Harbor Breeze E-ER56ORB3LKLR Instructions Manual

ITEM #0219421

MONTE BELLO CEILING FAN

Harbor Breeze® is a registered trademark

of LF, LLC. All Rights Reserved.

MODEL #E-ER56ORB3LKLR

Español p. 23

Federal regulations require ceiling fans with light kits manufactured or imported after

January 1, 2009, to limit total wattage consumed by the light kit to 190W. Therefore,

this fan is equipped with a wattage limiting device.

ATTACH YOUR RECEIPT HERE

Serial Number

Questions, problems, missing parts? Before returning to your retailer, call or contact our

customer service department at 1-800-527-1292, 8:30 a.m. - 5:00 p.m., CST, Monday - Friday.

E192641

Purchase Date

1

TABLE OF CONTENTS

Safety Information ....................................................................................................................... 2 - 3

Product Overview ............................................................................................................................ 4

Package Contents ........................................................................................................................... 5

Hardware Contents ......................................................................................................................... 6

Preparation ...................................................................................................................................... 6

Initial Installation ........................................................................................................................ 7 - 8

Fan Mounting ............................................................................................................................ 8 - 11

Wiring Remote Control and Fan ............................................................................................ 11 - 13

Final Installation ...................................................................................................................... 13 - 16

Automated Learning Process/Activating Code ...................................................................... 16 - 17

Changing Reverse Switch Setting ................................................................................................ 17

Operation Instructions for Remote Control and Fan ............................................................. 18 - 19

Care and Maintenance .................................................................................................................. 19

Troubleshooting ............................................................................................................................. 20

Warranty ........................................................................................................................................ 21

Replacement Parts List ................................................................................................................. 22

SAFETY INFORMATION

READ AND SAVE THESE INSTRUCTIONS

Please read and understand this entire manual before attempting to assemble, install or operate the

product. If you have any questions regarding the product, please call customer service at

1-800-527-1292, 8:30 a.m.- 5:00 p.m., CST, Monday - Friday.

• Do not discard fan carton or foam inserts. Should this fan need to be returned to the factory for

repairs, it must be shipped in its original packaging to ensure proper protection against damage that

might exceed the initial cause for return.

• Make sure that all electrical connections comply with local codes, ordinances, the National Electrical

Code and ANSI/NFPA 70-1999. Hire a qualified electrician or consult a do-it-yourself wiring handbook,

available at Lowe's, if you are unfamiliar with installing electrical wiring.

• Make sure the installation site you choose allows a minimum clearance of 7 feet from the blades to

the floor and at least 30 in. from the end of the blades to any obstruction.

• After you install the fan, make sure that all connections are secure to prevent the fan from falling.

• The net weight of this fan including the light kit is: 21.27 lbs. (9.65 kg).

2

SAFETY INFORMATION

WARNINGS

To reduce the risk of fire, electrical shock, or personal injury, mount fan to outlet box

marked "ACCEPTABLE FOR FAN SUPPORT OF 35 LBS (15.9 KG) OR LESS" and use

mounting screws provided with the outlet box. Most outlet boxes commonly used for the

support of lighting fixtures are not acceptable for fan support and may need to be replaced.

Consult a qualified electrician if in doubt.

When mounting fan to a ceiling outlet box, use a METAL octagonal outlet box. Secure the outlet

box directly to the building structure. The outlet box and its support must be able to support the

moving weight of the fan (at least 35 lbs.). Do NOT use a plastic outlet box.

To avoid personal injury, the use of gloves may be necessary while handling fan parts with

sharp edges.

To reduce the risk of fire, electrical shock, or personal injury, wire connectors provided with this

fan are designed to accept only one 12-gauge house wire and two lead wires from the fan. If your

house wire is larger than 12-gauge or there is more than one house wire to connect to the two fan

lead wires, consult an electrician for the proper size wire connectors to use.

To reduce the risk of fire or electrical shock, do not use the fan with any solid state speed

control device or control fan speed with a full range dimmer switch.

To reduce the risk of fire, electrical shock, or personal injury, do not bend the blade arms when

installing them, balancing the blades, or cleaning the fan. Do not insert objects between the

rotating fan blades.

To reduce the risk of personal injury, use only parts provided with this fan. The use of parts

OTHER than those provided with this fan will void the warranty.

CAUTIONS

Before proceeding, be sure to shut off electricity at main switch or circuit breaker in order to avoid

electrical shock.

Read all instructions and safety information before installing your new fan. Review the

accompanying assembly diagrams.

3

PRODUCT OVERVIEW

Congratulations on your purchase of this Harbor Breeze®

Ceiling Fan! This product has been specifically designed to

give you all the performance you’ll ever need. Harbor Breeze®

is the perfect fusion of smart innovation and beautiful style.

Designed for more than just air movement, our products are

built to function flawlessly... day after day. Expect showroom

quality at an exceptional price with Harbor Breeze® - available

exclusively at Lowe’s.

Harbor Breeze® is a registered trademark

of LF, LLC. All Rights Reserved.

Determining how you want your ceiling fan to look and operate is an important step prior to

installation. You can save installation time by deciding which options are best suited for your needs

before beginning the steps outlined in this manual.

Your fan can be installed on a normal or angled ceiling. Two points to remember before you hang

your ceiling fan:

• Downrod style mounting is best suited for ceilings 8 ft. (2.44 m) high or higher. For taller ceillings

you may want to use a longer downrod (sold separately) than the one provided.

• Angle style mounting is best suited for angled or vaulted ceilings. A longer downrod is sometimes

necessary to ensure proper blade clearance.

Your fan must be installed with the light kit included with your model.

Your fan must also be used with the remote control included with your model.

4

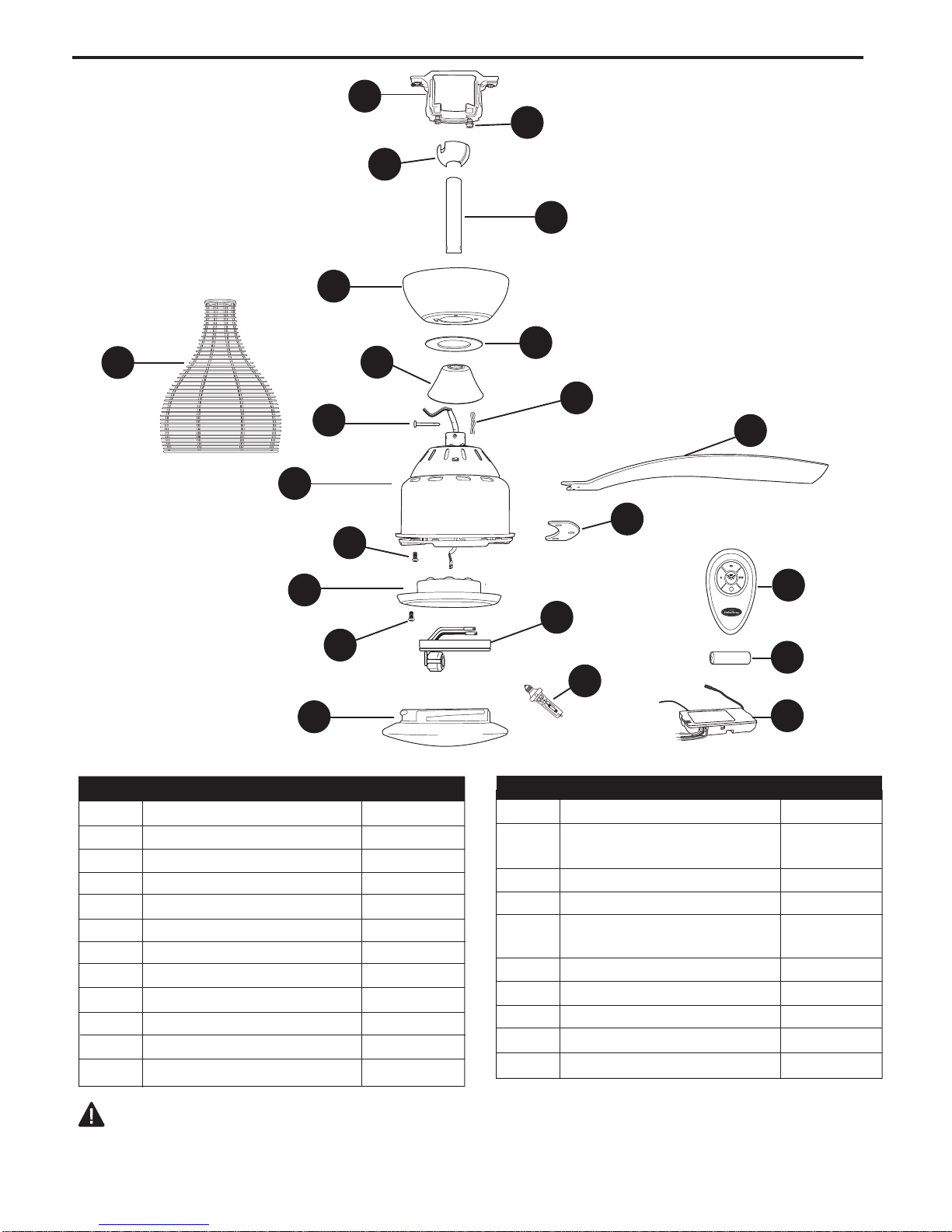

PACKAGE CONTENTS

V

C

N

K

A

B

I

D

M

L

G

E

J

P

T

O

PART DESCRIPTION QUANTITY

A

B

C

D

E

F

G

H

I

J

K

L

Downrod 1

Canopy

Mounting Bracket

Yoke Cover

Motor Housing

Blade Plate

Blade

Light Kit Fitter

Canopy Cover

Fitter Plate Screw

Hanging Ball

Pin (preassembled)

1

1

1

1

3

3

1

1

3

1

1

F

Q

H

12V Size A23

R

U

S

PART DESCRIPTION QUANTITY

M

Clip (preassembled)

N

Canopy Mounting Screw

O

P

Q

(preassembled)

Glass Shade

Shade Fitter

Remote Control

Transmitter

R 12-volt Battery

S Remote Control Receiver

T Shade Fitter Screw

U Halogen Bulb

V Wire Cage

1

2

1

1

1

1

1

3

1

1

IMPORTANT REMINDER: You must use the parts

provided with this fan for proper installation and safety.

5

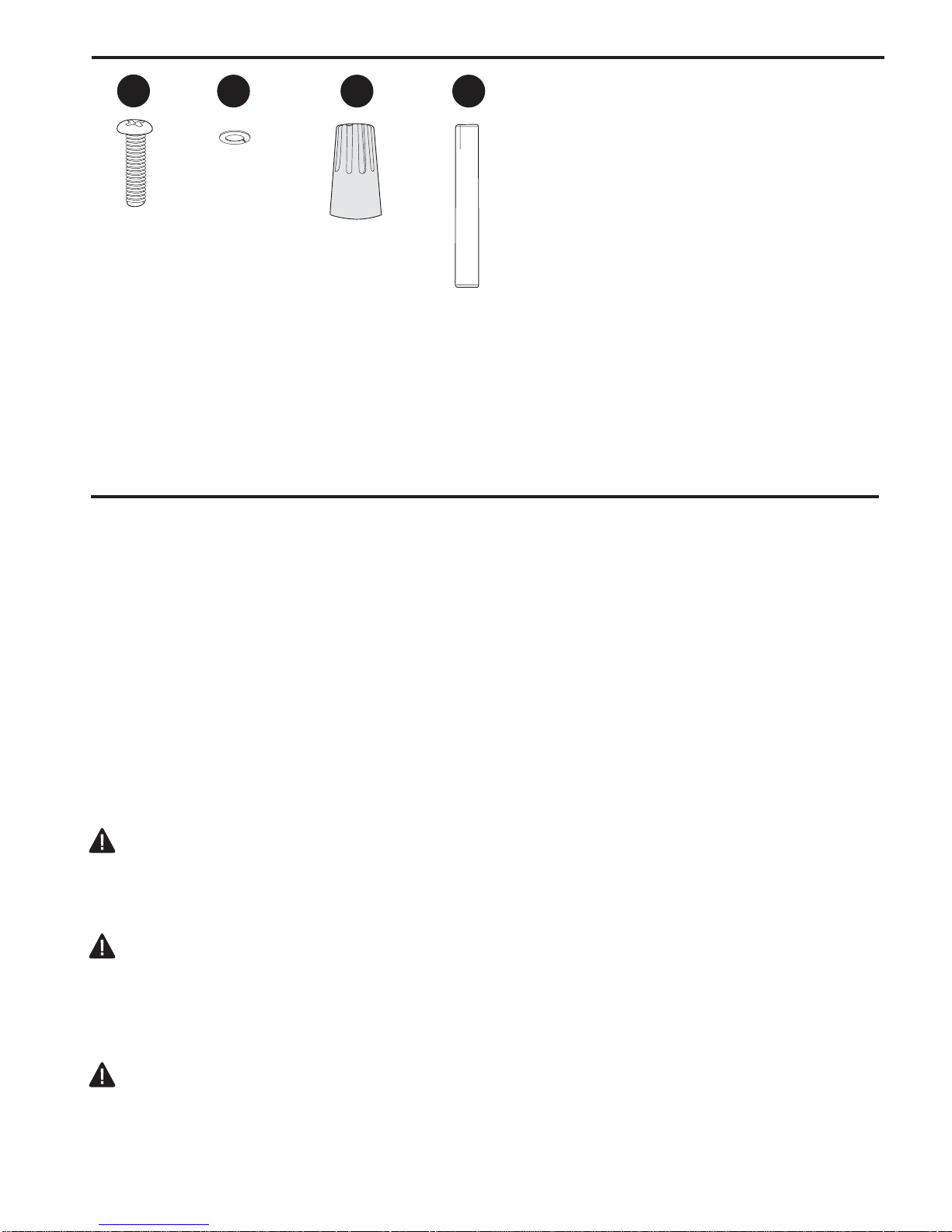

HARDWARE CONTENTS (shown actual size)

AA

BB CC

DD

Lock

Washer

Blade

Screw

Qty. 9

Qty. 9

E3 Wire

Connector

Qty. 10

Stop

Pin

Qty. 1

PREPARATION

Before beginning assembly of product, make sure all parts are present. Compare parts with package

contents list and hardware contents above. If any part is missing or damaged, do not attempt to

assemble the product. Contact customer service for replacement parts.

Estimated Assembly Time: 120 minutes

Tools Required for Assembly (not included): Electrical Tape, Phillips Screwdriver, Pliers, Safety

Glasses, Stepladder and Wire Strippers

Helpful Tools (not included): AC Tester Light, Tape Measure, Do-It-Yourself-Wiring Handbook

(available at Lowe’s) and Wire Cutters

Bulb Required (included): One 75-watt max. halogen bulb, size JD E11

DANGER: When using an existing outlet box, make sure the outlet box is securely attached to

the building structure and can support the full weight of the fan. Failure to do this can result in serious

injury or death. The stability of the outlet box is essential in minimizing wobble and noise in the fan

after installation is complete.

CAUTION: Be sure outlet box is properly grounded and that a ground wire (green or bare) is

present.

After opening top of carton, remove mounting hardware package from foam inserts. Remove motor

from packing and place on carpet or on foam to avoid damage to finish.

CAUTION: Carefully check all screws, bolts and nuts on fan motor assembly to ensure that they

are secured.

6

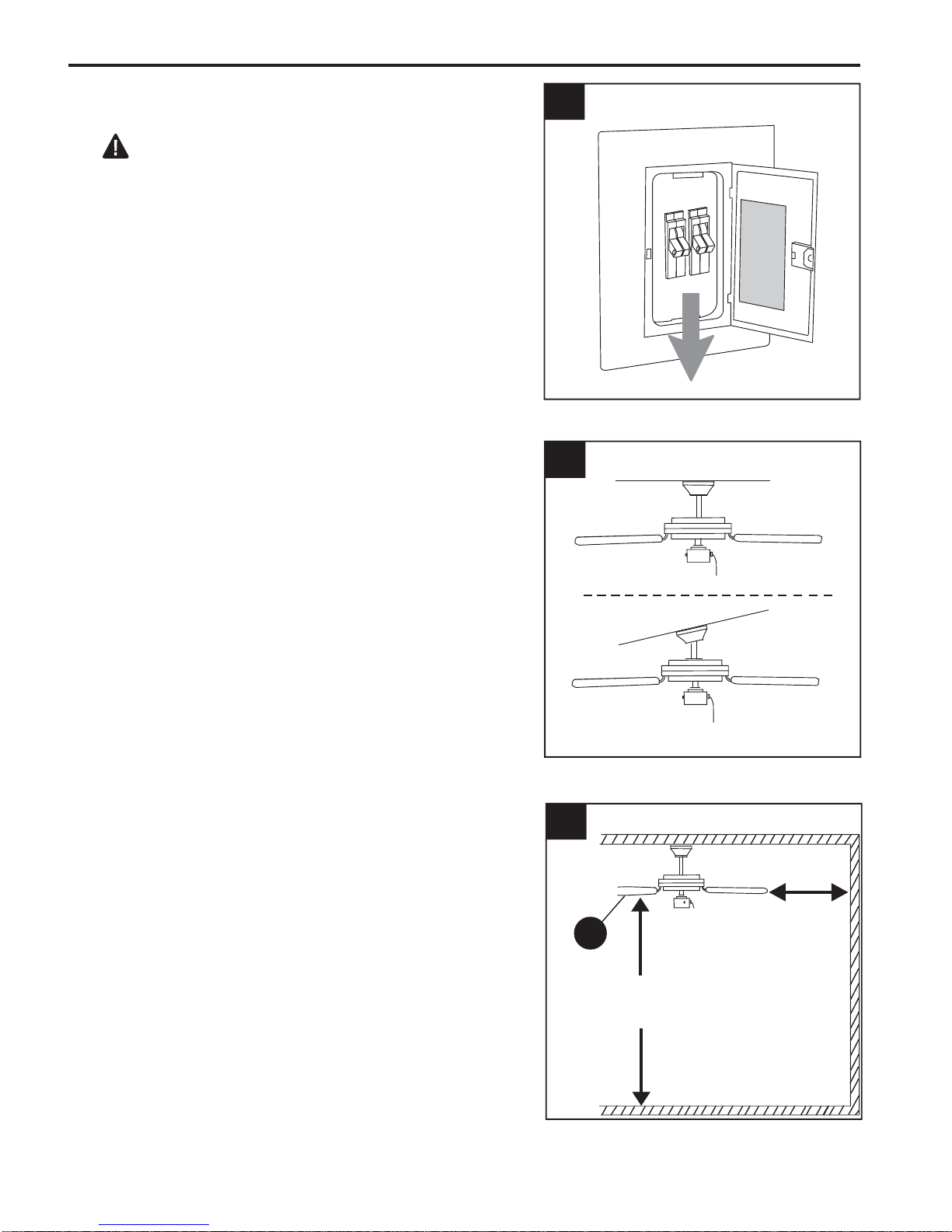

INITIAL INSTALLATION

1.

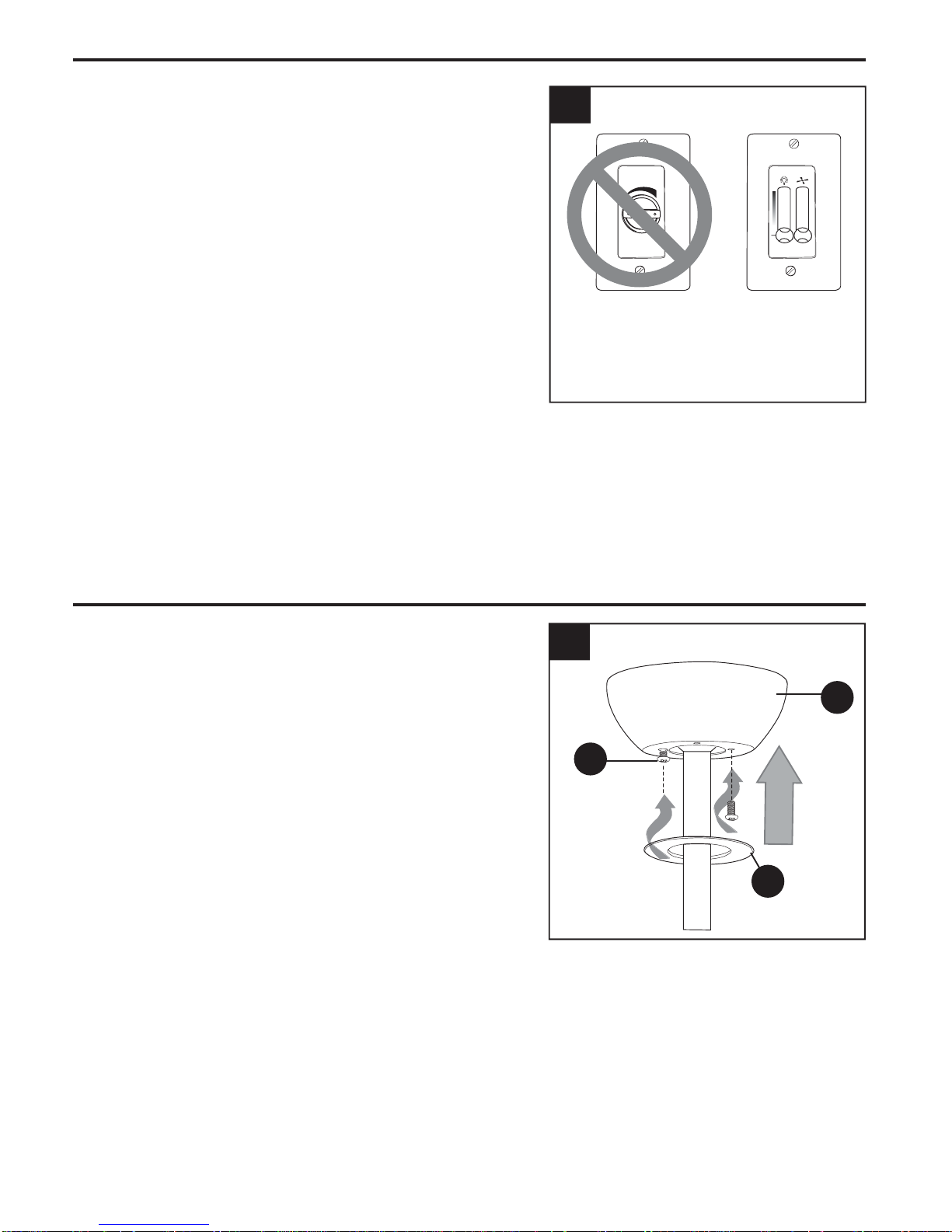

Turn off circuit breakers and wall switch to the fan

supply line leads. (Fig. 1)

DANGER: Failure to disconnect power supply

prior to installation may result in serious injury or

death.

Determine mounting method to use. (Fig. 2)

2.

A. Normal mount

B. Angle mount

Important: If using the angle mount, check to

make sure the ceiling angle is not steeper than 19°.

1

2

ON

ON

OFF

OFF

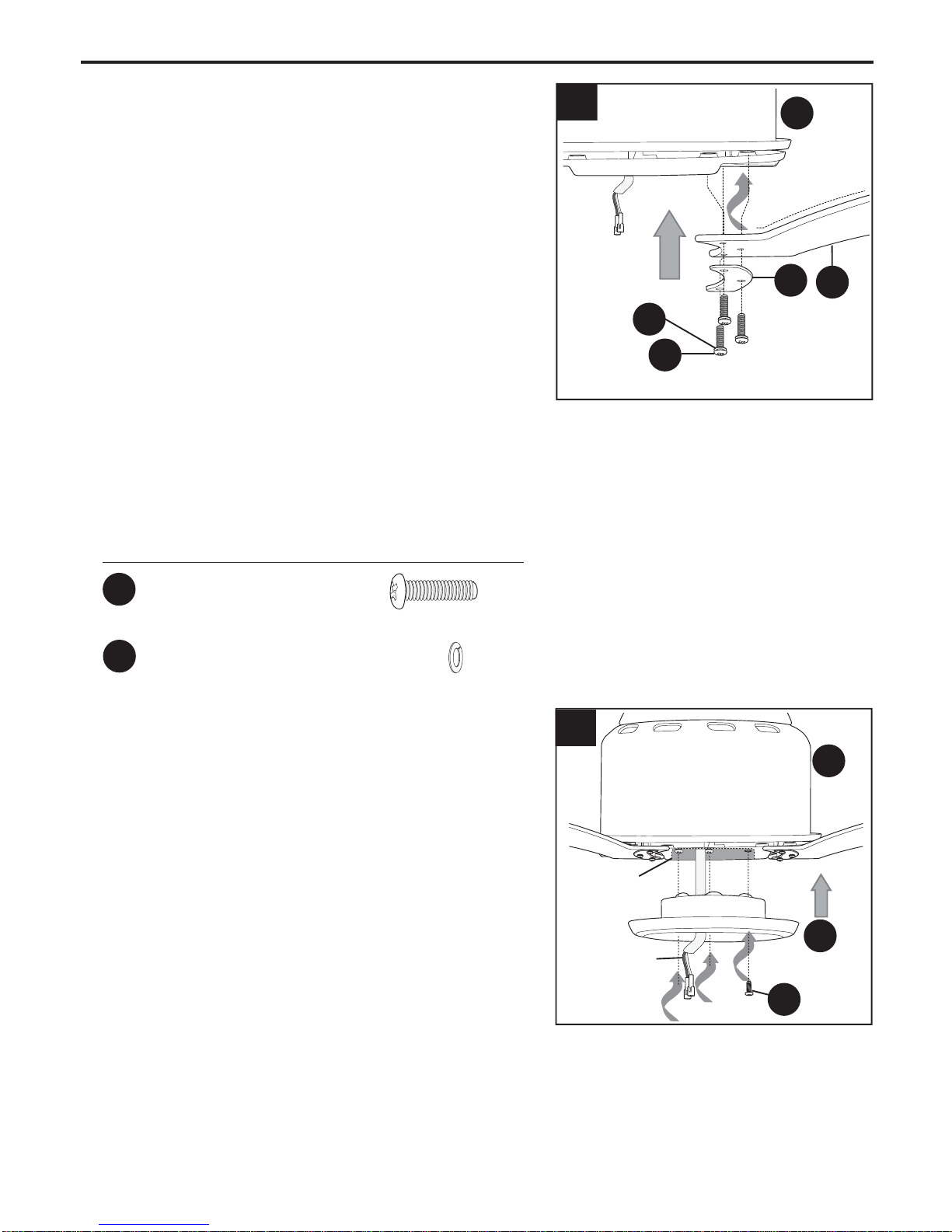

Check to make sure blades (G) are at least 30 in.

3.

from any obstruction. Check downrod (A) length to

ensure blades (G) are at least 7 ft. above the floor.

(Fig. 3)

3

3

A

B

G

30 in.

min.

7 ft.

min.

7

INITIAL INSTALLATION

Secure mounting bracket (C) to outlet box using

4.

screws, spring washers, and flat washers provided

with the outlet box. (Fig. 4)

*NOTE: It is very important that you use the proper

hardware when installing the mounting bracket (C)

as this will support the fan.

IMPORTANT: If using the angle mount, make sure

open end of mounting bracket (C) is installed

facing the higher point of the ceiling.

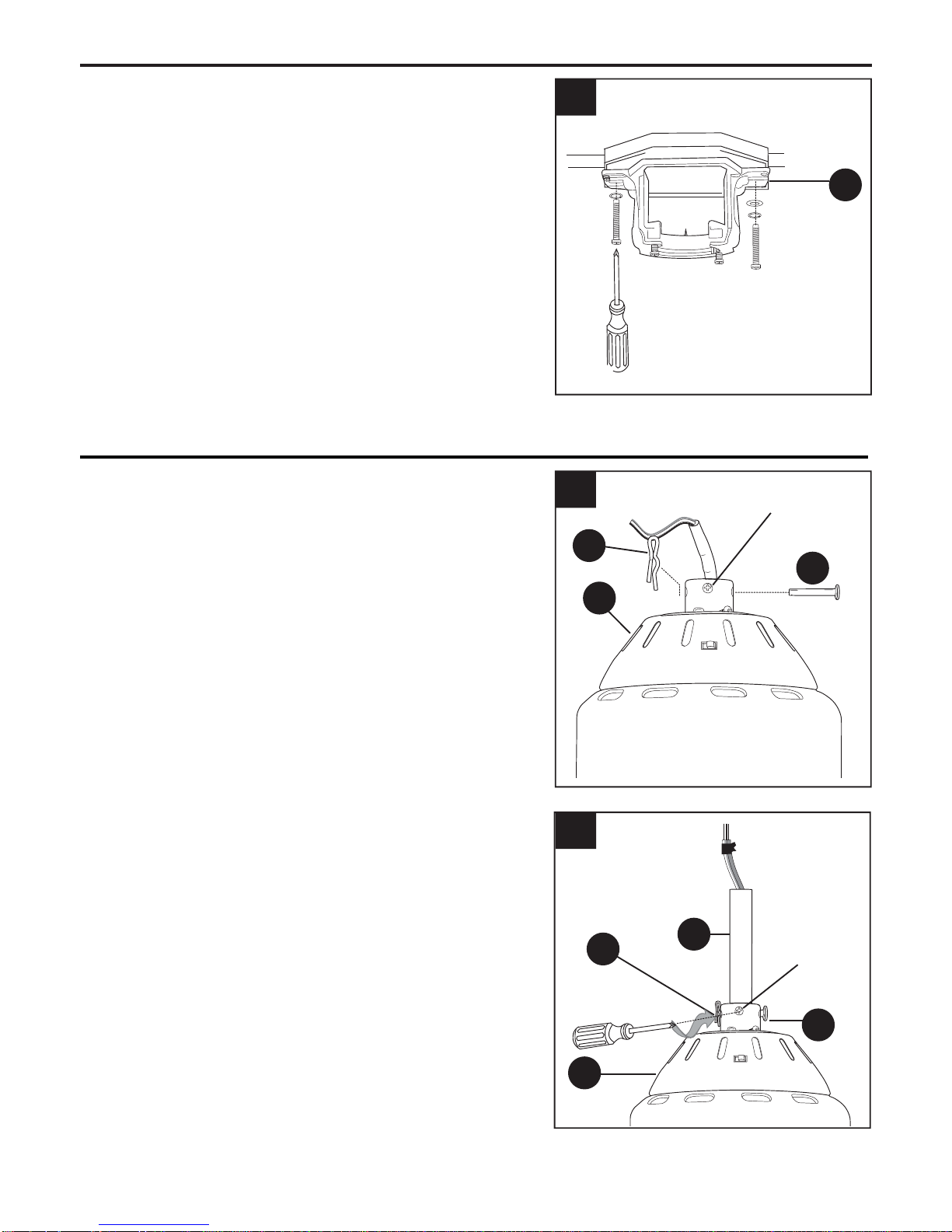

FAN MOUNTING

1.

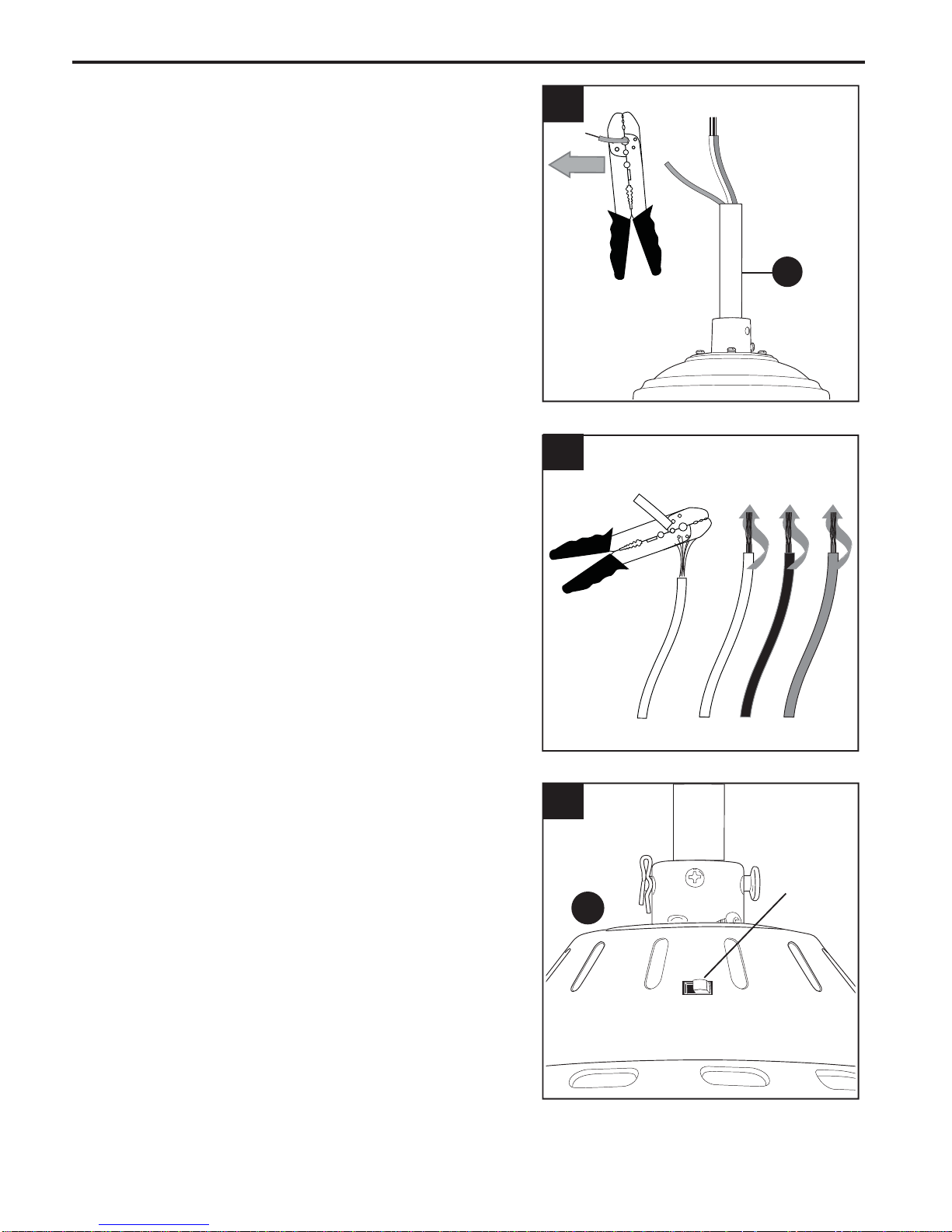

Remove pin (L) and clip (M) from motor housing

yoke at top of motor housing (E) and partially

loosen set screws. (Fig. 1)

*Helpful Hint: Downrod style mounting is best

suited for ceilings 8 ft. (2.44 m) high or higher. For

taller ceilings you may want to use a longer

downrod (not included) than the one provided.

Angle style mounting is best suited for angled or

vaulted ceilings. A longer downrod is sometimes

necessary to ensure proper blade clearance.

4

1

C

Set

Screw

M

L

E

2.

Thread wires from motor housing (E) through

downrod (A). Slip downrod (A) into housing

yoke, align holes and re-install pin (L) and clip

(M). Tighten downrod (A) set screws and then

tighten nuts. (Fig. 2)

2

M

E

8

A

Set

Screw

L

FAN MOUNTING

3.

Depending on the length of downrod (A) you

use, you may need to cut the lead wires back to

simplify the wiring. If you decide to cut back the

lead wires, it is suggested that you do so in the

following manner:

Take the lead wires and make sure that you

have pulled them all the way through the top of

the downrod (A). Start at the TOP of the

downrod (A) and measure 8 in. of lead wire, and

then cut the excess wire off with wire cutters (not

included). (Fig. 3)

NOTE: If you do not cut back the lead wires,

Steps 3 and 4 are not necessary and you may

proceed to Step 5 instead.

4.

If you decided to cut back the lead wires in

Step 3, strip 1/2 in. of insulation from end of

white wire. (Fig. 4) Twist stripped ends of each

strand of wire within the insulation with pliers

(not included). Repeat Step 4 for black, blue (if

applicable) and green wires.

3

A

4

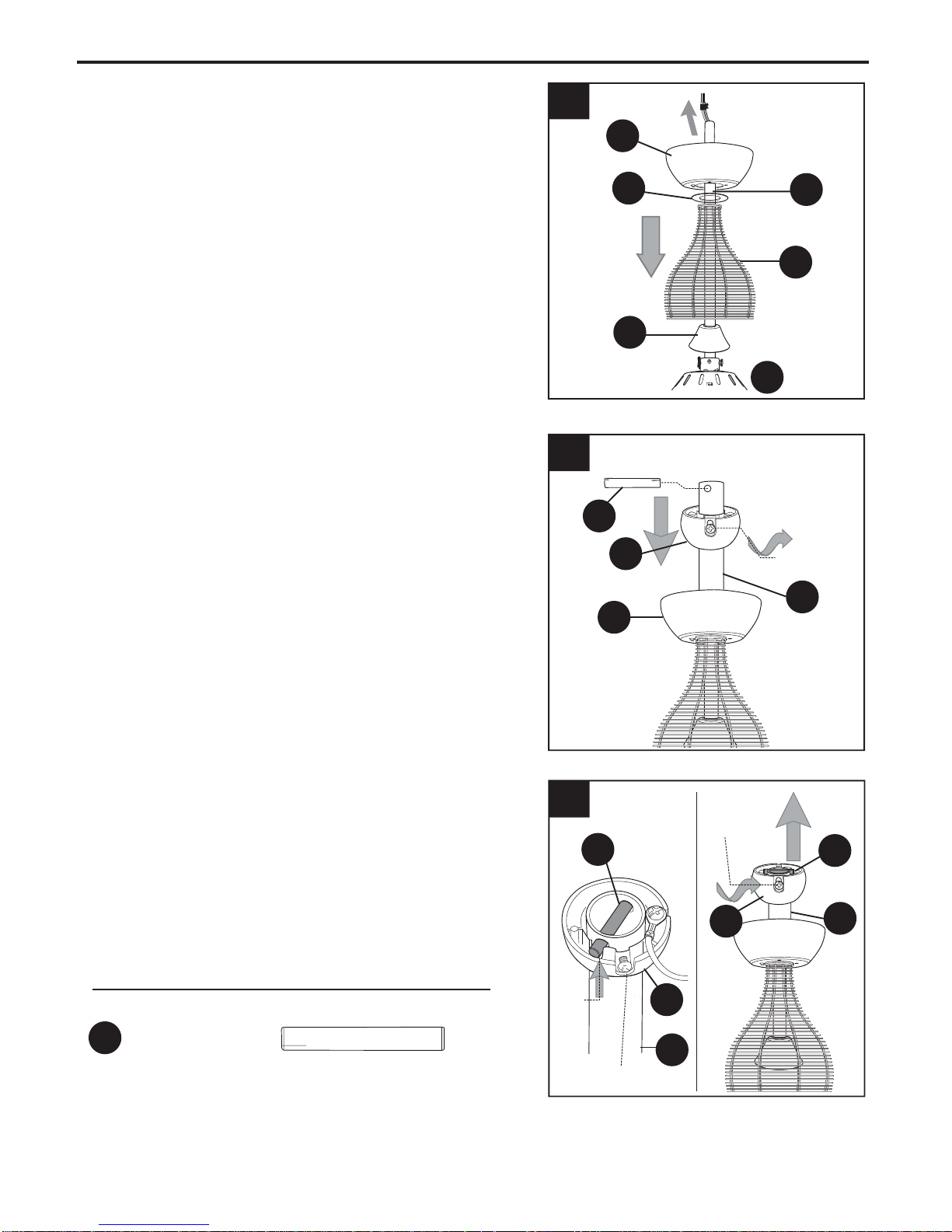

5.

Set the reverse switch--located on the top of the

motor housing (E)--to the LEFT position for a

downward airflow to create a wind chill effect or

to the RIGHT position to create an upward

airflow that will help move hot air off the ceiling.

You will need to listen for a CLICK to be sure

the switch has been moved completely to the

left or completely to the right. (Fig. 5)

IMPORTANT: If you do not hear a click, the

switch is not set properly and the fan will not

function.

For further information on the reverse switch,

please see Step 2 on pages 18 and 19 in

“Operation Instructions for Remote Control and

Fan”.

5

Reverse

E

9

Switch

FAN MOUNTING

6.

Slide yoke cover (D) onto downrod (A) followed

by wire cage (V), canopy cover (I) and canopy

(B). [Note: Canopy cover (I) must be turned with

the shiny side toward the motor housing (E).]

(Fig. 6)

Locate hanging ball (K) and stop pin (DD). Check

7.

inside of hanging ball (K) with finger to be sure

surface is smooth; if it is not, partially loosen set

screw on side of hanging ball (K).

6

7A

DD

B

D

I

A

V

E

Thread wires from top of downrod (A) through

hanging ball (K) and then slide hanging ball (K)

onto downrod (A)--hanging ball (K) must be turned

with the rounded part facing the motor housing

(E). Slide stop pin (DD) through holes at top of

downrod (A), centering the stop pin (DD) in the

downrod (K) so equal amounts show on each side

of the downrod (A). Make sure all three wires

remain on the same side of the stop pin (DD). (Fig.

7A)

Locate slots inside hanging ball (K), turn hanging

ball (K) so slots align with stop pin (DD) and raise

hanging ball (K) to top of downrod (A). [NOTE: It is

extremely important the top of the hanging ball

(K) is flush with the top of the downrod (A); the

stop pin (DD) must sit COMPLETELY inside of the

slot in the hanging ball (K).] Securely tighten set

screw at top of downrod (A). (Fig. 7B)

Hardware Used

7B

Slot

DD

B

K

K

Set

Screw

K

Set Screw

A

DD

A

DD

Stop Pin x1

A

Set Screw

10

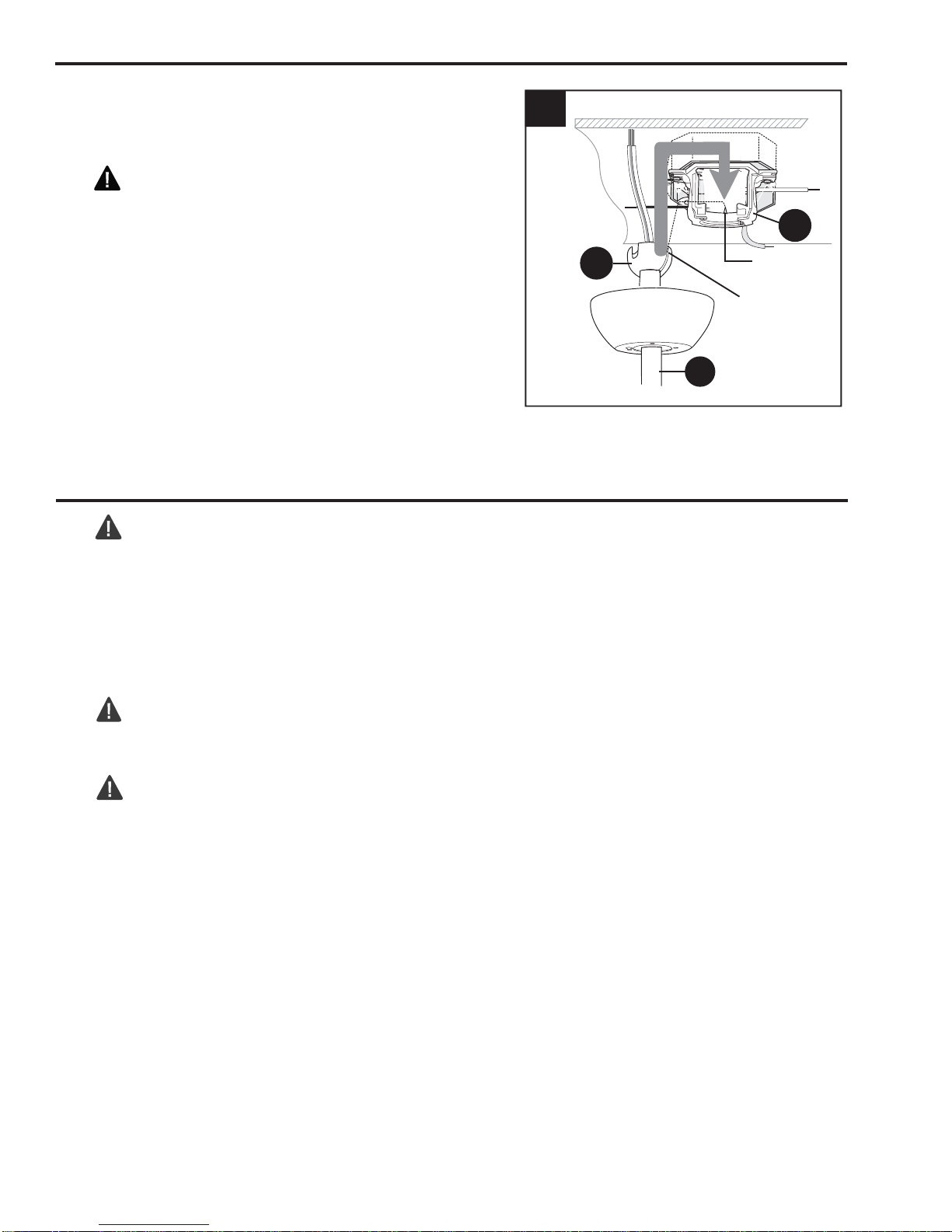

FAN MOUNTING

8.

Install hanging ball (K) on downrod (A) into

mounting bracket (C) opening. Align slot in hanging

ball (K) with tab in mounting bracket (C). (Fig. 8)

DANGER: Failure to align slot in hanging ball

(K) with tab may result in serious injury or death.

8

C

WIRING

WARNING: To reduce the risk of fire,

electrical shock, or personal injury, wire connectors

provided with this fan are designed to accept only

one 12-gauge house wire and two lead wires from

the fan. If your house wire is larger than 12-gauge

or there is more than one house wire to connect to

the two fan lead wires, consult an electrician for the

proper size wire connectors to use.

CAUTION: Be sure outlet box is properly

grounded and that a ground (green or bare) wire is

present.

K

Tab

Hanging

Ball Slot

A

WARNING: If house wires are different colors

than referred to in the following steps, stop

immediately. A professional electrician is

recommended to determine wiring.

NOTE: Black wire is hot power for fan. Blue wire is

hot power for light kit. White wire is common for fan

and light kit. Green or bare wire is ground.

NOTE: Please refer to installation and operating

instructions for remote control.

11

WIRING

Make the necessary wiring connections for remote

1.

control operation according to Fig. 1. For each wire

connection, use one of the wire connectors (CC)

provided, making sure to screw wire connector

(CC) on in a clockwise direction. [Make sure to

connect all GROUND (GREEN) wires together from

fan (on hanging ball (K) and mounting bracket (C))

to BARE/GREEN wire from ceiling.]

WIRING TIP: Wiring your fan's remote control

requires extreme patience. Take mandatory breaks

while wiring to allow your arms to rest.

Wrap electrical tape (not included) around each

2.

individual wire connector (CC) down to the wire as

shown in Fig. 2.

1

BLACK

BLACK

2

120 V Power

FROM CEILING

WHITE

WHITE

BLUE BLUE

BLACK

WHITE

BARE GREEN

AC SUPPLY

S

BLACK

WHITE

ANTENNA

K

C

A

WARNING: Make sure no bare wire or wire

strands are visible after making connections. Place

green and white connections on opposite side of

box from the black connections.

Hardware Used

CC

E3 Wire Connector x4

3.

Gently slide remote control receiver (S), smooth

side up, into mounting bracket (C). (Fig. 3) Turn

spliced/taped wires upward and gently push wires

and wire connectors (CC) into outlet box. Let

antenna from remote control receiver (S) hang to

the side.

Note: The remote control included with this fan

meets the following requirements:

a. Not for use with solid state fans.

b. Electrical rating: 120V / 60 Hz; motor

amps:1.5 MAX.;

light watts: 300 (Incandescent only).

Should you choose to use a different remote control

with this fan, it must also meet these same

requirements.

CC

3

Antenna

CC

CC

C

S

A

12

WIRING

4.

IMPORTANT: Using a full range dimmer switch (not

included) to control fan speed will cause a loud

humming noise from fan. To reduce the risk of fire or

electrical shock, do NOT use a full range dimmer

switch to control fan speed. (Fig. 4)

4

3

2

1

FINAL INSTALLATION

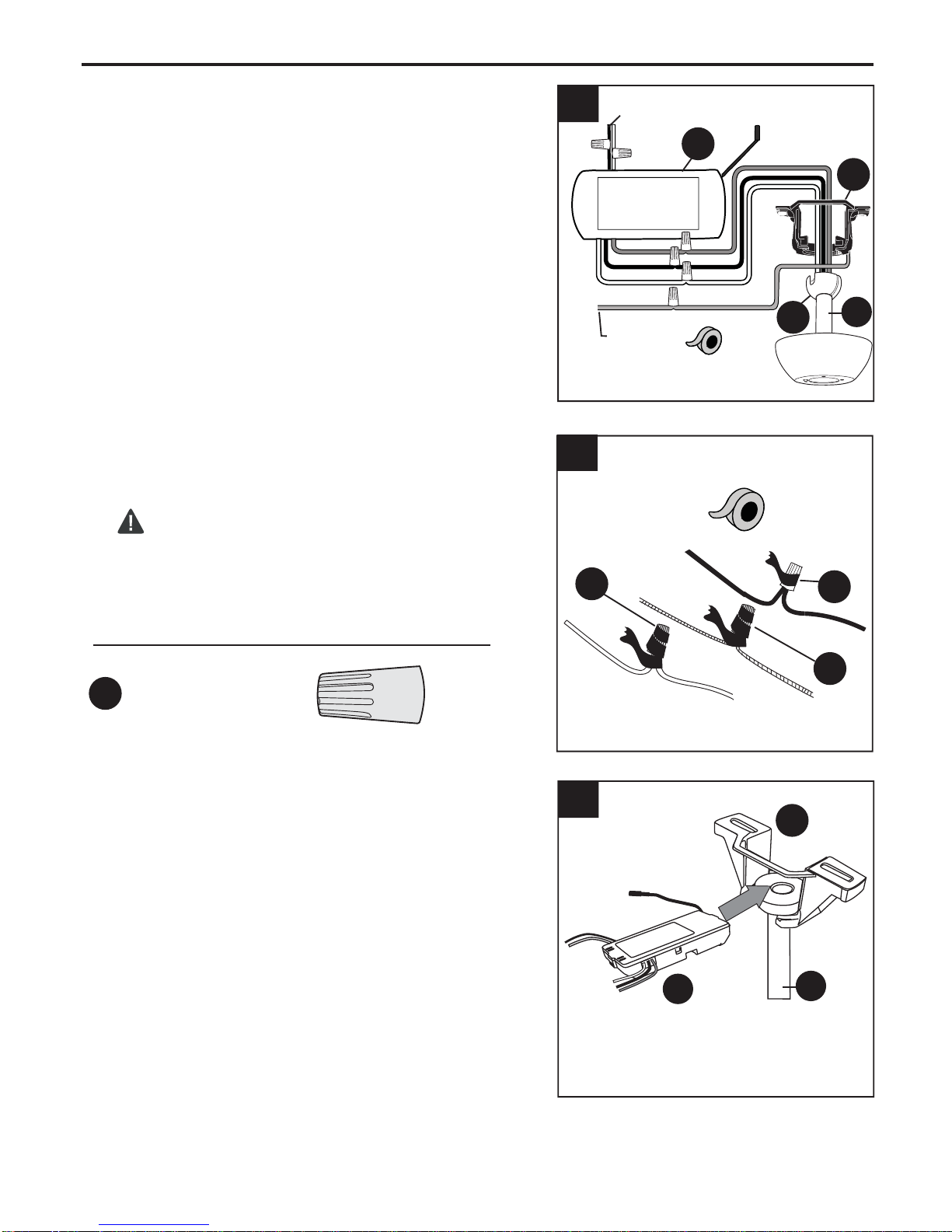

1.

Locate two canopy mounting screws (N) on

underside of mounting bracket (C) and remove

canopy mounting screw (N) closest to the open end

of the mounting bracket (C). Partially loosen the

other canopy mounting screw (N). Lift canopy (B) to

mounting bracket (C). Place rounded part of slotted

hole in canopy (B) over loosened canopy mounting

screw (N) in mounting bracket (C) and push up.

Twist canopy (B) to lock. Re-insert canopy mounting

screw (N) that was removed, and then tighten both

canopy mounting screws (N). Slide canopy cover (I)

up to canopy (B), aligning rounded part of slotted

holes in canopy cover (I) with screwheads in bottom

of canopy (B). Turn canopy cover (I) to the right

(clockwise) until it stops. (Fig. 1)

Dimmer

Switch

Speed

Switch

For illustrative purposes only--not

intended to cover all types of controls

1

B

N

I

13

FINAL INSTALLATION

Place one blade plate (F) over blade (G), aligning

2.

holes, with numbered side in blade plate (F) facing

up. After inserting one blade screw (AA), along

with one lock washer (BB), through center hole in

blade plate (F) and blade (G), align that blade

screw (AA) with center hole in one set of three

holes on underside of motor housing (E) to attach

blade plate (F) and blade (G) to motor. (Make

sure to attach blade (G) so that the curved part

of the blade (G) arcs UPWARD. Note label

indicating THIS SIDE UP.) Turn center blade

screw (AA) with fingers first, and then partially

insert the other two blade screws (AA), along with

lock washers (BB), with fingers also. Once all

three blade screws (AA) have been partially

inserted, tighten each blade screw (AA) with a

Phillips screwdriver (not included) starting with the

one in the middle. (Fig. 2) Repeat procedure with

remaining blades (G) and blade plates (F), making

sure to completely secure each blade (G) and

blade plate (F) before proceeding with the next.

2

BB

AA

E

Upward Arc

F

G

Hardware Used

AA

Blade Screw x9

BB

Lock Washer x9

Remove one fitter plate screw (J) from fitter plate

3.

(on underside of motor) and loosen the other two

fitter plate screws (J). Align slotted holes in middle

of shade fitter (P) with loosened screws in fitter

plate, allowing molex connections from motor

housing (E) to come through hole in middle of

shade fitter (P). Twist shade fitter (P) to lock.

Re-insert fitter plate screw (J) that was just

removed, and then tighten all three fitter plate

screws (J) securely. (Fig. 3)

3

E

Fitter

Plate

P

Molex

Connections

J

14

Loading...

Loading...