SKU 45656 For technical questions, please call 1-800-444-3353.

Page 16

TROUBLESHOOTING GUIDE

Turntable rotates in only one direction.

Reverse Pedal (59E) broken. Check entire Reverse Assembly.

Turntable does not rotate.

Belt (16D) broken. Replace Belt

Reverse Pedal (59E) broken. Check entire Reverse Assembly.

Problem with Motor (10D). Check for loose wires in the Motor,

Plug, or Socket. Replace Motor.

Turntable locks while mounting/removing tire.

Belt loose. Adjust Belt Tension.

Jaws (17C) slow to open/close.

Silencer (36 E) clogged. Clean or replace Silencer.

Turntable does not lock the wheel rim correctly.

Jaws worn. Replace Jaws.

Defective Piston (26C). Replace Plate Cylinder Gaskets (23C).

Tool touches the wheel rim during tire mounting/removing process.

Locking Plate (12C) incorrectly Adjust, or replace Locking Plate.

adjusted or defective.

Plate Locking Screw (14C) loose. Tighten Screw.

Bead Breaker Pedal and Jaw Clamp Pedal lock out of position.

Return Spring (24E) broken. Replace Spring.

Bead breaking operation difcult.

Silencer (36E) clogged. Clean, or replace Silencer.

Valve Shaft O-Ring (31E) broken. Replace O-Ring.

WARNING:

For your safety, major service and repair procedures should be performed by a qualied

technician. Replace or repair damaged or worn parts immediately. Use only identical

replacement parts. Only use accessories intended for use with this product. Approved

accessories are available from Harbor Freight Tools.

Page 16SKU 45656 For technical questions, please call 1-800-444-3353.

Page 17

PARTS LIST/ASSEMBLY DIAGRAM A

NOTE: When referring to the parts listed/shown below, include the letter “A” after

the part numbers. Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Part Description

1A Arm Pin

2A Washer

3A Nut

4A Hand Grid Adjuster

5A Swinging Arm

6A Locking Block

7A Locking Block Support

8A Hand Grid Adjuster

9A Cap

10A Cover

11A Spring

Part Description

12A Locking Plate

13A Tools Shaft

14A Bushing

15A Mounting Head

16A Pulley

17A Pin

18A Washer

19A Column

20A Protection sheet1

21A Protection sheet 2

22A Mounting head complete

Page 17SKU 45656 For technical questions, please call 1-800-444-3353.

Page 18

PARTS LIST/ASSEMBLY DIAGRAM B

NOTE: When referring to the parts listed/shown below, include the letter “B” after

the part numbers. Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Part # Description Part # Description

1B Front panel 19B Seeger ring

2B Body 20B Spring

3B Side cover 21B Rubber ring

4B Nut 22B Rubber support

5B Washer 23B Screw

6B Screw 24B Arm

7B Cylinder body 25B Screw

8B Fitting 26B Washer

9B V-seal 27B Shovel

10B Piston 28B Hand grid

11B Washer 29B Rubber support

12B V-seal 30B Screw

13B O-ring 31B Rubber support

14B Lid 32B Rotating pin

15B Bead-breaker rod 33B Nut

16B L-union 1/4” 34B Oil box

17B Screw 35B Complete Cylinder

18B Pin 36B Safety valve

Page 18SKU 45656 For technical questions, please call 1-800-444-3353.

Page 19

PARTS LIST/ASSEMBLY DIAGRAM C

NOTE: When referring to the parts listed/shown below, include the letter “C” after

the part numbers. Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Part Description

1C Turn Table

2C Control Plate

3C Connecting Rod

4C Bushing

5C Seeger Ring

6C Seeger Ring

7C Washer

8C Distributor

9C Washer

10C Screw

12C Plate

13C Washer

14C Screw

16C Slide

17C Jaw

18C U-Bolt

19C Piston Assembly

20C Lid

21C Screw

Part Description

22C Front Bottom

23C Gasket

24C Nut

25C Washer

26C Piston

27C Cylinder Barrel

28C Stem

29C V Gasket

31C Rear Bottom

32C Fitting

33C Tightener

34C Nut

35C Fitting

36C Fitting

37C Fitting

38C Screw

40C Gasket

41C Shaft Sleeve

42C Bolt M8x15

REV 08l

Page 19SKU 45656 For technical questions, please call 1-800-444-3353.

Page 20

PARTS LIST/ASSEMBLY DIAGRAM D

NOTE: When referring to the parts listed/shown below, include the letter “D” after

the part numbers. Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Part Description

1D Gearbox Assembly

5D Washer

6D Screw

10D Motor

11D Washer

12D Nut

13D Cable

14D Pulley

15D Locking Screw

16D Belt

17D Key

18D Pulley

19D Washer

Part Description

21D Bottom Cover

23D Bearing

26D Ring Gear

27D Washer

28D Bearing

29D Screw

30D Upper Cover

32D Oil Plug

34D Gasket

35D Bearing

36D Worm Screw

38D Gasket

Page 20SKU 45656 For technical questions, please call 1-800-444-3353.

Page 21

PARTS LIST E

NOTE: When referring to the parts listed/shown below, include the letter “E” after

the part numbers. Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Part Description

2E Screw

5E Switch Support

6E Screw

8E Washer

9E Spring

10E Connecting Rod

11E Switch Lever

12E Nut

13E Screw

14E Screw

15E Seeger Ring

16E Washer

17E Wire Holder

18E Cord

19E Switch Cover

20E Switch

21E Feed Cord

22E Complete Switch

23E Complete Pedal

24E Spring

25E Frame

26E Jaw Clamp/Bead Breaker Pedals

27E Pedal Shaft

28E Complete Valve (Center Chuck)

31E O-Ring

32E Valve Shaft

Part Description

33E Spacer

34E Screw

36E Silencer

37E Connector

38E L-Union

39E Valve Block

40E Air Hose

41E Complete Valve (Bead Break)

42E Pin

43E Valve Shaft

44E Valve Block

45E T-Union

46E Connector

47E Air Hose

48E Air Hose

49E Nut

50E Washer

51E Screw

52E Washer

53E Connecting Rod

54E Screw

55E Control Cover

56E Cam

57E Spring

58E Nut

59E Reverse Pedal

PARTS LIST F

NOTE: When referring to the parts listed below, include the letter “F” after

the part numbers. Some parts listed below may not be available individually

as replacement parts.

Part Description

1F Bead Lifting Lever

2F Water Separator/Lubricator

3F Inating Hose

4F Inating Hose w/Gauge

5F Pressure Regulator

Page 21SKU 45656 For technical questions, please call 1-800-444-3353.

REV 03/03

Page 22

ASSEMBLY DIAGRAM E

REV 03/03

Page 22SKU 45656 For technical questions, please call 1-800-444-3353.

Page 23

PNEUMATIC SCHEMATIC

Page 23SKU 45656 For technical questions, please call 1-800-444-3353.

Page 24

GRAPHIC OPERATING (DEMOUNTING)

1. Deate the tire fully!!! Open

the bead breaker arm by hand by

pushing it towards the outside. Place

the wheel up against the Rubber

Buffer. Bring the Paddle against the

bead about 10mm from the edge of

the rim.

2. Depress the bead breaker pedal

fully to activate the paddle. Release

pressure on the bead breaker pedal.

When the blade has reached the

end of its travel and / or when the

tire bead is broken.

Rotate the tire slightly, and repeat

the procedure around the entire

circumference of the wheel rim until

the bead is completely detached

from the rim.

3. Lock the wheel on the turntable

by depressing the jaw clamp pedal.

4. Lower the tools shaft until the

mounting head rests next to the

wheel rim and on top of the tire.

Then, lock the tools shaft in position,

using the block support.

5. With the mounting head in

position, spread tire grease (or a

similar lubricant) liberally on the

complete circumference of the

broken tire bead.

6. Insert the lever between the tire

bead and the front section of the

mounting head.

Page 24SKU 45656 For technical questions, please call 1-800-444-3353.

Page 25

7. Then…

8. Move the tire bead over the

mounting head.

9. With the lever (or hands) held

in position, rotate the turntable

in a clockwise direction by fully

depressing the reverse pedal.

10. Continue until the tire is

completely separated from the wheel

rim. And remove the inner tube (if

there is one).

11. Insert the lever between the

other side of the tire bead and

the front section of the mounting

head. Move the tire bead over the

mounting head.

12. Repeat the above steps for the

other side of the tire.

Page 25SKU 45656 For technical questions, please call 1-800-444-3353.

Page 26

GRAPHIC OPERATING (MOUNTING)

1. Lock the wheel rim, using the inner

part of the jaws.

4. When you are working with

wheel rims of the same size, it is

not always necessary to lock and

unlock the tools shaft. Instead, move

the swinging arm sideways with the

tools shaft locked.

2. Put the tire on the rim.

bead passes below the front section

of the mounting head and is brought

up against the edge of the rear

section of the mounting head.

3. Lower the tools shaft until the

mounting head rests next to the

wheel rim and on top of the tire.

Then, lock the tools shaft in position,

using the block support.

6. Look from the other side.5. Move the tire so that the nether

Page 26SKU 45656 For technical questions, please call 1-800-444-3353.

Page 27

7. Rotate the turntable in a clockwise

direction by fully depressing the

reverse pedal.

8. Continue until the nether bead of

the tire is completely onto the wheel

rim.

9. Insert the inner tube (if there is

one). And spread tire grease (or

a similar lubricant) liberally on the

complete circumference of the tire

bead.

10. Move the tire so that the bead

passes below the front section of

the mounting head and is brought up

against the edge of the rear section

of the mounting head.

11. Keep the tire bead pressed

down into the wheel rim channel

with your hands (or the lever). Then,

depress the reverse pedal to rotate

the turntable clockwise.

12. Continue this process throughout

the entire circumference of the wheel

and tire.

Page 27SKU 45656 For technical questions, please call 1-800-444-3353.

Page 28

13. If the tire has locked in above

step, pull the reverse pedal up to

rotate the turntable counterclockwise

to unlock it. Check the wheel rim and

the tire are of the same size. And try

again.

14. Unlock the tools shaft, move the

swinging arm sideways.

15. Inate the tire with brief jets of air!!

Checking the air pressure frequently.

Once the proper air pressure has

been reached, disconnect the nozzle

from the valve stem and screw a

valve cap onto the stem.

Page 28SKU 45656 For technical questions, please call 1-800-444-3353.

Loading...

Loading...