Happy Industrial Corporation HCD2 Instruction Book

D2N401-11

Computerized Single Head Embroidery Machine

INSTRUCTION BOOK

HCD2

-D2 -2

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS.. 1-1

WARNING LABELS & THEIR LOCATIONS .....

1-2

SETTING UP THE MACHINE

Assemble machine unit .......................... 2-1

How to carry machine............................. 2-2

Machine installation ................................ 2-2

Assemble safety sensor (Option) ........... 2-4

Assemble Wide X-carriage (Option) ......2-4b

Assemble table (Option) ......................... 2-5

Assemble border frame (Option) ...........2-5b

Assemble Expand side table (Option)..............

2-5c

Assemble bobbin thread guide (Option) . 2-6

Grounding instruction ............................. 2-7

Disposal of a battery............................... 2-7

MAIN PARTS ............................................ 3-1

HOW TO READ

THESE

INSTRUCTIONS .............

3-3

MESSAGES .............................................. 3-4

TURNING THE MACHINE ON

How to turn on the machine.................... 3-5

Calendar and clock setting ..................... 3-7

THE CONTROL BOX................................ 3-8

DRIVE MODE ........................................... 3-9

GUIDE....................................................... 3-D

INSERTING A NEEDLE............................ 4-1

SELECT NEEDLES AND THREADS....... 4-2

BACKING MATERIALS............................. 4-3

BOBBIN WINDING

Winding the bobbin (Option)................... 4-4

Removing the bobbin.............................. 4-5

Inserting the bobbin ................................ 4-5

Adjusting bobbin thread tension ............. 4-5

Inserting the bobbin case ....................... 4-5

THREADING THE MACHINE

How to thread upper thread.................... 4-6

MACHINE SETTINGS............................... 5-1

LOCK STITCHES.....................................5-3b

SEQUIN SETTINGS (Option) .................. 5-3c

PREPARATION OF PATTERN DATA

Connecting to a PC ................................ 5-4

Reading embroidery pattern data from the PC

5-4b

Reading embroidery pattern data ........... 5-5

Selection of folders .................................................. 5-9

How to select patterns from memory...... 5-A

Erasing patterns from memory ............... 5-B

NEEDLE BAR SELECTION ...................... 5-E

SEWING WITH TUBULAR FRAMES

Installing and removing the frame holder arm....

6-1

How to hoop ........................................... 6-2

Mounting the hoop on the machine ........ 6-3

Starting to embroider .............................. 6-4

CAP FRAME (option)

Cap frame settings in the control box ..... 7-1

Installing and removing the cap frame driver .

7-2

Normal cap frames ................................. 7-5

Wide cap frames..................................... 7-8

Starting to embroider .............................. 7-B

ADJUSTING THE THREAD TENSION..... 8-1

ADJUSTING THE LASER POINTER (OPTION)...

8-2

SEWING

What to do if the thread breaks while sewing.

9-1

Stopping and resuming sewing .............. 9-1

Loss of power while embroidering .......... 9-2

Moving the hoop while embroidering and then returning to

the correct location (Position) .......................................

9-3

Moving back to the starting point

(Origin).

9-3

Going back to the beginning of the design (Top) ....

9-4

Placing the design in the center of the selected

embroidery frame

(Center) ..................................

9-4

Rotating and mirroring designs (Convert) ......

9-5

Starting in the middle of a design (Position)...

9-6

DISPLAYING THE PATTERN IN SETTING MODE.

10-1

PATTERN

Locking pattern data ............................. 11-1

Trace type............................................. 11-2

Export ................................................... 11-3

Renaming patterns ............................... 11-5

Copying pattern data ............................ 11-6

Moving pattern data.............................. 11-7

Renaming folders ................................. 11-9

Sort ....................................................... 11-A

Thread break report.............................. 11-B

Retrieve built-in data from machine......11-C

PATTERN SETTINGS ............................ 12-1

Scaling.................................................. 12-2

Width adjustment.................................. 12-3

0_1 N401

0-1

-D2 -3

CONTENTS

0_2 N401

0-2

Angle .................................................... 12-4

Repeat sewing...................................... 12-5

Auto origin ............................................ 12-7

Offset.................................................... 12-8

Frame out ............................................. 12-D

NEEDLE BAR SELECTION .................... 13-1

Auto setting........................................... 13-2

Thread color ......................................... 13-3

Color change data registration ............. 13-5

Color change data read ........................ 13-6

Repetition of color group setting........... 13-7

READING

Join....................................................... 14-1

Pattern Read Settings .......................... 14-4

POSITION ALIGNMENT BY DEFINING 2 POINTS.

15-1

BORER (Option) ..................................... 15-4

POSITION ............................................... 16-1

Piece number ....................................... 16-2

LOCATE.................................................. 17-1

Entry ..................................................... 17-2

Return................................................... 17-3

LETTER .................................................. 18-1

QUEUE ................................................... 19-1

Alter and Execution .............................. 19-2

Needle bar selection and Pattern settings...

19-4

Registration of QUEUE setting............. 19-5

Read QUEUE setting............................ 19-6

FRAME CONFIRMATION....................... 20-1

Frame selection...........................................

20-2

Adjusted for embroidery area ............... 20-4

User-defined frames (1 ~ 5)..................20-7

User-defined frames (6 ~ 20).................20-A

How to change center point of frame (1 ~ 5, 6 ~ 20) ..

20-J

Non registered ....................................... 20-L

i-CUSTOM............................................... 21-1

OTHER SETTINGS

Create network ..................................... 22-1

Version information and software update....

22-3

Language.............................................22-3b

Calibrate .............................................. 22-3c

Report................................................... 22-4

User maintenance mode ...................... 22-5

SCREEN SAVER .................................... 22-7

SPECIFICATIONS • MAINTENANCE

Specifications ....................................... 23-1

Oiling .................................................... 23-1

Cleaning the rotary hook

Cleaning the thread cutting knife .......... 23-2

ERRORS AND WHAT TO DO ................ 24-1

INITIALIZING OF MACHINE SETTINGS

Re-Initialization of machine system ...... 25-1

Initializing of machine speed ................ 25-2

HELPFUL HINTS .................................... 26-1

EMBROIDERY TERMS .......................... 26-2

BUILT-IN FONT LIST.............................. 26-3

-CD -4

IMPORTANT SAFETY INSTRUCTIONS

1_1 F701

1-1

When using an electrical appliance, basic safety precautions should always be followed, including the following.

Read all instructions before using this appliance.

DANGER - To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this appliance

from the electric outlet immediately after using and before cleaning.

WARNING

- To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this appliance is used

by or near children.

2. Use this appliance only for its intended use as described in this manual. Use only attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it

has been dropped or damaged, or dropped into water. Return the appliance to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10.Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11.Always use the proper needle plate. The wrong plate can cause the needle to break.

12.Do not use bent needles.

13.Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14.Switch the sewing machine off (“0”) when making any adjustments in the needle area, such

as threading needle, changing needle, threading bobbin, or changing presser foot, etc.

15.Always unplug sewing machine from the electrical outlet when removing covers, lubricating,

or when making any other user servicing adjustments mentioned in the instruction manual.

SA VE THESE INSTRUCTIONS

-D2 -5

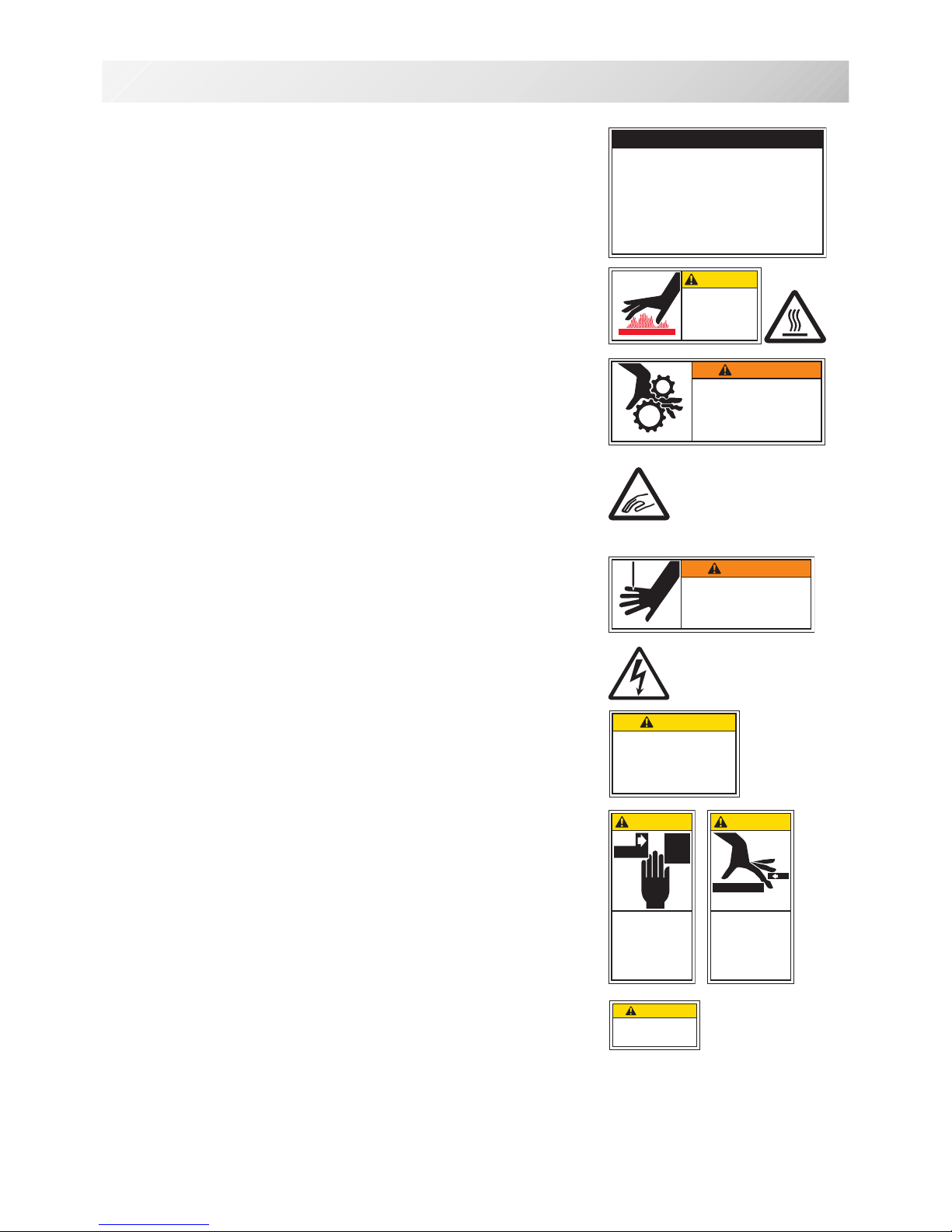

WARNING LABELS & THEIR LOCATIONS

1_2 M101

1-2

Safety Instruction Sticker for servicing, operating and

maintaining

Caution Sticker for hot surface

( on all pulse motors, the motors may reach a certain temperature after

long time running, which can reach up to 60°(C )

Trapping hazard

( please see sketch for location )

Trapping hazard wherever this label is found

Injury risk warning for all needles

Shock hazard on all electrical components

Injury risk on moving head(s)

Injury risk on frame and carriage

Laser beam (Class 1)

Do not stare into the beam.

ES-HMF-5113-0

WARNING

Shut the cover when starting the

machine. Do not put hands in

while the machine is running.

Fear of serious injury.

ES-HMF-5127-0

SAFETY INSTRUCTIONS

1. Machine must be operated by well trained

person only.

2. Machine must be used for original purpose

only, do not use for other purpose.

3. Shut machine off to oil, adjust or service.

4. Do not operate machine fill close and fix

cover.

5. Do not leave running when unattende.

ES-HMF-5128-0

Do not touch

hot surfaces.

CAUTION

ES-HMF-5112-1

Fear of serious injury.

Keep fingers away from

the needles while

the machine is running.

WARNING

ES-HMF-5117-0

CAUTION

Keep hands away from the

moving heads while the

machine is running.

Possibility of injury.

ES-HMF-5114-0

CAUTION

Possibility

of injury.

Keep hands away

from the drive

frame while

the machine

is running.

ES-HMF-5115-0

CAUTION

Possibility

of injury.

Do not put fingers

in holes or grooves

of the table.

Laser beam (Class 1)

CAUTION

Do not stare into the beam.

-D2 -8

SETTING UP THE MACHINE

2_1 N401

2-1

Assemble machine unit

1. Insert thread stand felt on the thread stand.

2. Turn the thread guide pillar clockwise with a

3 mm hexagonal driver until tight.

3. Install the thread guide bracket with

supplied screws (pan head screw M4 X 8 2

pcs).

4. Loosen the screw with a offset driver and

remove the red shipping collars that are

equipped on the both side of the guide bar.

(

Keep the shipping collars. It is necessary

when packing.)

5. Raise slowly the control box to the front

then fix it with 2 screws (upper and lower).

6. Install the tubular frame arm for embroidery.

Please refer to (page 6-1) "Installing and

removing the tubular frame arm".

Or, Install the cap frame for the cap

embroidery. Please refer to (page 7-1)

"Installing and removing the cap drive

frame".

7. Insert built-in stylus into the holder (slot) of

control box.

When taking the machine apart in case of

packing, the process is opposite of

assembling the machine. Please do exactly

the opposite way of assembling.

When packing the machine up for

transportation, be sure to select the eighth

needle and fix it with shipping collars on the

both side of the guide bar.

1

2

3

Thread stand

felt

Thread guide pillar

Thread guide

5

Screw

4

Screw

Screws

Stylus

7

-D2M4 -92-2 LC01

2-2

SETTING UP THE MACHINE

for qualified personnel only

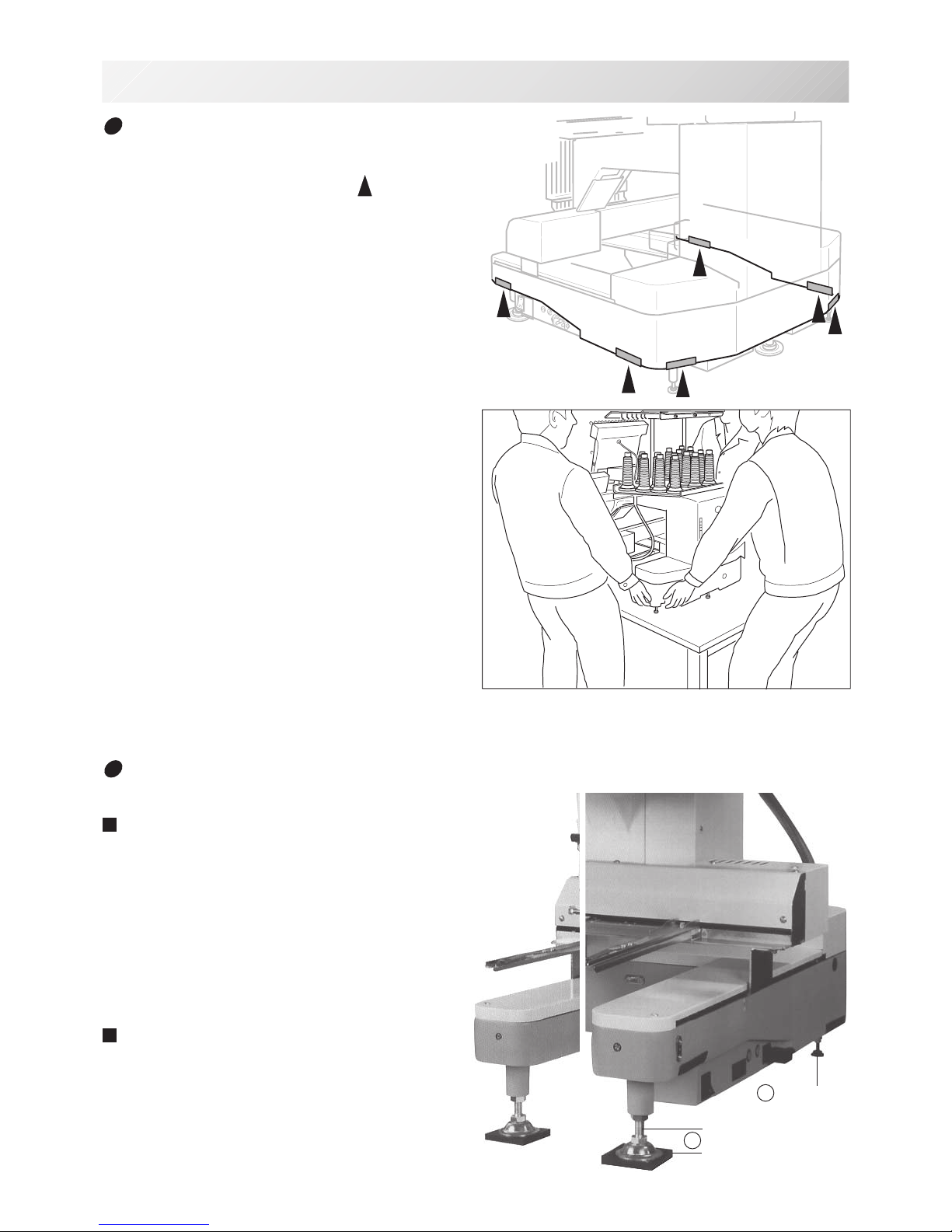

How to carry machine

The unpacked machine should be carried by 3

person with the hand position at

mark

shown in photos.

2

Ocasional

adjusters

Adjusters

Rubber mount

1

Right side

Left side

Rear side

Machine installation

Do not run the machine before setting it

properly.

Make sure of taking the following steps to

set the machine.

1. Pick up rubber mount (3 places) on the

stand then mount machine on the stand.

Then adjust machine level by adjuster on

foot and lock the each nut.

Be sure to use rubber mounts. Also be sure

to use robust stand that enables to adjust

level of the machine and endure machine

weight and vibration.

2. Please two occasional adjuster light touch

to stand and lock.

-D22-3 M201

2-3

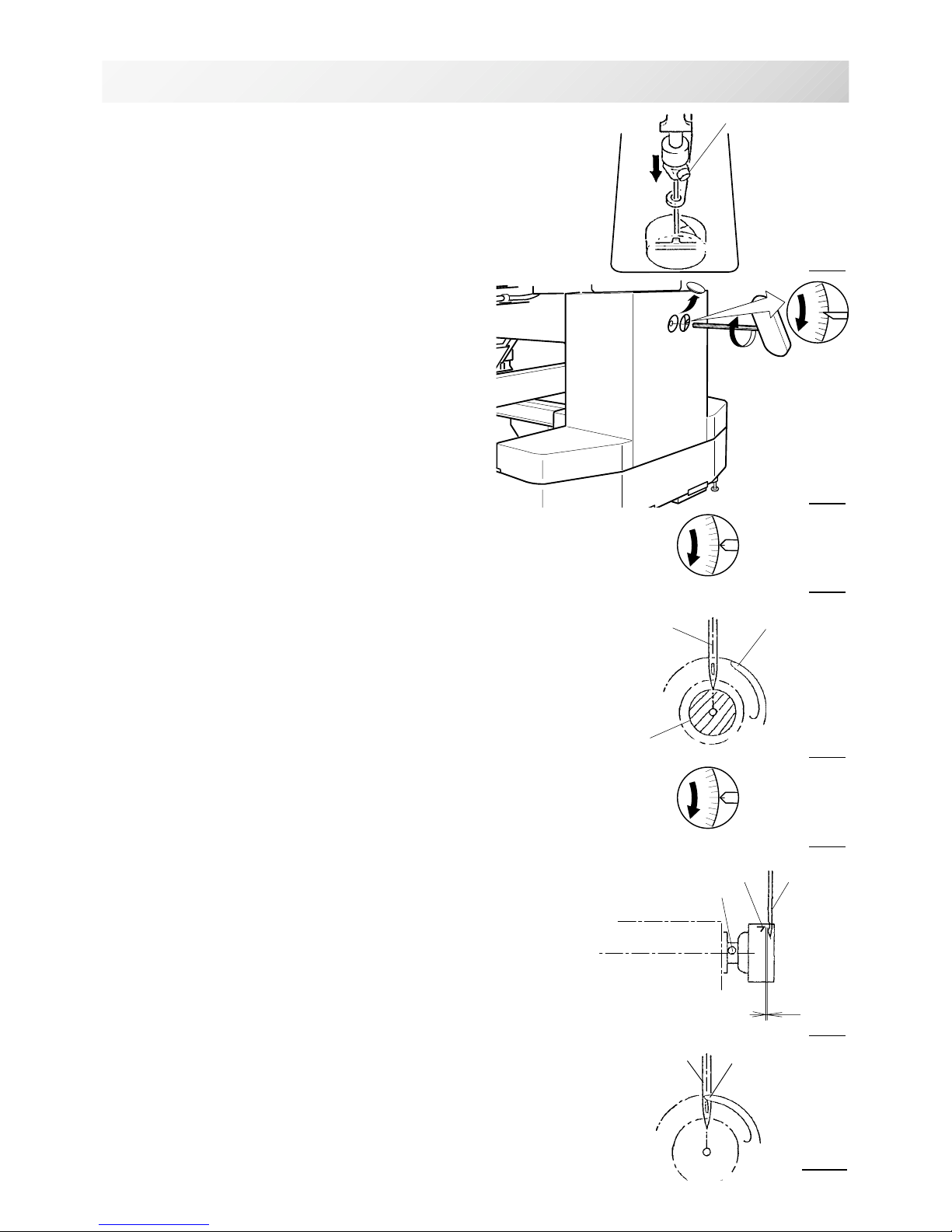

SETTING UP THE MACHINE

for qualified personnel only

3. Remove needle plates and bobbin cases

from all the heads.

4. Lower the needle holder by pressing down

with fingers on Fig. 4.

5. Turn main shaft by using the hexagonal

driver in direction shown with arrow mark on

Fig. 5 and set the angle of the adjustment

disk as shown in fig. 6.

6. Check the needle depth on all needles.

Pull white plastic ø17 measuring gauge in

and out of rotary hook in fig. 7. If height

gauge brushes lightly against tip of needle,

needle height is correct. If not, loosen

needle bar block screw to adjust, then retighten after adjustment.

(Remove the gauge when finished).

Note: Height gauge is contained in tool box.

7. Turn main shaft slightly in direction shown

by the arrow mark.

Then set the angle of adjustment disc as

shown in Fig. 8.

Note the space or timing between needle

and tip of rotary hook as shown Fig. 9, 10.

If the space is too open or too close, loosen

3 screws of shuttle to adjust. Make sure to

tighten 3 screws after adjusted the space.

(The timing is set exactly at the factory.

However, in some cases timing is inadvertently thrown off from handling during shipment.)

8. Turn main shaft in direction and set to C

point.

Place the bobbin and bobbin case in the

hook and replace the needle plate and

tighten.

9. Machine is now ready for sewing.

Needle holder

Tip of rotary hook

Needle

L+5°

Cord

Rotary hook

Needle

ø17 Measuring gauge

L+23°

Screws

Needle

Tip of rotary hook

0.1~0.15mm

Head bed

C

Fig. 10

Fig. 9

Fig. 8

Fig. 7

Fig. 6

Fig. 5

Fig. 4

-D2 -102-4 M101

2-4

SETTING UP THE MACHINE

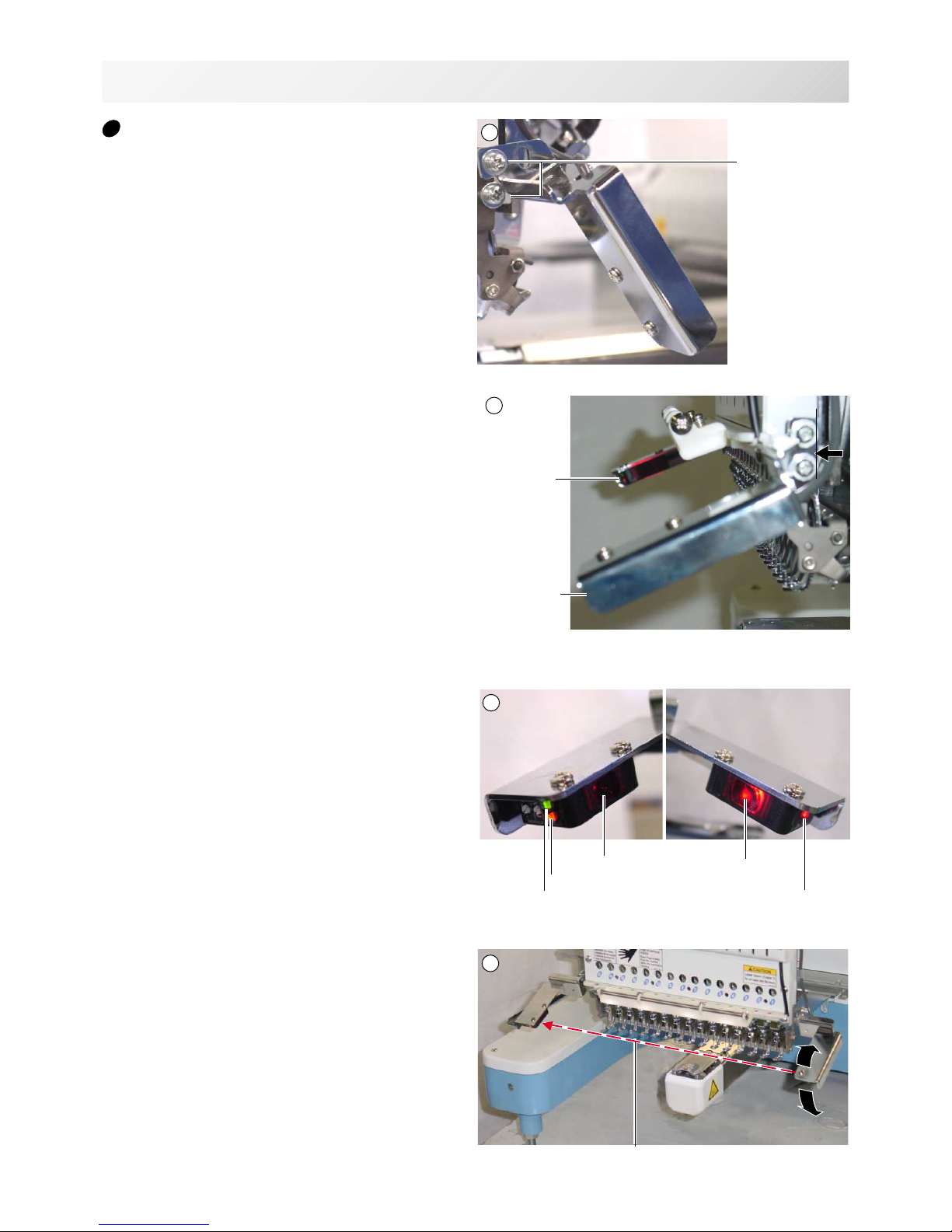

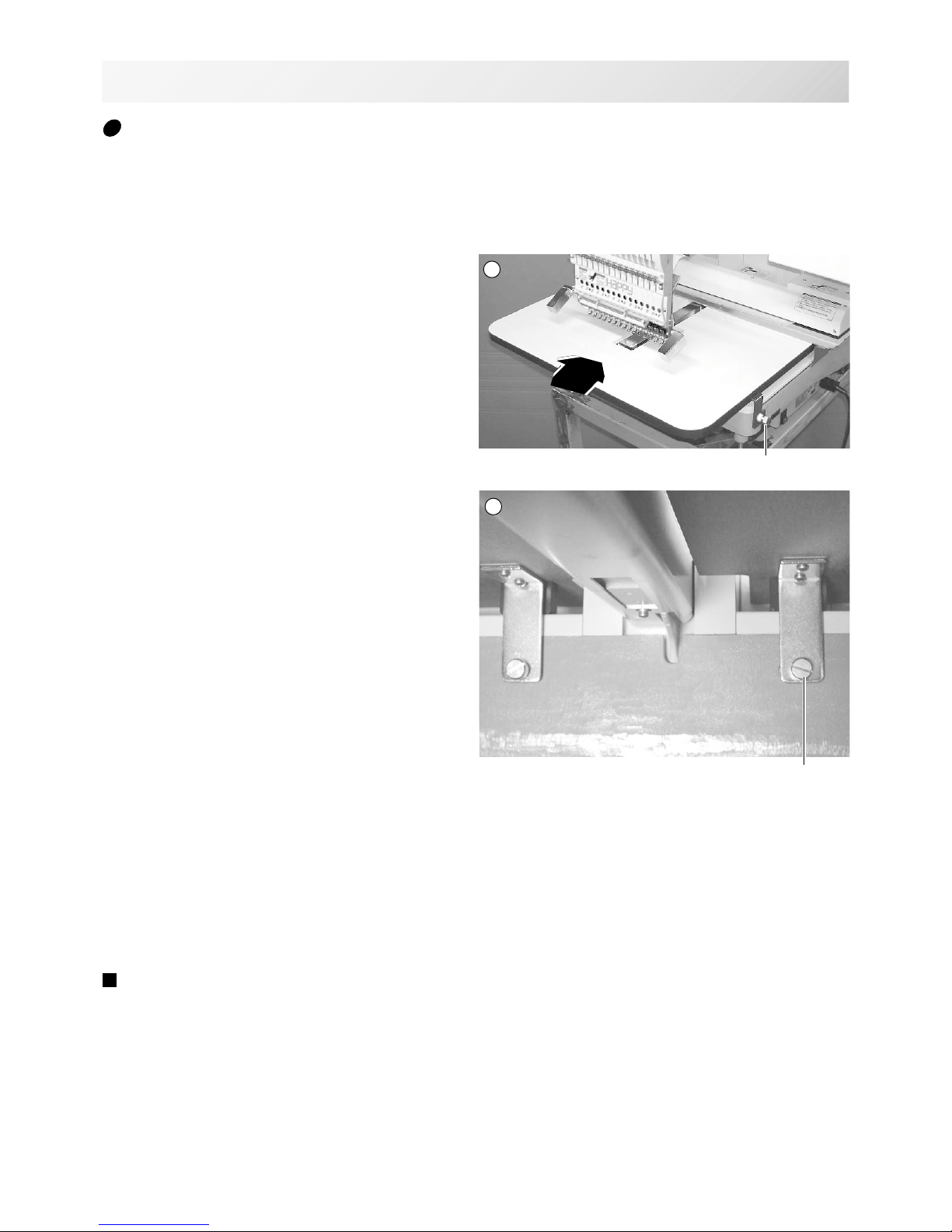

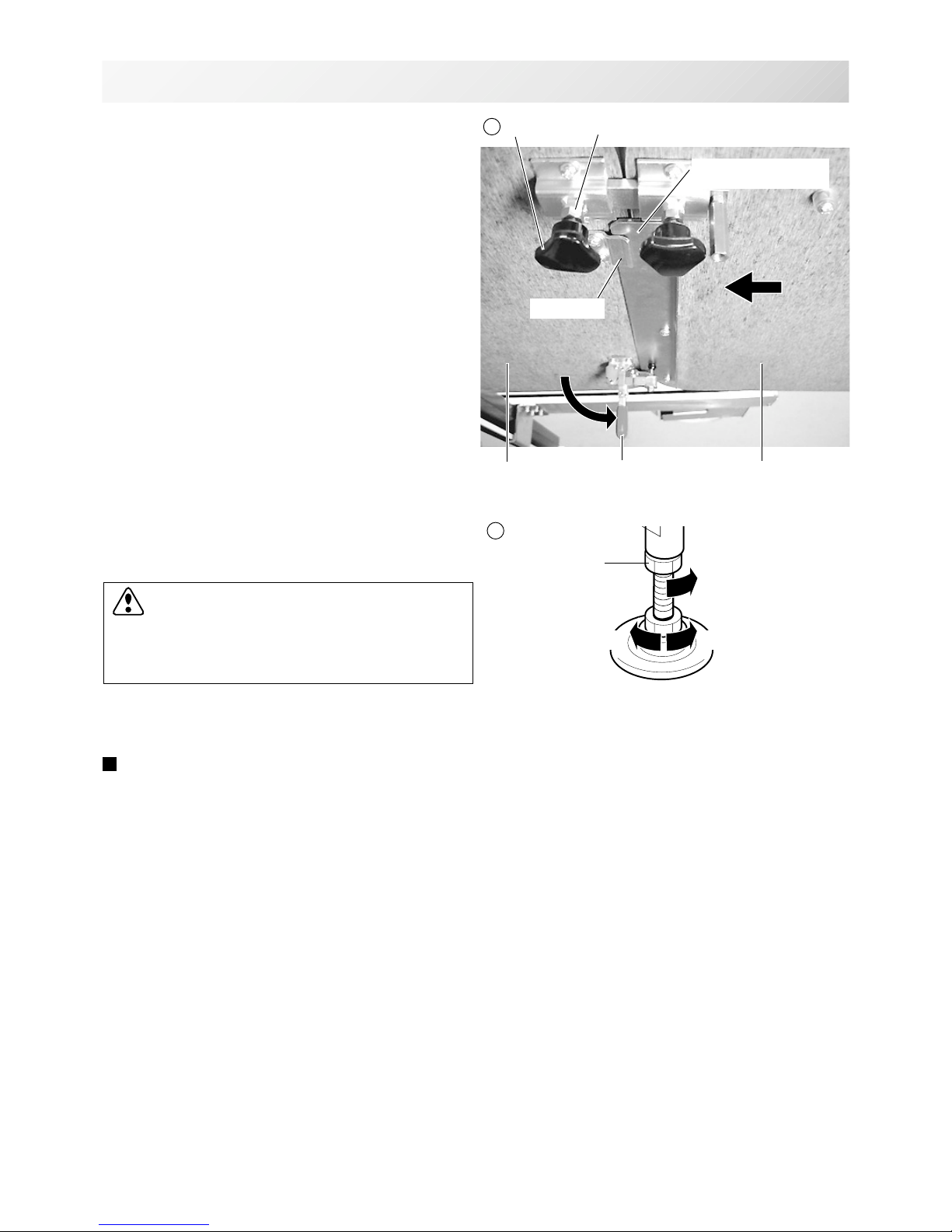

Assemble safety sensor (Option)

Safety sensors are set at a provisional position

for transportation. Please reset the safety sensors at normal positions for adjustment.

1. Unscrew set screws at lower points on the

safety sensors on right and left sides.

Loosen set screws slightly at upper points

on the safety sensors.

2. Set the right and left safety sensors at the

positions as shown in a photo by turning

them to the front side.

At this time, make sure the part on the

sensors indicated by an arrow shall be set

vertically, and set safety sensors both right

and left at parallel positions each other with

viewing them from the side.

The set screw on the right safety sensor

shall be tightened to the level that the

positions of the safety sensors can be

adjusted vertically.

3. Turn on the machine and confirm a lamp for

receiving ray (orange) is on when the way of

sensor ray is not blocked.

4. Confirm if the lamp for receiving ray

(orange) is turned off by blocking the way of

sensor ray by a hand or other.

Tighten the set screw firmly.

1

2

3

Set screw

Sensor left

Sensor right

Sensor right

Sensor left

Ray receiver

Ray projector

Power indicator

Lamp for receiving ray

Power indicator

Way of sensor ray

4

-D22-4b M201-9

2-4b

SETTING UP THE MACHINE

Assemble Wide X-carriage

(Option)

Wide X-carriage is packed separately from

machine.

When you set machine up, please install Wide

X-carriage on machine.

1. Move Stay at middle of Y-carriage.

2. Put Wide X-Carriage on Stay and adjust

screw hole position.

3. Fix Carriage by Flat head screw (M4x8) at

hole position [1] and [2](for the purpose of

positioning).

4. [3][4] Fix Carriage by Fixing screw (Cap

M4x8, Spring washer, Plain washer) at hole

position [3] and [4].

5. Unscrew Flat head screw from [1] and [2]

and fix by Fixing screw (Cap M4x8, Spring

washer, Plain washer).

6. Loosen screws on BOX terminal and take

cover out.

7. Insert X-Motor cable into BOX terminal and

connect with X-Motor relay cable.

Fix terminal for earth connection for X-Motor

cable and X-Motor relay cable together.

8. Fix X-Motor cable by Cable clamp.

9. Close cover of BOX terminal.

Please be sure cables do not get caught by

cover.

Please reverse procedure when remove the

X-Carriage.

Wide X-carriage

X-Motor cable

1

2

Cable clamp

Terminal for earth connection

Stay (left)

Stay (right)

Stay (left)

Stay (right)

1

4

3

2

1

4

3

2

X-Motor relay cable

BOX terminal

Cover of

BOX

terminal

8

9

3 4

5

6

7

Front

-D2 -122-5 M419

2-5

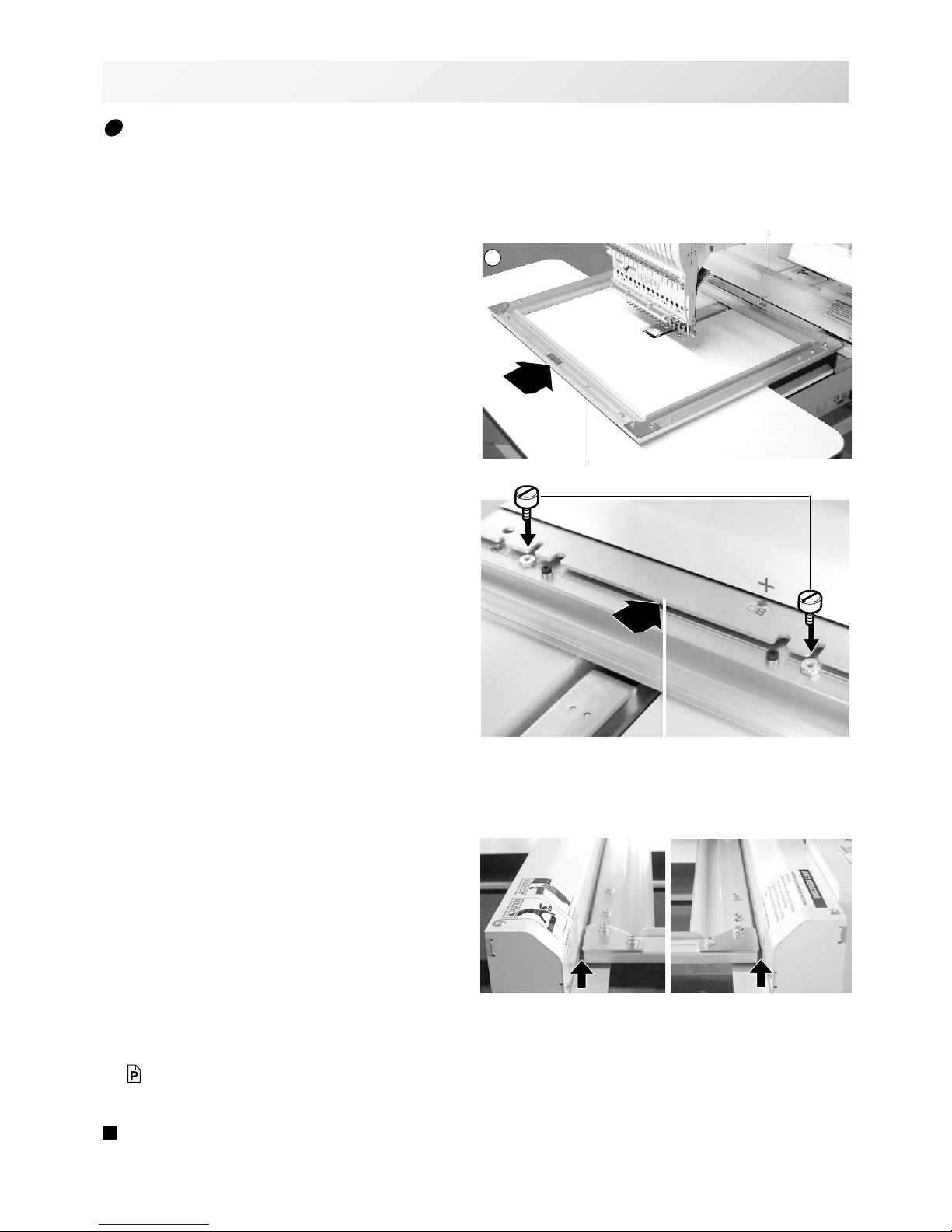

SETTING UP THE MACHINE

1. Insert Knob screw to right and left side of

machine.

And set table like right side picture.

Please insert table bracket trench to the

knob screw.

2. Tight 2 knob screw on under the table for fix

table.

3. Tight 2 knob screw on side of the table.

Please reverse procedure when remove the

table.

Knob screw

Knob screw

1

Assemble table (Option)

Installing theTable or the Table (border).

2

-D2 -13

2-5b M419

2-5b

SETTING UP THE MACHINE

1. Fix the border frame under the bracket of

the X carriage and tighten the knob screw

completely.

Clearance between X-carriage and Border

Frame at right edge and left edge should be

equal.

2. Select Frame Type “Border”.

Please refer in this manual page “FRAME

CONFIRMATION” for “Frame selection”.

20-2

Please reverse procedure when remove the

border frame.

1

X carriage

Border frame

Assemble border frame (Option)

Bracket

Knob screw

-CD -152-5c J520

2-5c

SETTING UP THE MACHINE

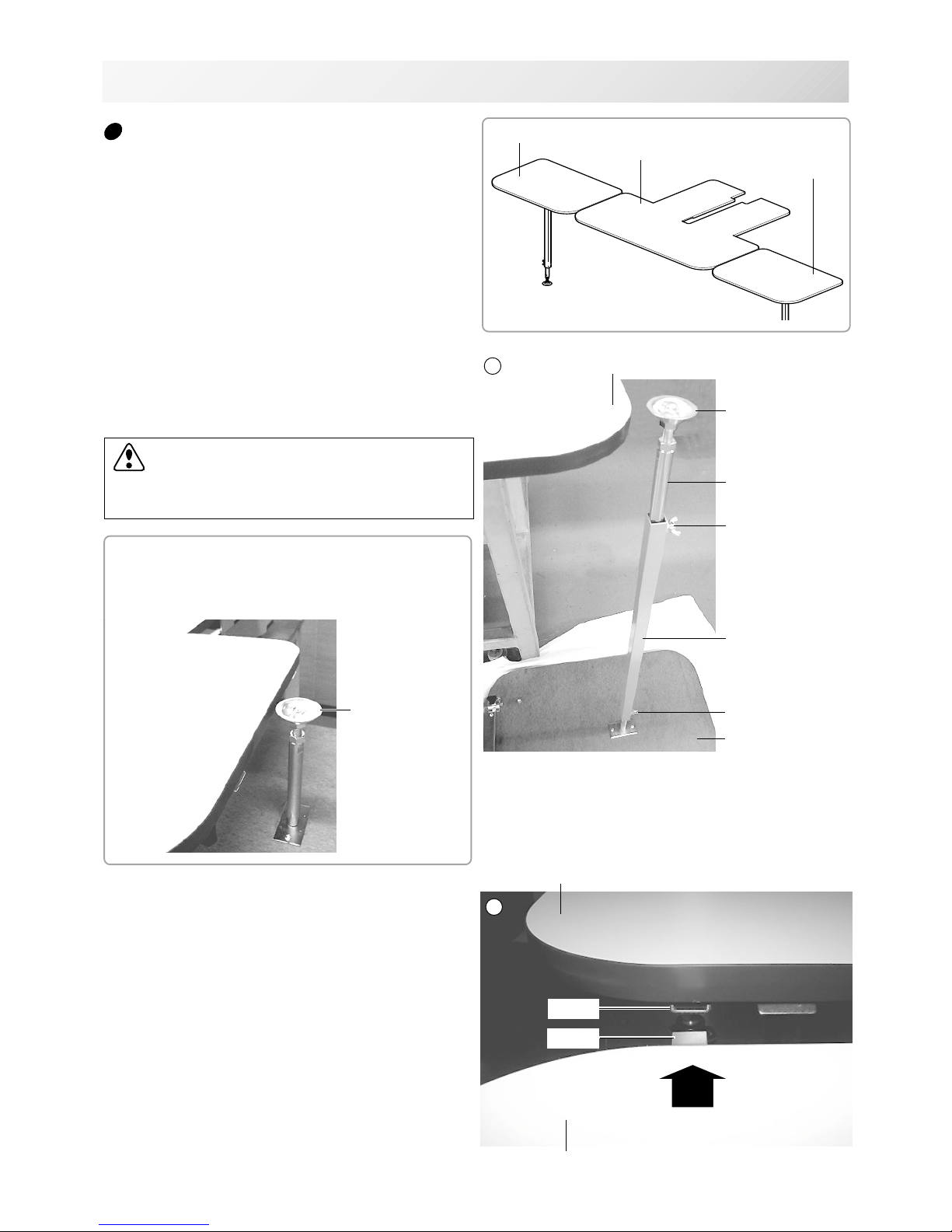

Assemble Expand side table (Option)

1. Set Stay on Expand Side table.

Put Expand Side Table under Border table

and set Stay by Wing Bolt.

Adjust height of Adjuster by Wing bolt to the

same height as surface of border table.

Stay A

Border table

1

2

Wing bolt

Stay B

Adjuster

Wing bolt

Expand side table

In case you need to set Expand Side Table

on same level of machine stand (or table), set

Adjuster to Stay A directly.

Adjuster

2. Turn Expand Side Table and join tables with

inserting Prop B into Prop A.

Border table

Expand side table (Left)

Expand side table

(Right)

CAUTION: To prevent accidents.

Table may be slanted.

Tighten Wing bolt to fix height of stay.

Border table

Expand side table

Prop A

Prop B

-CD -16

3. Confirm that Middle support plate enters to

the space between table and Prop plate and

there is no opening between tables.

Tighten Knob bolt of Prop A at Border table

and fix Lock nut.

Then set Clamp.

4. Adjust height of Expand Side Table by

Adjuster and fix by Lock nut.

Please reverse procedure when remove the

Expand Side Table.

2-5d J520

2-5d

SETTING UP THE MACHINE

Lock nutKnob bolt

Clamp

Prop plate

Middle table support

plate

Border table

Expand side

table (R)

3

Lock nut

Fix by Lock nut

Higher Lower

4

CAUTION: To prevent accidents.

Table may be slanted.

Please do not load any objects on Expand

side table.

-CD -122-6 FB01

2-6

SETTING UP THE MACHINE

Assemble bobbin thread guide

(Option)

1. Install the bobbin thread guide with supplied

screws (pan head screw M4 X 6 2 pcs).

( Showing following pictures, Please square

left end of sticker with right end of thread

stand)

Bobbin thread guideScrews

Sticker

1

-CS -11

Grounding instruction (for type of 120V)

This product must be grounded. In the event of malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This product is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a

risk of electric shock. The conductor with insulation having an outer surface that is green with or

without yellow stripes is the equipment-grounding conductor. If repair or replacement of the cord

or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded.

Do not modify the plug provided with the product – if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the

plug illustrated in sketch A in Figure. A temporary adaptor, which looks like the adaptor illustrated in sketches B and C, may be used to connect this plug to a 2-pole receptacle as shown in

sketch B if a properly grounded outlet is not available. The temporary adaptor should be used

only until a properly grounded outlet can be installed by a qualified electrician. The green colored rigid ear, lug, and the like, extending from the adaptor must be connected to a permanent

ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be

held in place by the metal screw.

2_6 I916

2-7

SETTING UP THE MACHINE

Disposal of a battery

A battery is had built-in to this embroidery machine.

When you dispose of a battery, according to each country or a method determined in each area,

please dispose appropriately.

Metal screw

Cover of grounded

outlet box

Grounding pin

Grounding means

Grounding methods

Adapter

A

B

C

-D2 -14

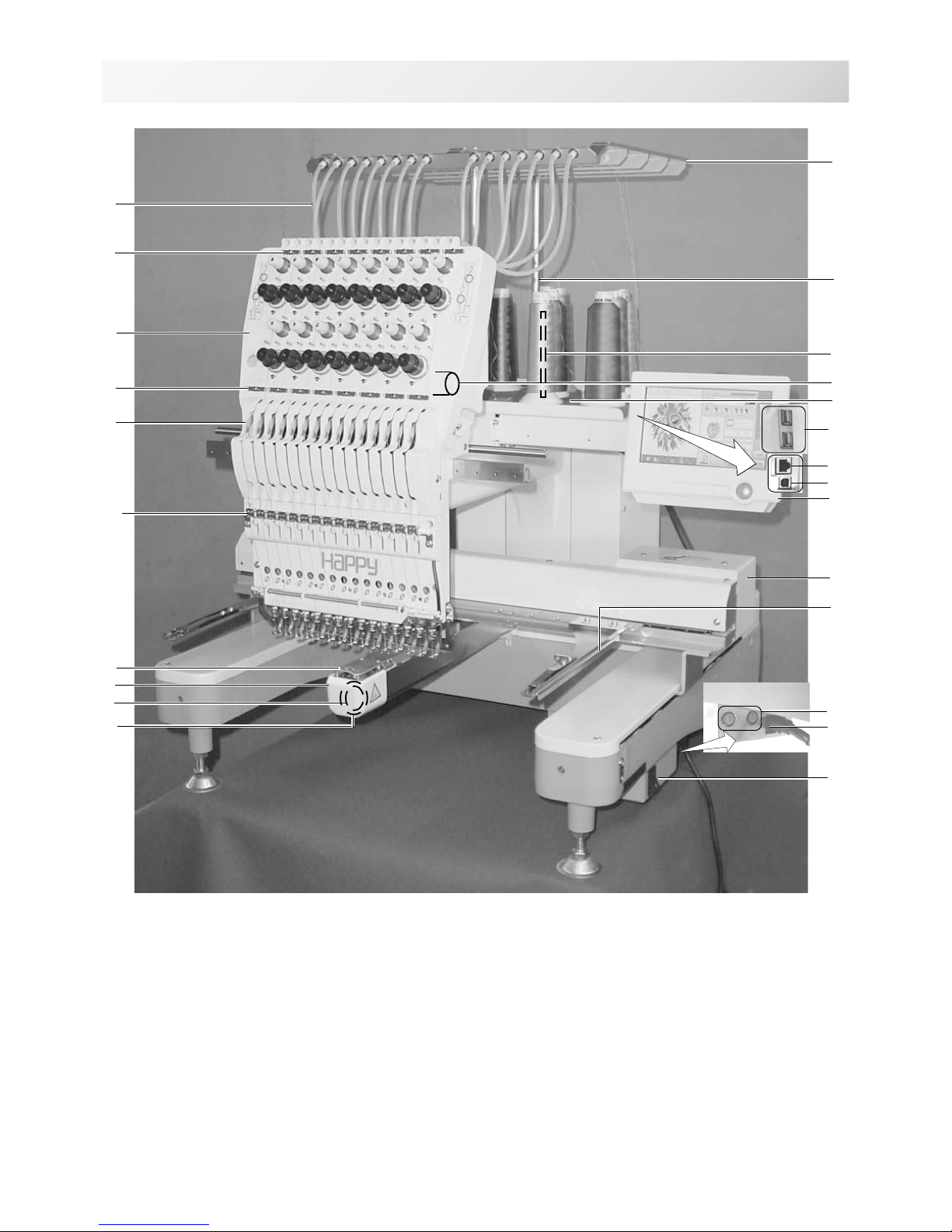

MAIN PARTS

1. Hook cover

2. Hook

3. Bobbin case

4. Needle plate

5. Take-up lever

6. Lower rectifier

7. Thread tension

8. Upper rectifier

9. Guide tube

10. Thread guide support

11. Thread guide

12. Thread check spring

13. Thread stand pin

14. Thread stand felt

15. Needle bar selection knob

16. Control box

17. LAN port

18. USB port

(Standard-A receptacle)

19. Frame hold arm

20. Carriage

21. Fuse (6A)

22. Terminal box

23. Power switch

24. USB port

(Standard-B receptacle)

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

19

3_1 M620

3-1

20

21

22

23

18

6

17

24

-D2 -153_2 M717

3-2

MAIN PARTS

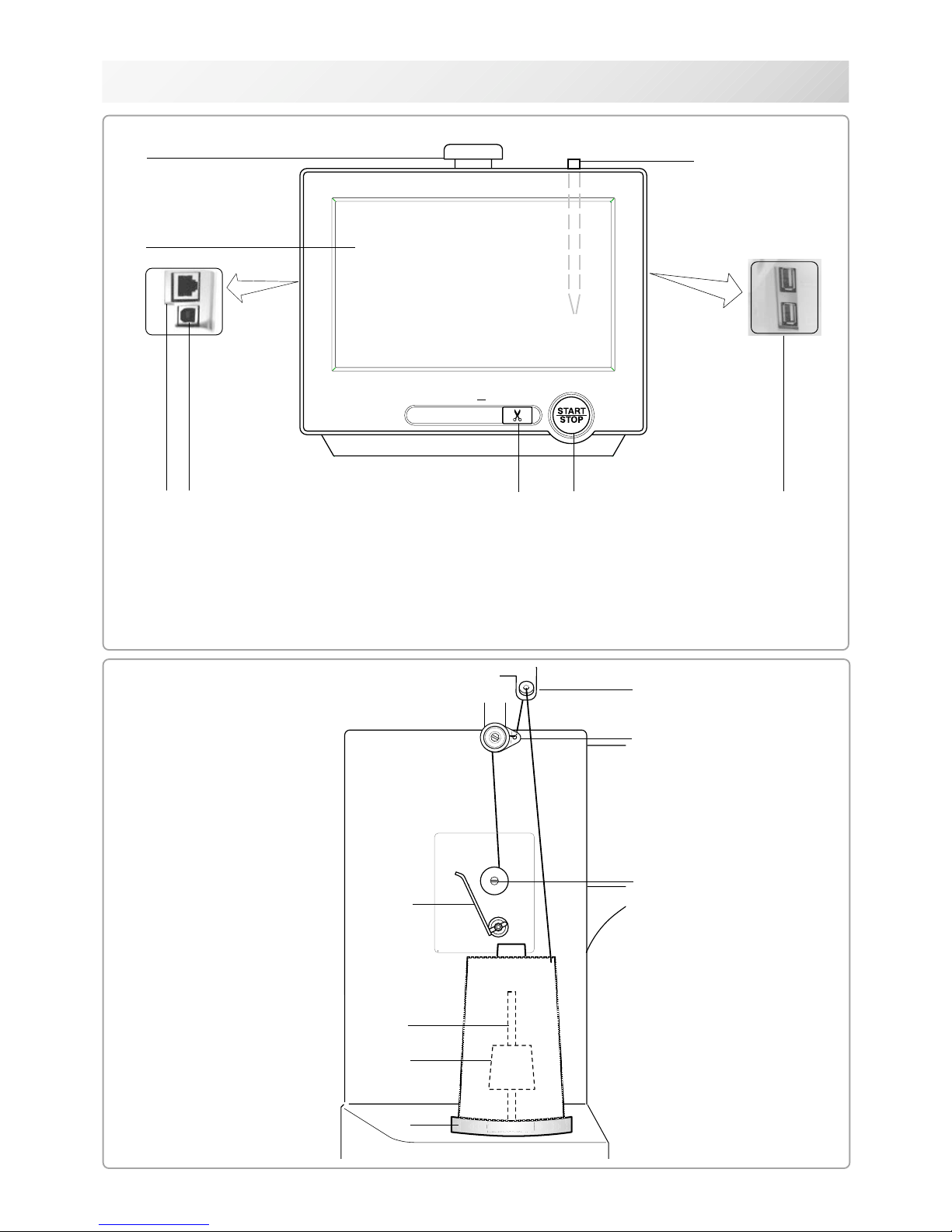

CONTROL BOX

4

5

1. Emergency stop button

2. Display (L.C.D.)

3. LAN port

4. Thread cut button

5. Start/Stop button

6

5

7

6

1

4

2

3

1. Thread guide

2. Thread tension

3. Spindle

4. Lever

5. Thread stand pin

6. Plastic spring

7. Thread stand felt

BOBBIN WINDING (Option)

3

7

1

2

16

8

6. USB port (Standard-A receptacle)

7. USB port (Standard-B receptacle)

8. Stylus

-S2 -12

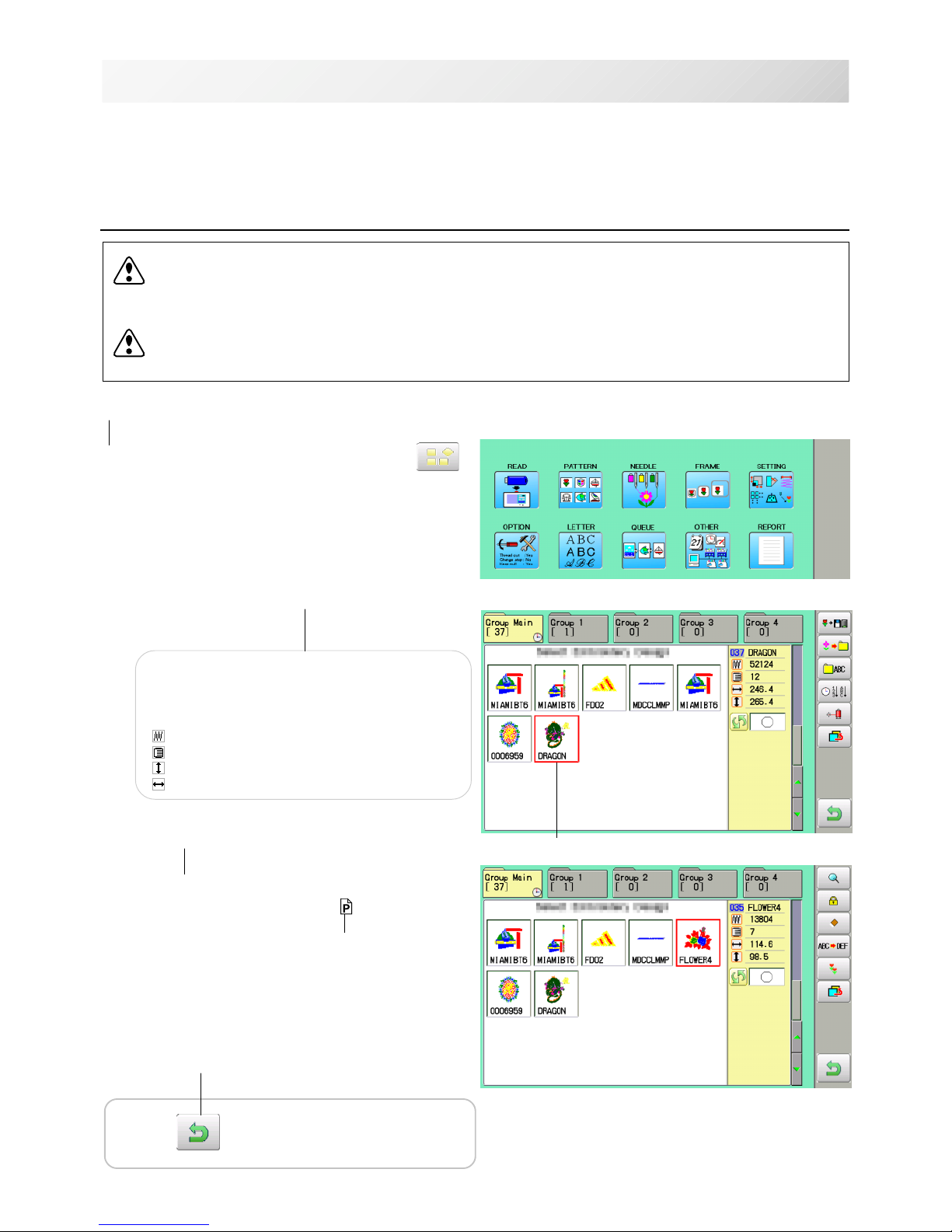

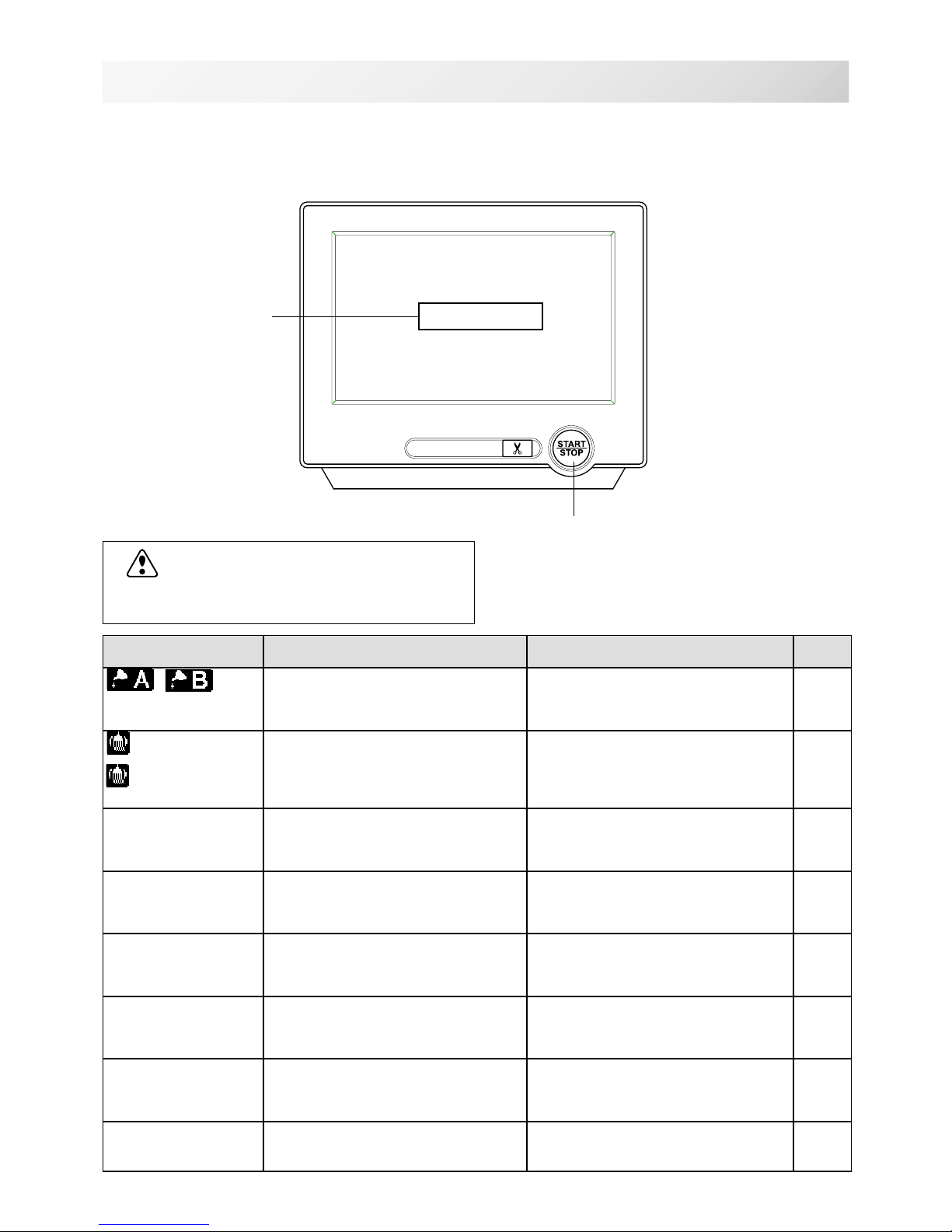

HOW TO READ THESE INSTRUCTIONS

3-3

3_3 MB15

The instructions in this manual have been formatted as follows:

Written instructions will be provided on the left side of the page while graphics depicting the

necessary steps are provided on the right.

Graphics on the far right will show the display after performing the steps indicated.

This indicates an additional

explanation on an operation

elsewhere in the manual for

more detail.

AWords marked with a "*" are explained in

"EMBROIDERY TERMS" at the end of this

instruction manual.

CAUTION: To prevent accidents.

This will appear for items related to your safety.

CAUTION: To avoid problems.

This will appear for items related to potential problems.

Order of operation

Indicates supplementary

explanation regarding a

given operation or action.

1. When the machine is stopped, press .

2. Select "PATTERN".

The display indicates the current pattern.

The left side of display shows the number, name

and details for the current pattern.

Number of stitches

Number of Color change number

Height

Width

3. Select *pattern data.

This pattern will be selected.

3-3

Selected pattern data

Press to return to Menu mode.

Operation key

-D2 -16

MESSAGES

3-4

3_4 2NC17

Below is a list of possible messages that may appear while operating the machine, along with

an brief explanation and suggested actions to take as a result.

Press the screen (any location is okay), then message will disappear.

EGASSEM NOITANALPXE NOITAREPO EGAP

liootecalP

yalpsidehtnoretteldetangiseD

.detacirbuleboteudsi

detacidninoitacolehtetacirbuL

.BroAyb

niegapdetacidniehtotrefeR

.launamsiht

1-32

fogninaelC

koofyrator

fogninaelC

tucdaerht

efink

ehtdnakoohyratorehtnaelC

.efinkgnittucdaerht

ehtninoitcurtsnihtiwnaelC

.egapecnerefer

2-32

hctiwSpotS>>

deppotssienihcamehT

sawnottubpotsehtesuaceb

ehtgnirediorbmeelihwdesserp

.ngised

otnottubpots/tratsehtsserP

.gniwesemuser

dnE>>

deppotssienihcamehT

ehtdehsinifsahtiesuaceb

.ngised

,niagangisedwesothsiwuoyfI

nometidepoohylwenesaelp

pots/tratssserp&enihcam

.nottub

potSegnahC>>

uoyesuaceb,deppotsenihcaM

egnahcroloctapotS"desu

.noitcnuf"tniop

pots/tratsehtsserpuoynehW

tceleslliwenihcameht,nottub

emuserdnaroloctxeneht

.yllacitamotuagnirediorbme

?roloC>>

ehtesuacebdeppotsenihcaM

neebtonsahroloctxen

.detceles

eldeentxentcelesesaelP

noitceleseldeenybrebmun

tratsehtsserpnehtnottubpots/

.nottub

kaerBdaerhT>>

esuaceb,deppotsenihcaM

.nekorbdaerhtnibbobroreppu

rodaerhtreppudaerhtesaelP

sserpnehtdaerhtnibbobkcehc

emuserotnottubpots/trats

.gniwes

dneecarT>>

deppotssienihcamehT

ehthtiwdehsinifsahtiesuaceb

.ecartngised

.KOfinottubpots/tratsehtsserP4-6

C-7

Start/Stop button

Message

>>Stop Switch

CAUTION: To prevent accidents.

The embroidery frame may move. Please

keep hands clear for your safety.

-D2 -17

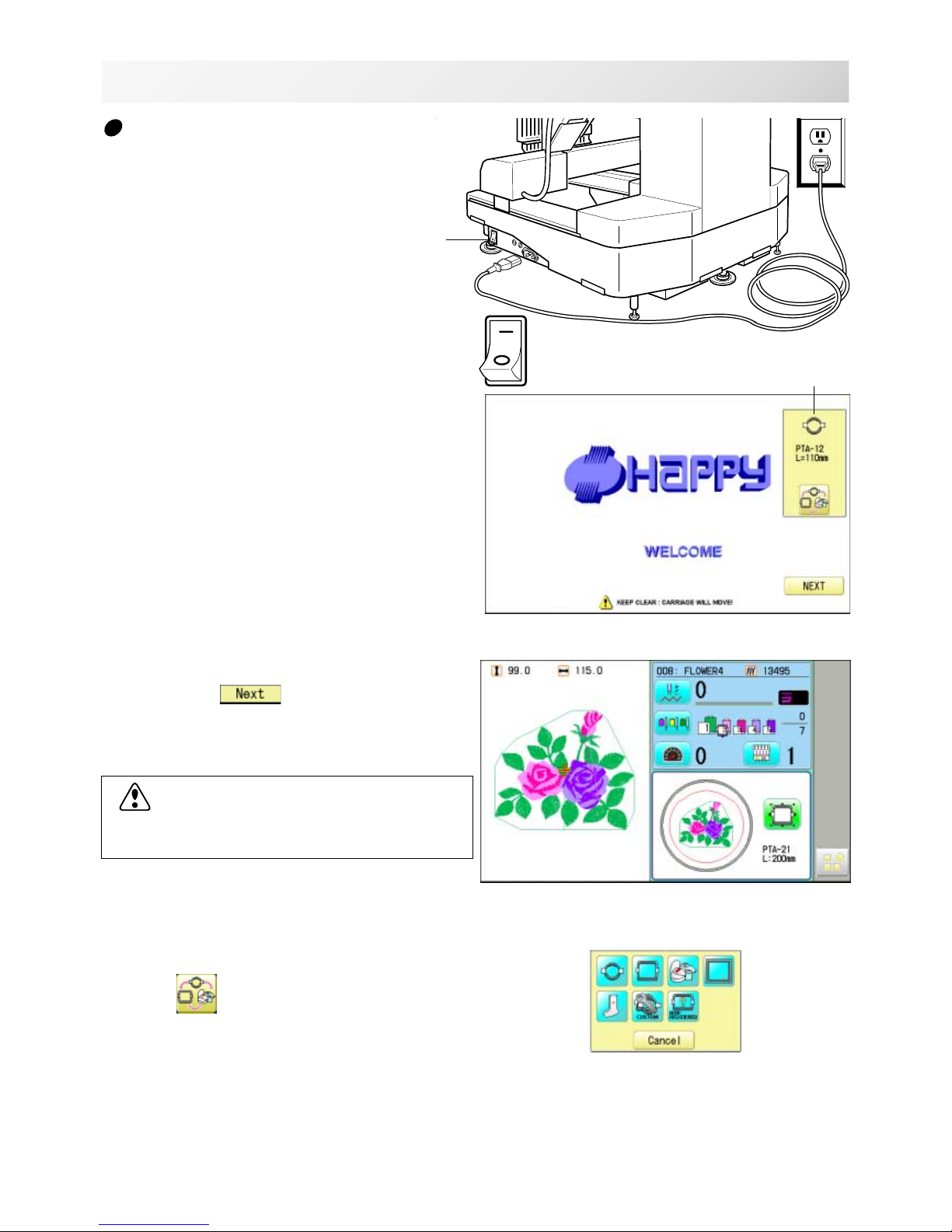

TURNING THE MACHINE ON

2. Connect the power plug to an electrical

outlet.

3. Turn on the power switch.

Indicates the select frame.

Please confirm the emergency stop button has

been released.

Push the power switch firmly so it will remain on.

4. In case you do not need to change frame

type, Press

.

After the carriage and frame move slightly, the

embroidery frame will return to the previous

position automatically.

Machine becomes ready for operation.

3_5 M620

3-5

How to turn on the machine

CAUTION: To prevent accidents.

The embroidery frame and carriage will move.

Please keep hands clear for your safety.

Power switch

1. Connect the power cord to the inlet on the

right side of the machine.

In case you want to change frame type,

Press

.

ON

OFF

Selected frame

-D2 -18

TURNING THE MACHINE ON

3_6 N101

3-6

DANGER: To reduce the risk of electric shock.

Never leave the machine unattended when plugged in.

Always unplug this machine from the electrical outlet immediately after use and before performing any maintenance on it.

WARNING: To reduce the risk of burns, fire, electric shock, or injury to persons.

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

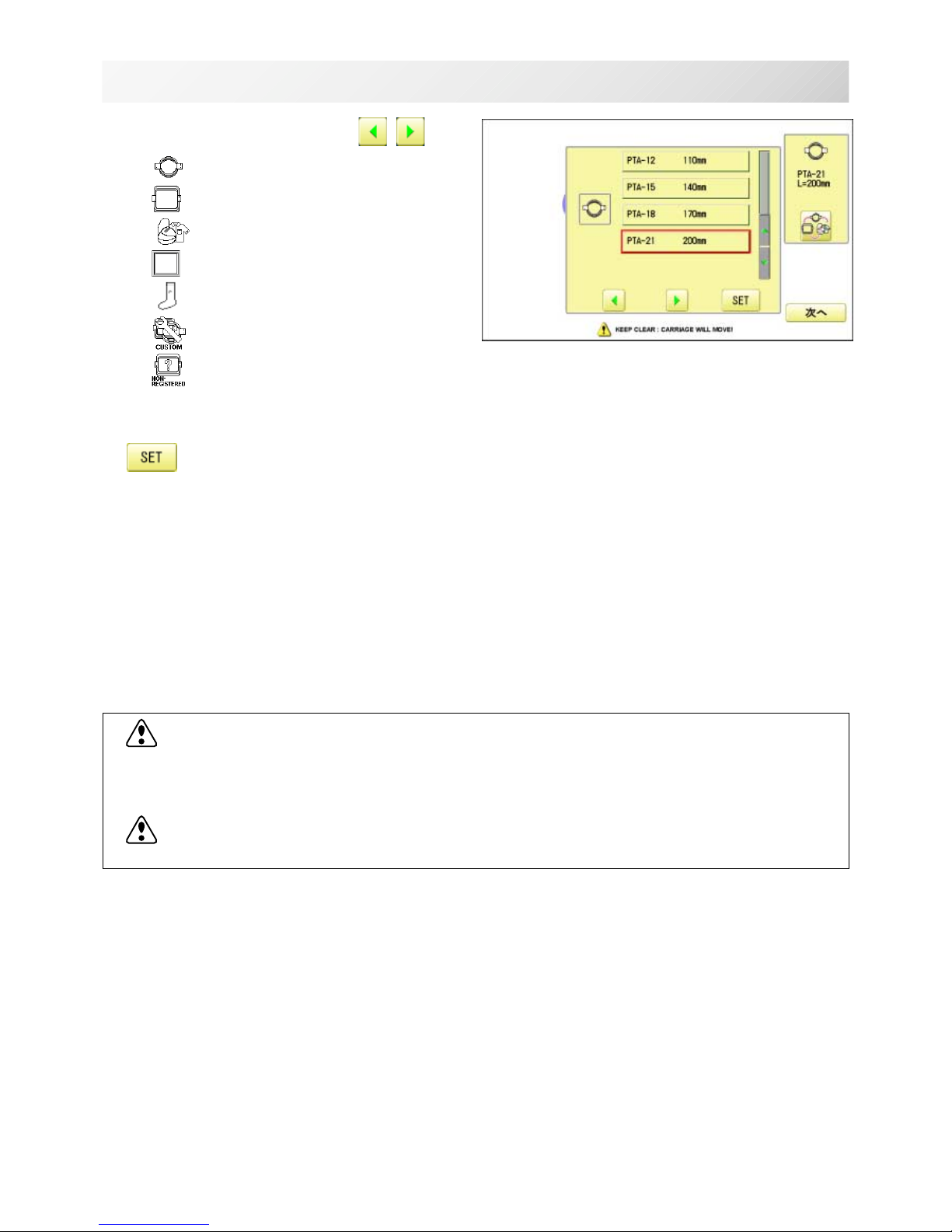

5. Select the desired frame with

.

: Tubular round frame

: Tubular square frame

: Cap and One-point frame.

: Border frame (for HCD2)

: Sock frame

: User-defined frame

: Non registered

6. Select desired type of frame and Press

.

The display returns to the view of Step 3.

To disconnect, switch the power switch to the

off position, then remove plug from outlet.

-D2 -19

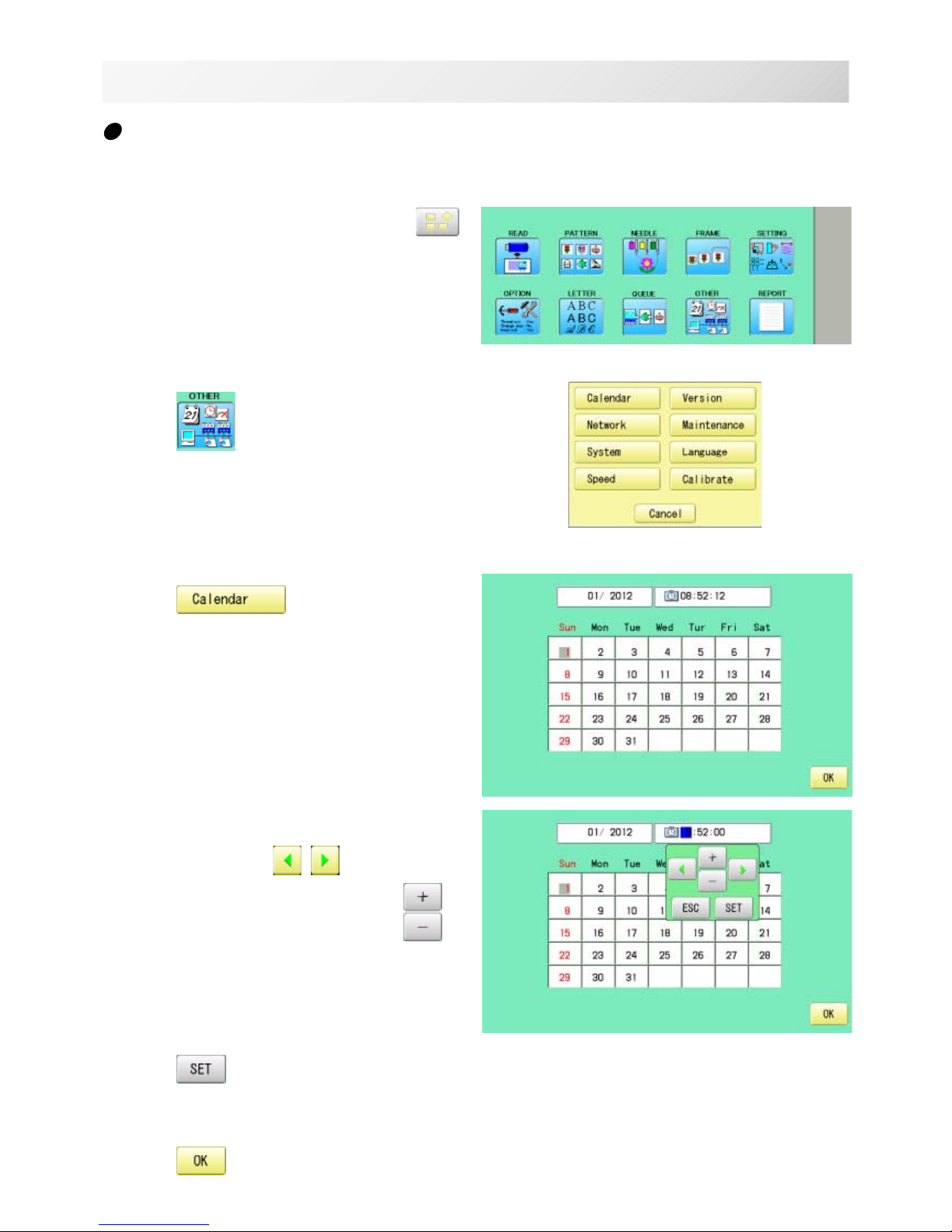

1. When the machine is stopped, press .

2. Press

.

3. Press .

Current year, month date and time is displayed.

4. Select year/month, time or date.

Press right /left of to select the

setting point, and press up/down of

to

select the number of year, month and time.

5. Press

.

The date is fixed.

6. Press to return to Menu mode.

Calendar and clock setting

Setting the calendar and clock lets the machine advise when oiling and other maintenance is

scheduled to occur.

TURNING THE MACHINE ON

3-7

3_6 M620

-D2 -21

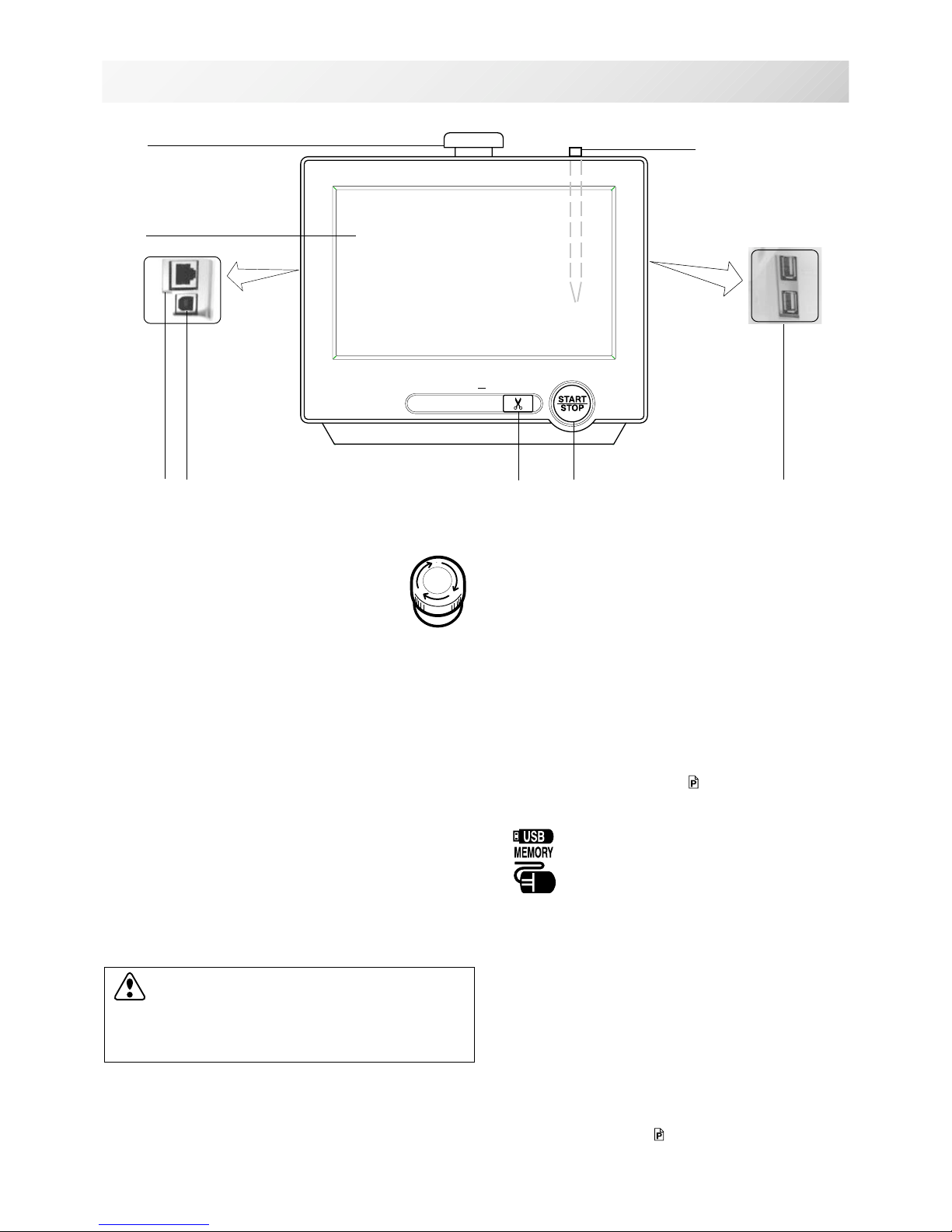

THE CONTROL BOX

3_8 M717

3-8

2. Display

Shows the embroidery design name, the number of

the current needle and other machine generated

messages.

Menu and keys in the display can be operated with

a finger or built-in stylus.

3. LAN port

You can connect PC with a LAN.

4. Thread trim button

The Machine will cut the upper and lower thread

when this button is pressed.

In case you press and keep (around 2 sec.), you

can cut only bobbin thread.

5. Start/Stop button

This button starts the machine.

When pressed, while the machine is running, the

machine will stop.

Green .......... Machine ready to sew.

Main menu also accessible by

pressing MENU, which causes menu

to display.

Blinking red .Indicates the upper thread has

broken or the Bobbin thread has run

out.

Red .............Machine is running.

Orange ........ Machine has detected an error.

An error number will be shown on

the Display. 24-1

6. USB port (Standard-A receptacle)

USB memory socket.

USB mouse socket.

Menu and keys in the display can be operated with

a commercial USB mouse.

Press right mouse button to show a mouse pointer

in the display.

7. USB port (Standard-B receptacle)

Use this port to connect the machine with PC via

USB.

8. Stylus

Stylus can be used for pressing menu and keys in

place of fingers.

Most operation can be done by fingers. Stylus is

required for some operation such as calibration for

the touch panel LCD. 22-3c

Insert a stylus into the holder (slot) of control box

when not used to prevent loss of the stylus.

CAUTION: To prevent accidents.

If you Press thread trim button, the needle will

penetrate the fabric. Please keep your hands

clear for your safety.

1

2

4

5

6

16

1. Emergency stop button

When pressed , the power is switched off

and the machine stops immediately.

The emergency button locks when

pressed.

To unlock, turn the emergency button to

the right

(Arrow direction) then release. The button will

unlock.

Use this button only for emergency.

73

8

-D2 -21

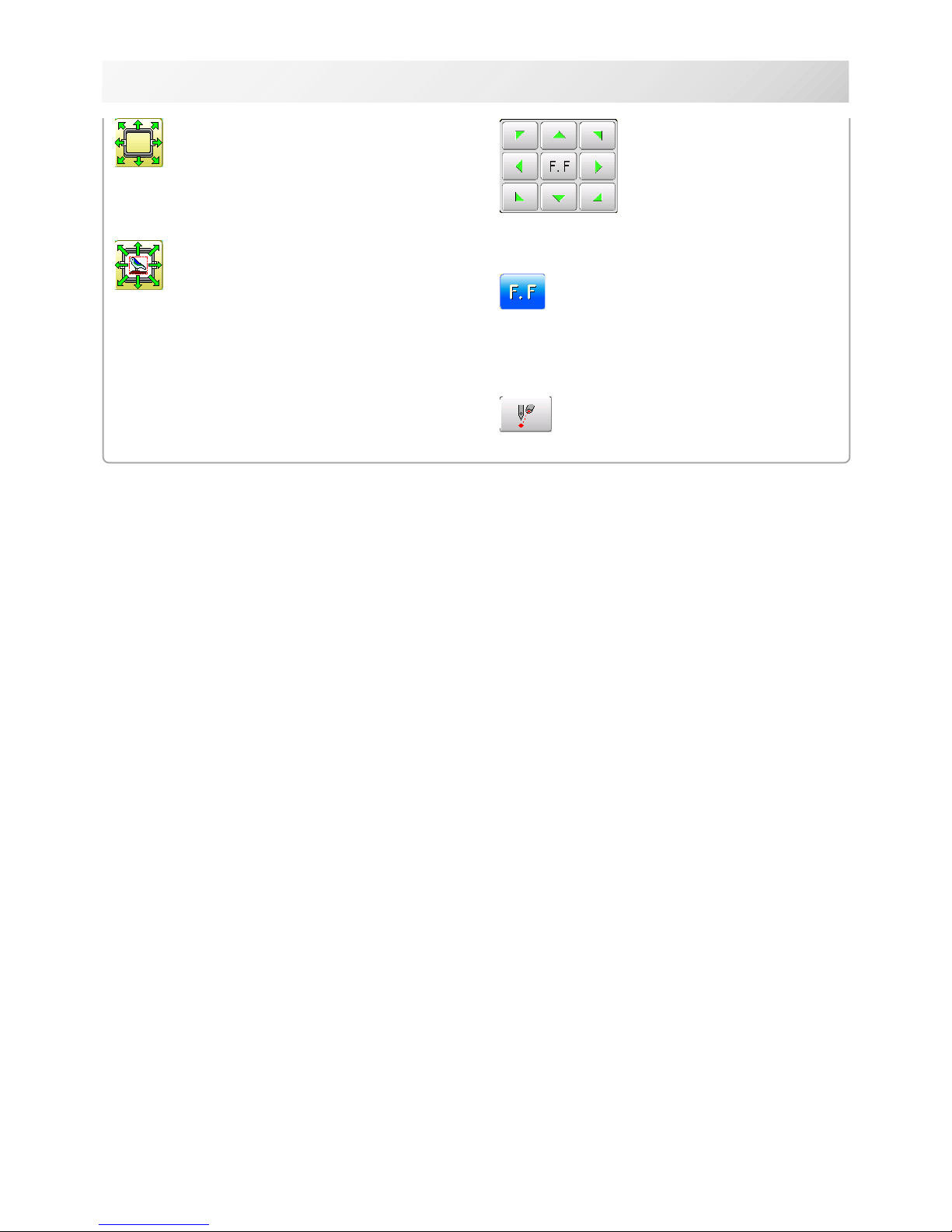

3_A MB14

3-9

DRIVE MODE

Drive key

The each key menu will be shown.

Frame forward

This creates direct designations to the position and

data to the designated sewing position.

Piece 16-2

If "Repeat" is set, this allows the frame to move to

the beginning of any piece at will.

Change (Color position ) 9-7

This moves the frame to the beginning of any Color

change number at will beginning of color.

Stitch (Number of stitches ) 9-6

This moves the frame to any stitch at will.

Forward and Back-ward

Needle bar

selection

Speed control

Needle change

Drive speed

Control embroidery speed.

The speed can be controlled while embroidering.

Speed control

Press the + button to increase the machine sewing

speed and the - button to lower the machine speed.

is displayed on the LCD display.

i-Custom

(default display)

Frame move

Needle bar selection 5-E

For each color change in a given pattern, the needle number loaded with the correct color thread is

assigned by the operator.

Low speed operation (OFF state)

Press the button to turn "ON" state.

Low speed operation (ON state)

Press the button to turn "OFF" state.

Speed setting by needle (OFF state)

Press the button to turn "ON" state.

Speed setting by needle (ON state)

Press the button to turn "OFF" state. 3-9c

Color position forward

Move the frame to the beginning embroidery

position of the previous or later color position

number

Stitch number forward

Move the frame forward or backward by the

stitch number displayed in each button.

-D2 -22

Frame move

Selection the way of frame movement and

Move frame.

Frame change

Change the frame to be used.

Design centering

Move design to the center of frame.

Center

Moves the embroidery frame to the center automatically.

Frame out

Move frame to the front position which was set

before.

Press (Position) to return the frame to the

original position before frame out position.

It is convenience if hand work is required in the

middle of embroider process.

Position

When sewing is interrupted in the middle of a

design, this returns the frame to current sewing

position regardless of where frame may have

been moved with the arrow keys after interrupt.

target design.

3_A MB14

3-9b

DRIVE MODE

Needle change

Change the needle bar directly to the indicated

needle number on the button.

Change

Move the sewing head to the adjacent needle in

the direction of the arrows.

Jump (Off)

The machine can embroider.

Jump (On)

Machine becomes jump and the machine

doesn't embroider.

i-Custom 21-1

You can place frequently used display and key icons freely on the right side of Drive mode screen.

Original point return

This returns the frame to *pattern origin point.

After performing this action once, repeating this

again will cause the frame to return to the

previous

position.

Origin registration

Register the current frame position as origin.

Trace

When pressed while at the beginning of design,

the embroidery frame moves following the outer

edge of the design. This allows you to compare

the design size and position against the frame

before sewing.

Indicate target design on LCD panel when nonshowing design.

If you press this key and hold, re-display your

Locate

Locate will restore the position of the frame to

the last point before a power failure even if the

point of origin or the pattern itself were

changed.

-D2 -24

3_A MB14

3-9c

DRIVE MODE

Frame move key

The frame moves toward direction of the arrow

mark.

Fast move

Press this key one time to move the frame

faster toward the direction of the arrow.

Press this key one more time to cancel this

function.

Pointer (Option)

Turn on and off the laser pointer.

Quick move

First press this key and then the arrow key to

move the frame toward the edge of the embroidery

area in the direction of the arrow.

Quick embroidery design data position move

First press this key and then the arrow key to

move the frame where the design data can be

embroidered at

the edge in the direction of the arrow.

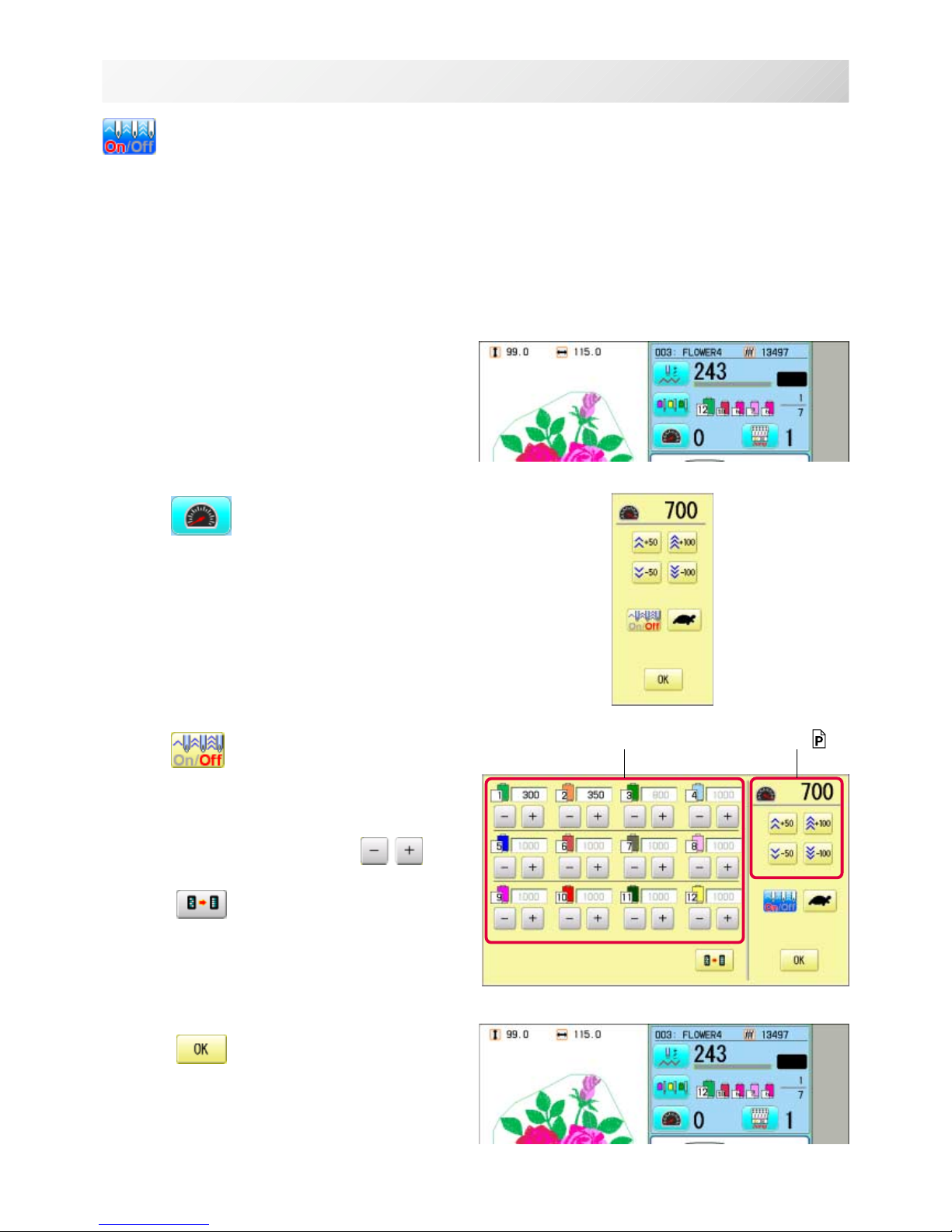

-S2 -16

3_A MA05

3-9d

DRIVE MODE

Speed setting by needle (ON state)

Embroidery speed can be set by needle.

If speed by needle exceeds the speed set at Drive speed setting, the value of speed turns gray

and speed by the needle is applied to the speed set at Drive speed setting.

You can be set up taking the following steps.

1. Press .

2. Press

.

3. Change the setting on the needle number

you would like to change with

.

Press when returning the setting on all the

needle numbers to maximum.

4. Press .

The screen returns to Drive mode.

Speed setting by needle Drive speed setting 3-9

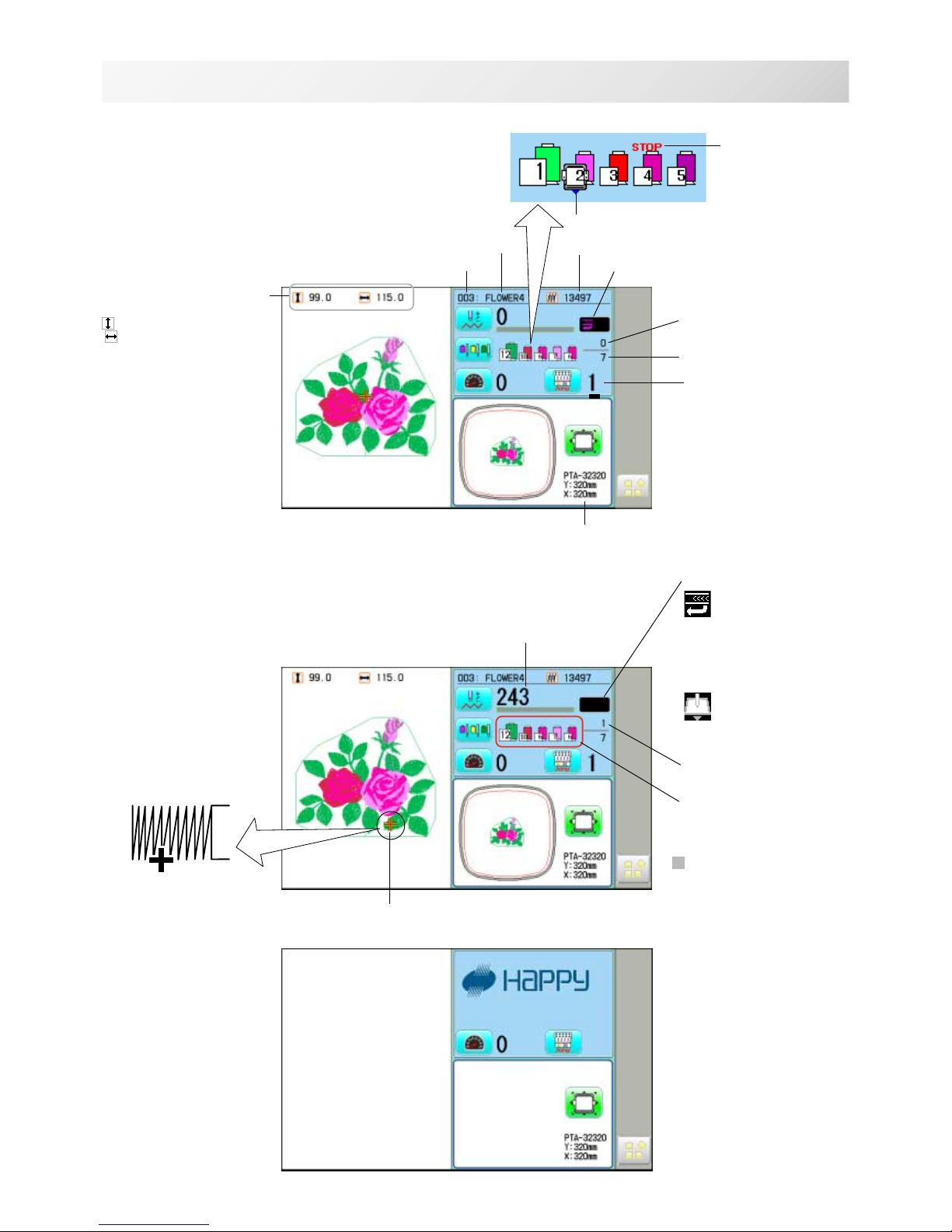

-D2 -24

Memory # of selected pattern

Currently-selected

needle

Number of stitches sewn up to now

Name of selected pattern

Top

When beginning an embroidery

Machine stopped during embroidering

Display example

Status

Top

This indicates that the

machine is ready to start

sewing from the "top"

memory position of the

pattern.

Frame out

This indicates that a

frame out is occuring.

3_A M620

3-A

DRIVE MODE

Pointer

Color change number

sewn up to now

Stitches of pattern

Needle number and color

*Color change number

Pointer indicates the

position of actual stitch

point.

If a needle number is not

assigned to a Color

change number, the

default color will be

assigned automatically.

Shift to left when color

change.

Size of pattern and distance

Heigh

t Width

Current *Color change

number

Mark for color

change stop

Mark for frame out

Selected frame

Display if the machine has no design

in memory

Loading...

Loading...