SAO512-6

INSTRUCTION BOOK

Program Ver. *1.34 ~

HCS2

Computerized Compact Single Head Embroidery Machine

Original instructions

-SA -3

INDEX

IMPORTANT SAFETY INSTRUCTIONS.. 1-1

WARNING LABELS & THEIR LOCATIONS .....

1-2

SETTING UP THE MACHINE

Remove the machine from box............... 2-1

Accessories ............................................ 2-2

Assemble machine unit .......................... 2-3

Machine installation ................................ 2-4

Grounding instruction ............................. 2-6

Disposal of a battery............................... 2-6

MAIN PARTS ............................................ 3-1

HOW TO READ THESE INSTRUCTIONS and SCROLLBAR

3-3

MESSAGE ................................................ 3-4

TURNING THE MACHINE ON

How to turn on the machine.................... 3-5

Calendar and clock setting ..................... 3-7

THE CONTROL BOX................................ 3-8

DRIVE MODE ........................................... 3-9

GUIDE....................................................... 3-D

INSERTING A NEEDLE............................ 4-1

SELECT NEEDLES AND THREADS....... 4-2

BACKING MATERIALS............................. 4-3

BOBBIN WINDING

Winding the bobbin................................. 4-4

Removing the bobbin.............................. 4-5

Inserting the bobbin ................................ 4-5

Adjusting bobbin thread tension ............. 4-5

Inserting the bobbin case ....................... 4-5

THREADING THE MACHINE

How to thread upper thread.................... 4-6

MACHINE SETTINGS............................... 5-1

LOCK STITCHES.....................................5-3b

PREPARATION OF PATTERN DATA

Connecting to a PC ................................ 5-4

Reading embroidery pattern data from

the PC ..........................................................

5-4b

Read embroidery pattern data................ 5-5

Reading pattern data .............................. 5-6

Selection of folders ................................. 5-9

How to select patterns from memory...... 5-A

Erasing patterns from memory ............... 5-B

NEEDLE BAR SELECTION ...................... 5-E

SEWING WITH TUBULAR FRAMES

Installing and removing the frame base.. 6-1

How to hoop ........................................... 6-2

Putting the hoop on the machine............ 6-3

Starting to embroider .............................. 6-4

CAP FRAME (OPTION)

Changing the needle plate...................... 7-1

Installing and removing the cap drive frame...

7-2

Normal cap frame ................................... 7-5

Wide cap frame ...................................... 7-8

Starting to embroider .............................. 7-B

ADJUSTING THE THREAD TENSIONS .. 8-1

ADJUSTING THE LASER POINTER (OPTION)...

8-2

SEWING

What to do if the thread breaks while sewing.

9-1

Stopping and resuming sewing .............. 9-1

Loss of power while embroidering .......... 9-2

Moving the hoop while embroidering and then returning to

the correct location (Position) .......................................

9-3

Moving back to the starting point (Origin)9-3

Going back to the beginning of the design (Top) ....

9-4

Placing the design in the center of the selected

embroidery frame

(Center) ..................................

9-4

Rotating and mirroring designs (Convert) ..

9-5

Starting in the middle of a design (Position)...

9-6

DISPLAYING THE PATTERN IN SETTING MODE.

10-1

PATTERN

Locking pattern data ............................. 11-1

Trace type............................................. 11-2

Export ................................................... 11-3

Renaming patterns ............................... 11-5

Copying pattern data ............................ 11-6

Moving pattern data.............................. 11-7

0_1 N401

0-1

-SA -4

INDEX

0-2

Renaming folders ................................. 11-9

Sort........................................................11-A

Thread break report...............................11-B

Retrieve built-in data from machine...... 11-C

Searching pattern data ......................... 11-D

PATTERN SETTINGS ............................ 12-1

Scaling.................................................. 12-2

Width adjustment.................................. 12-3

Angle .................................................... 12-4

Repeat sewing...................................... 12-5

Auto origin ............................................ 12-7

Offset.................................................... 12-8

Frame out ............................................. 12-D

NEEDLE BAR SELECTION .................... 13-1

Auto setting........................................... 13-2

Thread color ......................................... 13-3

Color change data registration ............. 13-5

Color change data read ........................ 13-6

Repetition of color group setting........... 13-7

READING

Join....................................................... 14-1

Pattern Read Settings .......................... 14-4

POSITION ALIGNMENT BY DEFINING 2 POINTS.

15-1

POSITION ............................................... 16-1

Piece number ....................................... 16-2

REGISTER.............................................. 17-1

Entry ..................................................... 17-2

Return................................................... 17-3

LETTER .................................................. 18-1

QUEUE ................................................... 19-1

Alter and Execution .............................. 19-2

Needle bar selection and Pattern settings...

19-4

Registration of QUEUE setting............. 19-5

Read QUEUE setting............................ 19-6

FRAME CONFIRMATION....................... 20-1

Frame selection...........................................

20-2

Adjusted for embroidery area ............... 20-4

User-defined frames (1 ~ 5).................. 20-7

User-defined frames (6 ~ 20).................20-A

How to change center point of frame (1 ~ 5, 6 ~ 20) ..

20-J

Non registered ....................................... 20-L

i-CUSTOM............................................... 21-1

USER MANAGEMENT

Registration of administrator................. 21-3

Registration of user .............................. 21-6

Selection of user (Login)....................... 21-8

Selection of user (Login) at power ON . 21-9

OTHER SETTINGS

Create network ..................................... 22-1

Version information............................... 22-3

Language............................................. 22-3b

Calibrate .............................................. 22-3c

Report................................................... 22-4

User maintenance mode ...................... 22-5

SCREEN SAVER.................................... 22-7

SPECIFICATIONS • MAINTENANCE

Specifications ....................................... 23-1

Oiling .................................................... 23-1

Cleaning of rotary hook ........................ 23-2

Cleaning of thread cutting knife (Rev. A).....

23-2

Cleaning of thread cutting knife (Before Rev. A).

23-4

ERRORS AND WHAT TO DO ................ 24-1

INITIALIZING OF MACHINE SETTINGS

Re-Initialization of machine system ...... 25-1

Initializing of machine speed ................ 25-2

HELPFUL HINTS .................................... 26-1

EMBROIDERY TERMS .......................... 26-2

BUILT-IN FONT LIST.............................. 26-3

BUILT-IN PATTERNS LIST .................... 26-4

0_2 O212

-CS -3

IMPORTANT SAFETY INSTRUCTIONS

1_1 F201

1-1

When using an electrical appliance, basic safety precautions should always be followed, including the following.

Read all instructions before using this appliance.

DANGER - To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this appliance

from the electric outlet immediately after using and before cleaning.

WARNING

- To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this appliance is used

by or near children.

2. Use this appliance only for its intended use as described in this manual. Use only attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water. Return the appliance to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10.Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11.Always use the proper needle plate. The wrong plate can cause the needle to break.

12.Do not use bent needles.

13.Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14.Switch the sewing machine off (“0”) when making any adjustments in the needle area, such

as threading needle, changing needle, threading bobbin, or changing presser foot, etc.

15.Always unplug sewing machine from the electrical outlet when removing covers, lubricating,

or when making any other user servicing adjustments mentioned in the instruction manual.

SA VE THESE INSTRUCTIONS

-S2 -7

WARNING LABELS & THEIR LOCATIONS

1_2 M201

1-2

Trapping hazard

Shut the cover when starting the machine.

Do not put hands in while the machine is running.

Trapping, Puncture, Cut hazard wherever this

label is found

Shock hazard on all electrical components

Injury risk on moving head(s)

Keep hands away from the moving heads while the

machine is running.

Laser beam (Class 1)

Do not stare into the beam.

ES-HMF-5113-0

WARNING

Shut the cover when starting the

machine. Do not put hands in

while the machine is running.

Fear of serious injury.

ES-HMF-5117-0

CAUTION

Keep hands away from the

moving heads while the

machine is running.

Possibility of injury.

CAUTION: Injury risk on frame and carriage

Keep hands away from the drive

frame while the machine is

running.

Catch a finger in the X-carriage.

WARNING: Injury risk warning

for all needles

Keep fingers away from

the needles while

the machine is running.

Laser beam (Class 1)

CAUTION

Do not stare into the beam.

-BD -5

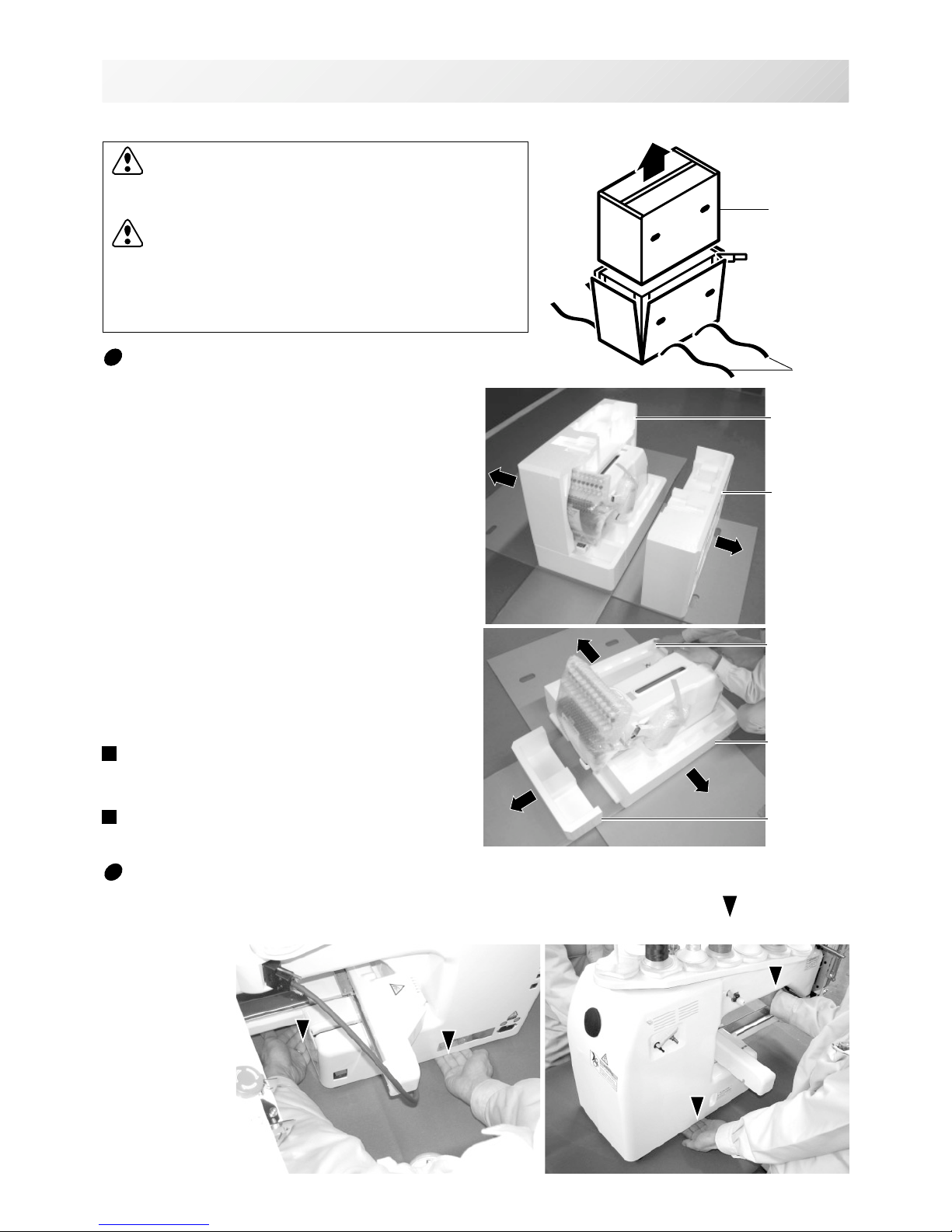

SETTING UP THE MACHINE

2_1 K101

2-1

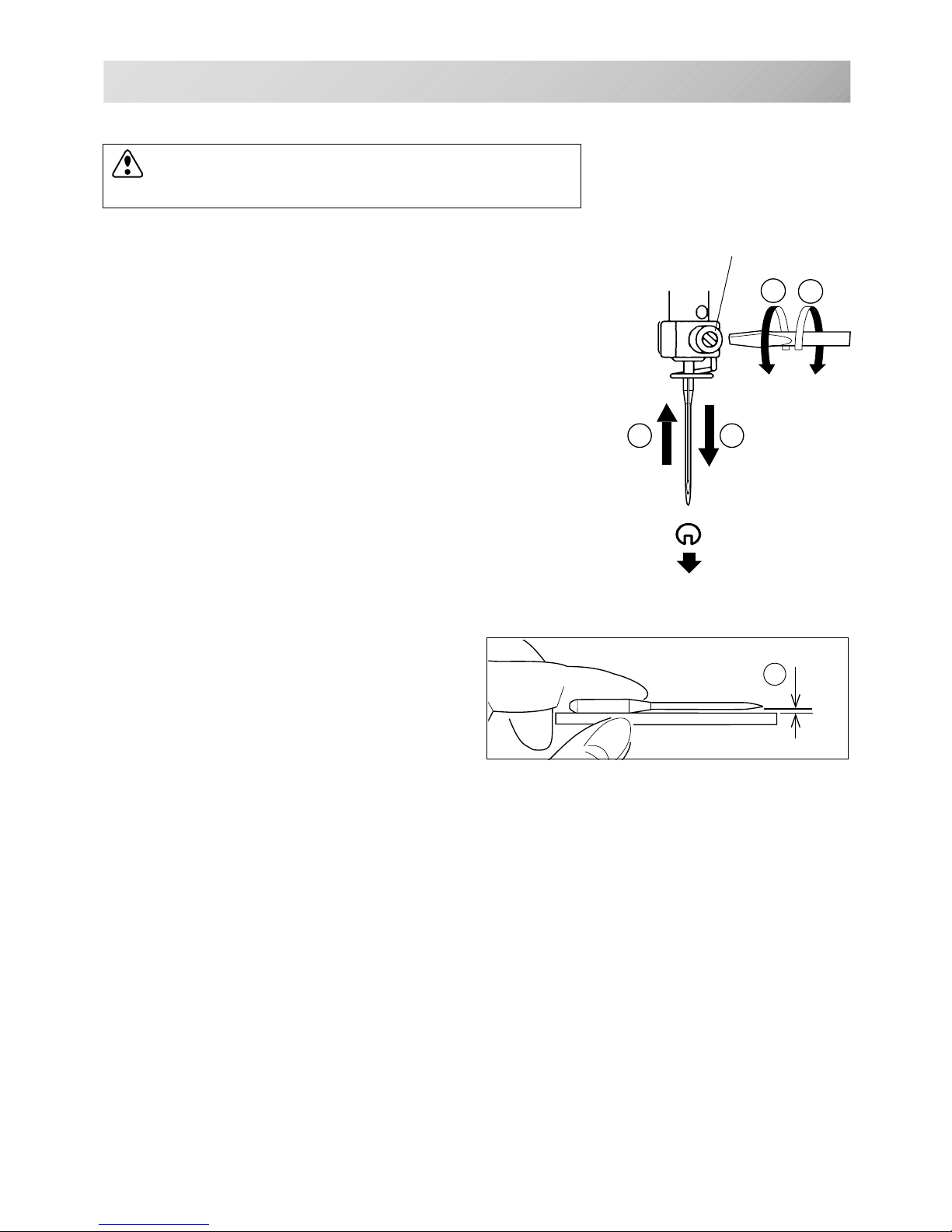

CAUTION: To prevent accidents.

The machine is quite heavy for one person to carry.

Please use two persons when unpacking or carrying.

CAUTION: To avoid problems.

Make sure to hold bottom of the machine body when

removing from the box.

Do not hold any other place. (bed, moving head,

control box etc.).

We recommend unpacking should be done where it has enough room.

Remove the machine from box

1. Remove 2 straps from the carton.

2. Lift the box (upper) to remove.

3. Take out the accessories.

Refer to the next page.

4. Take out the styrene foam (right) and (left).

5. Take out the styrene foam (lower front),

(lower right), and (lower left).

Be careful not fall down the machine, tilt the

machine slightly when taking out the styrene

form (lower right) and (lower left).

6. Carry the machine to installation location.

Please keep those packing materials in

case of necessary for repair or other reasons.

Packing procedure is the reverse from

unpacking procedure.

Straps

Box (upper)

Styrene foam

(lower front)

Styrene foam

(lower right)

Styrene foam

(lower left)

How to carry machine

The unpacked machine should be carried by 2 person with the hand position at mark shown

in photos.

Right side

Left side

The person holding

the machine from

left side need to

hold the machine

arm by right hand.

Styrene

foam (lright)

Styrene

foam (left)

-S2 -7

SETTING UP THE MACHINE

2_1b M628

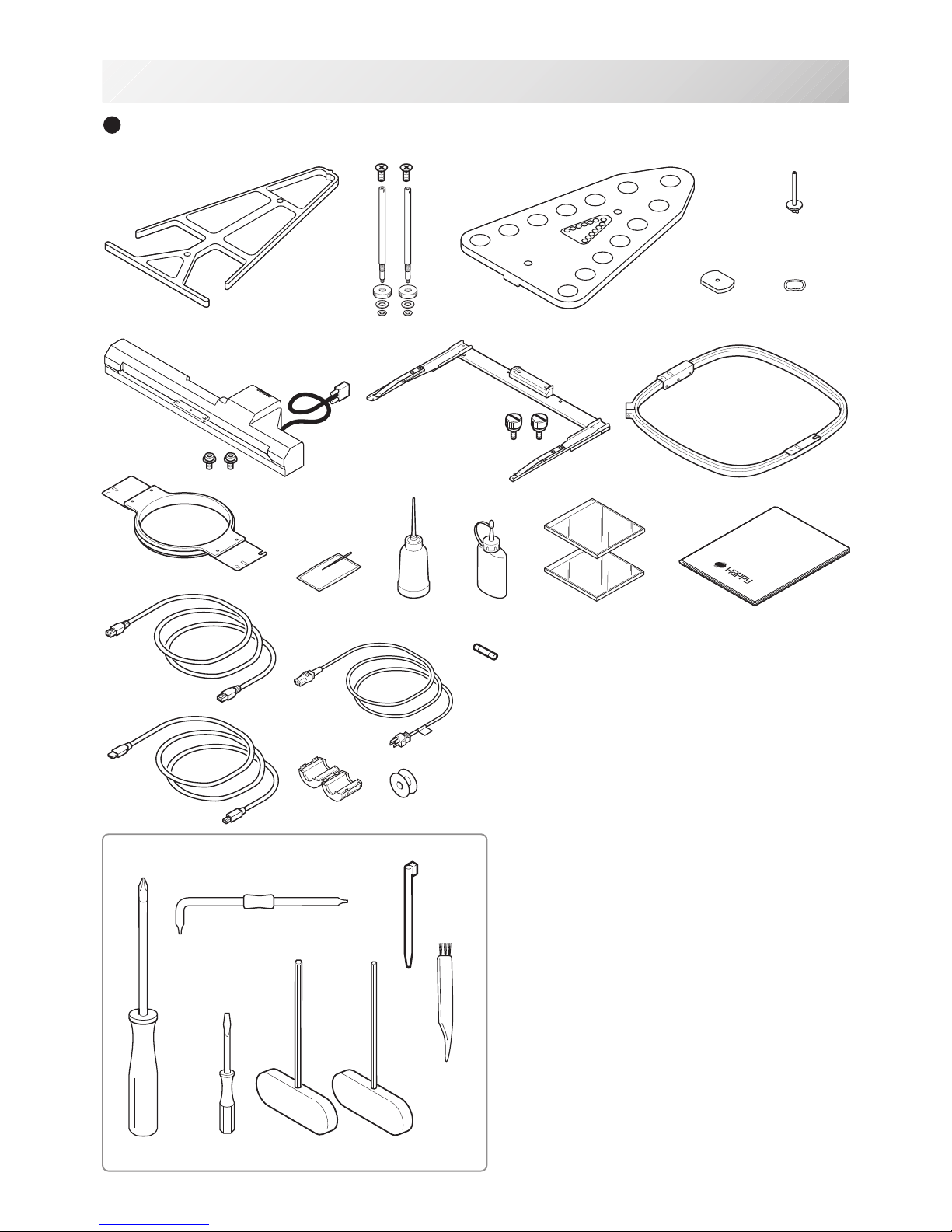

2-1b

Placement of Accessories

Confirm all the accessories are contained when unpacking.

Frame base

CD-ROM (Instruction manual, Parts list)

CD-ROM (Happy Link Software)

Instruction manual

Embroidery frame (Round)

Embroidery frame (Square)

Thread stand

Thread guide bracket

Carriage

Thread stand felt (13 pcs)

LAN cable

USB cable

Power line cord ass'y

Tool set

Needle (10 pieces)

Fuse (6A)

Oiler

Sewing machine oil

Thread guide pillar (2 pcs)

Thread stand pin (13 pcs)

Wave washer (13 pcs)

A

-S2 -8

18

19

SETTING UP THE MACHINE

Accessories

Please confirm you have received the following.

2_2 N909

2-2

1. Thread guide bracket

2. Thread guide pillar (2 pcs)

3. Thread stand

4. Thread stand felt (13 pcs)

5. Thread stand pin (13 pcs)

6. Wave washer (13 pcs)

7. Carriage

8. Frame base

9. Embroidery frame (square) PTA-32320-360

10. Embroidery frame (Round)

PTA-15-360

11. Needle (DB X K5) (10 pcs)

12. Oiler

13. Sewing machine oil

14. CD-ROM (Happy Link)

15. CD-ROM (Instruction manual, Parts list)

16. Instruction book (How to open the CD-ROM)

17. LAN cable

18. Power line cord ass'y (A shape will be changed

depending on a destination)

19. Fuse (6A)

20. Off set screw driver

21. #2 (+) Screw driver

22. 2 mm (-) Screw driver

23. 3 mm hexagonal driver

24. 2.5 mm hexagonal driver

25. Brush

26. Bobbin (1 pc)

27. Clamp filter

28. Stylus

29. USB cable

T ools

1

2463

7

8

9

11

12 13

15 16

20

21

22

23

24

5

25

14

28

29

17

10

27

3

26

-S2 -9

1

2

3

4

5

6

Assemble machine unit

1. Insert the thread stand pin with wave washer on the

thread stand by turning clockwise, Then insert thread

stand felt.

2. Put the thread stand on to the machine and insert the

thread guide pillar.

(set nut knob nut into the thread guide pillar and 2

washers)

Turn the thread guide pillar clockwise with a 3 mm

hexagonal driver until tight.

Turn the knob nut clockwise with a 3 mm hexagonal

driver until tight.

3. Install the thread guide bracket with supplied screws

(pan head screw M6 x 10 2 pcs).

4. Loosen the screw with a offset driver and remove the

red shipping collars that are equipped on the both side

of the guide bar. (

Keep the shipping collars. It is nec-

essary when packing.)

5. Put the carriage and carriage arm together with screw

(M4 X 8 2 pcs).

2 pins in the upper carriage arm will fit into holes on

the lower carriage.

6. Raise slowly the control box to the front then fix it with

2 supplied screws (M4 1 pcs).

7. Connect the cable of carriage to the machine with

fixed screw.

8. Install the arm for tubular embroidery. Please refer to

(page 6-1) "Installing and removing the frame base".

Or, Install the cap frame for the cap embroidery.

Please refer to (page 7-1) "Installing and removing the

cap drive frame".

9. Insert built-in stylus into the holder (slot) of control

box.

When taking the machine apart in case of packing,

the process is opposite of assembling the machine.

Please do exactly the opposite way of assembling.

When packing the machine up for transportation,

be sure to select the sixth needle and fix it with

shipping collars on the both side of the guide bar.

2_3 N401

2-3

SETTING UP THE MACHINE

7

2

9

-CS -7

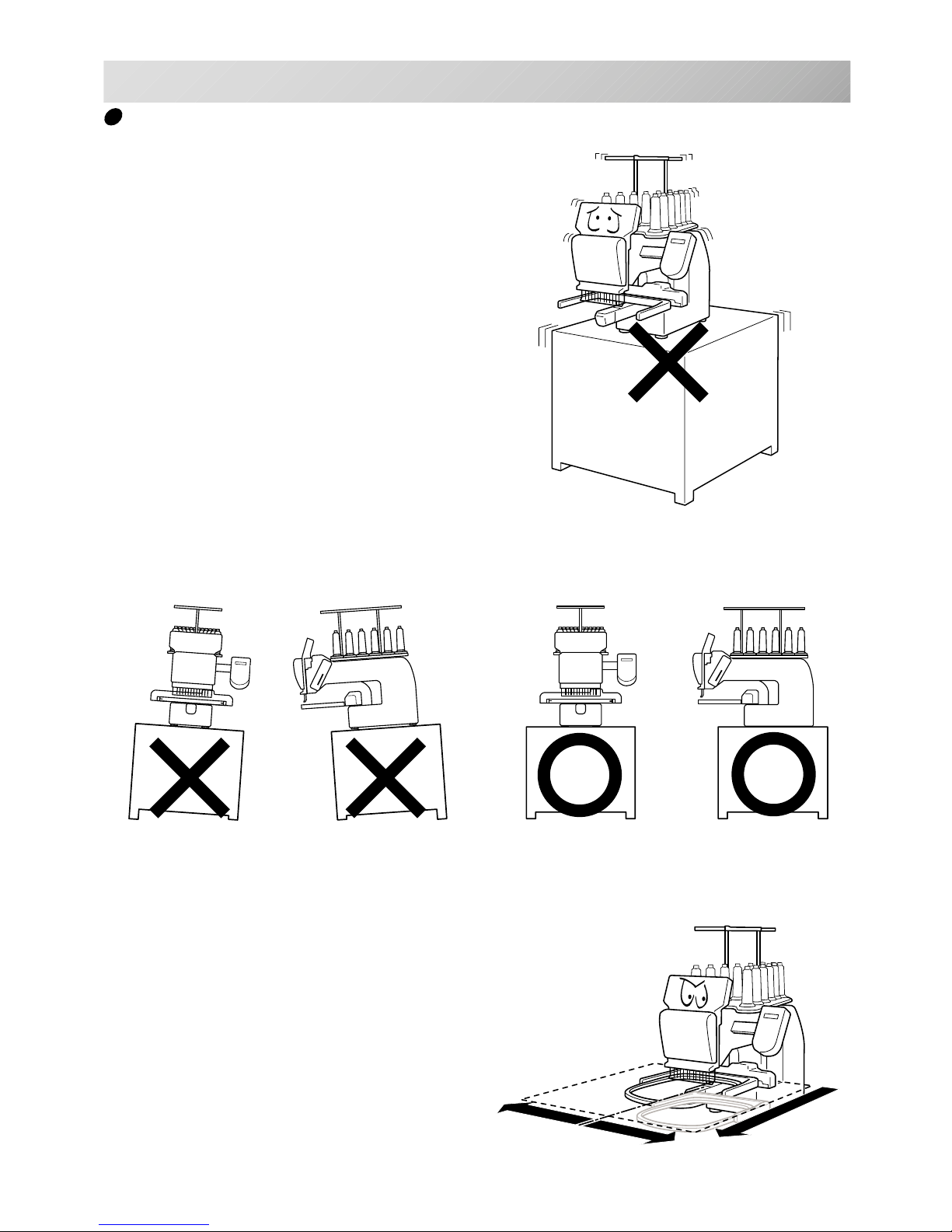

Machine installation

1. Please use a stout table to set the machine

on.

Please check for any shaking or excessive vibrating of the machine table when the machine is

running.

If you have a problem, Please use a stronger

table for the machine.

2_4 D607

2-4

SETTING UP THE MACHINE

350 mm

350 mm

720 mm

2. Please sit the machine level on the table.

3. Please be sure you have this much room

around your machine for it to move.

It is possible for the embroidery frame to hit you

and cause injury.

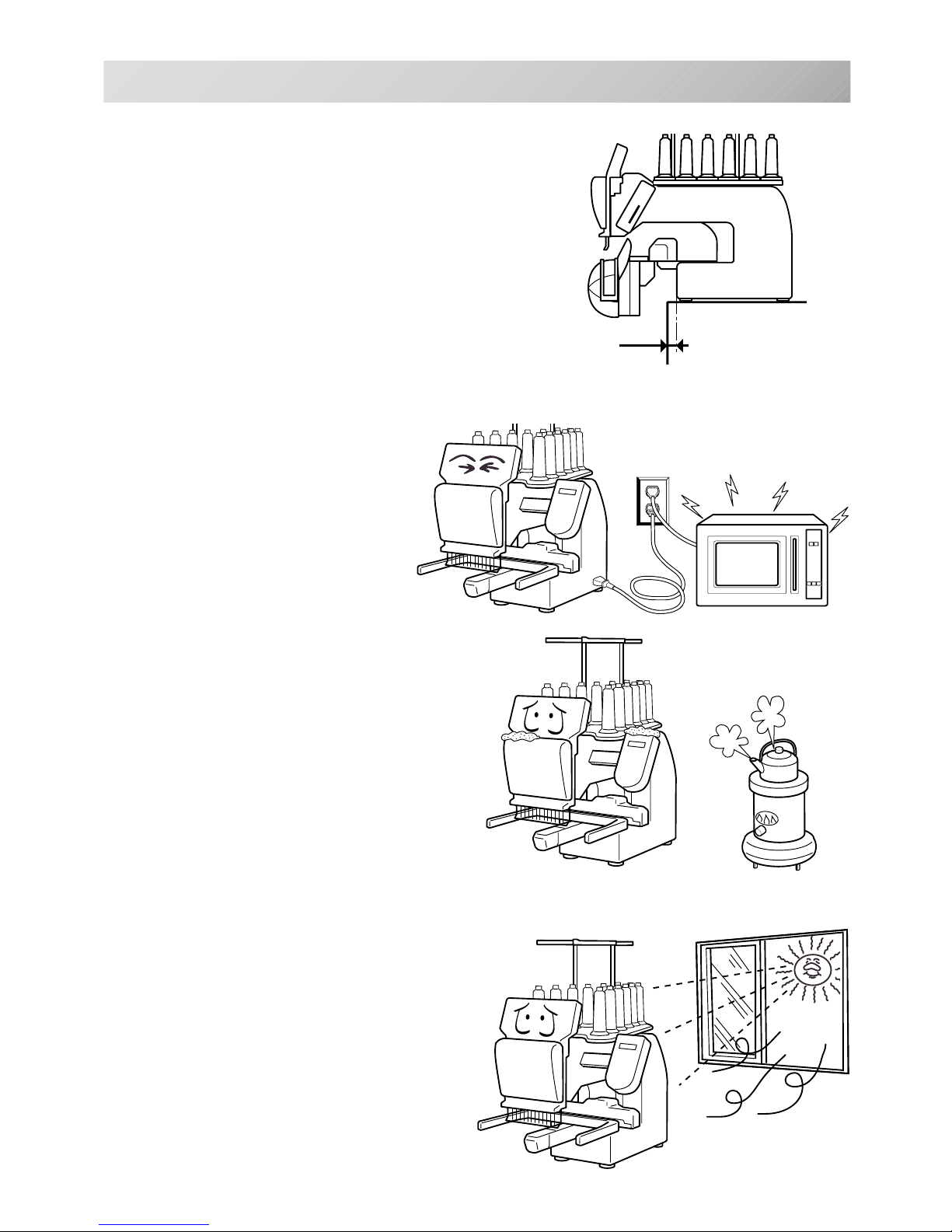

-CS -82_5 D607

2-5

SETTING UP THE MACHINE

0 ~ 10 mm

4. Please be sure you have this much room around

your cap drive for it to move.

Please machine on the table positioning like right side

drawing.

5. Please do not sit the machine near any

kind of other electric equipment

(Examples: Microwave or electric tool).

Has possible to wrong movement of the

machine.

6. Please keep away from dusty and high moisture environments.

Has case of rusting or damaging.

7. Please do not sit the machine in direct

sunshine or windy locations.

Has case of rusting or damaging.

-CS -11

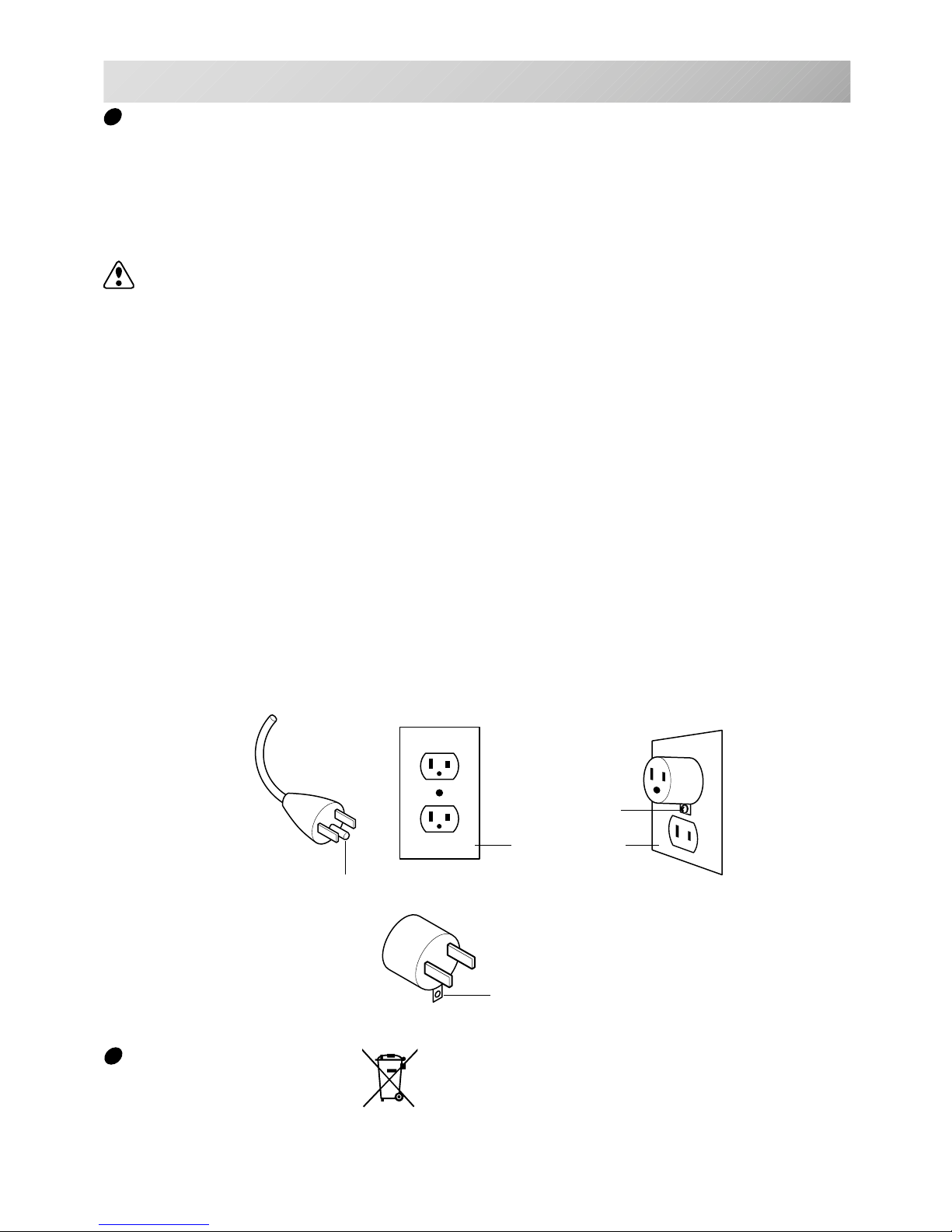

Grounding instruction (for type of 120V)

This product must be grounded. In the event of malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This product is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a

risk of electric shock. The conductor with insulation having an outer surface that is green with or

without yellow stripes is the equipment-grounding conductor. If repair or replacement of the cord

or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded.

Do not modify the plug provided with the product – if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the

plug illustrated in sketch A in Figure. A temporary adaptor, which looks like the adaptor illustrated in sketches B and C, may be used to connect this plug to a 2-pole receptacle as shown in

sketch B if a properly grounded outlet is not available. The temporary adaptor should be used

only until a properly grounded outlet can be installed by a qualified electrician. The green colored rigid ear, lug, and the like, extending from the adaptor must be connected to a permanent

ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be

held in place by the metal screw.

2_6 I916

2-6

SETTING UP THE MACHINE

Disposal of a battery

A battery is had built-in to this embroidery machine.

When you dispose of a battery, according to each country or a method determined in each area,

please dispose appropriately.

Metal screw

Cover of grounded

outlet box

Grounding pin

Grounding means

Grounding methods

Adapter

A

B

C

-S2 -10

MAIN PARTS

3_1 N909

3-1

1. Hook cover

2. Bobbin case

3. Hook

4. Needle plate

5. Thread check spring

6. Take-up lever cover

7. Take-up lever

8. Lower rectifier

9. Thread tension

10. Detecting roller

11. Minor thread tension

12. Thread guide support

13. Thread guide

14. Upper rectifier

15. Thread stand pin

16. Thread stand felt

17. Thread stand

18. Needle bar selection knob

19. Control box

20. USB port

(Standard-B receptacle)

21. USB port

(Standard-A receptacle)

22. LAN port

23. Frame base

24. Carriage

25. Fuse (6A)

26. Terminal box

27. Power switch

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

23

24

25

26

27

14

21

16

22

20

-S2 -113_2 M717

3-2

MAIN PARTS

BOBBIN WINDING

7

5

6

1

5

2

3

1. Upper Thread guide

2. Thread stand pin

3. Thread stand felt

4. Thread guide

5. Thread tension

6. Spindle

7. Lever

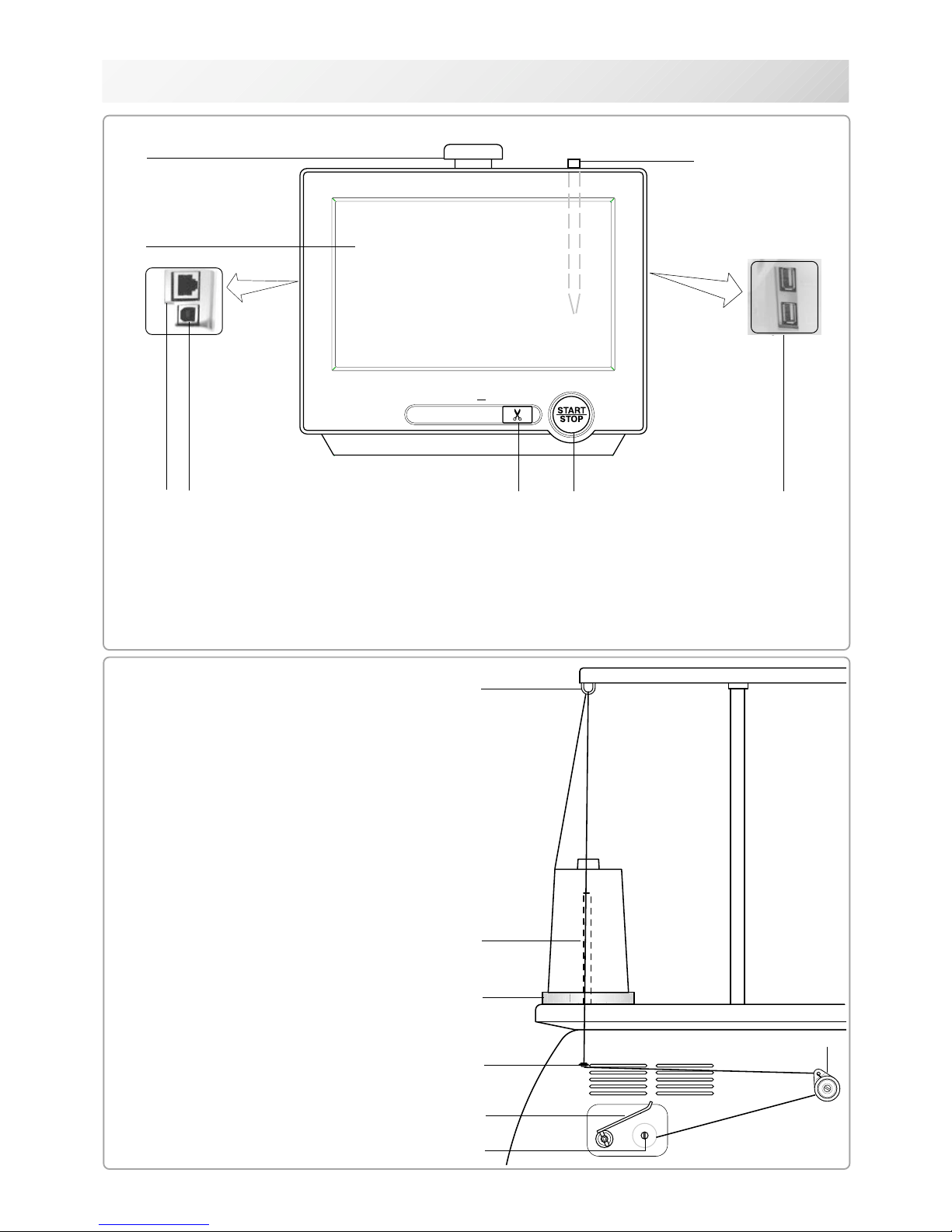

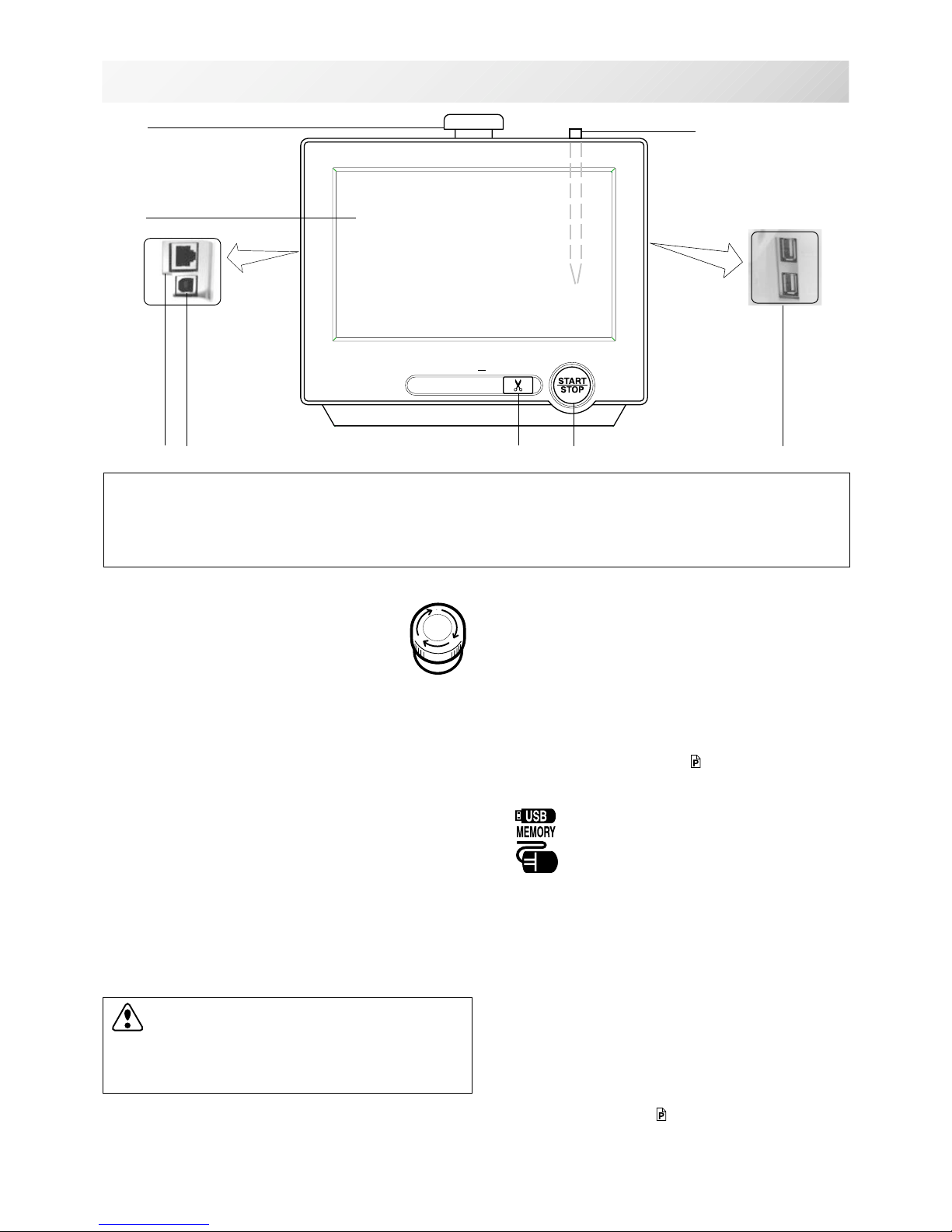

CONTROL BOX

4

5

1. Emergency stop button

2. Display (L.C.D.)

3. LAN port

4. Thread cut button

5. Start/Stop button

6

3

7

1

2

16

8

6. USB port (Standard-A receptacle)

7. USB port (Standard-B receptacle)

8. Stylus

-SA -12

HOW TO READ THESE INSTRUCTIONS and SCROLLBAR

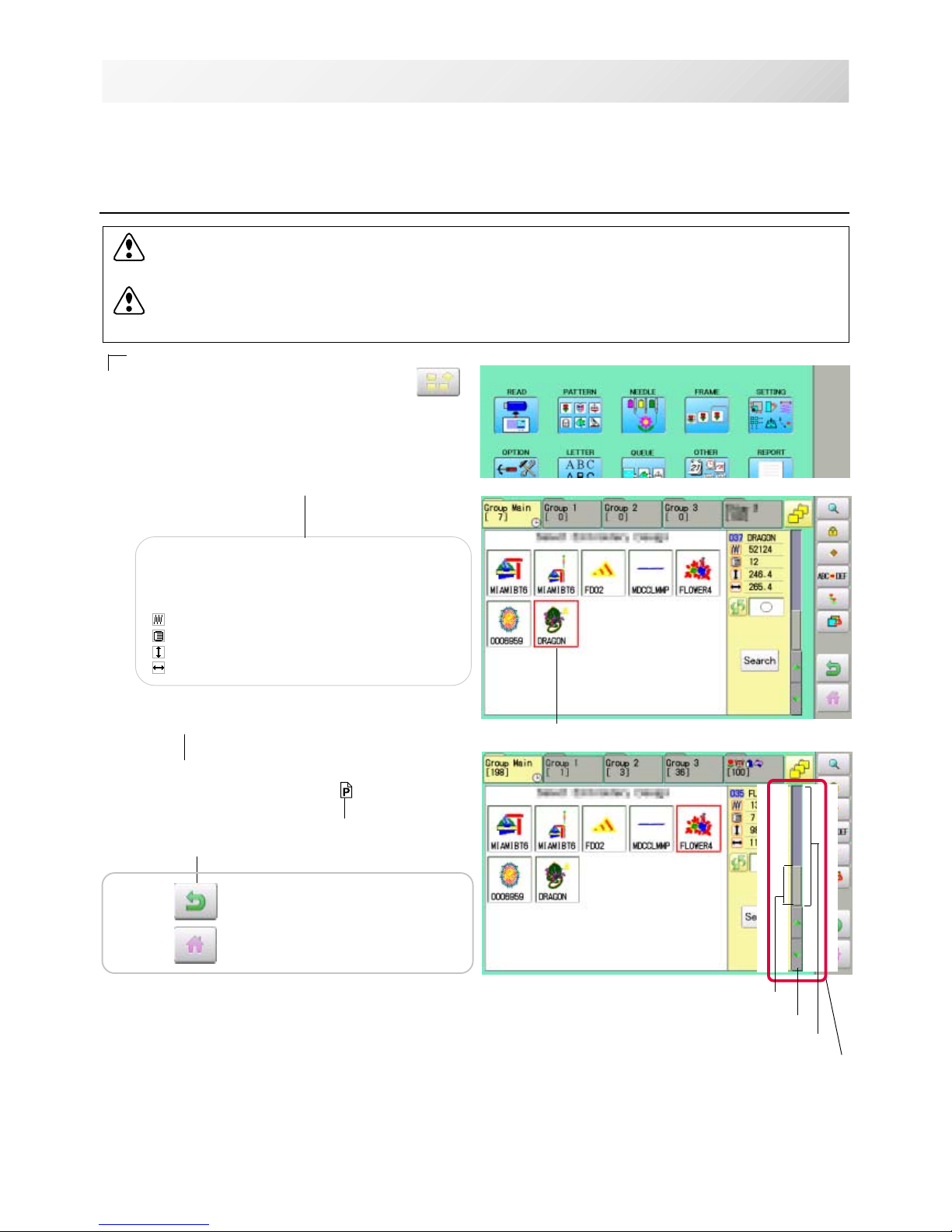

3-3

3_3 NB01

The instructions in this manual have been formatted as follows:

Written instructions will be provided on the left side of the page while graphics depicting the

necessary steps are provided on the right.

Graphics on the far right will show the display after performing the steps indicated.

This indicates an additional

explanation on an operation

elsewhere in the manual for

more detail.

AWords marked with a "*" are explained in

"EMBROIDERY TERMS" at the end of this

instruction manual.

CAUTION: To prevent accidents.

This will appear for items related to your safety.

CAUTION: To avoid problems.

This will appear for items related to potential problems.

Order of operation

Indicates supplementary

explanation regarding a

given operation or action.

1. When the machine is stopped, press .

2. Select "PATTERN".

The display indicates the current pattern.

The left side of display shows the number, name

and details for the current pattern.

Number of stitches

Number of Color change number

Height

Width

3. Select *pattern data.

This pattern will be selected.

3-3

Selected pattern data

Operation key

Press to return to Menu mode.

Press to return to Drive mode.

Scrollbar

Display area

Scroll area

Arrow key

Scrollbar

If the data are too much to fit into display screen, you can use scrollbar.

Display area : It shows the area which is displayed.

Arrow key : You can scroll the display area to arrow marked direction.

Scroll area : It shows the whole area of the data.

You can push arbitrary point of Scroll area to display the desired location.

-SA -16

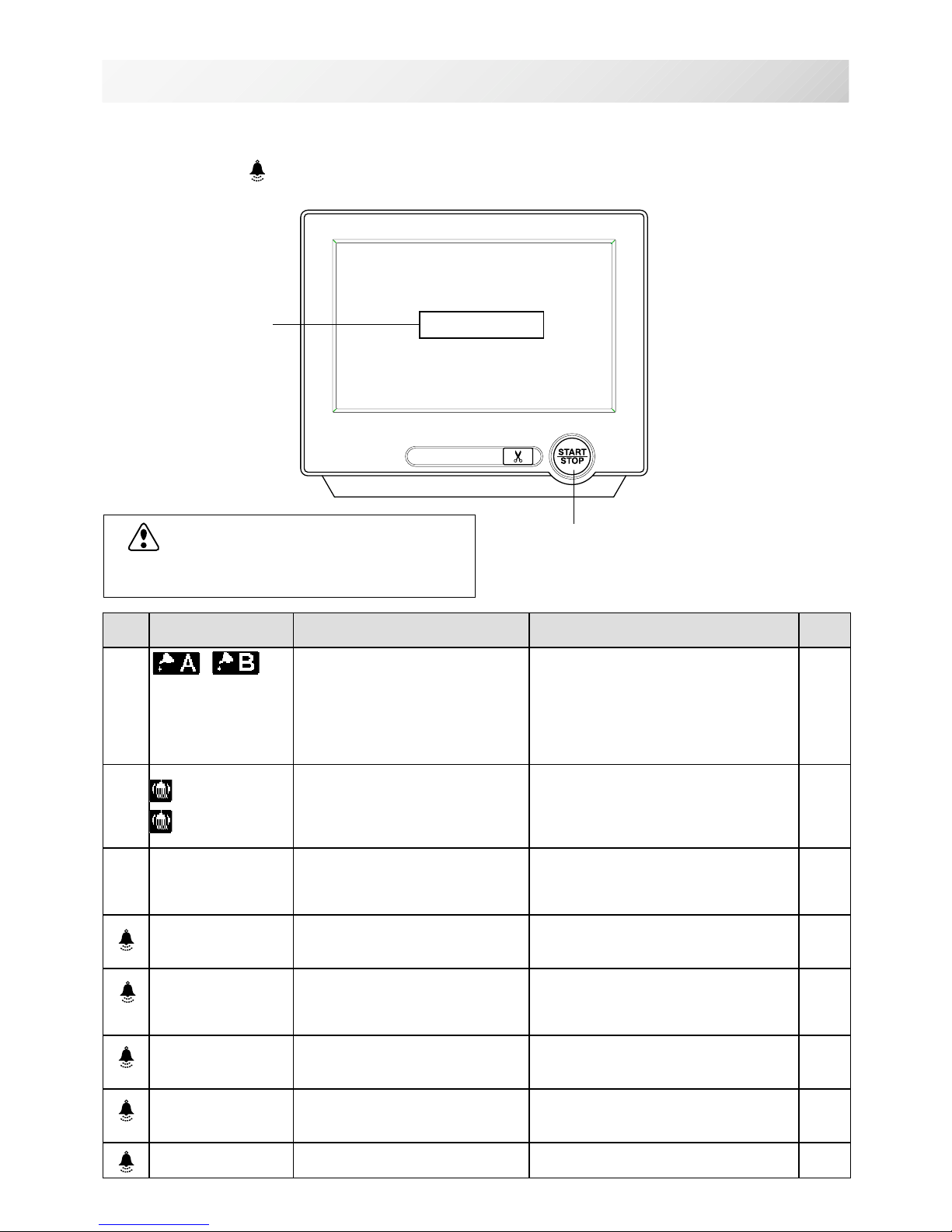

MESSAGES

3-4

3_4 O512

Below is a list of possible messages that may appear while operating the machine, along with

an brief explanation and suggested actions to take as a result.

The message with

mark will be appeared with beep sound.

Press the screen (any location is okay), then message will disappear.

Start/Stop button

Message

>>Stop Switch

CAUTION: To prevent accidents.

The embroidery frame may move. Please

keep hands clear for your safety.

MESSAGE EXPLANATION OPERATION PAGE

Place to oil

Designated letter on the display

is due to be lubricated.

Push [Done] and lubricate indicated

location with instruction in

the reference page.

Push [Leter], if you can not lubricate

right away.

The message will be disappeared

temporary, but it will come up later.

23-1

Cleaning of

rotary fook

Cleaning of

thread cut

knife

Clean the rotary hook and the

thread cutting knife.

Clean with instruction in the

reference page.

23-2

>>Stop Switch

The machine is stopped

because the stop button was

pressed while embroidering the

design.

Press the start/stop button to resume

sewing.

>>End

The machine is stopped

because it has finished the

design.

If you wish to sew design again,

please newly hooped item on

machine & press start/stop button.

>>Change Stop

Machine stopped, because you

used "Stop at color change

point" function.

When you press the start/stop button,

the machine will select the next color

and resume embroidering

automatically.

>>Color ?

Machine stopped because the

next color has not been

selected.

Please select next needle number by

needle selection button then press

the start/stop button.

>>Thread Break

Machine stopped, because

upper or bobbin thread broken.

Please thread upper thread or check

bobbin thread then press start/stop

button to resume sewing.

>>Frame out

The "Frame out" function has

been executed.

Press the start/stop button if OK.

12-D

-SA -14

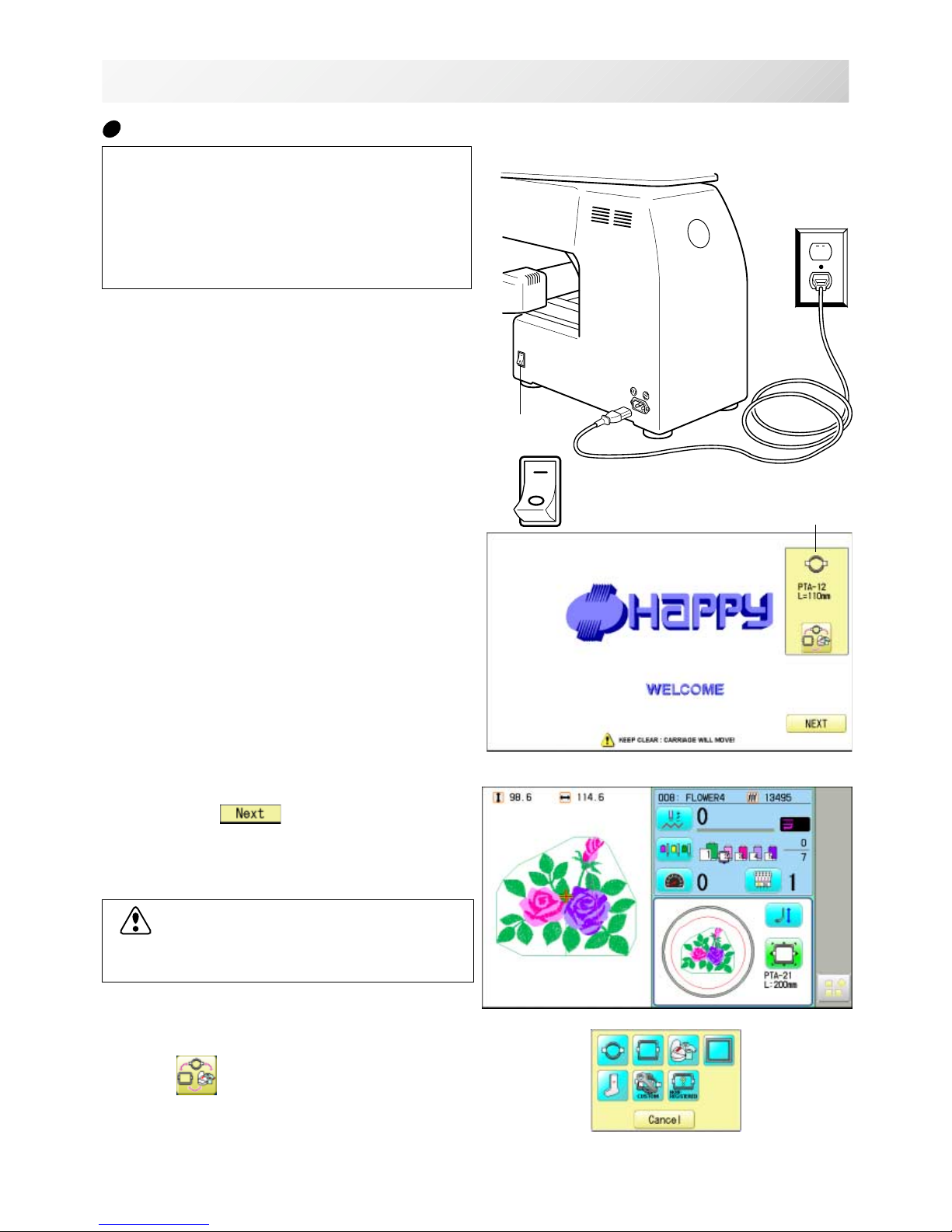

TURNING THE MACHINE ON

1. Connect the power cord to the inlet on the

right side of the machine.

2. Connect the power plug to an electrical

outlet.

3. Turn on the power switch.

Please confirm the emergency stop button has

been released.

Push the power switch firmly so it will remain on.

4. In case you do not need to change frame

type, Press

.

After the carriage and frame move slightly, the

embroidery frame will return to the previous

position automatically.

Machine becomes ready for operation.

3_5 NB25

3-5

ON

OFF

Power switch

CAUTION: To prevent accidents.

The embroidery frame and carriage will move.

Please keep hands clear for your safety.

Selected frame

In case you want to change frame type,

Press

.

CAUTION

The touch screen can be operated by finger,

but in some cases sensitivity of the screen will

be affected by condition of the finger.

In such cases, please use the fingertip or

built-in stylus to hit small touch targets.

How to turn on the machine

-D2 -18

TURNING THE MACHINE ON

3_6 N101

3-6

DANGER: To reduce the risk of electric shock.

Never leave the machine unattended when plugged in.

Always unplug this machine from the electrical outlet immediately after use and before performing any maintenance on it.

WARNING: To reduce the risk of burns, fire, electric shock, or injury to persons.

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

5. Select the desired frame with

.

: Tubular round frame

: Tubular square frame

: Cap and One-point frame.

: Border frame (for HCD2)

: Sock frame

: User-defined frame

: Non registered

6. Select desired type of frame and Press

.

The display returns to the view of Step 3.

To disconnect, switch the power switch to the

off position, then remove plug from outlet.

-D2 -19

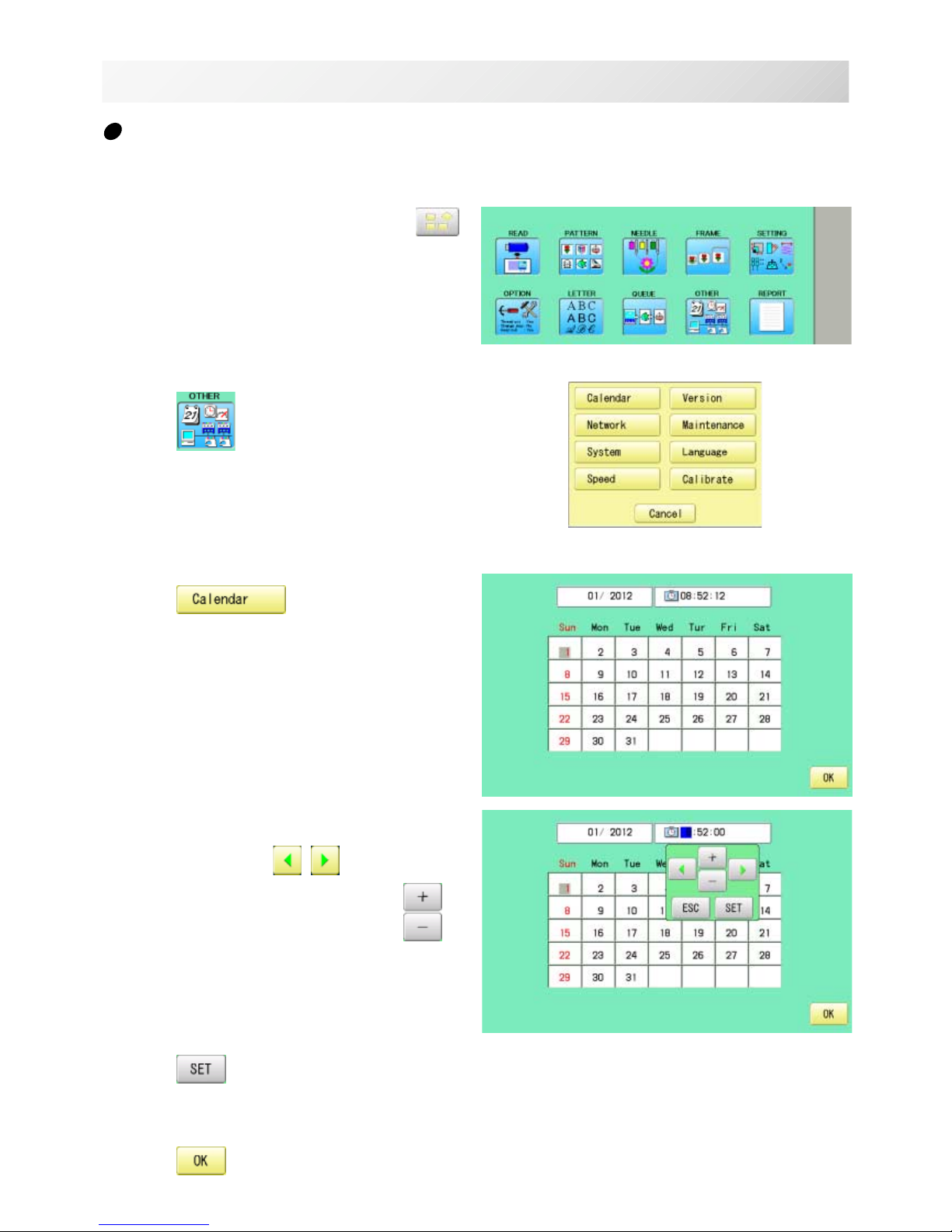

1. When the machine is stopped, press .

2. Press

.

3. Press .

Current year, month date and time is displayed.

4. Select year/month, time or date.

Press right /left of to select the

setting point, and press up/down of

to

select the number of year, month and time.

5. Press

.

The date is fixed.

6. Press to return to Menu mode.

Calendar and clock setting

Setting the calendar and clock lets the machine advise when oiling and other maintenance is

scheduled to occur.

TURNING THE MACHINE ON

3-7

3_6 M620

-D2 -21

THE CONTROL BOX

3_8 NB25

3-8

5. Start/Stop button

This button starts the machine.

When pressed, while the machine is running, the

machine will stop.

Green ..........Machine ready to sew.

Main menu also accessible by

pressing MENU, which causes menu

to display.

Blinking red .Indicates the upper thread has

broken or the Bobbin thread has run

out.

Red ............. Machine is running.

Orange ........ Machine has detected an error.

An error number will be shown on

the Display. 24-1

6. USB port (Standard-A receptacle)

USB memory socket.

USB mouse socket.

Menu and keys in the display can be operated with

a commercial USB mouse.

Press right mouse button to show a mouse pointer

in the display.

7. USB port (Standard-B receptacle)

Use this port to connect the machine with PC via

USB.

8. Stylus

Stylus can be used for pressing menu and keys in

place of fingers.

Most operation can be done by fingers. Stylus is

required for some operation such as calibration for

the touch panel LCD. 22-3c

Insert a stylus into the holder (slot) of control box

when not used to prevent loss of the stylus.

CAUTION: To prevent accidents.

If you Press thread trim button, the needle will

penetrate the fabric. Please keep your hands

clear for your safety.

1

2

4

5

6

16

1. Emergency stop button

When pressed , the power is switched off

and the machine stops immediately.

The emergency button locks when

pressed.

To unlock, turn the emergency button to

the right

(Arrow direction) then release. The button will

unlock.

Use this button only for emergency.

2. Display (Touch screen)

Shows the embroidery design name, the number of

the current needle and other machine generated

messages.

Menu and keys in the display can be operated with

a finger or built-in stylus.

3. LAN port

You can connect PC with a LAN.

4. Thread trim button

The Machine will cut the upper and lower thread

when this button is pressed.

In case you press and keep (around 2 sec.), you

can cut only bobbin thread.

7

3

8

CAUTION

The touch screen can be operated by finger, but in some cases sensitivity of the screen will

be affected by condition of the finger.

In such cases, please use the fingertip or built-in stylus to hit small touch targets.

-SA -18

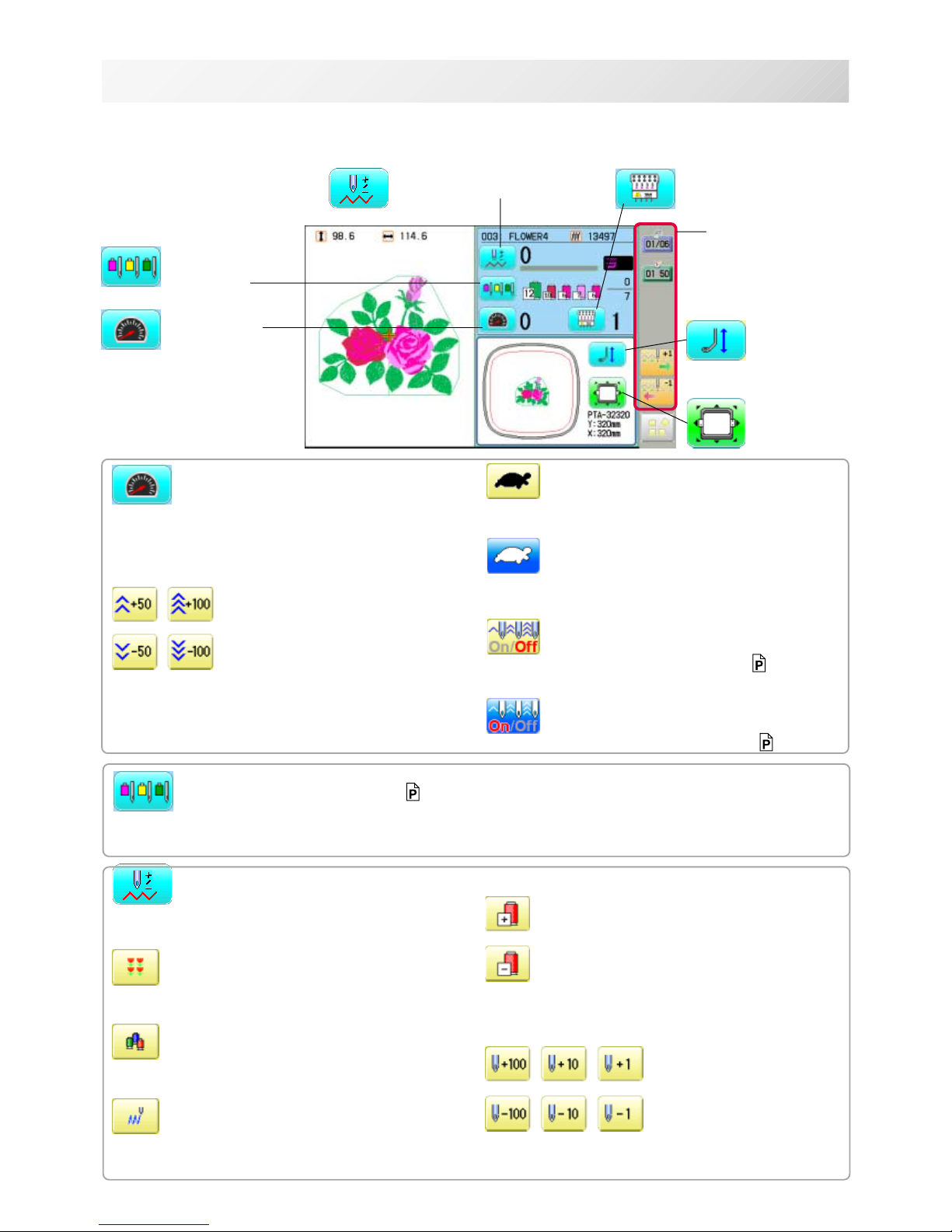

3_9 O512

3-9

DRIVE MODE

Drive key

The each key menu will be shown.

Frame forward

This creates direct designations to the position and

data to the designated sewing position.

Piece

If "Repeat" is set, this allows the frame to move to

the beginning of any piece at will.

Change (Color position )

This moves the frame to the beginning of any Color

change number at will beginning of color.

Stitch (Number of stitches )

This moves the frame to any stitch at will.

Frame forward

Needle bar

selection

Drive speed

Needle change

Frame move

i-Custom

(default display)

Pressure foot

Drive speed

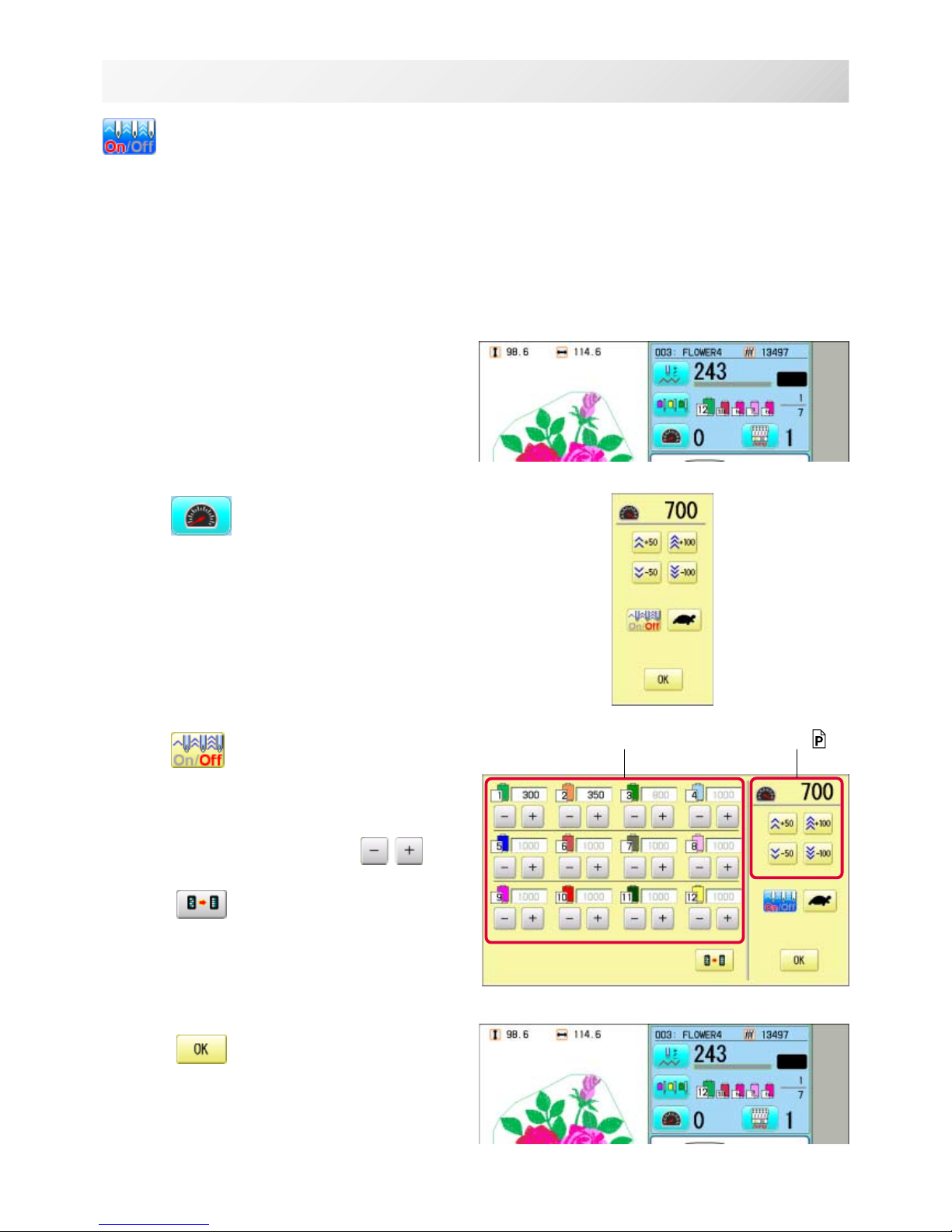

Control embroidery speed.

The speed can be controlled while embroidering.

Speed control

Press the + button to increase the machine sewing

speed and the - button to lower the machine speed.

is displayed on the LCD display.

Low speed operation (OFF state)

Press the button to turn "ON" state.

Low speed operation (ON state)

The drive speed will be reduced to "200 rpm".

Press the button to turn "OFF" state.

Speed setting by needle (OFF state)

Press the button to turn "ON" state. 3-9d

Speed setting by needle (ON state)

Press the button to turn "OFF" state. 3-9d

Needle bar selection 5-E

For each color change in a given pattern, the needle number loaded with the correct color thread is

assigned by the operator.

Color position forward

Move the frame to the beginning embroidery

position of the previous or later color position

number

Stitch number forward

Move the frame forward or backward by the stitch

number displayed in each button.

-SA -193_9b O512

3-9b

DRIVE MODE

Needle change

Change the needle bar directly to the indicated

needle number on the button.

Change

Move the sewing head to the adjacent needle in

the direction of the arrows.

Jump (Off)

The machine can embroider.

Jump (On)

Mchine becomes jump and the machine doesn't

embroider.

-RA -223_9c O512

3-9c

DRIVE MODE

Original point return

This returns the frame to *pattern origin point.

After performing this action once, repeating this

again will cause the frame to return to the previous

position.

Origin registration

Register the current frame position as origin.

Trace

When pressed while at the beginning of design,

the embroidery frame moves following the outer

edge of the design. This allows you to compare

the design size and position against the frame

before sewing.

Indicate target design on LCD panel when nonshowing design.

If you press this key and hold, re-display your

Register

Register will restore the position of the frame to

the last point before a power failure even if the

point of origin or the pattern itself were changed.

6

Frame move

Selection the way of frame movement and

Move frame.

Frame change

Change the frame to be used.

Design centering

Move design to the center of frame.

Center

Moves the embroidery frame to the center automatically.

Frame out

Move frame to the front position which was set

before.

Press (Position) to return the frame to the

original position before frame out position.

It is convenience if hand work is required in the

middle of embroider process.

Position

When sewing is interrupted in the middle of a

design, this returns the frame to current sewing

position regardless of where frame may have

been moved with the arrow keys after interrupt.

target design.

5

i-Custom 21-1

The following display and key icons are set as default. You can place other frequently used icons freely on

the right side of Drive mode screen.

Calendar

Current year, month date is displayed.

Clock

Current time is displayed.

Stitch number forward

Move the frame forward or backward by the

one

When the key is pressed continuously, the "Key

lock" function is activated and the frame will move

continuously even the finger is released from the

key.

When the key is pressed much longer, the step of

"Stitch number forward" will be changed from one

stitch to 10 stitches. 5-2

When you stop it, press (Start/Stop button).

The "Key lock" and "Fast forward" function will

be activated after setting through ÅgMachine

SettingÅh menu. 5-2

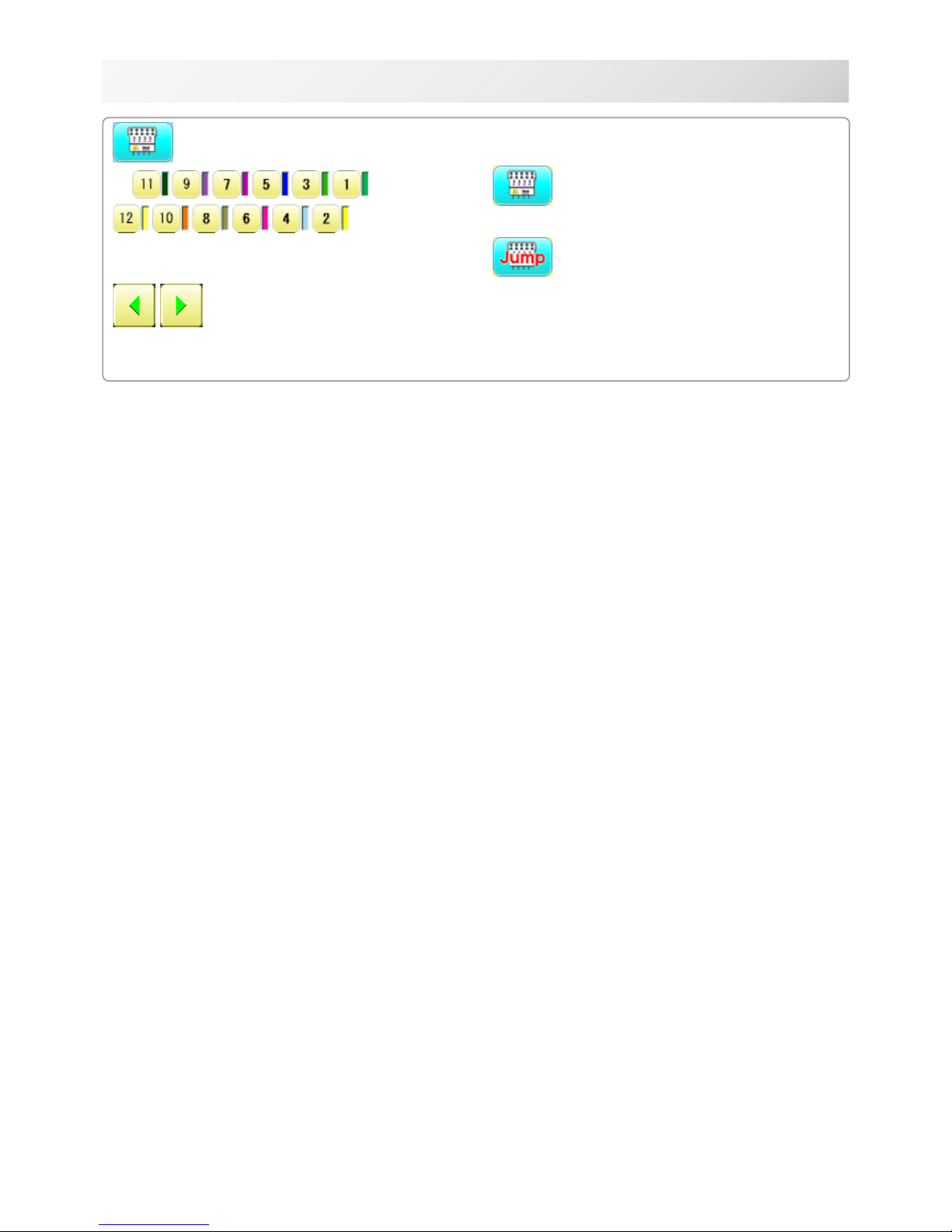

-RA -23

3_9d O512

3-9d

DRIVE MODE

Fast move (OFF state)

Press the button to turn "ON" state.

Fast move (ON state)

Press this key one time to move the frame faster

toward the direction of the arrow.

Press the button to turn "OFF" state.

Fast move speed setting (High)

Fast move speed setting (Middle)

Fast move speed setting (Low)

The speed of "Fast move" can be adjusted.

Pointer (Option)

Turn on and off the laser pointer.

X Direction frame move

YDirection frame move

The frame can be moved with specified distance

along X axis or Y axis. (Unit: mm)

The function allows you to move the frame

precisely with a pitch of 0.1mm.

Select the number, and press .

The frame will move specified distance.

Changing is cancelled.

Numbers are deleted.

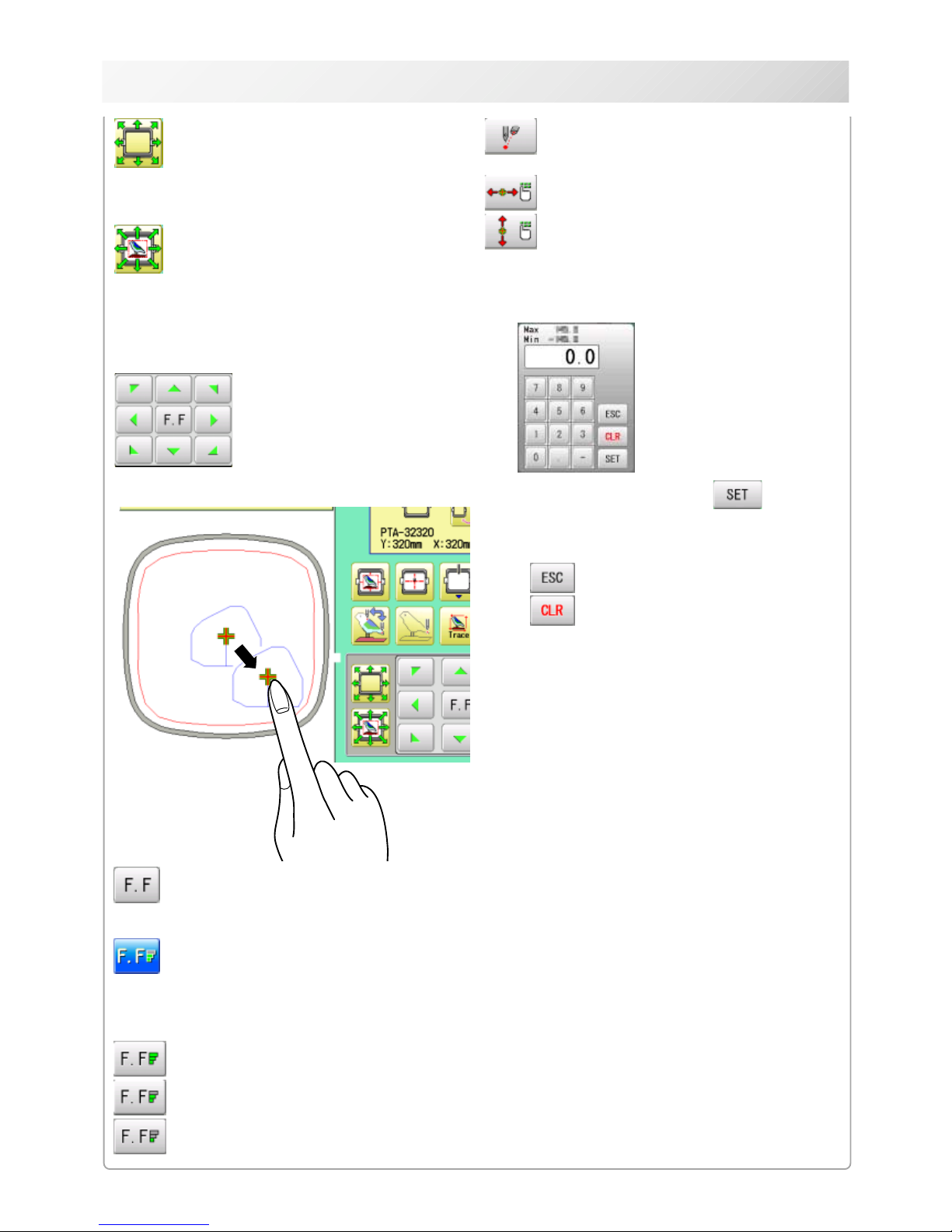

Quick move

First press this key and then the arrow key to

move the frame toward the edge of the embroidery area in the direction of the arrow.

Quick embroidery design data position

move

First press this key and then the arrow key to

move the frame where the design data can be

embroidered at

the edge in the direction of the arrow.

Frame move key

The frame moves toward direction of the arrow

mark.

You can move the

embroidery frame by

pressing desired

position on the

screen.

-SA -17

3_9d NB01

3-9e

DRIVE MODE

Speed setting by needle (ON state)

Embroidery speed can be set by needle.

If speed by needle exceeds the speed set at Drive speed setting, the value of speed turns gray

and speed by the needle is applied to the speed set at Drive speed setting.

You can be set up taking the following steps.

1. Press .

2. Press

.

3. Change the setting on the needle number

you would like to change with

.

Press when returning the setting on all the

needle numbers to maximum.

4. Press .

The screen returns to Drive mode.

Speed setting by needle Drive speed setting 3-9

-D2 -25

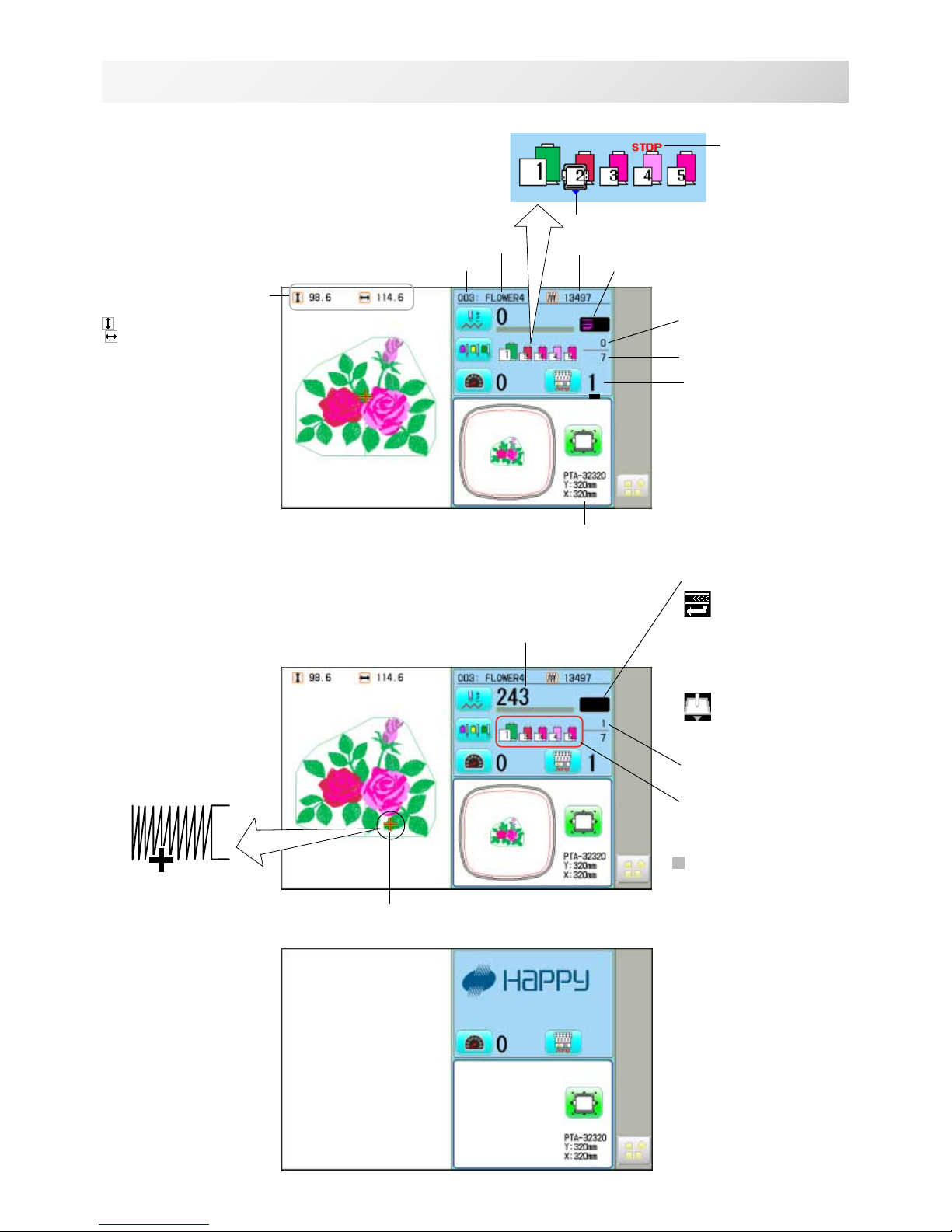

Memory # of selected pattern

Currently-selected

needle

Number of stitches sewn up to now

Name of selected pattern

Top

When beginning an embroidery

Machine stopped during embroidering

Display example

Status

Top

This indicates that the

machine is ready to start

sewing from the "top"

memory position of the

pattern.

Frame out

This indicates that a

frame out is occuring.

3_A NB01

3-A

DRIVE MODE

Pointer

Color change number

sewn up to now

Stitches of pattern

Needle number and color

*Color change number

Pointer indicates the

position of actual stitch

point.

If a needle number is not

assigned to a Color

change number, the

default color will be

assigned automatically.

Shift to left when color

change.

Size of pattern and distance

Heigh

t Width

Current *Color change

number

Mark for color

change stop

Mark for frame out

Selected frame

Display if the machine has no design

in memory

-D2 -26

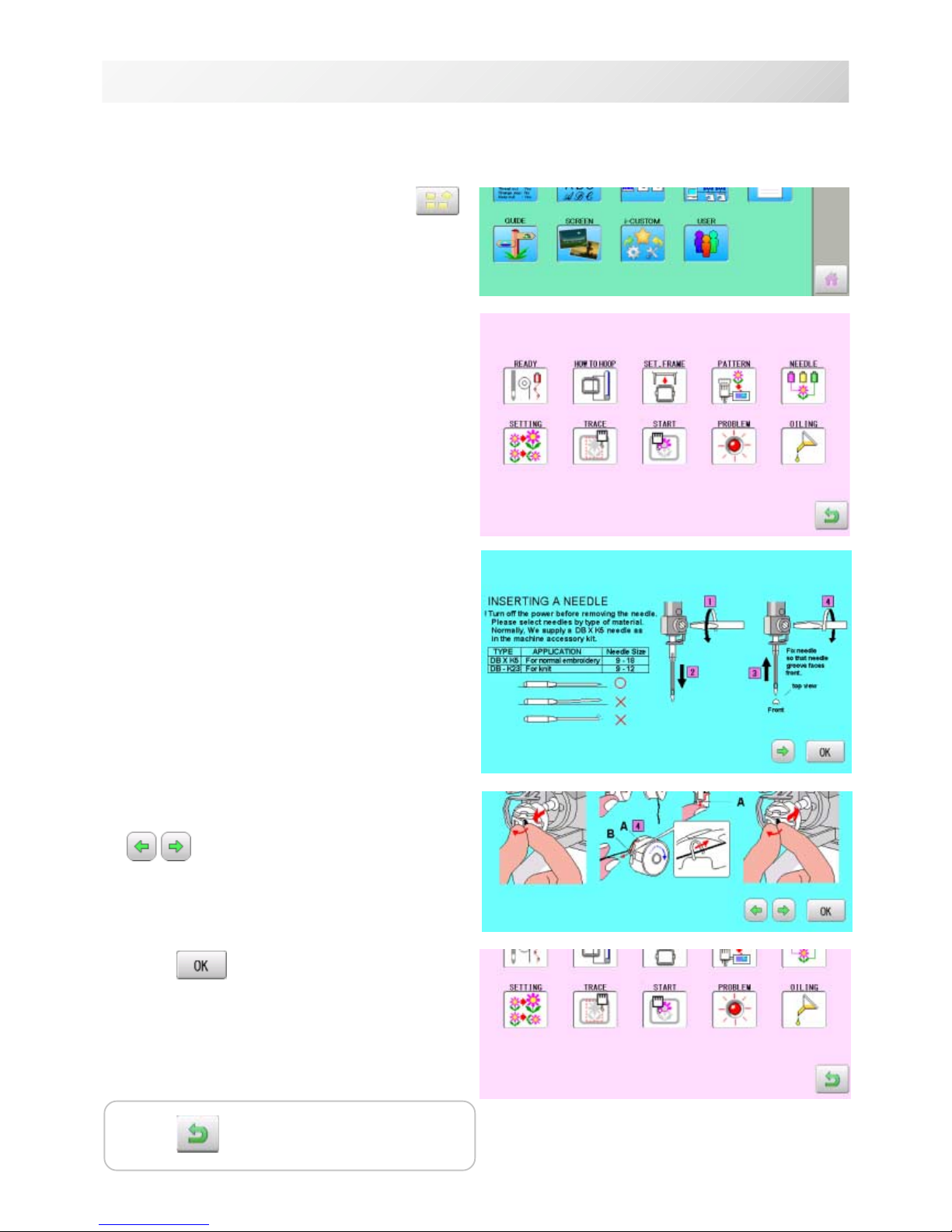

GUIDE

3_D NB01

3-D

1. When the machine is stopped, press .

2. Select "GUIDE".

3. Select desired item.

4. You can move to next page by pressing

.

5. Press .

You will return to the guide menu.

The GUIDE offers tips and step-by-step help for embroidering with the machine.

In each stage of embroidery operation there is an easy to follow guide available.

Press to return to Menu mode.

-CS -19

Select a needle of the right type. See the following “SELECT THREADS”.

1

2

4

3

A

4_1 D424

4-1

Needle clamp screw

INSERTING A NEEDLE

Front

T

S

CAUTION: To prevent accidents.

Turn off the power before removing the needle.

1. Loosen the needle clamp screw slightly with the screw-

driver.

2. Remove the needle.

3. Insert a new needle into the needle clamp with push it up

as far as it will go keeping the slotted side of the needle in

front.

4. Tighten the needle clamp screw with the screwdriver.

A. Do not use a bent or blunt needle.

Place the needle on a flat surface and check

for straightness.

-CS -20

SELECT NEEDLES AND THREADS

About needle

Please select needles by type of material .

Normally, We supply a DB X K5 needle as in the machine accessory kit.

4_2 D607

4-2

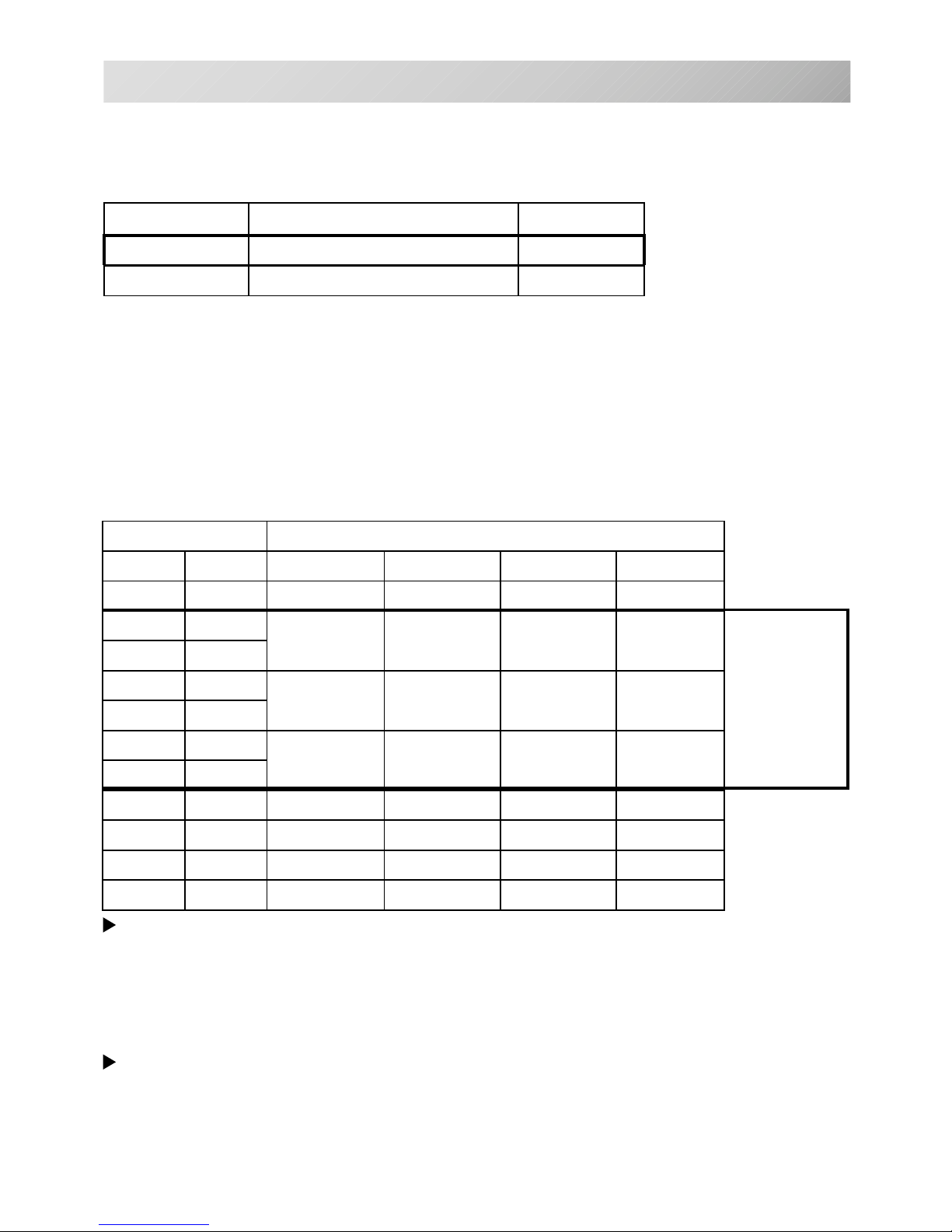

Relation of needle and upper thread

Please select type of needle and upper thread by flowing list.

eziSdaerhtreppudnaeldeenfonoitaleR

nagrOnamreG#nottoCkliSretseyloPnoyaR

8#06#031~001061~041002~05107~05

956

08~07021~001051~031001~07

0107

1157

06~05001~08031~001031~001

2108

3158

04~6307~06001~08051~031

4109

5159

6100163~0306~0508~06061~051

71501

8101103~4205~0406~05032~081

Normal embroidery field

Normal use embroidery needle and upper thread.

Upper thread : Rayon 120 d/2 (120 denier)

Polyester 120 d/2 (120 denier)

Needle : #11 ( DB X K5 )

If the relationship of needle size and thread type is incorrect, it is possible to have any of the

following problems.

• Thread break

• Skip stitch (Upper thread does not catch bobbin thread)

• Other stitch quality problem

EPYTNOITACILPPA

eziSeldeeN

32K-BDtinkroF21~9

5KXBDyrediorbmelamronroF81~9

-CS -21

BACKING MATERIALS

Backing

Generally, Backing is used for hooped embroidery fabric. Knit fabrics particularly require the use

of embroidery backings.

Embroidery backings will allow the hoop to move the fabric more accurately, creating a more

beautiful embroidery.

Select backing type

Choose the thickness and number of sheets by the type of material and embroidery condition.

Generally, you should consider the following items.

•Embroidery stitch quality

•Contraction or compression of fabric caused by sewing, etc.

•Stiffness of fabric

In case, if you sew lace and leather, you may not need backing sheet.

Example of using a backing

4_3 D607

4-3

Embroidery frame (Inner frame)

Fabric

Backing sheet

Outer frame

-CS -24

BOBBIN WINDING

Winding the bobbin

4_4 K101

4-4

Thread the bobbin winder as shown below:

1. Upper Thread guide

2. Thread guide

3. Thread tension – Be sure to thread through the

small eye before going between the disks.

4. Bobbin (Place the bobbin on the bobbin winder

spindle.)

5. Press the limit lever as indicated by the arrow

to start the winder. The lever stops the winder

automatically after the winding is complete.

1

2

3

4

5

Increase Decrease

Tension

When adjusting bobbin winder tension:

• Ensure thread winds evenly on bobbin as

shown.

Confirm that the bobbin is wound properly..

• Keep the tension constant while winding.

Tighten thread tension if thread winds too loosely.

CAUTION: To prevent accidents.

When lever is pressed down, the bobbin

winder spindle and the bobbin start turning.

Keep fingers and body away until the bobbin

winder stops turning.

-CD -29

B

A

4_5 K101

4-5

A

B

B

C

B

A

A

BOBBIN WINDING

Removing the bobbin

1. Open hook cover (A) to front.

2. Grasp bobbin case latch (B) and withdraw

bobbin case from hook taking care not to

damage the thread keeper.

Inserting the bobbin case

1. After threading bobbin in case, open bobbin

case latch (A), grasping it in fingers as

shown.

Slip bobbin and case on stud of rotary hook

body, and press in securely. Release bobbin case latch. Press the bobbin case in to

be sure it is fully seated.

2. Close hook cover.

Inserting the bobbin

1. Hold the bobbin case in left hand. Hold the

bobbin in your right hand with thread on top

leading from left to right.

2. Insert bobbin in case and draw thread up

into slot in case.

3. Draw thread under tension spring (A) and

wind into guide coil (B). The bobbin should

turn clockwise in the case when the thread

is pulled.

Adjusting bobbin thread tension

1. Hold bobbin thread and jerk upward approx.

an inch. Thread should unspool further

approx. the same amount.

2. The screw on the tension spring is for adjusting bobbin tension. This adjustment is

very delicate. Please turn the screw only a

small amount. Only 1/8 of a turn maximum.

CAUTION: To prevent accidents.

Please watch out for the point of the rotary

hook when you replace the bobbin.

Increase

Decrease

The attached bobbin case is available only

for this machine. Thread may be caught in

thread guide coil if other types are used.

CAUTION: To

prevent accidents.

Keep hook cover close

and fingers away while

the machine is running.

-CS -24

THREADING THE MACHINE

4_6 AF27

4-6

How to thread upper thread

Pass upper threads in order according to the figure:

1. Thread stand

Set thread cone on the stand.

Small cones can also be used as shown.

2. Thread guide

Thread through the thread guide above each

thread cone.

3. Upper rectifier

Continued next page

2

3

1

Small cone

-CS -25

THREADING THE MACHINE

4_7 D620

4-7

CAUTION: To prevent accidents.

Please be careful of the sharp point of the

needles when threading upper threads

through the needle.

4. Minor thread tension

5. Guide pin upper

6. Detecting roller

7. Guide pin lower

8. Thread tension

Wind upper threads one time around rotary

tension disc clock-wise.

9. Upper thread guide

10.Lower thread guide

11.Lower rectifier

12.Thread guide plate upper

13.Thread adjusting spring

14.Thread guide plate upper

15.Take-up lever

16.Thread guide plate upper

17.Thread guide plate lower

18.Needle bar thread guide

19.Needle

Thread from front side of needle.

Pull upper threads slowly and see that the detecting roller moves smoothly by pulling the thread

downward as much as possible.

20.Thread holding spring

Push thread into spring.

4

6

7

8

9

10

11

15

12,14,16

13

20

17

18

19

5

-SA -23

No. Display

Setting

Difult is underlined

Contents

1 Fine mode

Yes.............

No

...............

The machine emphasizes stitch quality by controlling embroidery speed.

By default it is set to "No".

2 Tightness

level

‑ (Loose)

□

(Normal)

+ (Tight)

The machine adjusts thread tightness level by controlling the timing of frame

move.

By default it is set to "Normal".

3 TRD. break

back

Yes

No

On thread breaks, this causes sewing position & frame to move backwards by

several stitches before the detected break before stopping.

5 Width data

limit

1-13

mm

(13=12.7)

When stitch length exceeds this length, the machine divides it by this jump

length and creates multiple movements. Width data limit becomes 12.7mm only

when setting value is set to 13.

Please use a smaller number when you use thick and heavy material.

6 Quick start

mode

Yes.............

No...............

If you set to "No", the machine will increase speed slowly. Please select "No."

when you have a problem with skipped stitches on the beginning stitch after

thread trim.

• The machine sews up to 3 stitches slowly after thread cut.

• The machine sews up to 5 stitches slowly after thread cut.

7 Auto thread

cut

Yes

No

This performs automatic thread cut after color change and stop.

8 Cut at jump

data

1~8(3

)......

0..................

When a set number of continuous jumps exists in pattern data, the machine

cuts threads before jumping.

• Machine trims the thread on setting number of constant jump.

• Does not trim.

9 Cut at null

jump

Yes

.............

No...............

This sets thread cuts before null jumps (isolated jumps with no net movement)

• Does trim on empty jump data.

• Does not trim on empty jump data.

10 CHG. always

cut

Yes.............

No

...............

Forces a trim at every color change.

• Always thread trim before color change.

• If data does not have trim function at color change point, machine does not

trim.

11 Length of

TRD.cut

Max.

Long

Normal

Short

Min.

Needle........

The machine cuts upper threads to a longer length.

• The upper threads of each needle will be cut off by registered length. 5-2b

13 Width data

all

-1.0 ~ 1.0mm

0.0mm.......

This is to alter the widths of all satin stitches for all the designs in the memory.

• Adjust satin stitch width by selected amount.

• Does not adjust width.

14 TRD. break

detect

Quick 3

~

~

Norma

~

~

Slow 3

Off

Needle........

Sensitivity selection of the thread break detect sensor.

By default it is set to "Normal".

• You can set sensitivity of thread break detection needle by needle. 5-3

15 Convert cap

Yes

No

When you install the cap drive frame on the machine, the machine will convert

(rotate) your design automatically.

16 Revers frame

move

Yes

No

Frame will be moved in the opposite direction of the arrow key.

17 STR.Auto

Position

Yes

No

Machine remembers & returns to last sewn position after sewing interruption

even if operator has moved the frame after interrupt.

18 Embroidery

weight

Light

Middle

Heavy

This setting for heavy duty material depends by material weight.

Normally, please select "middle" or "Heavy" for Border frame.

Machine speed is decreased automatically, when you sellect "middle " or

"heavy".

5-1

MACHINE SETTINGS

5_1 O512

Before embroidering, check the basic settings of the machine.

The rest of the settings can be left at default values (as indicated by underline below).

-RA -32

MACHINE SETTINGS

5-2

5_2 O512

yalpsiD.oN

gnitteS

denilrednusitlufiD

stnetnoC

19 Expand cap

limit

1 ~ 10mm

0mm..........

The direction of Y-axis of the embroidery area (standard) is extended in the

direction of the brim of the cap.

If the embroidery area is extended too much, there is a possibility that a

needle and pressure foot may hit a frame and may be damaged.

Before start sewing, please check carefully the embroidery area by trace

function etc..

• The embroidery area is extended with the set-up size.

• The embroidery area is not extended.

20 Frameout

position

0 ~ 100

~ 780mm

Set movement of frameout in the drive menu.

21 Display inch

Yes

No

• Display the unit of dimensions at an inch.

• Display the unit of dimensions by millimeters meter.

22 Trace speed

0 ~ 100 ~ 300

You can change the Tracing speed. "100" mean the normal speed.

If you change the number bigger, the speed decrease.

23 Display off

timer

0 ~ 240 (min.)

The machine turns off the display screen when the time without any operation

exceeds the time entered in the parameter.

Timer function is "off" when setting value is set to "0"

24 Design disp

mode

All

Change

• When drive mode, highlight all color change number on the LCD Display.

• Highlight only current color change number.

25 Drawing

“ Real

Pattern”

Yes

No

Display pattern with realistic image on the screen.

26 Operation

Sound

Yes

No

Make beep sound when button or key of touch panel is pressed.

27 Notificati-

on Sound

Yes

No

Make beep sound when the machine is stopped.

28 FW/BW Lock

Count(1st.)

0 ~ 100

In "Stitch number forward", set number of stitches until "Key lock" function is

activated

The "Key lock" function will be disabled when the number of stitches is set to

"0".

29 FW/BW Lock

Count(10st.)

0 ~ 100

Set number of stitches until step of “ Stitch number forward” is changed from

one stitch to 10 stitches.

The “ Stitch number forward” function will be disabled when the number of

stitches is set to “ 0” .

-SA -24

MACHINE SETTINGS

5-2a

5_2a O512

1. When the machine is stopped, press .

2. Select "OPTION".

3. Select

.

4. Select desired setting item and change the

setting.

You can move to next page by pressing

.

Press to return to Menu mode.

Press

to return to Drive mode.

-D2 -30

5-2b

MACHINE SETTINGS

5_2b MA05

Detailed explanation of machine settings

11 Length of TRD.cut

If you select "Needle" with this setting, the upper threads of each needle will be cut off by registered length.

The length of each thread can be set up taking the following steps.

1. Follow the steps 1.- 3. on the previous page

and the display shows machine setting

page.

2. Press .

3. Change the setting on the needle number

you would like to change with

.

Press when returning the setting on all the

needle numbers to default.

4. Press .

Needle number

13 Width data all

This function adds additional width to all satin

stitches in a design. 12-3

This is otherwise set in the "Settings" function, in which case any changes made to the setting

from this screen will have no effect.

-D2 -31

5-3

MACHINE SETTINGS

5_3 MA05

Needle number

15 TRD. break detect

If you select "Needle" with this setting, you can set sensitivity of thread break detection needle

by needle.

You can be set up taking the following steps.

1. Follow the steps 1.- 3. on the page 5-2 and

the display shows machine setting page.

2. Press

.

3. Change the setting on the needle number

you would like to change with

.

Press when returning the setting on all the

needle numbers to default.

4. Press .

-SJ -29

LOCK STITCHES

5-3b

5_3b NB01

1. When the machine is stopped, press .

2. Select "OPTION".

3. Select

.

4. Select desired setting item and change the

setting.

Press when returning the setting on all the

needle numbers to default.

SETTING ITEM SETTING RANGE CONTENTS

1 Cut Lock stitch

OFF : Remove lock stitch when the machine cuts threads.

ON : Add lock stitch per SETTING ITEM 2 and 3 when the machine cuts threads.

AUTO : Add lock stitch when length of the stitch before thread cut is longer than length

set at SETTING ITEM 2.

2 Cut Lock Length 0.4~0.5~1.2mm : Set lock stitch length when "ON" or "AUTO" on SETTING ITEM 1 Cut Lock

stitch is selected.

3 Cut Lock Count 1 ~ 2 ~ 3 : Set number of lock stitch when "ON" or "AUTO" on SETTING ITEM 1 Cut Lock

stitch is selected.

4 STR. Lock stitch Add Lock stitch when the machine starts sewing.

OFF : Remove lock stitch when the machine stars.

ON : Add lock stitch per SETTING ITEM 5 and 6.

AUTO : Add lock stitch when length of the stitch before the machine starts sewing cut is

longer than length set at SETTING ITEM 5.

5 STR. Lock Length 0.4~0.5~1.6mm : Set length of lock stitch when "ON" or "AUTO" on SETTING ITEM 4 Cut Lock

stitch is selected.

6 STR. Lock Count 1 ~ 2 : Set number of lock stitch when "ON" or "AUTO" on SETTING ITEM 4 Cut Lock

stitch is selected.

Settings to lock stitches.

Press to return to Menu mode.

Press

to return to Drive mode.

-D2 -34

USB port

5-4

PREPARATION OF PATTERN DATA

5_4 MB29

Connecting to a PC

This embroidery machine will allow you to read design data from a connected PC.

A USB cable or a LAN cable can be used for the connection.

Install the clampfilter

In order to avoid unexpected trouble caused by electric noise, install attached clamp filter on

the embroidery machine side on USB cable or LAN cable.

Install attached clamp filter when also using other cable than attached cable.

1. Please set clampfilter on new cable as

picture.

Clampfilter should be located close to

machine.

Cable should be turned around

clampfilter as picture.

2. Please confirm filter is closed completely.

When the filter is removed, please press

latch (2 positions) on clampfilter by thin

rod.

Clampfilter opens and it can be removed

from cable..

Machine

USB connection (

based on the

USB 1.1, 2.0)

Connect by USB cable between USB port (Standard-B receptacle) of the machine and USB port

of the PC.

When you connect the USB cable, make sure that the machine is powered and set into drive mode, and

that the PC is also turned on.

After recognizing USB in your PC, start-up the "Happy Link".

Please refer to instruction book of "Happy Link" for more precise information.

USB

-D2 -35

Reading embroidery pattern data from the PC

Designs can be transferred to the machine along with some functions by using the “Happy Link

LAN” software.

Please refer to the “Happy Link” or “Happy Link LAN” software manual for instructions.

LAN connection

Connect the LAN cable between the LAN port of the machine and the network of the PC.

Multiple and different type of machines can be connected to a PC which has Happy Link LAN software

installed.

Please refer to instruction book of "Happy Link LAN" for more precise information.

Connect to the Switching

HUB or the Wireless LAN

device.

Please refer to instruction

book of "Happy Link LAN" for

more precise information.

LAN port

PREPARATION OF PATTERN DATA

5-4b

5_4b M620

-D2 -285_5 M201

5-5

PREPARATION OF PATTERN DATA

Read embroidery pattern data

Read the pattern to be embroidered from the memory media.

These types of memory media can be used.

This machine is able to read different kinds of memory media, which are generally used.

•USB memory

If you initialize the memory media with your PC, please proceed with FAT or FAT32 format.

Handling note of memory media.

Do not bend, drop, disassemble, charge or heat the memory media.

Keep away from humidity or direct sunlight.

To insert a USB memory

1. Insert the USB memory all the way into the

USB memory port of the machine (right side

of controller).

2. Read embroidery design data according to

following “Memory card reading” in the next

section.

To remove a USB memory

Please handle USB memory carefully.

-D2 -36

Reading pattern data

This reads pattern data and writes into memory.

When the HAPPY format pattern data with *various function settings are read in memory, various functions such as needle bar selection, pattern data adjustments and etc. will be set automatically. (It is necessary to set “etc.func read”. 14-4)

In addition to memory media, this machine can read pattern data saved in the PC connected

with "Happy Link LAN".

Design folder settings on the "Happy Link LAN" is required before reading pattern data.

Please refer to "Happy Link LAN" System INSTRUCTION MANUAL regarding the settings

method.

The pattern data can be read through the designated folder and sub-folders by accessing from

the machine.

If the Happy or Tajima pattern data has Barudan or ZSK *data. (Tajima file : DSB

[Barudan] or DSZ [ZSK])

The machine can read HAPPY and Tajima pattern data normally when "Auto" is selected at

SETTING RANGE of SETTING ITEM 7 data format of Pattern read settings on page 14-4.

If the machine dose not read pattern data cannot at "Auto", please try with other data format

such as Brd (Barudan) or Zsk (Zsk). The machine might be able to read the data. 14-4

5-6

PREPARATION OF PATTERN DATA

5_6 NB01

1. Insert the USB memory into the machine

as described in "Inserting USB memory”.

2. When the machine is stopped, press .

3. Select "READ".

4. Select

(USB memory) or (Pattern

data in the PC).

Indicates pattern data.

TAP : HAPPY

DST : Tajima

DSB : Tajima (Barudan)

DSZ: Tajima (ZSK)

Folder : Contents of folder will be displayed

when you select this icon.

The designs new ID number in the machines memory.

Free memory

Folder

--- Serch pattern ---

Un-recognized device will be shown with gray color.

-D2 -37

5-7

PREPARATION OF PATTERN DATA

5_7c NB01

5. Select pattern data.

1 % of free memory is equivalent to about

400,000 stitches.

If there are more stitches than remaining space,

you may need to delete some designs to make

room for the new patterns.

Once design is read.

Enable to read other pattern data.

If you wish to read another design, continue to read

other pattern data.

If you press , the display will return to step 3.

Switch the source you would like to extract pattern

data from.

When the screen displays pattern data in

the folder, is displayed.

When

is pressed, the screen moves

off from the current folder.

--- Check pattern data ---

--- Reading ---

Press to return to Menu mode.

Press to return to Drive mode.

The icon allows you to read the all

designs at once which are located in the

currently opened folder or directory.

-D2 -38

5-9

PREPARATION OF PATTERN DATA

5_9 NB01

Selection of folders

The pattern data memory is consist of 20 individual folders.

Select desired folder to choose or input pattern data.

Selected folder

1. When the machine is stopped, press .

2. Select "PATTERN".

The pattern data of the selected folder will

appear on the display.

3. Go on to step 4, if you want to select pattern

from displayed folder.

Press

to select from whole folders.

4. Select desired folder.

The selected folder has been switched.

You cannot switch to the folder without pattern

data.

Selected folder

Press to return to Menu mode.

Press

to return to Drive mode.

-D2 -39

5-A

PREPARATION OF PATTERN DATA

1. When the machine is stopped, press .

2. Select "PATTERN".

The display indicates the current pattern.

The right side of display shows the number,

name and details for the current pattern.

Number of stitches

Number of Color change number

Height

Width

3. Select pattern data.

This pattern will be selected.

5_A NB01

How to select patterns from memory

To select an embroidery design previously stored into the machine memory.

Selected pattern data

Selected pattern data

Press to return to Menu mode.

Press to return to Drive mode.

-D2 -40

5-B

PREPARATION OF PATTERN DATA

5_B NB01

1. When the machine is stopped, press .

2. Select "PATTERN".

3. Press from right submenu.

4. Select desired pattern.

Mark will appear left of the pattern.

Make will be cleared by press it again.

Multiple pattern data can be selected.

: Select all the pattern data

: Cancel pattern data erasing

Erasing patterns from memory

This is to erase an unnecessary design data from the machine memory.

Pattern data cannot be erased if the lock is set.

Mark

-SA -27

5-C

PREPARATION OF PATTERN DATA

5_C O512

5. Press .

6. Push "OK" to delete.

The item will be deleted.

To delete other patterns, repeat steps 3 to 6.

Press “Cancel” to cancel the delete.

The display will return to step 2.

Delete pattern? < 2>

Cancel OK

Showing number of delete design(s)

Press to return to Menu mode.

Press

to return to Drive mode.

Erasing all patterns from memory

This is to erase alldesign data from the machine memory.

Patterndatacanbeerasedifthelockisset.

1. When the machine is stopped, press

.

2. Select "PATTERN" while pressing the

and

3. Press .

The item will be deleted.

-SA -22

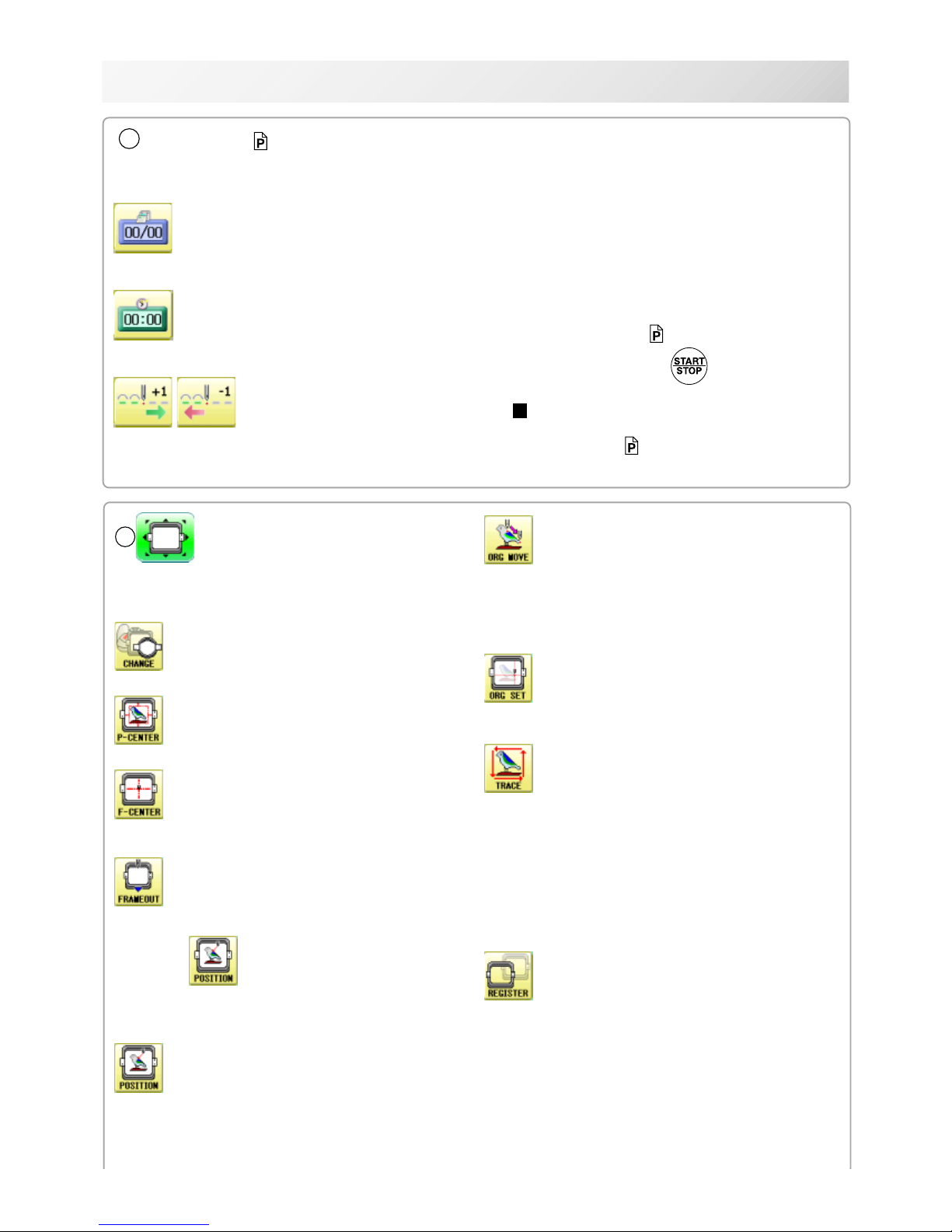

1. When the machine is stopped, press .

2. Select "NEEDLE".

The screen of color number 1 selection is displayed.

The current color number is showed in the pattern

data display portion.

3. Select the needle number.

After setting the needle number on color number,

the following color number selection is displayed.

You can also select color number directly.

You can switch color change numbers with

if the color change number has more

than 5.

4. Select the needle number on all the color

change numbers.

Press

to return to Menu mode.

Press

to return to Drive mode.

5-E

NEEDLE BAR SELECTION

5_E NB01

For each color change in a given pattern, the needle number loaded with the correct color

thread is assigned by the operator. When this is set, the machine automatically changes to the

programmed needle when the design reaches that point in the course of sewing the design.

You can not setting "NEEDLE" for selected "LOCK" design.

Please release "LOCK" from design.

11-1

Needle

number

Current color

change number

Needle number

Color change number

Press to on the sub menu to check

the setting.

Number of color

change number

-D2 -44

5-F

NEEDLE BAR SELECTION

5_F MA05

Color change stop mark

Frame out mark

Color change stop function

When a color change stop is set to a color change number, the machine will stop after it

finishes sewing the marked needle number, then following message will be shown:

When you wish to start again, Press (Start/Stop button).

1. Select a color change number and press

.

The mark is displayed on the color change number.

2. Set it to the same on other color change number if necessary.

Selection of color change number

Set Color change number to execute frameout.

A frame out command can be added to a design. By setting frameout to a *Color change

number in a design, you can move the frame to a desired position automatically and stop it

after the machine finishes sewing of that color change number.

When you resume operation, the frame has an automatic return to previous position and you

can continue sewing.

12-D

1. Select a color change number and press

.

The mark is displayed on the color change number.

2. Set it to the same on other color change number if necessary.

When you turn frameout "On" without setting the move distance of frameout, this results in

the same action as color a change stop.

No thread cut after color change

When "no thread cut after color change" is set on a color change number, thread cut is not

done after color

change at the specified color change number and the machine switches to the next color

change number.

"No thread cut after color change" function can be set by combining color change stop or

frame out function.

No thread cut mark

-SA -23

6-1

SEWING WITH TUBULAR FRAMES

6_1 NB01

1. When the machine is stopped, press .

2. Press

.

3. Select or .

: Tubular round frame

: Tubular square frame

: User-defined frame

4. Select desired type of frame.

Installing and removing the frame base

Please attach the frame base to the carriage when you wish to use a tubular embroidering hoop.

Please remove it in the reverse order of

installation.

-SA -24

6-1b

SEWING WITH TUBULAR FRAMES

5. Press button.

6. Move the carriage to the position shown by

press

.

7. Place the frame base on the carriage guide

and tighten the knob bolt on the tubular arm

holder completely.

Move the frame base right or left when it is hard

to tighten the knob bolts.

6_1b NB01

Carriage

Fixing base

Knob bolt

Guide

Frame base

Pushing

against

Press to return to Menu mode.

-CS -51

6-2

SEWING WITH TUBULAR FRAMES

6_2 D610

How to hoop

Inner frame

Cloth

Backing

Outer frame

Please stretch the embroidery cloth in the

directions of the arrow to

smooth the cloth.

Do not stretch the elastic cloth too much.

Please smooth the embroidery cloth while adjusting

tightness of outer frame.

i

Loosen

Tighten

-CS -49

6-3

SEWING WITH TUBULAR FRAMES

6_3 H402

Putting the hoop on the machine

1. Move the frame base to the approximate

center position before inserting the tubular

embroidering frame.

2. Insert the embroidery frame.

Make sure that the holder pins are inserted into

the positioning holes of the frame base on each

side.

Holder

Holder

Embroidering hoop

Positioning hole

Positioning pin

Positioning hole

Positioning pin

Frame base

1

2

CAUTION: To avoid problems.

Please do not hit or

push embroidering hoop

to presser foot.

-S2 -18

6-3b

SEWING WITH TUBULAR FRAMES

6_3b M701

Use TAJIMA made tubular frame

You can use TAJIMA made tubular fame which has the same installation width (space between left and right positioning pin) as HAPPY's frame by changing the position of both left

and right hold springs and left and right hold spring bases.

Follow the procedure below after removing tubular frame.

1. Loosen screws (2 each at both left and right).

2. Move both left and right hold spring bases deep into screws.

3. Move both left and right hold springs forward until the spring touches screws and stops

moving.

4. Tighten screws (2 each at both left and right).

5. Install tubular frame and check if the tip of both left and right hold springs enters receiving

hole on tubular frame.

If the tip dose not enter receiving hole, loosen screw, rotate hold springs left or right so

that the tip can enter the hole, and tighten screw.

Please reverse the procedure above when returning to the position of something before

change has been made.

HAPPY

TAJIMA

Hold spring

Hold spring base

Screws

Positioning pin

1

2

3

455

Receiving hole

-SA -26

6-4

SEWING WITH TUBULAR FRAMES

6_4 NB01

Starting to embroider

1. Press and move the frame to the

original point with the

.

2. Press

.

Press , and the embroidering frame moves

for the design trace. 14-5

Make sure that the pressure foot and needle do

not touch the frame.

Press , and trace is stopped.

Go on to step 4 if you want to start embroidering

without tracing.

3. Press after the trace is completed.

The embroidering frame has moved to the first

stitch point of the pattern.

4. Press .

The embroidery will start.

5. After embroidering your design is complete,

show ">>End" and the machine will stop.

The embroidery frame returns to the original

point automatically if the "Auto origin" function

has been activated.

: Original point

(Start point)

You can confirm outline

trace and the position of

the design.

>>End

Forward only when pressing

Pose

Backward only when pressing

Pressure

foot

-CS -55

7-1

CAP FRAME (OPTION)

7_2 N401

Changing the needle plate

You need to change the needle plate when you

embroider a cap.

1. Remove the set screw (2 pieces) by offset

driver and remove the needle plate.

2. Put the needle plate for cap on the bed and

tighten with the set screw.

3. Loosen the set screw (upper side) of pressure foot and unscrew the set screw (lower

side).

4. Press up the pressure foot and tighten set

screw (upper side) and tighten set screw

(lower side) as it shown in the diagram.

Set screw

Pressure foot

Needle plate for

cap frame

1

2

3

4

-SA -27

7-2

CAP FRAME (OPTION)

Installing and removing the cap drive frame

You need to install the cap drive frame into the carriage when you embroider a cap.

Please remove by reverse order of these step.

CAUTION: To prevent accidents.

The frame moves quickly.

Keep hands away from the frame.

7-2 NB01

2. Turn off the power switch.

3. Hold the arc guide by hand and the rail

bracket has to be faced downward, then

install into the bed as showing picture.

When you hold the cap drive frame assembly, be

sure to hold the arc guide of the cap drive frame

assembly.

If you hold the rail bracket, your fingers will be

pout between the rail bracket and the rail bracket

rotary cylinder and rail bracket can get out of

place.

ON

OFF

Rail bracket

Arc guide

Rotary cylinder

1. Press and Press .

The embroidery frame will move to the center .

-S2 -28

7-3

CAP FRAME (OPTION)

7-3 N909

4. Move the cap drive frame backwards away

from you and rotate the rotary cylinder until

the rail bracket is upward as shown at right.

5. Move the cap drive frame in the direction of

the arrow, adjust right-and-left mount base

to carriage arm and fix them by knob bolts.

6. Fix the rail bracket to fixing base by knob

bolts.

You can move the fixing base right or left when it

is hard to tighten the set screw.

Knob bolt

Mount base

Carriage

Rail bracket

Carriage arm

Fixing baseKnob bolt

-S2 -25

7-4

CAP FRAME (OPTION)

7_4 M424

CAUTION: To prevent accidents.

The frame moves quickly.

Keep hands away from the frame.

7. Turn on the power switch.

Selected frame is indicated.

8. In case required Cap frame is already

selected, please jump to operation no.10.

In case selected frame type is not same as

your requirement, Press

.

9. Select the desired frame.

10.Press

.

The embroidery frame will move to the center

automatically.

ON

OFF

Selected frame

-CS -50

7-5

CAP FRAME (OPTION)

4_5 E201

Adjustment

When you hoop a cap on the cap frame, please