Page 1

40 LB. PRESSURIZED

SANDBLASTER

ASSEMBLY and OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd. / Camarillo, CA 93011

Copyright © 1997 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in any

shape or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

SPECIFICATIONS

Capacity: 40 lbs.

Working Pressure 60-125 PSI

Delivery Rate 6-25 CFM

Overall Dimensions 33.5" x 18.75" x 13"

Weight: 57 lbs.

SAVE THIS MANUAL

You will need the manual for the safety warnings and cautions, assembly instructions, operating

procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice

with this manual. Write the invoice number on the inside of the front cover. Keep both this manual

and your invoice in a safe, dry place for future reference.

SAFETY WARNING & CAUTIONS

WARNING: When using pneumatic equipment, basic safety precautions should always be followed

to reduce the risk of personal injury and hazards due to over pressurization. READ ALL

INSTRUCTIONS BEFORE USING THIS TOOL!

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. OBSERVE WORK AREA CONDITIONS. Do not use tools in damp, wet, or poorly lit locations.

Don’t expose to rain. Keep work area well lit. Do not use electrically powered air compressors

in the presence of flammable gases or liquids.

3. KEEP CHILDREN AWAY. Children must never be allowed in the work area. Do not let them

handle machines, tools, or hoses.

4. STORE IDLE EQUIPMENT. When not in use, tools must be locked up in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which

it was intended. Do not use inappropriate attachments in an attempt to exceed the tool’s

capacities.

6. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or attachment

to do the work of a larger industrial tool. Do not use a tool for a purpose for which it was not

intended.

7. DRESS PROPERLY. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Non-skid footwear is recommended. Wear restrictive hair covering to contain long

hair. Always wear the hood (included), a dust mask, and heavy duty canvas gloves.

8. USE EYE AND EAR PROTECTION. Always wear ANSI approved chemical splash

goggles when working with chemicals. Always wear ANSI approved impact safety goggles

at other times. Wear a full face shield if you are producing metal filings or wood chips.

Wear and ANSI approved dust mask or respirator when working around metal, wood, and

chemical dusts and mists.

Page #2 -- SKU 34202 REV 12/05

Page 3

9. DO NOT ABUSE THE POWER CORD. Do not yank compressor’s cord to disconnect it

from the receptacle. Do not carry tools by the cord.

10. DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach over

or across running machines.

11. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect

compressor’s cord periodically and, if damaged, have them repaired by an authorized

technician. Inspect all hoses for leaks prior to use. The handles must be kept clean, dry,

and free from oil and grease at all times.

12. REMOVE ADJUSTING KEYS AND WRENCHES. Make it a habit to check that keys and

adjusting wrenches are removed from the tool or machine work surface before plugging it

in.

13. AVOID UNINTENTIONAL STARTING. Make sure the nozzle valve is in the off position

when not in use, and before plugging in air compressor.

14. STAY ALERT. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

15. CHECK DAMAGED PARTS. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts or

mounting fixtures; and any other condition that may affect proper operation. Any part that is

damaged should be properly repaired or replaced by a qualified technician. Do not use the

tool if any switch does not turn on and off properly.

16. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

17. DO NOT OPERATE TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS.

Read warning labels on prescriptions to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

18. DRAIN COMPRESSOR EVERY DAY. Do not allow moisture to build up inside the

compressor. Do not allow compressor to sit pressurized for longer than one hour.

19. MAKE SURE ALL EQUIPMENT IS RATED TO THE APPROPRIATE CAPACITY. Make

sure that regulator is set at no higher than 125 PSI.

20. PERIODICALLY CHECK THE ABRASIVE MEDIUM DELIVERY EQUIPMENT. All

equipment that comes in contact with the abrasive medium after it leaves the pressure

tank is subjected to the sandblasting action so will wear out more quickly than other

components.

21. RELEASE THE AIR PRESSURE OF THE TANK BEFORE OPENING. Open the air

supply valve and the nozzle to release pressure. Make sure pressure gauge reads “0”

before opening.

Page #3 -- SKU 34202

Page 4

22. MAINTAIN CORRECT AIR PRESSURE WHENEVER WORKING. Do not allow pressure

to exceed 125 PSI. If the safety valve does not release excess air pressure, stop all work

and use the air compressor to release pressure in the tank. Do not attempt any repairs to

the Sandblaster until its gauge reads “0”.

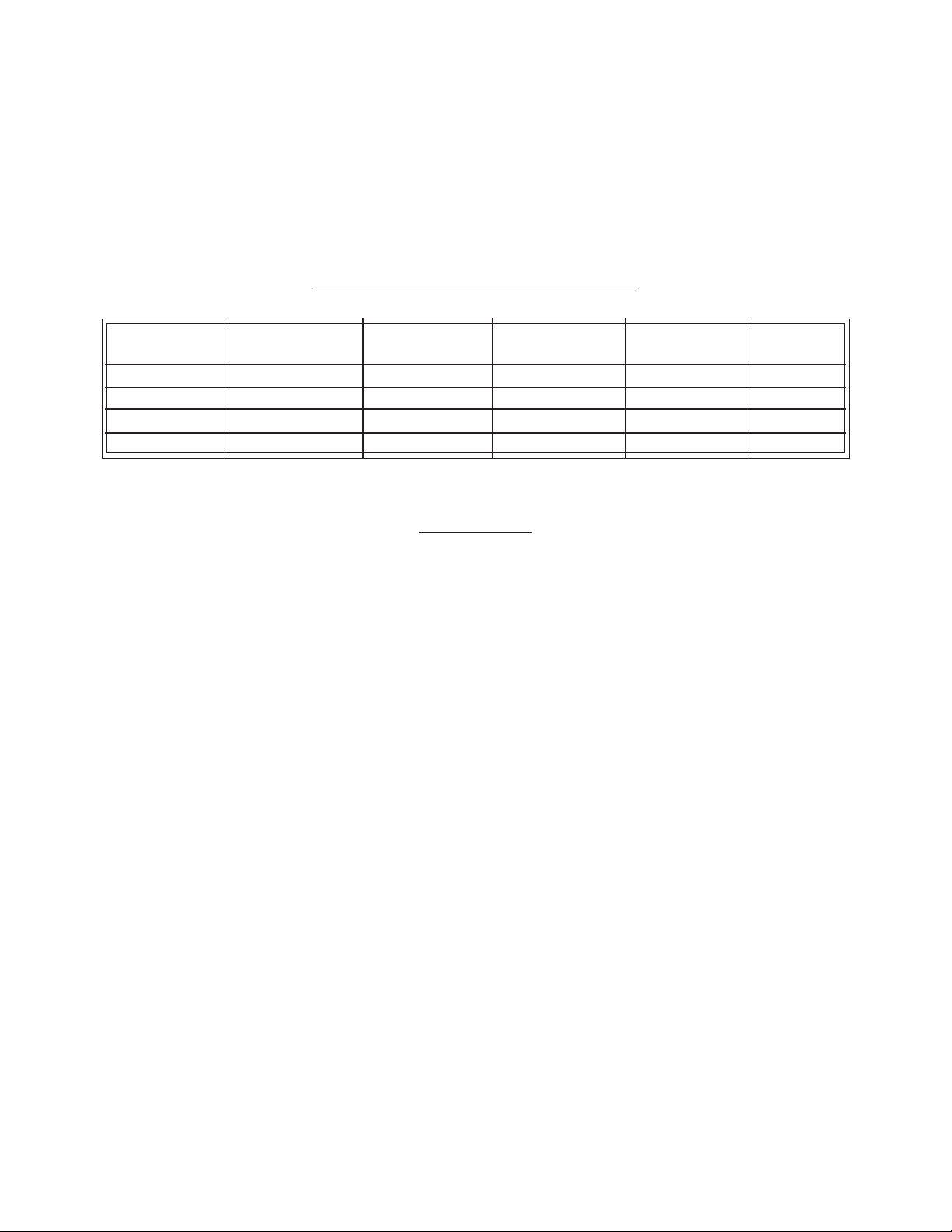

AIR/SAND SUPPLY REQUIREMENTS

Hose Hose Nozzle Compressor CFM Sand Use

ID Length ID HP @ 125 PSI Per Hour

3/8" 50 ft. 0.1" 2 6 60 lbs.

3/8" 25 ft. 0.125" 4 12 100 lbs.

1/2" 50 ft. 0.15" 7 20 150 lbs.

1/2" 25 ft. 0.175" 10 25 200 lbs.

UNPACKING

When unpacking, sort all pieces and check according to the parts list and diagram to make sure all

parts are included. All sizes listed are approximate. All Valve Assemblies are individually packed. If

any parts are missing or broken, please call Harbor Freight Tools at the number on the cover of this

manual.

Page #4 -- SKU 34202

Page 5

ASSEMBLY

NOTE: Use Teflon® Pipe Tape on all threaded joints. Make sure all joints are

securely tighten.

Intake Manifold

Pressure

Refer to Figure 1.

Gauge

Manifold

(#15)

Step1: Get out the INTAKE MANIFOLD (#14),

PRESSURE GAUGE (#15), BRASS

THROTTLING VALVE (#18A), 3/8" 1/4"

NIPPLE CONNECTOR (#20), and JOINT

PIPE (#13).

Brass

Throttling Valve

(#18A)

Intake

(#14)

Step2: Attach the PRESSURE GAUGE to the

top of the INTAKE MANIFOLD. Turn

PRESSURE GAUGE so that it’s face is

over the lower side hold of the INTAKE

MANIFOLD.

Step3: Attach the BRASS THROTTLING VALVE to the bottom of the INTAKE MANIFOLD.

Step4: Attach the 3/8" end of the NIPPLE CONNECTOR to the other end of the BRASS

THROTTLING VALVE.

Step5: Attach the JOINT PIPE to the lower side hole of the INTAKE MANIFOLD.

Joint Pipe

(#13)

Nipple

Connector

(#20)

Figure 1 — Intake Manifold Assembly

Page #5 -- SKU 34202

Page 6

Water Trap

Refer to Figure 2.

Male/Female

Adapter

Nipple Connector

(#16)

(#19)

Brass Air

Supply Valve

(#18)

Water Trap

(#17)

Figure 2 — Water Trap Assembly

Step1: Get out the WATER TRAP (#17), two 3/8" NIPPLE CONNECTORS (#16), the BRASS

AIR SUPPLY VALVE (#18), and the MALE/FEMALE ADAPTER (#19).

Step2: Attach the 3/8" NIPPLE CONNECTORS to either side of the WATER TRAP.

Step3: On the top of the WATER TRAP is an arrow. Attach the BRASS AIR SUPPLY VALVE to

the NIPPLE CONNECTOR that the arrow is facing away from.

Step4: Attach the MALE/FEMALE ADAPTER to the BRASS AIR SUPPLY VALVE.

Page #6 -- SKU 34202

Page 7

Sand Control Valve

Refer to Figure 3.

Step1: Get out the TANK (#1), the SAND

CONTROL VALVE (#18B), two NIPPLE

CONNECTORS (#16), and the SAND

OUTLET MANIFOLD (#22).

Step2: Attach one of the NIPPLE

CONNECTORS to the bottom of the

TANK (#1).

Step3: Attach the SAND CONTROL VALVE to

the other end of the NIPPLE

CONNECTOR.

Step4: Attach the other NIPPLE CONNECTOR

to the other end of the SAND CONTROL

VALVE.

Step5: Attach the other end of the NIPPLE

CONNECTOR to the side hole of the

SAND OUTLET MANIFOLD.

Nozzle Shut Off Valve

Refer to Figure 4.

Step1: Get out the

HOSE ADAPTER

(#25), the STEEL

SHUT OFF VALVE

(#18C), a NIPPLE

CONNECTOR (#16),

the GASKET (#26),

the desired size

NOZZLE (#27A-D),

and the NOZZLE CAP

NUT (#28).

Steel Shut

Off Valve

(#18C)

Gasket

(#26)

Nozzle Cap

Nut

(#28)

Figure 4 — Nozzle Shut Off Valve

Tank

(#1)

Sand Control

Valve

(#18B)

Nipple

Connector

(#16)

Sand Outlet

Manifold

(#22)

Figure 3 — Sand Control Valve Assembly

Hose Adaptor

(#25)

Nipple

Connector

(#16)

Nozzle

(#27A-D)

Step2: Put the front of the NOZZLE through the NOZZLE CAP NUT.

Step3: Attach the NOZZLE CAP NUT to the NIPPLE CONNECTOR with the GASKET between

the NIPPLE CONNECTOR and the NOZZLE. The flat end of the GASKET should face the

NIPPLE CONNECTOR.

Step4: Attach the other end of the NIPPLE CONNECTOR to one side of the STEEL SHUT OFF

VALVE.

Page #7 -- SKU 34202

Page 8

Step5:Attach the HOSE ADAPTER to the other end of the STEEL SHUT OFF VALVE.

Sand Control Valve/ Nozzle Shut Off Valve

Refer to Figure 5.

Sand Hose

Sand Control

Valve Assembly

Hose Clamp

(#23)

Nozzle Shut Off

Valve Assembly

Figure 5 — Sand Control Valve / Shut Off Valve Assembly

Step1: Get out the Sand Control Valve & Nozzle Shut Off Valve Assemblies, the SAND HOSE

(#24), and the two HOSE CLAMPS (#23).

Step2: Slide the HOSE CLAMPS over either side of the SAND HOSE. Do not tighten yet.

Step3: Slide one end of the SAND HOSE onto the Nozzle Shut Off Valve Assembly’s HOSE

ADAPTER (#25). Tighten the HOSE CLAMP very securely.

Step4: Slide the other end of the SAND HOSE onto the Sand Control Valve Assembly’s SAND

OUTLET MANIFOLD (#22). Tighten the HOSE CLAMP very securely.

Page #8 -- SKU 34202

Page 9

Top Assembly

Refer to Figure 6.

Air Cap

(#12)

Gasket

(#11)

Nipple

Connector

(#16)

Joint Pipe

(#13)

Nipple

Connector

(#16)

Tank

(#1)

Air Hose

(#21)

Figure 6 — Top Assembly

Step1: Get the Intake Valve Assembly, the Water Trap Assembly, the Tank Assembly, the TANK

CAP (#12), the O-RING (#11), and the AIR HOSE (#21).

Step2: Attach the Water Trap Assembly’s NIPPLE CONNECTOR (#16) to the upper side

INTAKE MANIFOLD (#14).

Step3: Attach the JOINT PIPE (#13) to the upper side port of the TANK (#1).

Step4: Put the O-RING into the fill port of the TANK.

Step5: Screw the TANK CAP onto the fill port of the TANK.

Step6: Attach the female end of the AIR HOSE to the BRASS THROTTLING VALVE’S (#18A)

NIPPLE CONNECTOR (#16).

Step7: Attach the male end of the AIR HOSE to the SAND OUTLET MANIFOLD(#22),

underneath the TANK.

Page #9 -- SKU 34202

Page 10

Handle Bars

Refer to Figure 7.

Right Handle

(#6-R)

Handle Grip

(#7)

Handle Bar

Left Handle

(#6)

(#6-L)

Screw

(#8)

Washer

(#31)

Nut

(#9)

Figure 7 — Handle Bar Assembly

Step1: Get out the two HANDLE BARS (#6), the two HANDLE GRIPS (#5), the four SCREWS

(#8), four NUTS (#9), and four WASHERS (#31).

Step2: Slide the HANDLE GRIPS onto the HANDLE BARS.

Step3: Attach both HANDLE BARS to the TANK (#1) using the four SCREWS, NUTS, and

WASHERS. The HANDLE BARS must curve back and the holes in their bottoms must

be parallel to each other. The WASHERS go between the NUTS and the TANK.

REV 01/01Page #10 -- SKU 34202

Page 11

Wheels and Foot

See Figure 8.

3

2

3

5

2

4

3

Figure 8 - Wheel and Foot Attachment

Step 1: Get out the two WHEELS (#2), the three COTTER PINS (#3), the FOOT (#4) and the

AXLE (#5).

Step 2: Attach the FOOT to the TANK (#1) using one of the COTTER PINS.

Step 3: Attach one of the WHEELS to the AXLE using one of the COTTER PINS.

Step 4: Slide the AXLE through the hole in the bottom of the two HANDLE BARS (#6).

Step 5: Attach the other WHEEL to the AXLE using the remaining COTTER PINS.

Safety Valve

Step 1: Screw the SAFETY VALVE (#10) into the hole in the top of the TANK (#1).

Page #11 -- SKU 34202

Page 12

Loading Abrasives

OPERATIONS

Step 1: Check to insure the abrasives are dry and clean

so that they do not clog the unit.

Always wear your hood, dust

Warning!

mask, and heavy-duty canvas

Step 2: Close the AIR SUPPLY VALVE (#18) by turning it to

the horizontal position.

Step 3: Open the NOZZLE SHUT OFF VALVE (#18C) by turning it to the vertical position.

Step 4: Make sure the PRESSURE GAUGE (#15) reads “0”.

Step 5: Remove the TANK CAP (#12).

gloves when operating the

Sand Blaster.

Note:

Place your Air Compressor in

Step 6: Using the FUNNEL (#29), pour the selected

abrasive medium into the TANK (#1). Do not fill more than

3/4 of the TANK. If humidity in your region is 90% or more,

only fill the tank 1/2 way, and check the WATER TRAP (#17) more frequently.

Step 7: Close the TANK CAP.

Step 8: Close the NOZZLE SHUT OFF VALVE and open the AIR SUPPLY VALVE.

Step 9: Check for leaks at the TANK CAP as pressurization begins.

another room to prevent

damage to it.

Step 10: Open the NOZZLE SHUT OFF VALVE to begin blasting.

Page #12 -- SKU 34202

Page 13

MAINTENANCE

1. Pay particular attention to the SAND HOSE (#24), the NOZZLE SHUT OFF VALVE (#18C),

and the NOZZLES (#27A-D) as they will wear out much more quickly than the other

pieces.

2. The SAND HOSE needs replacing when it’s side walls develop leaks or show blisters in

the surface. Do not use if any of these problems are present.

PARTS LIST

Item# Description Qty Item# Description Qty

1 Tank 1 18B 3/8" Steel Sand Control Valve 1

2 Wheel 2 18C 3/8" Steel Shut Off Valve 1

3 Cotter Pin 3 19 Male/Female Adapter 1

4 Foot 1 20 3/8" 1/4" Nipple Connector 1

5 Axle 1 21 Air Hose 1

6 * Handle Bar 2 22 Sand Outlet Manifold 1

7 Handle Grip 2 23 Hose Clamp 2

8 Pan Screw 4 24 Sand Hose 1

9 Hex Nut 4 25 Hose Adapter 1

10 Safety Valve 1 26 Gasket 1

11 O-Ring 1 27A 9/64" Nozzle 1

12 Tank Cap 1 27B 1/8" Nozzle 1

13 Joint Pipe 1 27C 7/64" Nozzle 1

14 Intake Manifold 1 27D 3/32" Nozzle 1

15 Pressure Gauge 1 28 Nozzle Cap Nut 1

16 3/8" Nipple Connector 5 29 Funnel 1

17 Water Trap 1 30 Hood 1

18 3/8" Brass Air Supply Valve 1 31 Washer 1

18A 3/8" Brass Throttling Valve 1 32 Instruction Manual 1

* Note: Left Handle is #6-L, Right Handle is #6-R.

REV 01/01Page #13 -- SKU 34202

Page 14

PARTS DRAWING

19

18

16

17

16

15

12

11

10

3

13

7

6

8

14

18A

20

24

14

31

9

2

3

1

23

16

18B

16

22

16

26

27A-D

28

21

5

25

18C

23

Page #14 -- SKU 34202

Loading...

Loading...