Harbor Freight Tools 35336 Product manual

Owner’s Manual & Safety Instructions

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the manual

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

near the assembly diagram (or month and year of purchase if product has no number). Keep this manual and

Keep this manual and the receipt in a safe and dry place for future reference.

the receipt in a safe and dry place for future reference.

REV 15e

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

When unpacking, make sure that the product is intact

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

please call 1-888-866-5797 as soon as possible.

Copyright© 2015 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

Diagrams within this manual may not be drawn proportionally. Due to continuing

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

improvements, actual product may differ slightly from the product described herein.

Copyright© 2015 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

any shape or form without the express written consent of Harbor Freight Tools.

Tools required for assembly and service may not be included.

Tools required for assembly and service may not be included.

Read this material before using this product.

Read this material before using this product.

Failure to do so can result in serious injury.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

SAVE THIS MANUAL.

Table of Contents

Safety ......................................................... 2

Setup .......................................................... 4

Operation .................................................... 5

SAFETY OPERATION MAINTENANCESETUP

Maintenance ............................................... 2

Parts List and Diagram ............................... 7

Warranty .................................................... 12

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INFORMATION

Read all safety warnings and all instructions.

Failure to heed these markings may result in personal injury and/or property damage.

1. Attach pipe bender securely to solid, flat and level

surface that can support weight of pipe bender

and pipe, with enough clearance for movement

of pipe. Do not lay pipe bender on its side. The

hydraulic ram may leak or not function properly.

2. Keep hands away from ram, pipe

and rollers during use.

3. To prevent injury from burns, do

not apply heat to pipe.

4. Use only on free standing pipe. Do not

use on pipe that is part of an assembly

or that is installed into a structure.

5. Study, understand, and follow all instructions

before operating this device.

9. Wear ANSI-approved safety goggles,

heavy-duty work gloves, and steel-toe

work boots during set up and/or use.

10. Keep bystanders out of work area.

11. Do not leave the pipe bender

unattended when loaded.

12. Do not adjust safety valve.

13. Inspect before every use; do not use

if parts are loose, damaged.

14. Ram service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury.

6. Keep rollers clean. If pipe rests on obstruction,

it creates an uneven surface, causing

excess stress and possible breakage.

7. Do not use on painted pipe or

pipe that has debris on it.

8. STOP and release compression if you suspect

imminent structural failure. If safe, inspect

thoroughly and reposition pipe before proceeding.

Page 2 For technical questions, please call 1-888-866-5797. Item 35336

15. When servicing a ram, use only identical

replacement parts . Use of unauthorized

parts or failure to follow maintenance

instructions may create a risk of injury.

16. No alterations shall be made to this product.

17. Only use with accessories rated to handle the

forces exerted by this tool during operation. Other

accessories not designed for the forces generated

may break and forcefully launch pieces.

18. Use only with included ram.

19. Industrial applications must follow

OSHA requirements.

20. This product is not a toy. Keep it

out of reach of children.

21. Maintain labels and nameplates. These

carry important safety information. If

unreadable or missing, contact

Harbor Freight Tools for a replacement.

23. WARNING: The brass components of this product

contain lead, a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

24. WARNING: This product contains di (2-ethylhexyl)

phthalate (DEHP), a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

SAFETYOPERATIONMAINTENANCE SETUP

22. The warnings, precautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product,

but must be supplied by the operator.

SAVE THESE INSTRUCTIONS.

Specifications

Maximum Capacity

Pipe Type Schedule 40 or 80 malleable steel pipe

IMPORTANT! Before first use:

Check hydraulic fluid level and fill to 1/4″ below the

fill port as needed - see instructions on page 5.

Thoroughly test the Ram for proper operation. If it

does not work properly, bleed air from its hydraulic

system - see instructions on page 5.

16 Tons

(32,000 lb)

Page 3For technical questions, please call 1-888-866-5797.Item 35336

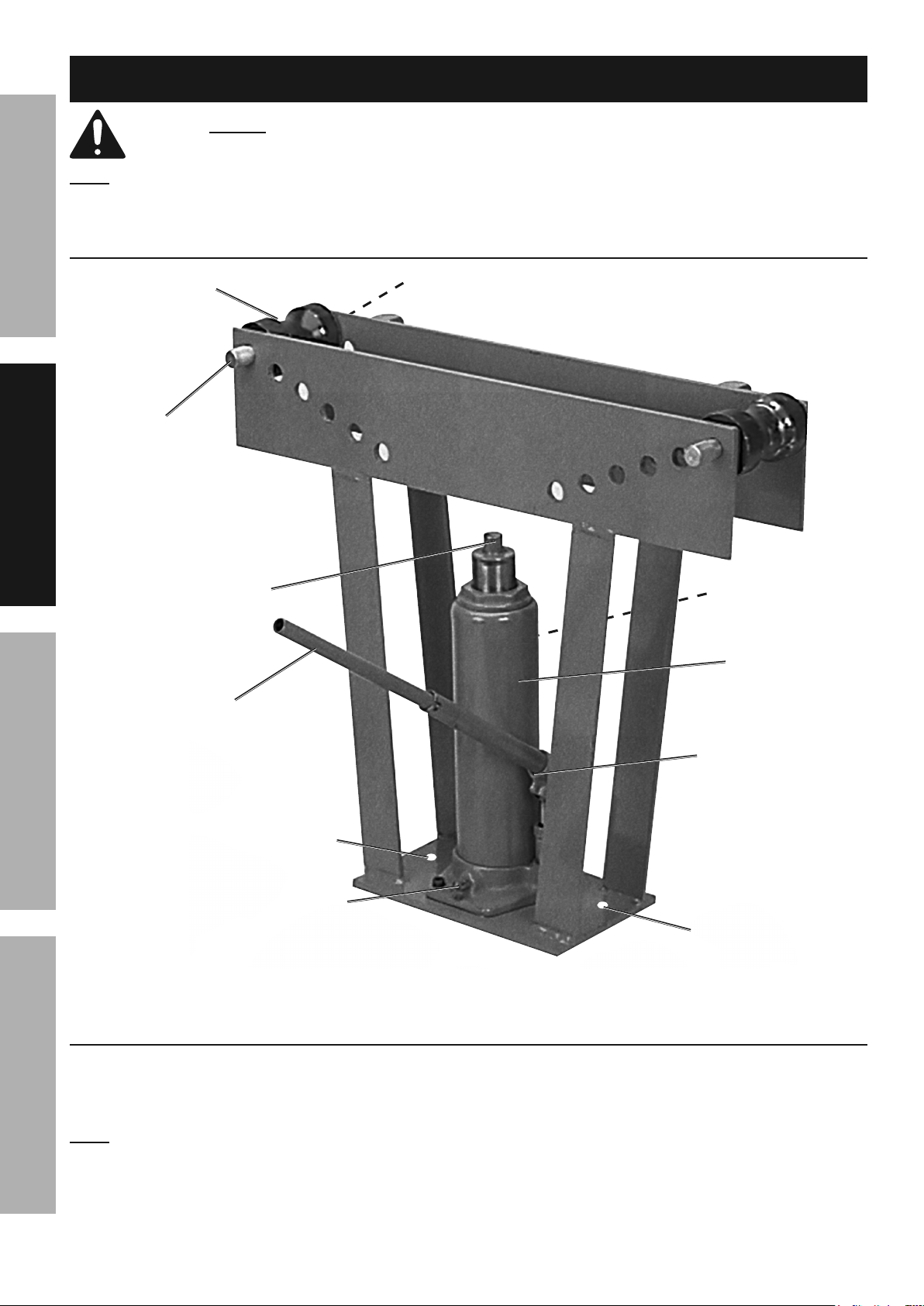

Setup - Before Use:

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

SAFETY OPERATION MAINTENANCESETUP

Note: For additional information regarding the parts listed in the following pages,

refer to Parts List and Assembly Diagram on page 10.

Functions

R-Pin

Roller

Cotter

Pin

2"

2-1/2"

3"

1-1/2"

1-1/4"

1"

3/4"

(on back)

1/2"

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3"

Mounting

Piston

Ram

Handle

Mounting

Hole

Release

Valve

Fill Plug

(on back)

Ram

Fulcrum

Mounting

Hole

Figure A

WARNING! Attach Pipe Bender securely to solid and level surface that can support

weight of Pipe Bender and pipe, with enough clearance for movement of pipe. Do not lay

pipe bender on its side. The hydraulic ram may leak and not function properly.

Note: Verify that mounting surface has no hidden

components before drilling or driving bolts.

2. Mount base to mounting surface

using appropriate hardware.

1. Use base to mark mounting holes

on mounting surface.

Page 4 For technical questions, please call 1-888-866-5797. Item 35336

Loading...

Loading...