Page 1

MINI VERMINI VER

®

MINI VER

MINI VERMINI VER

DRILLING MACHINEDRILLING MACHINE

DRILLING MACHINE

DRILLING MACHINEDRILLING MACHINE

TICAL MILLING/TICAL MILLING/

TICAL MILLING/

TICAL MILLING/TICAL MILLING/

44991

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2000 by Harbor Freight Tools®. All rights reser ved. No portion of

this manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

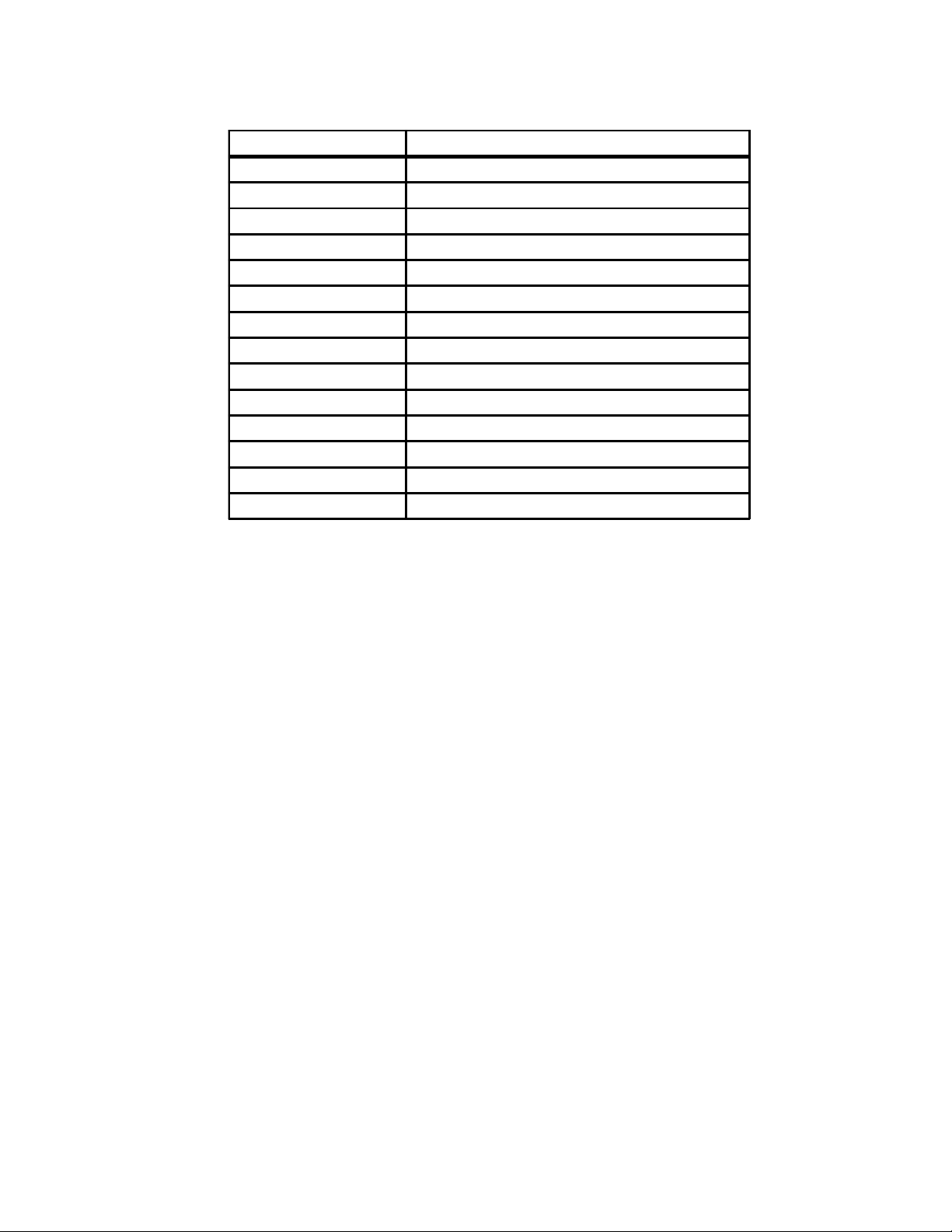

Specifications

ITEM DESCRIPT IO N

Power Consumpt ion 120 VAC, 60 Hz, single phase

Motor 4/5 HP

Speed Ranges 0 ~ 1100 low RPM and 0 ~ 2500 high RPM

Spindle R-8 Taper

Chuck JT33 Taper; 7/64 to 1/2 i nch capacity

End Mill Capacity 1/2 inch

Face Mill Capacity 1 inch

Drill Capacity 1/2 inch

Micro Feed Scale 0.002 inch per line

Depth Scale 0 to 12 inches in 1/16 inch increments

Table Slot W idth 1/2 inch

Table Size 15-7/8 (L) x 3-11/16 (W) inches

Unit Height 33-11/16 inches

Weight 115 lbs.

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

Page 2SKU 44991

Page 3

6. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this tool

was designed. Do not modify this tool and do not use this tool for a purpose for which

it was not intended.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings. Wear an ANSI approved dust

mask or respirator when working around metal and chemical dusts and mists.

9. Do not overreach. Keep proper f ooting and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

11. Disconnect power. Unplug tool when not in use.

12. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

13. Avoid unintentional starting. Be sure the switch is in the Off position when not in

use and before plugging in.

14. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

15. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be proper ly repaired or replaced by a qualified

technician. Do not use the tool if any switch does not turn On and Off properly.

16. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

17. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor

Freight Tools.

18. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

19. Use proper size and type extension cord. If an extension cord is required, it must be

Page 3SKU 44991

Page 4

of the proper size and type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or cause electrical damage to

the tool. This tool requires use of an extension cord of 0 to 10 amps capability (up to

50 feet), with wire size rated at 18 AWG. Longer extension cords require larger size

wire. If you are using the tool outdoors, use an extension cord rated for outdoor use.

(signified by “WA” on the jacket).

21. Maintenance. For your saf ety, service and maintenance should be performed

regularly by a qualified technician.

Note: P erformance of this tool (if powered by line v oltage) may vary depending on varia-

tions in local line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied b y the operator.

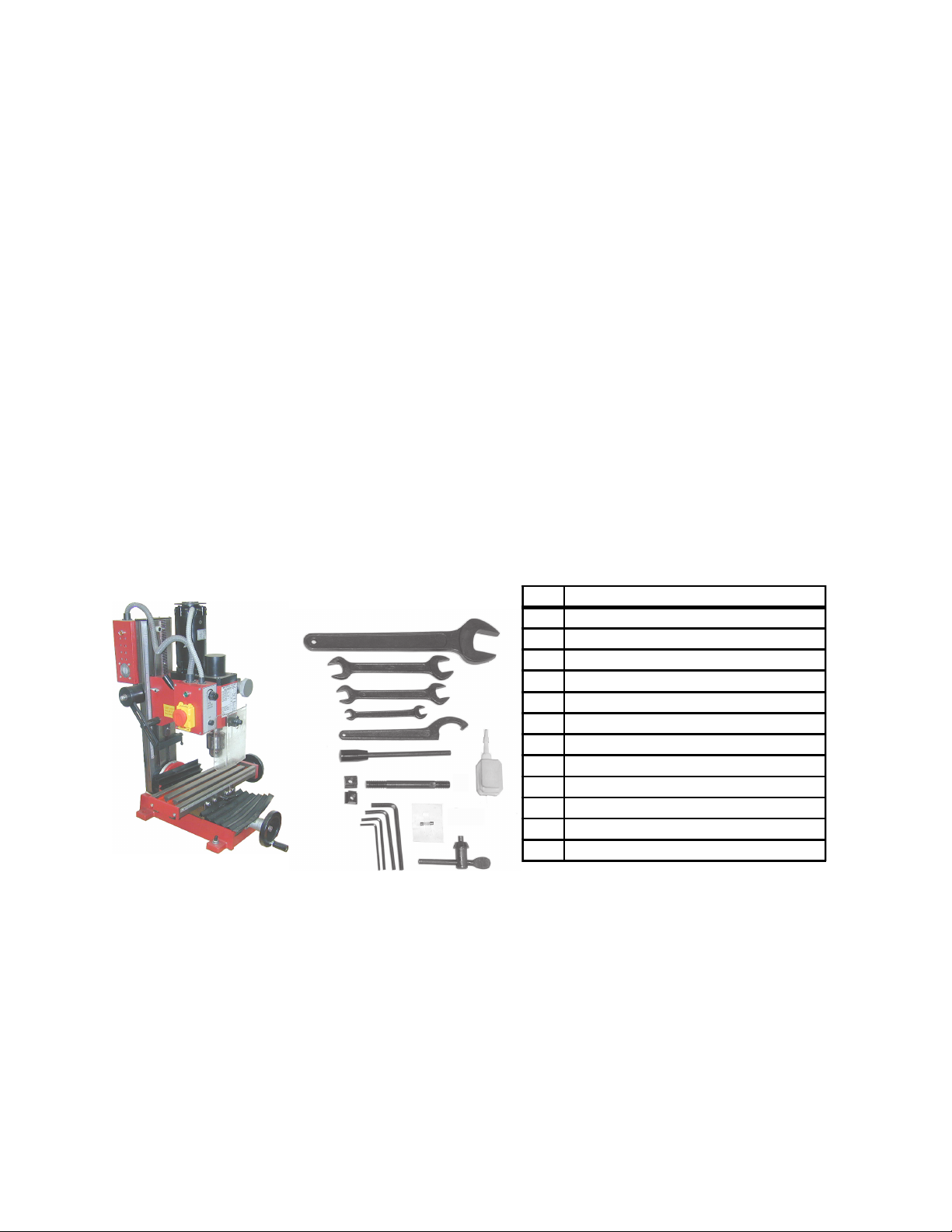

Unpacking

When unpacking, check to make sure the following parts and accessories are included.

ITEM DESCRIPTION

A La rge Wrench

A

G

G

G

F

B

L

J

I

D

E

K

H

C

B 13 mm Dri ll Chuck wi th Ta per Shank

C Oil Bottle

D Fixing Pin

E L - Hex. Wrenche s, S: 3, 4, 5, 6

F Socket H ead Wrench, D: 45-52

G Dou ble-end Wrenche s, 8-10, 14-17 , 17-19

HChuck Key

IHandle

J T-nut

K F use, 5A (110 VAC )

LDraw Bar

If any parts are missing or broken, please call Harbor Freight Tools at the number on the

cover of this manual as soon as possible.

Installation

1. Place the machine on a level, flat, and heavy work table or bench; sufficient to support

weight and use of product and with sufficient light, and enough side room to allow

movement of the W orking Table (#19).

2. Secure the machine to the appropriate table or bench using four hex screws (not

supplied), by screwing them through the base mounting holes.

Page 4SKU 44991

REV 11/02

Page 5

3. An optional oil pan can be placed under the machine before it is mounted to the table.

4. Before operation, loosen the slide, worktable, and drill-mill spindle. They were locked

for shipping.

5. Remove all packing material and clean machine with nonflammable solvent. Oil the

machine according to the lubrication requirements before running the machine.

Assembly

1. Install the Chuck.

- Thoroughly clean the tapered hole in the Chuck (164) and the Spindle (79) shaft of

all dirt, grease, oil, and protective coatings (paint thinner may be necessary).

- Slide the Chuck onto the Spindle shaft.

- Turn the Chuck sleeve clockwise and open the jaws completely.

- Tap the nose of the Chuck lightly with a piece of wood to securely set the Chuck.

2. If necessary, screw the Handles into the Small Hand Wheels.

3. Check the angle of the Vertical Support (68) for true vertical. Check all bolts for

tightness.

Operation

This Mini Milling/Drilling Machine is capable of machining metal and nonmetallic stock by

cutting, drilling, and milling. It can cut circular surfaces, both inside and out, cones, mill

planes or grooves, and other cutting functions depending on the tools used.

The machine consists of the following main components as shown in the photo below.

Motor (127)

Electrical Box (69)

V ertical Support (68)

Balance Mechanism Assy.

Emergency Stop Switch (37)

Limit Block (65)

Connecting Strut (72)

Small (fine) Feed Wheel (93)

Headstock and Spindle Box (49)

Speed Control Knob (134)

Longitudinal Feed Hand Wheel

Base (1)

Working T ab le (19)

Saddle (35)

Cross Feed Hand Wheel (5)

Page 5SKU 44991

Page 6

Checks before Operation

1. Turn on the machine by lifting the cov er and pulling out the Emergency Stop Switch

(137).

2. Tur n the Speed Control Knob (134) and verify spindle speed changes.

3. Verify that the spindle is rotating clockwise.

4. Operate the Longitudinal Axis (Working Table), Cross Axis (Saddle Seat), and Ver tical

Axis (Vertical Support), and verify their proper operation and movement.

Caution: Avoid injury to you or damage to machine. Unplug the power cord from the

electrical outlet before performing an y adjustments, tool replacement, or maintenance.

Installation of the Taper Shank Cutter

1. Pull off the Protective Cover (126).

2. Wipe the spindle sleeve and taper of all dirt and grease.

3. Unscrew Clamp Bolt (101) and remove Dust Guard

(126)

(A)

(100).

4. Place the Taper Shank (B) into the Spindle (79) sleeve.

(G)

Cover the Cutter (C) (not included) end with an oil cloth

to protect hands and machinery .

5. Insert the Fixing Pin (accessory D) on the right side of

(101)

(100)

the Spindle sleeve. Refer to page 4.

6. Using the #14 open end wrench (accessory G), tighten

(clockwise) the Spindle draw bar (A) to lock in the Taper

Shank Cutter into the Spindle.

7. Pull out the Fixing Pin and replace the Protective Cover.

Note: For illustration

Removal of the Taper Shank Cutter

1. Pull off the Protective Cover (126).

purposes only. Only

Chuck with Taper Shank

(164) is included.

(C)

2. Insert the Fixing Pin (accessory D) on the right side of the Spindle sleeve.

(D)

(B)

3. Using the #14 open end wrench (accessory G), loosen (counterclockwise) the Spindle

draw bar (A) to unlock the Taper Shank Cutter in the Spindle.

4. Using a plastic hammer, gently tap the Taper Shank (B) until it breaks free.

Place a cushion on the Working Table (19) to protect the assembly if it falls out.

5. Replace the Taper Shank Cutter with the Drill Chuck (or other tool) if desired.

Travel Adjustment

Adjusting the Limit Block (65) can control the travel of the Spindle Box.

1. Loosen Handle (30) attached to the Limit Block (65).

Page 6SKU 44991

REV 12/04

Page 7

2. Adjust the position of the Limit Block (65) up or down. Refer to the Ruler (67) on the

side of the Vertical Support (68).

3. Tighten the Handle.

Adjusting the Vertical Support Angle

1. Using the Large Wrench (accessory A),

(68)

loosen Lock Nut (70) only enough to allow

movement of the Vertical Support (68).

(70)

Caution: A void injury or damaging machine, hold

the Vertical Support in place to keep it from falling to the left or right during adjustment.

2. Adjust the Vertical Support angle as needed (45 degrees left or right, maximum).

Check Ruler (44) for angle.

3. When the Vertical Support is at the desired angle, tighten Lock Nut (70) again.

Basic Drilling and Milling Procedure

During the following procedure, it may be helpful to refer to the machine photo on page 5.

1. Make desired changes and adjustments to the machine for drilling or milling.

2. Set an appropriate speed for drilling or milling the workpiece.

Use the Speed Control Knob (134) to adjust the Spindle speed. For cutting metal, the

speed range should be between 200 to 2500 RPM. Faster speeds are generally used

when milling softer materials and drilling small holes; And slower speeds for milling

harder material and drilling larger holes.

3. Using a fixture (not supplied) mount the workpiece to the Working Table (19).

4. Adjust the Limit Block (65) height.

This will enable Spindle movement to the desired cut, and disable an over cut which

could damage the workpiece fixture or Work Table.

5. Adjust the Working Table Longitudinal Feed Hand Wheel (X-Axis) and the Cross Feed

(Y-Axis) Hand Wheel (5) into position for milling or drilling.

One step turn of the Hand Wheel moves the Work Table 0.03 mm; one complete turn

moves it 1.5 mm.

6. Remove any tools or obstacles from in and around the Work Table.

7. Tur n the machine on. Lift the Emergency Stop Switch (137) cover, and pull button out.

8. If necessary, adjust the Spindle speed with the Speed Control Knob (134).

9. Begin milling or drilling.

Use the Operating Lever (58) to make large adjustments to the Spindle height. For fine

adjustments, use the Fine Feeding Wheel (93). Refer to the ruler on the Vertical

Support to determine drilling or milling depth. Caution: Keep hands and fingers clear

of the working table and workpiece while the machine is in operation.

Page 7SKU 44991

Page 8

10. When the drilling or milling is completed, press in on the Emergency Stop Switch and

close its cover.

11. Unplug the line cord from the electrical outlet and clean the machine of all debris.

Maintenance

Caution: Avoid injuries or damage to equipment. Before performing any maintenance

on this machine, unplug the power cord from the electrical outlet.

Lubrication Requirements

1. Using a light oil and clean cloth, after each use, wipe down all metal parts of the

machine to prevent rusting.

2. Using machine lubrication grease, periodically apply to the X-axis feed screw (saddle

seat), Y-axis feed screw (working table), and Z-axis feed gear rack (vertical support).

Periodic General Maintenance

1. Inspect all moving parts for lack of lubrication. If necessary, lubricate as described

above.

2. Using compressed air, blow the machine clean of all foreign material. Wear eye

protection during this operation.

3. Check all adjustment screws, bolts, and handles for tightness.

4. Store cutting tools in a wooden box or other moisture proof package.

5. Cover the machine when not in use.

6. Sharpen cutting tools as soon as they become dull.

7. Always keep the taper shank clean.

8. Store all tools and accessories in a clean and dry location, near the machine.

9. Always use the supplied tools and wrenches to make repairs and adjustments.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUF ACTURER NOR DISTRIBUT OR

MAKES ANY REPRESENTA TION OR W ARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THA T ALL REP AIRS AND PARTS REPLA CEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NO T BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING

OUT OF HIS OR HER INST ALLATION OF REPLACEMENT PARTS THERETO .

Page 8SKU 44991

Page 9

Parts List

4

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

Page 9SKU 44991

REV 03/05

Page 10

with

Page 10SKU 44991

REV 11/02

Page 11

Longitudinal (Y) Axis and Cross (X) Axis Assembly Drawing

Page 11SKU 44991

Page 12

Vertical (Z) Axis Assembly Drawing

Page 12SKU 44991

Page 13

Spindle and Gear Box Assembly Drawing

Page 13SKU 44991

Loading...

Loading...