Page 1

Model

34951

®

BELT/DISC

SANDER

ASSEMBLY AND OPERATION INSTRUCTIONS

Due to continuing improvements, actual product may differ slightly from the product described herein.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright© 1996, 2006 by Harbor Freight Tools®. All rights reserved. No portion

of this manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Page 2

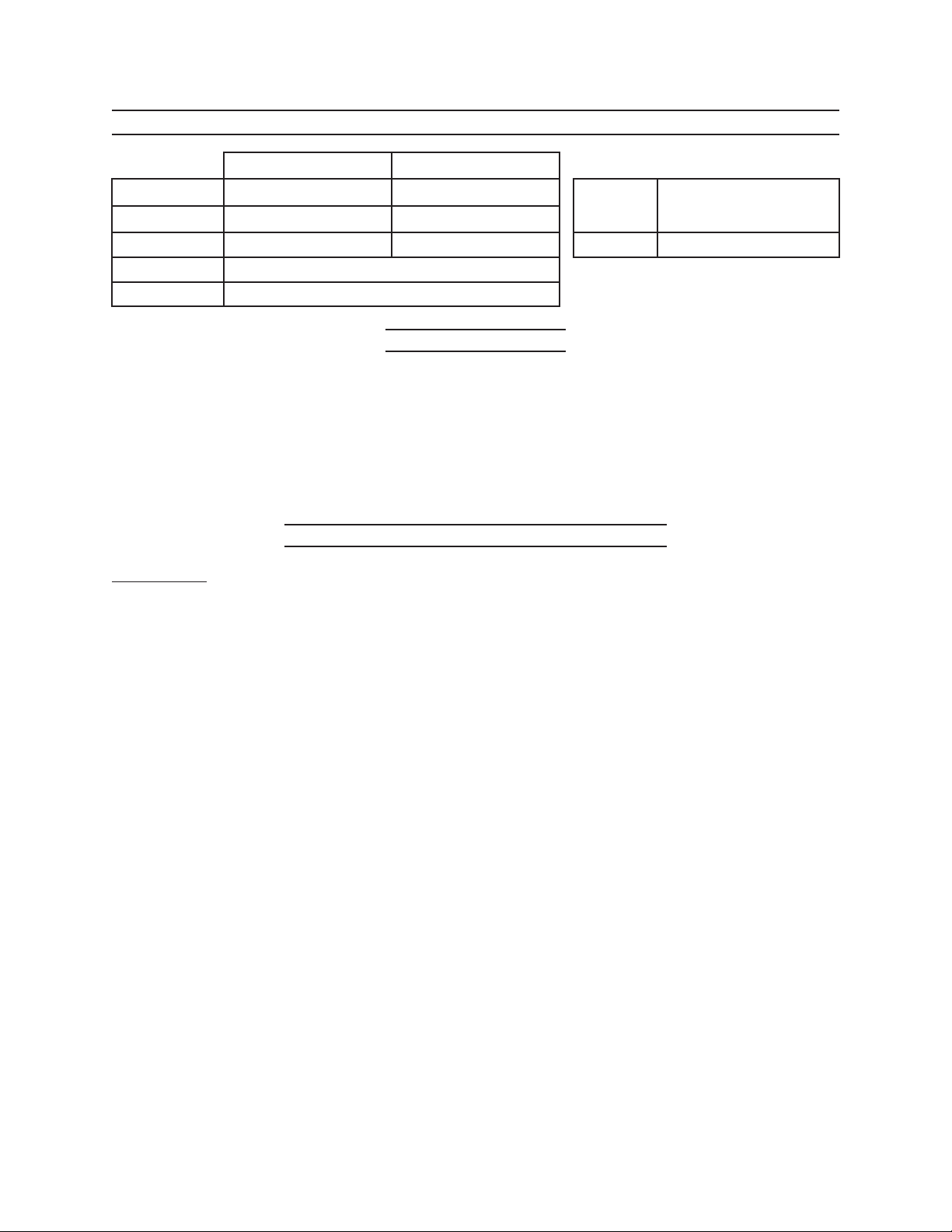

SPECIFICATIONS

Disc Belt

Size

Speed

Table

Table Tilt

Dust Chute 1-1/2” (both)

5” 1” x 30”

3450 RPM 3350 FPM

4” x 7-1/4” 5” X 5”

45° (both)

Save This Manual

You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Write the product’s serial number in the back of the manual near the assembly diagram, or write month and year of purchase if product has no number. Keep this manual

and invoice in a safe and dry place for future reference.

IMPORTANT SAFETY PRECAUTIONS

WARNING: When using electric tools, basic safety precautions should always be followed to

reduce the risk of fire, electric shock, and personal injury, including the following:

Motor

Weight

1/3 HP, 2.4 A, 110 V~,

60 Hz, Single Phase

17 Pounds

1.

2.

3.

4.

5.

6.

7.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

CONSIDER WORK AREA CONDITIONS. Don’t use machines or power tools

in damp, wet, or poorly lit locations. Don’t expose to rain. Keep work area well

lit. Don’t use tools in the presence of flammable gases or liquids.

KEEP CHILDREN AWAY. All children should be kept away from the work area.

Don’t let them handle machines, tools or extension cords.

STORE IDLE EQUIPMENT. When not in use, tools should be locked up in a dry

location to inhibit rust. If possible, store in an area out of reach of children.

DON’T FORCE THE MACHINE OR TOOL. It will do the job better and more safely

at the rate for which it was intended.

USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the work of a

larger industrial tool. Don’t use a tool for a purpose for which it was not intended.

DRESS PROPERLY. Don’t wear loose clothing or jewelry. They can be caught in

moving parts. Protective, electrically non-conductive gloves and non-skid footwear

are recommended when working. Wear protective hair covering to contain long hair,

preventing it from getting caught in machinery.

For technical questions, please call 1-800-444-3353.

Page 2SKU 34951

Page 3

8.

USE EYE AND EAR PROTECTION. Always wear ANSI-approved safety goggles.

Use a full face mask if the work you’re doing produces metal filings, dust or wood

chips. Wear a clean dust mask if the work creates a lot of fine or coarse dust. When

operating for extended periods of time, use approved ear protection.

9.

10.

11.

12.

13.

14.

15.

DON’T ABUSE THE POWER CORD. Do not yank it to disconnect it from receptacle.

Do not move bench-mounted or floor-standing machines with the power cord in the

outlet. Keep cord away from heat, oil, and sharp edges.

SECURE WORK. Use clamps or a vise to hold the work if possible. It’s safer than

using your hands and it frees both hands to operate the tool.

DON’T OVERREACH. Keep proper footing and balance at all times. Do not reach

over or across machines that are running.

MAINTAIN TOOLS WITH CARE. Keep belt and disc clean for better and safer per-

formance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and if damaged, have them repaired by a qualified technician.

Keep handles dry, clean, and free from oil and grease.

DISCONNECT POWER. Unplug when not in use, before servicing, and when chang-

ing accessories such as blades, bits, and cutters.

REMOVE ADJUSTING KEYS AND WRENCHES. Make it a habit to check that

keys and adjusting wrenches are removed from the tool or machine work surface

before plugging it in.

AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF position

when not in use and before plugging in.

16.

17.

18.

19.

STAY ALERT. Watch what you are doing, use common sense. Don’t operate any

tool when you are tired.

CHECK DAMAGED PARTS. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and other conditions that may affect its operation.

Any part that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere in the instruction manual. Have

defective switches replaced by a qualified technician. Don’t use the tool if switch

does not turn on and off properly.

REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical

replacement parts. Only use accessories intended for use with this tool. Approved

accessories are available from Harbor Freight Tools.

DO NOT OPERATE TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS.

Read warning labels on prescriptions to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate machine.

For technical questions, please call 1-800-444-3353.

Page 3SKU 34951

Page 4

20.

KEEP GUARDS IN PLACE. All guards and fences need to be in proper working

order and alignment. Check before every use.

21.

22.

23.

24.

25.

26.

NEVER LEAVE TOOL RUNNING UNATTENDED. Always turn off power. Do not

leave tool until it comes to a complete stop.

BE CAUTIOUS WHEN SANDING WOOD THEN METAL. Combining wood dust

and metal filings can create a fire hazard. Always clean away any wood dust before

attempting to use the sander on metal products.

MAINTAIN A CLEARANCE OF 1/16” OR LESS BETWEEN THE TABLE AND THE

SANDING BELT.

NEVER WEAR GLOVES OR HOLD THE WORKPIECE WITH A RAG WHEN

SANDING.

DO NOT SAND PIECES THAT ARE TOO SMALL TO BE SAFELY SUPPORTED

OR HELD. Such pieces should be sanded by hand.

WARNING: Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities, contains chemicals known [to the State of

California] to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

Lead from lead-based paints

Crystalline silica from bricks and cement or other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are spe-

cially designed to filter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the risk of electric shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the power cord plug provided with the tool.

Never remove the grounding prong from the plug. Do not use the tool if the

power cord or plug is damaged. If damaged, have it repaired by a service facility before use. If the plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

REV 12/06

For technical questions, please call 1-800-444-3353.

Page 4SKU 34951

Page 5

GROUNDED TOOLS: TOOLS WITH THREE PRONG PLUGS

1.

2.

3.

Tools marked with “Grounding Required” have a three wire cord and three prong

grounding plug. The plug must be connected to a properly grounded outlet. If the

tool should electrically malfunction or break down, grounding provides a low resis-

tance path to carry electricity away from the user, reducing the risk of electric shock.

(See 3-Prong Plug and Outlet.)

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool. The green wire in the cord must be the

only wire connected to the tool’s grounding system and must never be attached to

an electrically “live” terminal. (See 3-Prong Plug and Outlet.)

Your tool must be plugged into an appropriate outlet, properly installed and grounded

in accordance with all codes and ordinances. The plug and outlet should look like

those in the following illustration. (See 3-Prong Plug and Outlet.)

3-Prong Plug and Outlet Outlets for 2-Prong Plug

DOUBLE INSULATED TOOLS: TOOLS WITH TWO PRONG PLUGS

1.

2.

Tools marked “Double Insulated” do not require grounding. They have a special

double insulation system which satisfies OSHA requirements and complies with

the applicable standards of Underwriters Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code. (See Outlets for 2-Prong Plug.)

Double insulated tools may be used in either of the 120 volt outlets shown in the

preceding illustration. (See Outlets for 2-Prong Plug.)

EXTENSION CORDS

1.

2.

Grounded tools require a three wire extension cord. Double Insulated tools can

use either a two or three wire extension cord.

As the distance from the supply outlet increases, you must use a heavier gauge

extension cord. Using extension cords with inadequately sized wire causes a seri-

ous drop in voltage, resulting in loss of power and possible tool damage.

(See Table A.)

For technical questions, please call 1-800-444-3353.

Page 5SKU 34951

Page 6

3.

The smaller the gauge number of the wire, the greater the capacity of the cord. For

example, a 14 gauge cord can carry a higher current than a 16 gauge cord.

(See Table A.)

4.

5.

6.

7.

8.

When using more than one extension cord to make up the total length, make sure

each cord contains at least the minimum wire size required. (See Table A.)

If you are using one extension cord for more than one tool, add the nameplate am-

peres and use the sum to determine the required minimum cord size.

(See Table A.)

If you are using an extension cord outdoors, make sure it is marked with the suffix

“W-A” (“W” in Canada) to indicate it is acceptable for outdoor use.

Make sure your extension cord is properly wired and in good electrical condition.

Always replace a damaged extension cord or have it repaired by a qualified electri-

cian before using it.

Protect your extension cords from sharp objects, excessive heat, and damp or wet

areas.

RECOMMENDED MINIMUM WIRE GAUGE FOR EXTENSION CORDS*

NAMEPLATE

AMPERES

(at full load)

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

TABLE A

(120 OR 240 VOLT)

EXTENSION CORD LENGTH

25 Feet 50 Feet 75 Feet 100 Feet 150 Feet

* Based on limiting the line voltage drop to five volts at 150% of the rated amperes.

SYMBOLOGY

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

A

n0 xxxx/min.

Volts Alternating Current

Amperes

No Load Revolutions per Minute

(RPM)

UNPACKING

When unpacking, check to make sure that the item is intact and undamaged. If any

parts are missing or broken, please call Harbor Freight Tools at the number shown on the

cover of this manual as soon as possible.

For technical questions, please call 1-800-444-3353.

Page 6SKU 34951

Page 7

ASSEMBLY

The Belt Sander is shipped almost completely assembled. The major items to be attached are the disc table (58), the belt table (31), and the sanding belt (6). (These numbers

refer to the assembly diagram and parts list at the back of this manual.) We will refer to the

tall part of the sander angled toward you as the front. The “on/off” switch is to your right.

Belt Table Assembly

1.

2.

3.

4.

5.

1.

2.

3.

4.

Get out the table (31), 16mm screw (36), No. 8 washer (2), locking nut (32), knob

(33), spring (34), and screw (36).

Remove the cover (3) by removing the securing knob (1) and lifting up.

The screw (36) goes on the inside; the other pieces are installed from the outside.

The washer goes closer to the table, then the locking nut, followed by the knob,

spring, and finally the last screw.

The knob is used to lock the table in place when adjusting the angle.

Do not replace the cover until the belt has been installed. This is covered below.

Disc Assembly

Remove the cover (50).

Remove the dust collector (59).

Stick the sanding disc on the disc wheel (53).

Get the disc wheel to the shaft of the motor with the hex head bolt (52).

5.

1.

2.

3.

1.

2.

Replace the cover and dust collector.

Disc Table Assembly

Get out the table (58),4 x 22 pins (60), the No. 6 washers (55), and the wing nuts

(61).

Attach the table to the cover using the wing nuts and washers.

Drive in the pins so that the table can “swing” for tilting.

Miter Gauge Assembly

Get out the shaft (57), scale (56), No. 6 washer (55), and fastening knob (54).

Attach scale to shaft with washer and knob.

For technical questions, please call 1-800-444-3353.

Page 7SKU 34951

Page 8

INSTALLING AND REMOVING SANDING BELTS

1.

2.

3.

4.

5.

1.

2.

UNPLUG THE MACHINE FROM THE POWER SOURCE.

Unless it has already be taken off, remove the knob (1) from the top of the

sander. Remove the side cover (3).

Put the belt over the upper wheel (8) and large belt wheel (29).

Lift up on the belt tracking knob (19) and slide the belt over the lower belt

wheel.

Replace the cover.

ADJUSTING BELT TRACKING

The belt tracking adjustment was set at the factory, so the belt should run

true on its pulleys. If, however, the belt does run to one side or the other, or

if you’ve just installed a new belt, you can adjust the track using the tracking

knob (19).

Stand at the left side of the machine, on the far side from the “on/off’ switch.

Turn the tracking knob clockwise to move the belt away from you (your right

when standing in front). Turn the knob counterclockwise to move the belt

closer to you (your left from the front). This operation usually needs only a

very slight turn of the tracking knob.

1.

2.

3.

USE OF THE BACKSTOP

The backstop (26) is made of heavy gauge steel to support the workpiece

you’re sanding. The backstop should be no more than 1/16” away from the

back of the sanding belt.

If the backstop needs adjustment, there are two bolts (24) and two washers

(25) which hold the backstop in place. To move the backstop closer to the

belt, simply loosen these and move the backstop.

For some operations, such as polishing or strapping, it’s advisable to remove

the backstop entirely by unscrewing the two bolts, two washers, and the

backstop itself.

For technical questions, please call 1-800-444-3353.

Page 8SKU 34951

Page 9

PARTS LIST

Part Description Q’ty

1 Knob 1

2 No. 8 Washer 2

3 Belt Cover 1

4 M8 x 20 Bolt 2

5 Hex Key Wrench 1

6 Sanding Belt 1

7 No. 15 Spacer Bearing 2

8 Small Belt Wheel 2

9 Belt Drive Shaft 1

10 M6 x 10 Hex Bolt 1

11 Rotation Label 2

12 Belt Guard 1

13 Belt Tension Shaft 1

14 0.8 x 7 x 13 Spring 1

15 No. 5 Washer 1

16 Clip 1

17 3 x 20 Pin 1

18 Belt Tension Bracket 1

19 Tracking/Tension Knob 1

20 l x 10 x 18 Spring 1

21 Washer 1

22 M10 x 30 Bolt 1

23 1.4 x 8 x 35 Spring 1

24 M4 x 12 Hex Screw 2

25 No. 4 Washer 2

26 Belt Backstop 1

27 M10 Nut 1

28 M6 x 12 Screw 2

29 Large Belt Wheel 1

30 M8 x 25 Bolt 1

31 Belt Table 1

32 Locking Nut 1

33 Knob 1

Part Description Q’ty

34 0.8 x 7 x 10 Spring 1

35 Screw 1

36 M6 x 16 Screw 3

37 Motor 1

38 Label 1

39 Switch 1

42 Motor Wire Box 1

43 Capacitor 1

44 Wire Box Cover 1

45 3.5 x 13 Phillips Screw 6

46 Strain Relief 1

47 Cable 1

48 M5 x 12 Phillips Screw 4

49 No. 5 Washer 2

50 Disc Cover 1

51 M6 x 25 Bolt 2

52 M6 x 10 Hex Head Bolt 1

53 Disc Wheel 1

54 Fastening Knob 1

55 No. 6 Washer 3

56 Miter Gauge Scale 1

57 Miter Gauge Shaft 1

58 Disc Table 1

59 Dust Collector/Cover 1

60 4 x 22 Pin 2

61 M6 Wing Nut 2

62 Motor Washer 1

63 Base Plate 1

64 Rubber Pad 4

65 No. 8 Washer 2

66 M6 x 12 Screw 2

67 No. 35 Spacer Bearing 2

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER

OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER

THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR

SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS

TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

REV 03/98

For technical questions, please call 1-800-444-3353.

Page 9SKU 34951

Page 10

ASSEMBLY DIAGRAM

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

For technical questions, please call 1-800-444-3353.

REV 03/98

Page 10SKU 34951

Loading...

Loading...