Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Training:

HAPPY HCD-1501

Operations & Maintenance

Chapter 2: MACHINE SETUP & ORIENTATION

– Proper Machine Setup

• Machine environment page 2

• Upper threading page 3

• Bobbin threading & Tensioning page 5

– Control Panel 2

• Sewing controls, what your machine is telling you on the main screen page 6, 7

• Function Menu page 9

• 6 Important Main Menu functions in detail: Pattern, Setting, pages 10-27

Needle, Read, Frame, Position

Control Panel 2

Design Transfer

– Transferring Designs into the machine, detailed steps

• Transfer by USB cable connection from a PC page 29

• Transfer by Compact Flash or USB jump drive page 33

Updated 5/20/2010: Screenshotss and procedures updates for firmware version 1.24

Chapter 2: Machine Setup & Orientation

1

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Machine Setup

Proper Machine Setup: Environment

Temperature and Humidity-Controlled Environment

Set up/store your machine in a temperature and humidity-controlled environment to prevent

long-term corrosion and to protect the electronics. Don’t keep your machine anywhere you

wouldn’t keep a laptop or desktop computer !

Clean, Protected Electrical Power

grounded outlets: Your machine uses standard 110v household

current. Be sure you connect it to a grounded 3-prong outlet like

the one shown here. This is standard in most U.S. homes and

businesses today, but some older buildings may only have 2prong outlets.

surge protection: Protect your machine against occasional power

spikes (from electrical storms or electrical wiring problems) with at

least a basic surge protector. The electronics on your machine

can be very expensive to replace. Higher-end surge protectors

and UPS units are able to protect against higher energy strikes,

and often come with a guarantee.

Standard

3-prong

110v

outlet

Control Panel 2

Design Transfer

Basic surge

protector

Steady Table / Mounting Surface

Your machine will perform better (especially at higher speeds)

when operated on a strong, level and steady mounting surface.

Although on wheels, the optional stand provides plenty of

stability, and even more when the wheel brakes are applied at all

4 corners.

Chapter 2: Machine Setup & Orientation

Optional machine stand with accessory

shelf, casters and wheel brakes

2

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Machine Setup

Proper Machine Setup: Upper Thread

UPPER THREAD

-Proper Thread Routing: All threads must be

routed correctly at all points along the path through

the sewing head.

6

Needle

Needle

4

Needle

5

3

Needle

2

Needle

1

Needle

Needle

15

14

Needle

13

Needle

12

Needle

11

Needle

Needle

10

9

Needle

8

Needle

7

Needle

Control Panel 2

Design Transfer

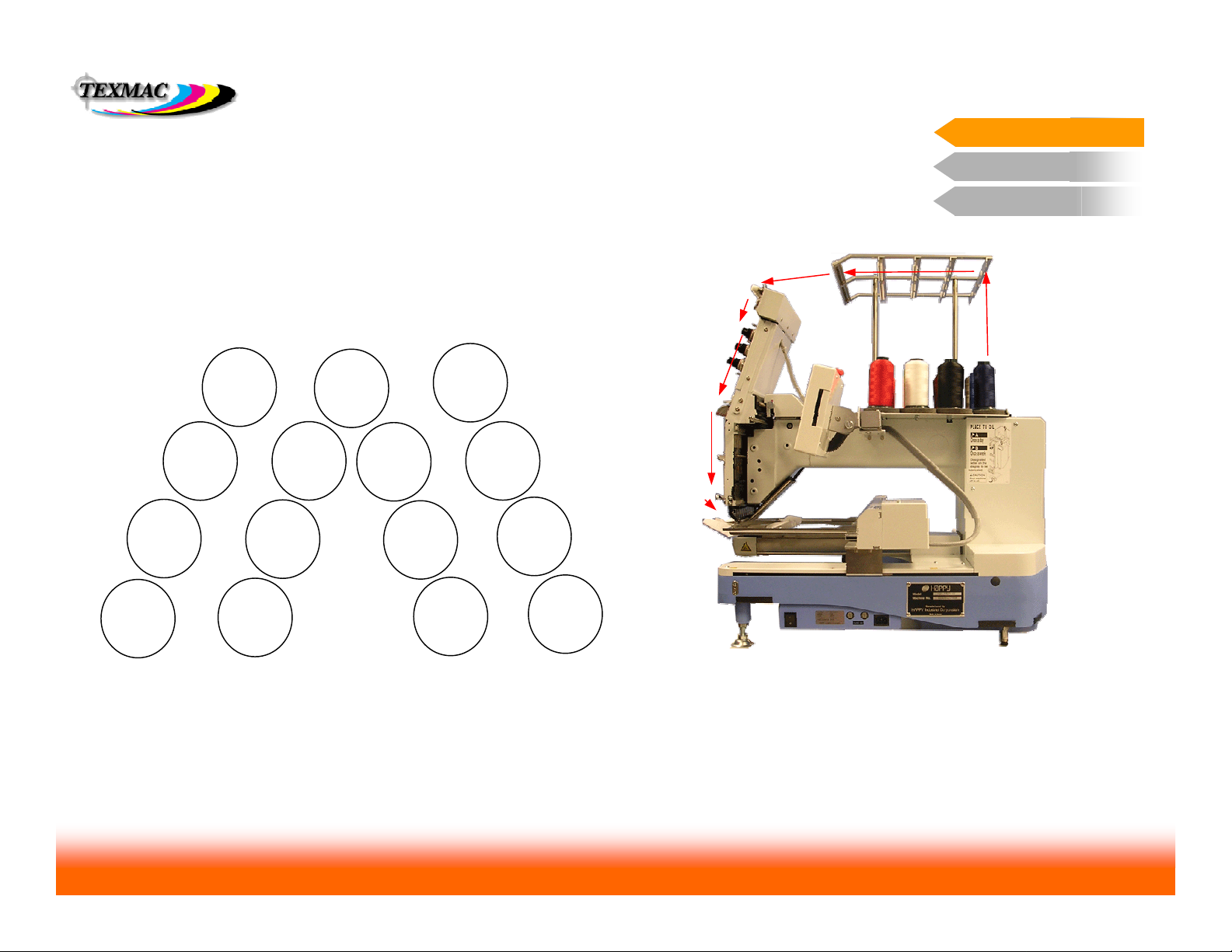

Layout of Cone/Needle Sequence

Needle numbers are arranged right to left, lowest number to highest.

Chapter 2: Machine Setup & Orientation

General Thread Route

Thread must pass up from cones through guide

holes in thread tree and through every specific

point along the face of the sewing head. Thread

must be “docked” at the thread holder spring.

3

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Machine Setup

Proper Machine Setup: Upper Thread

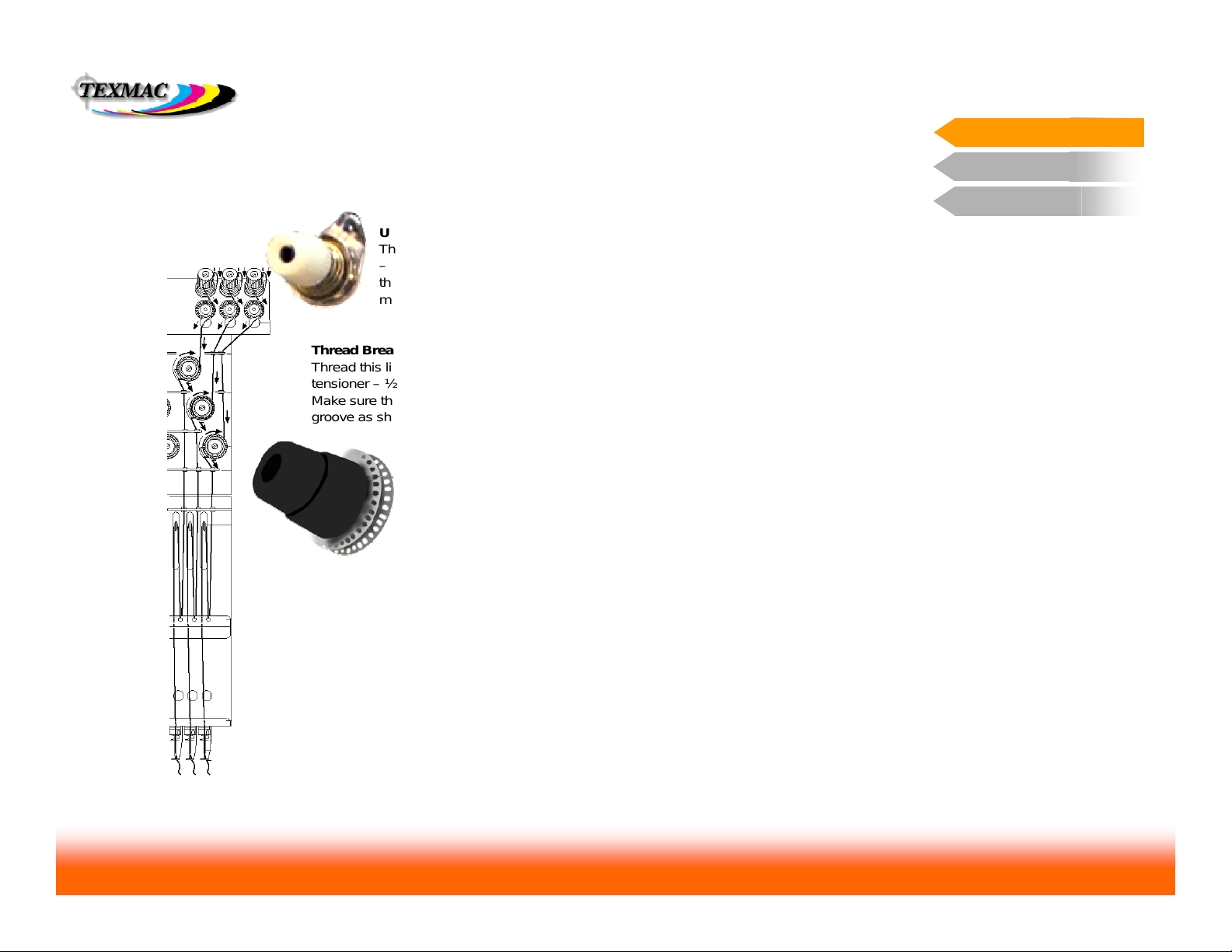

UPPER THREAD – complete route through moving head

Upper Tensioner

Thread only makes ½ turn

– make sure it passes to

the left between the 2

metal discs.

Thread Break Sensor

Thread this like the upper

tensioner – ½ turn to the left.

Make sure the thread falls in the

groove as shown.

Lower Tensioner

Thread makes 1 full turn

clockwise around the base

of the knob – make sure it

runs in the V-shaped

groove of the spoked

wheel.

-Proper Thread Routing: All threads must be routed

correctly at all points along the path through the sewing

head.

-Practice good thread “Discipline”: After threading

all needles, ensure there is no slack anywhere along

the thread path. Make sure to:

-Pull all threads – to ensure thread feeds

smoothly and turns the break sensor, and all

slack is removed from around thread cones

-“Dock” all thread ends from each needle onto

the thread-holding spring. Prevents thread from

coming loose and catching where not desired.

Control Panel 2

Design Transfer

Take-Up Levers

Thread makes 1 full turn clockwise

around the base of the knob – make

sure it runs in the V-shaped groove of

the spoked wheel.

Chapter 2: Machine Setup & Orientation

4

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Proper Machine Setup: Bobbin loading

and Tension check/ adjustment

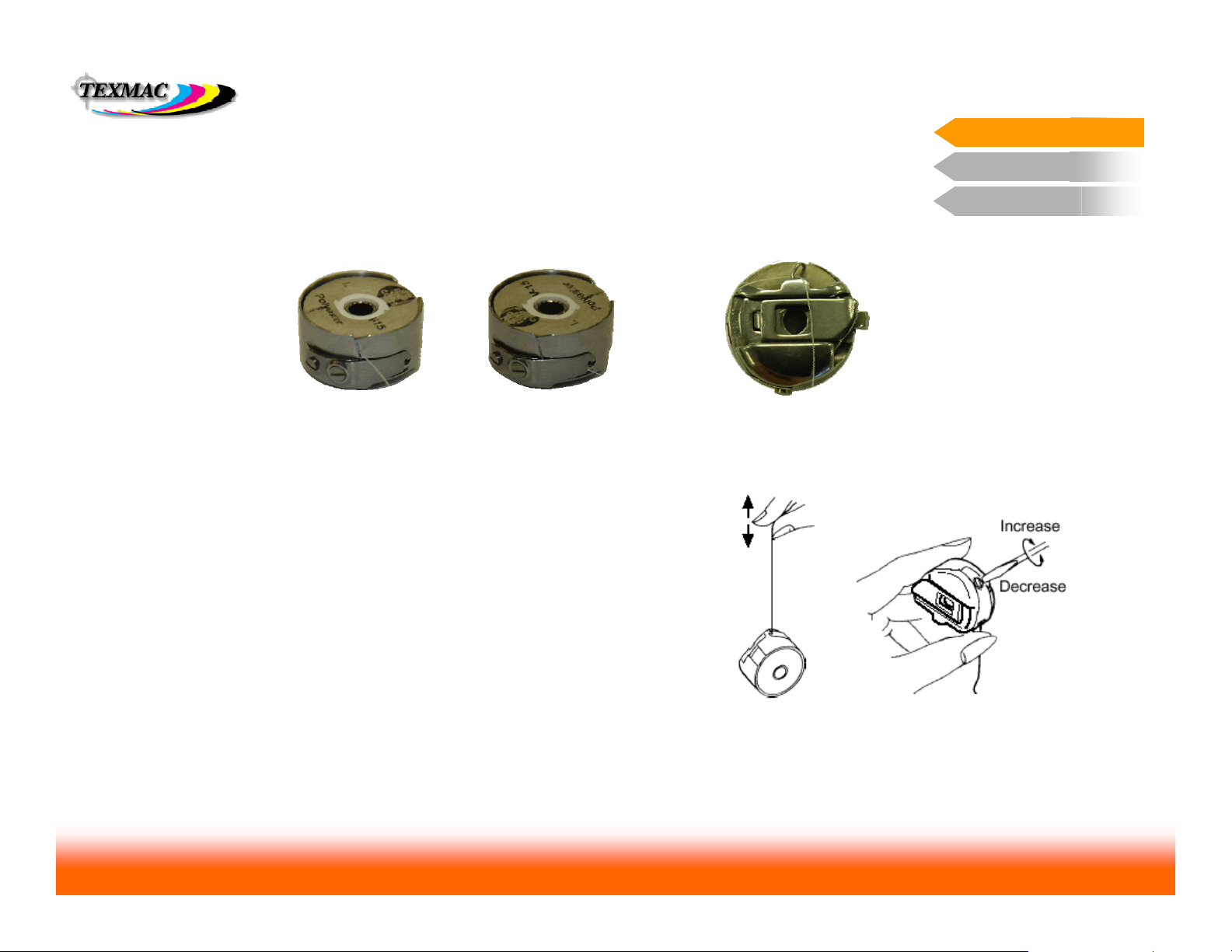

RE-LOADING THE BOBBIN CORRECTLY

The bobbin will need to be replaced frequently, allowing only 30,000 to 60,000 stitches

per spool. This has to be done correctly every time.

Machine Setup

Machine Setup

Control Panel 2

Design Transfer

1.Ensure bobbin turns

clockwise. Pull thread

through this slit.

CHECKING TENSION

• The “yo-yo” test is very exact in checking tension. Perform this quick

check each time you re-load the bobbin. Practice until you are comfortable

doing this.

• Check bobbin tension frequently when changing bobbins.

TAKE CARE TO RE-INSERT THE RELOADED BOBBIN CASE FULLY!

Your machine will not sew any stitches unless this is done. At worst, the

needle & needle bar may strike the side of a poorly-inserted bobbin case,

breaking the needle and possibly putting needle depth out of adjustment

for that needle.

Chapter 2: Machine Setup & Orientation

2. Feed thread through

eye at the end of the

tension flap.

3. Pass thread under wire

loop at the top front of

the bobbin case.

Make small adjustments

– no more than a ¼ or

½ turn in either

direction before rechecking tension.

5

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Sewing Controls

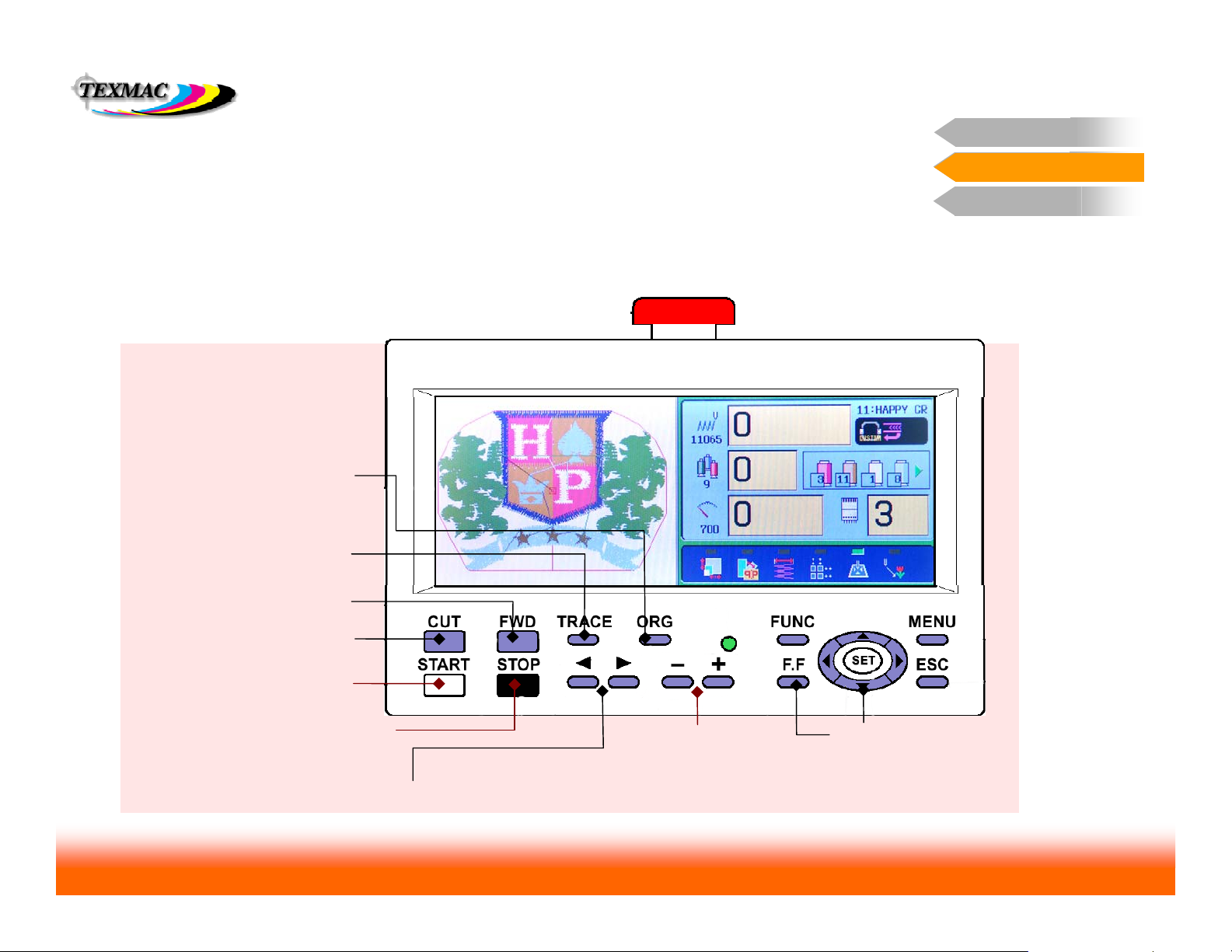

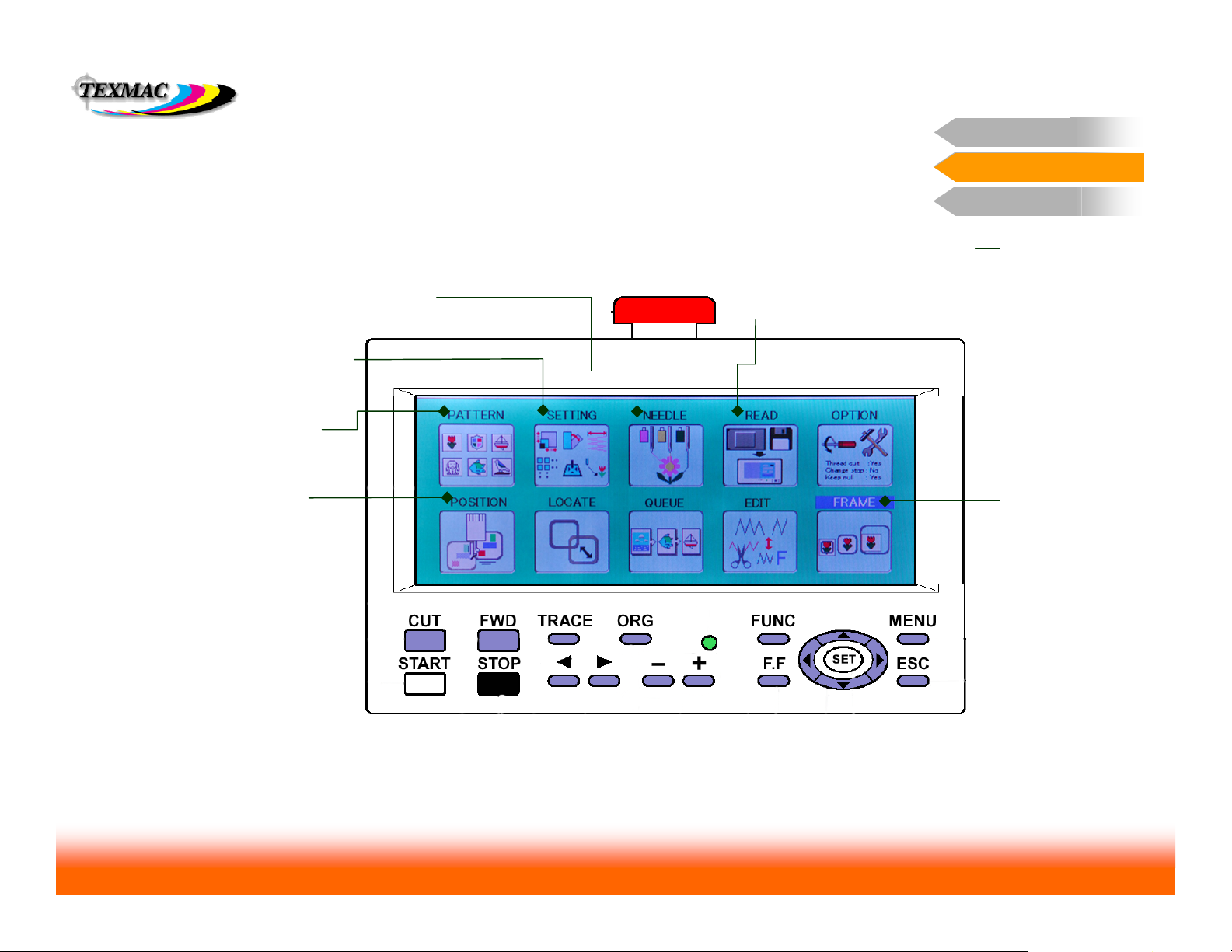

Basic Sewing Controls

On this page, learn the function of the important

sewing controls.

•Sewing Controls

Understand the functions

of these key sewing

controls.

ORG returns the sewing arm and

the sewing position to design Origin

point. Origin symbol re-appears.

TRACE only traces when design is

at Origin. Does slow trace when

held continuously.

FWD advances sewing position

forward while machine is stopped.

Control Panel 2

Control Panel 2

Design Transfer

Color Code

Items in black – function only when

machine is stopped.

Items in red – function when machine is

running or stopped.

CUT cuts current thread and tucks

end into thread holder.

START starts sewing. Bypasses

trace. Sews in “creep” mode when

held down.

STOP stops sewing. Also when stopped

moves sewing position backwards.

Useful after thread breaks.

Needle Select Keys change the currently-selected needle while machine is stopped.

Chapter 2: Machine Setup & Orientation

Speed control – adjusts

max sewing speed.

Sewing arm movement

move pantograph arm with

the 4 blue arrow keys, hold

FF at same time for quick

movement

6

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Main Screen Information

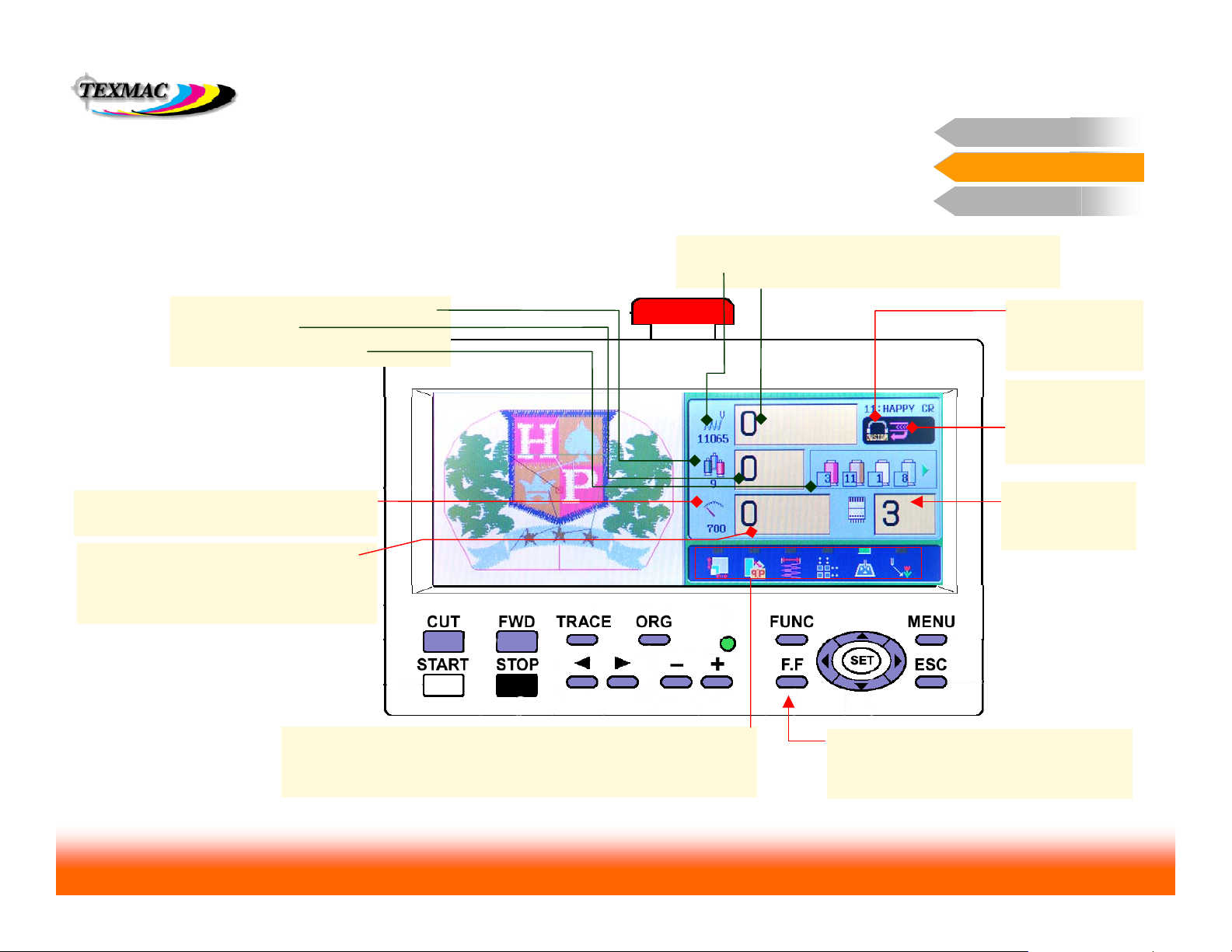

Information Display on the main Drive screen

This screen shows information about the design, its

position and fit, and current sewing status

Total # of color blocks in the design

current block #

next 4 colors in sequence

Max allowed speed – set this with the + and –

keys up to 1200 spm.

Actual sewing speed – machine sews at

speeds up to max allowed speed, but varies

according to stitch length. Longer stitches

take more time, requiring a slower speed.

# of Stitches in design

current stitch position in design

Control Panel 2

Control Panel 2

Control Panel 2

Design Transfer

Current Hoop:

shows what type of

hoop is currently in

use on the machine.

origin indicator –

indicates that sewing

position is at the

design origin, before

the trace.

Active needle:

shows the currently

selected needle #

Indicator lights: serve as reminders for any edits that may have been

done to the design from the control panel (in order from left to right,

scale, rotate, satin pull compensation, repeat, auto origin return, offset

Chapter 2: Machine Setup & Orientation

Show design position & fit in hoop: pressing

FAST at this screen shows a map on the right

side of the design position & size(in blue)

against the sewable area of the hoop (in red)

7

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

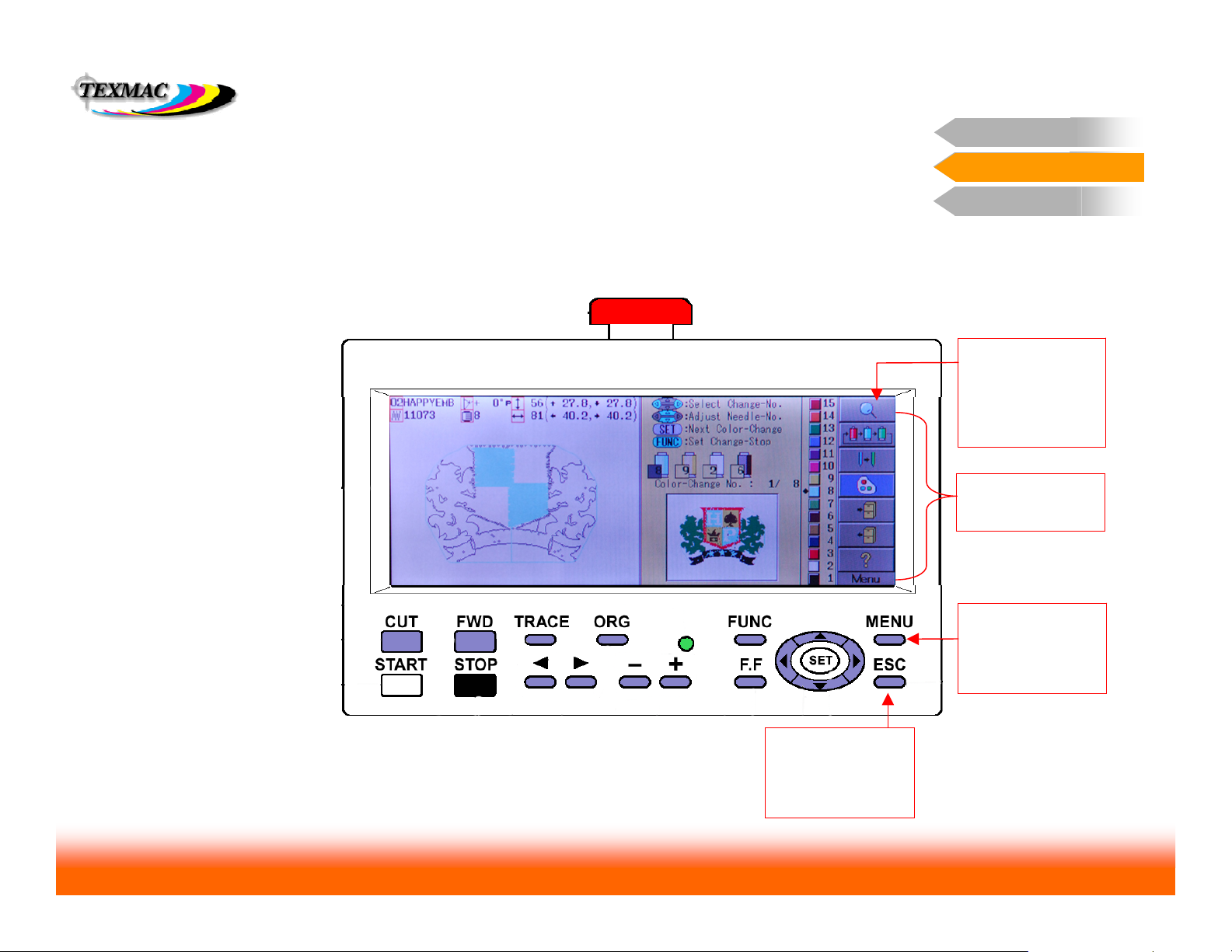

General Tips in Navigating Main Menu Screens

In many of the screens accessed from the main menu, there are additional

options that can be accessed in the same way. In the sample screen shown

below, we’ve illustrated a few simple rules:

Control Panel 2

Control Panel 2

Design Transfer

View Design: This

option displays the

design full-screen with

any current changes

you’ve made to it.

Sub-menu: Contains

additional options for a

given screen.

Press MENU to

access the sub-menu.

You’ll see the

uppermost icon

highlight in blue.

Chapter 2: Machine Setup & Orientation

Press ESC to exit the

sub-menus and return

the cursor to the rest

of the Needle screen

(example shown here)

8

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

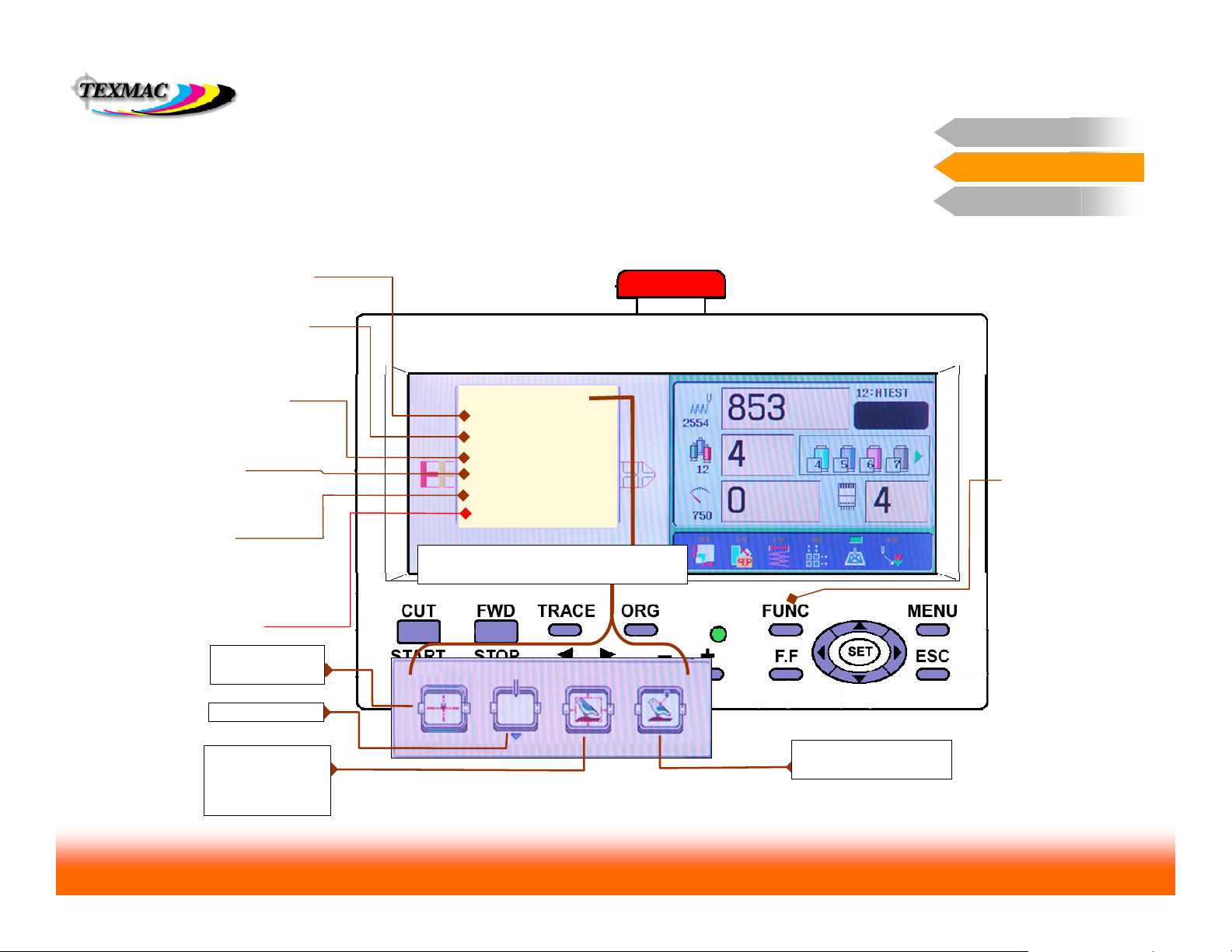

The Function Screen

The FUNC menu allows quick access for key machine functions directly in the

main drive screen.

Frame Type select here to tell the machine

to switch between tubular, cap, or border

frame sewing modes.

O Set: Positions the

origin (design) at the

current arm position.

TOP positions the hoop at

the top of the pattern.

Repeating returns hoop to

previous position.

Needle Jump alternatively

disengages (jump mode) or

engages (drive mode)

needle bar

LOG-IN: Set this to

log the machine on to

a Happy machine

network.

TURN-OFF: Always

try to power down the

machine from this

option, not at the

power switch.

FRAME POSITION displays the submenu

shown. Functions are shown below.

Frame position

Frame Type

O Set

Top

Needle Jump

Log – in

Turn-off

Control Panel 2

Control Panel 2

Design Transfer

Access this

menu by

pressing the

FUNC key.

CENTER centers

the hoop.

FRAME OUT

CENTER DESIGN

centers the hoop

and centers the

design in the hoop.

Chapter 2: Machine Setup & Orientation

POSITION moves hoop

to current stitch position.

9

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

The 6 Important Main Menu Screens

Important Main Menu Features

The options on the first page of the main menu have

the most important, useful functions.

Needle Screen is most important – for

assigning thread colors to the design.

Setting Menu allows you

to make useful changes to

the design.

Pattern Menu helps

manage designs

Position Function

lets you jump to any

point in the design

Frame Function allows you to fit and

locate a design in a selected hoop.

Read Screen allows you to read in

designs from the compact flash card.

Control Panel 2

Control Panel 2

Design Transfer

Chapter 2: Machine Setup & Orientation

10

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Needle Screen

Designs sew in a sequence of color blocks. In order that your machine sews each

color block with the correct color in the correct order, you can set that color sequence

in the Needle screen, shown here.

First match the thread color palette to the actual thread colors installed on the

machine. You’ll only need to do this once for all colors, then only for any time you

replace thread cones with other cone colors.

Control Panel 2

Control Panel 2

Design Transfer

NEEDLE

To set the color palette,

press MENU to access the

sub-functions on t he right

side, then arrow down to the

Palette icon.

Thread color

palette: lets you

tell the machine

which thread color

is assigned to a

given needle.

When properly

matched, it allows

a color-accurate

preview of the

design colors that

will actually sew.

Chapter 2: Machine Setup & Orientation

NEXT: THE COLOR PALETTE

11

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Needle Screen

Designs sew in a sequence of color blocks. In order that your machine sews each

color block with the correct color in the correct order, you can set that color sequence

in the Needle screen, shown here.

First match the thread color palette to the actual thread colors installed on the

machine. You’ll only need to do this once for all colors, then only for any time you

replace thread cones with other cone colors.

How to Change the color

assigned to each needle:

Use the blue arrow keys to

move the pointer to the

needle whose color you

wish to change. Then,

press SET, calling up a

color palette. Use the

arrow keys to choose a

different color and finally

press SET.

Selected needle number: move the

arrow to a needle number and press

SET to change the assigned color.

Control Panel 2

Control Panel 2

Design Transfer

NEEDLE

This lets you set the

garment color or

sewing background

NEXT: HOW TO SET THE COLOR SEQUENCE

Chapter 2: Machine Setup & Orientation

Press SET to call up

a color palette to

change the color.

12

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

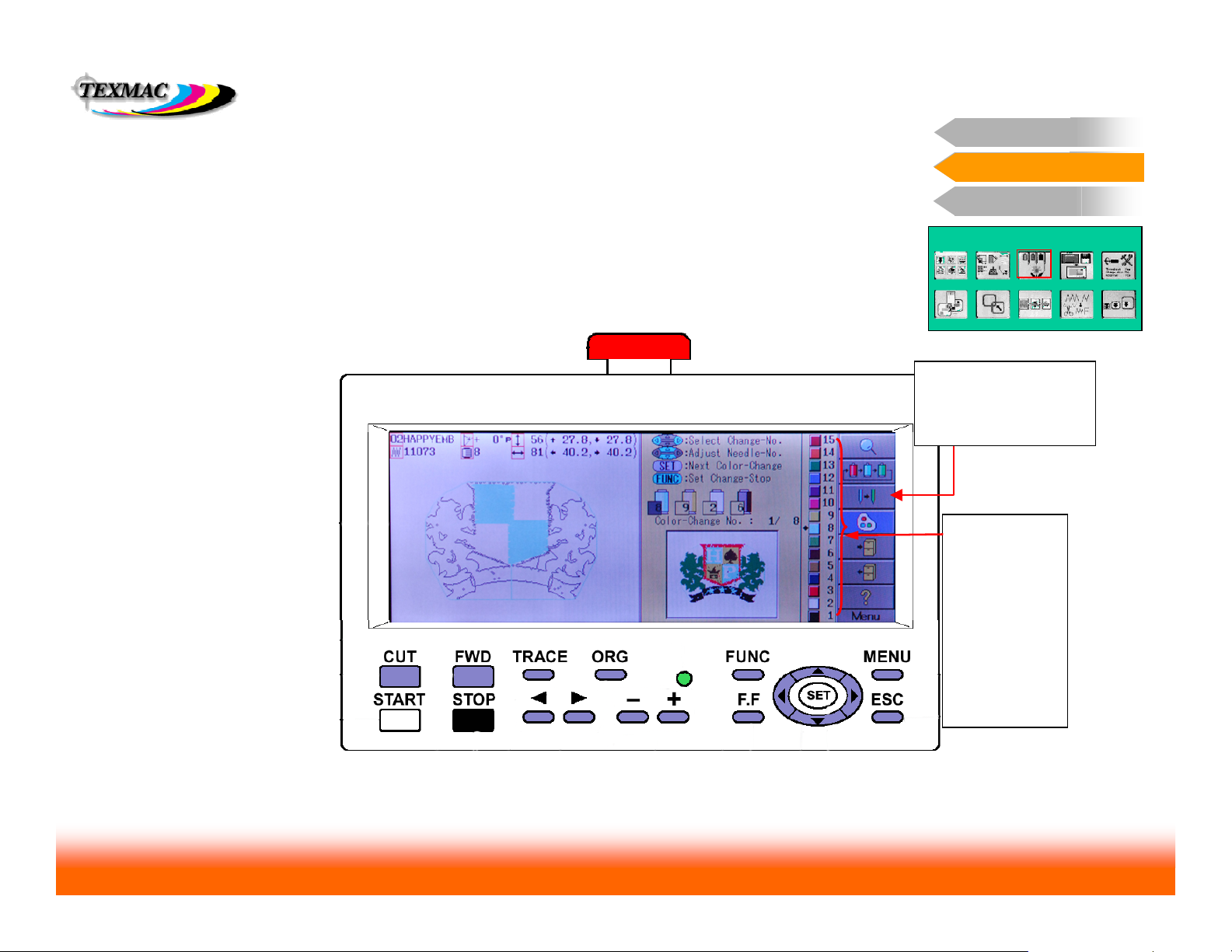

Important Main Menu Screens: Needle Screen

Designs sew in a sequence of color blocks. In order that your machine sews each

color block with the correct color in the correct order, you can set that color sequence

in the Needle screen, shown here.

Currently-selected color

block # / total color blocks

Use the up and down arrow

keys to choose the needle

number for the desired color.

How to Set the Color Block

Sequence for A Design:

Follow steps 1-4 on the right

to set the color sequence for

a design. When finished,

press ESC to return to the

main menu, and/or ESC

again to return to the main

sewing screen.

Note: if a color block isn’t

assigned a needle #, that

block will show a needle # of

zero. When reaching that

color block number during

sewing, the machine will stop

and prompt the operator to

select a color.

1. Select the color block #

you wish to edit using the left

or right arrow keys.

2. The selected color block

will highlight to help confirm

the part of the design you’re

setting the color for.

3. Change the needle number

by using the up/down arrow

keys. Up increases, down

decreases the value.

4. Arrow to the next color

and continue until a needle# is

selected for all the color blocks

in the design.

Left & right arrow keys

select the color block

number.

Control Panel 2

Control Panel 2

Design Transfer

NEEDLE

Only 4 color blocks show

in the list. To navigate to

other color blocks, press the

left or right arrow key to shift

and show color blocks

earlier or later in sequence.

Appliqué: Pressing the

FUNC key when the

arrow is next to a

particular color block sets

a stop command (marked

by an asterisk * ) causing

the machine to sew that

color and stop before

continuing.

Chapter 2: Machine Setup & Orientation

13

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Pattern Screen

The control panel can store a maximum of 1,000,000 stitches of designs, or 99 designs

total. The Pattern screen lets you choose from these designs if you wish to sew a

design other than the current active design, as well as perform other design

management functions such as deleting, re-naming, duplicating and locking designs.

How to choose a design

in the Pattern menu:

1.Use the blue arrow keys

to select a pattern.

2.Press the SET key to

make that pattern the

active pattern.

3.Press ESC to return to the

main menu.

Design Information –

shows:

- Design name & number

- Stitch count

- # of color changes

- Height in mm

- Width in mm

- Distances from origin

point to top & bottom

edges

- Distances from origin

point to left & right edges

This pattern is locked,

preventing accidental

deletion or modification.

NEXT: 2ndpage of right side menu options

Control Panel 2

Control Panel 2

Design Transfer

PATTERN

Additional Options (access

these by pressing MENU)

View pattern full-screen

Lock selected pattern

Delete 1 or more patterns

Select trace types (slower

outline trace or faster but

less accurate area trace)

Re-name selected pattern

Duplicate selected pattern

There are more options –

scroll below “Duplicate” to

jump to the second page,

shown on the next page.

Chapter 2: Machine Setup & Orientation

14

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Pattern Screen, right side options page 2

Shown here are the options on the second page of the right side menu.

Store designs in folder groups

With firmware 1.24, you can

divide designs into folder groups.

This indicator shows what folder

group you’re in.

Control Panel 2

Control Panel 2

Design Transfer

PATTERN

Second page of right-side

menu options

Save design back to flash

drive (card or USB stick)

Move design to folder

Create new folder

Sort designs by order

loaded or alphabetically

Thread break report for

selected design: shows

break locations (stitch #) of

last 30 thread breaks in a

design. Useful for

troubleshooting.

Chapter 2: Machine Setup & Orientation

NEXT: THE SETTING SCREEN

15

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Setting Screen

The Setting screen allows you to perform some useful modifications to the current

pattern. Any changes made to a design in the Setting screen will be saved with that

design and will be remembered as long as the design stays in the control panel

memory.

Left side of the Setting

screen shows:

- Design information

- Outline of the design to

display what’s being

done to the design i.e.

rotation, new size, etc.

Control Panel 2

Control Panel 2

Design Transfer

SETTING

The Setting screen

is divided into 4

tabbed sub-screens.

The functions on

each tab are

described on the

next 4 pages.

Chapter 2: Machine Setup & Orientation

NEXT: SETTING SCREEN 1stTAB

16

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Setting Screen

The Setting screen allows you to perform some useful modifications to the current

pattern. Any changes made to a design in the Setting screen will be saved with that

design and will be remembered as long as the design stays in the control panel

memory.

1stTab: useful design

editing functions

The functions found on the

default first tab perform

the most common edits:

re-scale, satin pull

compensation, and design

rotation.

Control Panel 2

Control Panel 2

Design Transfer

SETTING

Re-size design (no

stitch processor

Satin pull compensation

Rotate by degrees

Rotate or flip (in 90 deg.

increments

Chapter 2: Machine Setup & Orientation

NEXT: SETTING SCREEN 2ndTAB

17

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Setting Screen

The Setting screen allows you to perform some useful modifications to the current

pattern. Any changes made to a design in the Setting screen will be saved with that

design and will be remembered as long as the design stays in the control panel

memory.

2ndTab: Repeat

Function: This can be

useful if you wish to sew

the same design

repeatedly on a large

hoop i.e. to create a series

of patches.

Control Panel 2

Control Panel 2

Design Transfer

SETTING

Set number of rows

and columns

Spacing between columns

Spacing between rows

Toggle between “sew by

row” or “sew by column”

Chapter 2: Machine Setup & Orientation

NEXT: SETTING SCREEN 3rdTAB

18

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Setting Screen

The Setting screen allows you to perform some useful modifications to the current

pattern. Any changes made to a design in the Setting screen will be saved with that

design and will be remembered as long as the design stays in the control panel

memory.

3rdTab: Offset: This

function allows you to

program a design to sew a

design offset from center

by a given distance in mm

in the X and Y directions.

Note that –Y values move

the design lower in the

hoop and vice-versa. -X

values move the design to

the left in the hoop and

vice-versa.

Control Panel 2

Control Panel 2

Design Transfer

SETTING

Toggle auto origin on

or off

Set offset distance in

mm for X and Y values

Set offset to a corner of

the design

Set offset distance by

using the arrow keys

(sewing arm moves,

letting you “eyeball” the

offset)

Chapter 2: Machine Setup & Orientation

NEXT: SETTING SCREEN 4thTAB

19

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Setting Screen

The Setting screen allows you to perform some useful modifications to the current

pattern. Any changes made to a design in the Setting screen will be saved with that

design and will be remembered as long as the design stays in the control panel

memory.

4thTab: Frame-out for

applique

“Frame-Out” lets you

command the machine to

stop after sewing a specific

color block number and

then move the sewing arm

towards you by a specific,

pre-programmed distance.

As an example, this is

useful when sewing

appliqué, where sewing

needs to pause after the

marker stitch has been

laid. However, it can also

be done more simply in the

Needle screen (see page

12 in this chapter)

Control Panel 2

Control Panel 2

Design Transfer

SETTING

Choose color block # where

the frame-out occurs.

Set frame-out by moving

sewing arm

Set frame-out movement

numerically by entering

exact X and Y values in

mm

Chapter 2: Machine Setup & Orientation

NEXT: THE READ SCREEN

20

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Read Screen

The Read screen is used to read designs from a compact flash card or USB

jump drive.

Right side: design list from

Choose CF card or USB

Jump drive from the

selections shown on the

right when first selecting

“READ”.

Left side: “read settings”

for the design: allows you

to adjust the way the

machine reads in a design.

Some useful features are

illustrated here.

combine jump – net effect

reduces the number of trims

in a design

the card: shows 8 designs

at a time – to view the rest,

arrow down below the list

bottom or up to go higher.

Control Panel 2

Control Panel 2

Design Transfer

To access left

side options

To set left side

options back to

factory defaults

READ

stitch sweeper –always

turn on. removes

problematic short stitches.

sweep length –lets you

set the max size of the

stitches it deletes in tenths

of a mm. 4 is the

recommended value.

Chapter 2: Machine Setup & Orientation

NEXT: THE POSITION FUNCTION

21

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Position

Use the Position function if you wish to start sewing a design at any point other than

the beginning. Note that this is not used to return to position after a power fail recovery

or sewing interruption: in those cases, use the Position option accessed from the FUNC

key (when in the main “drive” screen)

Control Panel 2

Control Panel 2

Design Transfer

POSITION

Set sewing positon by

repeat # (if repeat function

is used

Set sewing position by

color block # - This is

used most commonly.

Set sewing position by

stitch# - Useful if you

remember the exact stitch

# where the machine left

off sewing

Chapter 2: Machine Setup & Orientation

NEXT: THE FRAME FUNCTION

22

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Frame Screen

The Frame function lets you choose a hoop for a design, check the design fit

and adjust the design position within the hoop.

HOW TO USE THE “FRAME” FUNCTION

Follow the steps on this page and the next to use the

Frame function.

1. Choose Frame from the

main menu.

2. Choose OK and press

SET at “Check the top of

pattern data”.

3. Choose frame type from

this menu.

Round,

Square,

Sock,

Custom

and

generic Non-registered

catch-all categories are

available. When finished

press SET.

Continued on next page

Control Panel 2

Control Panel 2

Design Transfer

FRAME

Chapter 2: Machine Setup & Orientation

23

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Frame Screen

The Frame function performs the same function as the FAST button in the Main/Drive

screen, (but with a few more options). It allows you to choose a hoop, then see/adjust

position and fit.

HOW TO USE THE “FRAME” FUNCTION

Follow the steps on this page to use the Frame function. (continued from previous page)

4. A screen appears showing

the available hoops for that

category. In the example on

the right, the Round hoop

category was chosen, so a

list of available round Hap py

hoops are shown. Sizes are

indicated in mm in the right

column (ignore the left

column of 2-digit numbers).

For example, if you wish to

choose a 12cm hoop, choose

“120”.

5. Press SET to select the

hoop. Design outline

appears in blue. Red line is

the safety margin for the

hoop. Black outline is outline

of hoop itself.

Control Panel 2

Control Panel 2

Design Transfer

FRAME

Choose a hoop and

press SET: the right

side numbers indicate

hoop size in mm.

(The left side number

is an internal

reference # and not

useful)

Chapter 2: Machine Setup & Orientation

24

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Frame Screen

The Frame function performs the same function as the F.F button in the Main/Drive

screen, (but with a few more options). It allows you to choose a hoop, then see/adjust

position and fit.

HOW TO USE THE “FRAME” FUNCTION

Follow the steps on this page to use the Frame function. (continued from previous page)

6. Check position and fit, use

the controls to adjust if

needed or desired. For

HAPPY hoops, the red

outline is an accurate

indicator of the safe, usable

area and position in the hoop.

Use the arrow keys to move

the design position (blue

outline) within the usable

area. If the blue outline is too

big for the red area, it means

the design is too large for the

selected hoop.

Control Panel 2

Control Panel 2

Design Transfer

FRAME

This is a map . . .

. . .of how you can use

these controls to

reposition the design.

To auto-center the design in

the hoop, you can press

FUNC, as indicated by the

control map on the right side

of the screen.

7. Press SET to confirm and

trace when finished before

exiting back to the main

menu and Drive screen.

Chapter 2: Machine Setup & Orientation

NEXT: HOW TO SET UP FOR CUSTOM HOOP SIZES IN THE FRAME SCREEN

25

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Frame Screen

On this page and the next, you’ll learn how to use the “user” option in the

Frame function to choose a non-standard hoop instead of the library of

HAPPY hoops.

STEPS FOR WORKING WITH CUSTOM SIZED HOOPS

.

1. Choose the Custom

frames category for frame

type using the left/right

arrow keys.

2. Select 1 of the 5 available

slots and press SET to

select a user-defined frame.

3. To edit/set up a selected

user-defined frame, pres s

MENU after selecting it.

This allows you to choose

the Data Entry mode for that

hoop. (shown top right).

P. FOOT

Control Panel 2

Control Panel 2

Design Transfer

FRAME

Option to set up

selected

custom hoops

Option to offset the

selected hoop –

useful for offcenter hooping

systems

Chapter 2: Machine Setup & Orientation

Continued on next page

26

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Important Main Menu Screens: Frame Screen

On this page and the next, you’ll learn how to use the “user” option in the

Frame function to choose a non-standard hoop instead of the library of

HAPPY hoops.

STEPS FOR WORKING WITH CUSTOM SIZED HOOPS

.

4. Set the hoop class –

choose round or rectangular

then press SET.

5. Set the hoop size –

For a round hoop, enter 1

number: the diameter in mm.

For a rectangular hoop,

enter 2 numbers: the height

(Y) and and width (X) in mm.

Control Panel 2

Control Panel 2

Design Transfer

FRAME

6. The new hoop size will

appear in this list

next to the custom slot

you’ve set up.

Chapter 2: Machine Setup & Orientation

P. FOOT

NOTE: On 3rd-party hoops, actual sewing area may differ from hoop’s stated size, based

on hoop shape presser foot clearance and other factors. Always test sewing area after

entering hoop dimensions. This is especially true of square/rectangular hoops.

Next: Transferring

Designs

27

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transferring Designs into Your Machine

In this section, we provide detailed steps about the 2 most common

ways to transfer a design into your machine to be sewn:

– USB connection or

– Compact flash card

Compact Flash Card – (shown

inserted into PCMCIA adapter

sleeve) inserts into this slot on the

side of the control panel. It works

like a floppy disk or a USB jump

drive: connect the Flash card to a

computer, save the design onto the

flash card, and insert the flash card

into the machine.

Control Panel 2

Design Transfer

Design Transfer

USB port is found on rear

wall of machine with other

ports. You can connect a

Windows PC to the machine

with a USB cable so you

can transfer designs and

perform other functions.

On the following pages, we’ll go over the steps for both

methods in detail. Next: USB connection

Chapter 2: Machine Setup & Orientation

28

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer via USB Connection

One-Time Set-up of the USB Connection (continued from last page)

Follow the steps on these pages to set up your PC for a USB connection. You’ll

only need to do this once.

2. Wait for the CD install screen to appear.

1. Run the CD that

came with your

machine before

connecting your

HAPPY machine to

your computer.

5. Launch the HAPPYLINK program you installed in

Step 3.

HAPPYLINK program window

3. Install

HAPPYLINK.

Install 3.07 or

newer for Vista 64

or Windows 7.

4. Click to install the

appropriate USB

driver for your

Windows Operating

system.

6. Click on File…Options until the dialog box shown below

appears. Ensure that the dialog box is set as shown below,

then click OK.

check “compatible”

set to 12 needles

set to USB

no borer

Control Panel 2

Design Transfer

Design Transfer

For 64-bit versions of

Windows Vista and all

versions of Windows 7,

choose USB-COM. You’ll

have to find the port# after

connecting your Happy

machine via USB cable

and letting the driver set

up, as in the next page.

Return to this screen here

on the left after finding the

virtual COM port#

assigned to your HAPPY

machine by Windows.

Chapter 2: Machine Setup & Orientation

29

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer via USB Connection

One-Time Set-up of the USB Connection (continued from last page)

Follow the steps on these pages to set up your PC for a USB connection.

5. Ensure that your HAPPY machine is

turned off, and connect a USB

cable between your PC and the

machine. You may use the cable that

came with your machine or purchase

a longer one at any computer supply

store. Ensure that any USB cable you

purchase is high-quality and under 16

feet.

6. Power on your HAPPY machine and watch your PC screen.

Windows should detect the machine, starting the Hardware

Installation Wizard, similar to what is shown below.

USB port

Connect

USB cable

Rear view of

machine

7. Continue through the prompts, ensuring that at some point, Windows

identifies the new hardware as “02 Happy Embroidery Machine” for

Windows XP / Vista 32, or, in Vista 64/Windows 7, lists it in the Device

Manager under Ports. Be sure to note the port#.

Any USB port

on your PC

Control Panel 2

Design Transfer

Design Transfer

8. Continue until the message “Your new hardware is installed and read y to use” or a similar message appears.

Chapter 2: Machine Setup & Orientation

30

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer via USB Connection

One-Time Set-up of the USB Connection (continued from last page)

Follow the 11 steps on these pages and the next to set up your PC for a USB

connection.

11. Launch the HAPPYLINK program again. If you’ve done everything correctly, the USB

connection indicator should appear as a solid grey icon in the top-left corner of the program

bar as shown below.

USB connection

indicator

Control Panel 2

Design Transfer

Design Transfer

NEXT: Actual Steps to Transfer a Design by USB Cable

Chapter 2: Machine Setup & Orientation

31

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer via USB Connection

Actual Steps to Transfer a Design by USB

Once you’ve properly set up HAPPYLINK and the USB drivers on your PC,

you’ll only need to follow the 5 steps on this page to actually transfer designs.

1. Ensure that the machine is powered on and at the main

(drive) screen. Your PC will only be able to transfer

designs from this screen.

This is the main

(drive) screen.

3. Launch the HAPPYLINK program and check to

ensure the USB icon is lit.

2. Connect the USB cable between machine and PC if you

haven’t already done so.

1. Choose format here

(either DST or TAP –

the machine will read

both.)

4. Open your design by clicking on File…Pattern Open.

The above dialog box appears. Follow the directions

indicated above, and your design should open (in grey

tones) into HAPPYLINK.

2. Browse here to

the folder where

your design is

saved.

Control Panel 2

Design Transfer

Design Transfer

3. Your design will

appear here.

Click once to

highlight it and

click OK.

5. Click the Send Pattern

Icon. The design will

transfer from your PC to

the machine.

Chapter 2: Machine Setup & Orientation

Send Pattern

icon

32

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer by CF card or Jump Drive

Which Compact Flash cards to buy

The slot located on the side of the machine’s control panel accepts flash memory cards, to allow you to

transfer designs into memory from a computer. To do this, you’ll need to buy the 3 items shown on

this page from most stores that sell computer or digital camera supplies.

3. USB to compact flash

card reader – needed if

your PC does not have a

PCMCIA slot. (most

don’t, though some

laptops have one).

Allows you to connect

your card to a computer

1. PCMCIA Adapter – Allows

the card to fit into the

machine’s flash card slot.

For PC’s (some laptops) that

also accept PCMCIA cards,

there is no need for (3) the

USB to compact flash

adapter.

2. Compact Flash card –

This is the memory card

itself. Your machine

accepts compact flash

cards up to 1 Gigabyte

in size.

and save designs to it.

Control Panel 2

Design Transfer

Design Transfer

USB “Jump” Drives are a little easier to work with they require no

adapter and plug directly into the USB port behind the control panel. They

are not as brand-specific. Larger capacity jump drives are more likely to

work. Be sure the drive is formatted in FAT32 for capacities larger than 1Gb.

Chapter 2: Machine Setup & Orientation

NEXT: ALTERNATE FORMS OF FLASH MEDIA

33

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer by CF card or Jump Drive

Other Types of Flash memory (What not to Buy)

Your HAPPY machine was designed to accept other types of Flash cards, but none have worked as

successfully as Sandisk-brand compact flash cards. For your assistance, we’ve identified other types of

flash memory cards available below. We have attempted to show the cards approximately to scale with

each other. Note that compatibility with these types may improve as revisions of the machine’s on-board

firmware and hardware are released.

GOOD

SanDisk brand

Compact Flash card:

This has worked with

the greatest success

with HAPPY machines,

and is widely available.

Other brands of

compact Flash card:

Some other types work,

although not all.

Memory Stick: This

has been the least

successful of the

other Flash media

types

SD Card: Few brands

of this type have been

found to work.

Control Panel 2

Design Transfer

Design Transfer

Jump Drive Brands: To

date, most brands of USB

jump drives have worked.

Most larger capacity

drives are even readable

(4Gb, 8Gb, etc)

Chapter 2: Machine Setup & Orientation

SmartMedia Card:

Few brands of this

type have been found

to work.

NEXT: HOW TO USE YOUR COMPACT FLASH CARD or JUMP DRIVE

Other Types of Adapter

Sleeves: All-in-1 adapter

sleeves have had limited

success, even Sandisk brand.

34

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer by CF card or Jump Drive

How to Use CF Cards or USB Jump Drives to Transfer Designs

Follow the steps on these pages to transfer designs from a PC into your HAPPY machine

with a Compact Flash card.

1. Connect the Compact Flash card or USB

Jump drive to your computer. For compact

Flash, nsert the card into a PCMCIA adapter first

(if your laptop has this type of slot) or otherwise

insert it into the USB reader.

To computer

To computer

USB reader

PCMCIA card

or

2. Start HAPPYLINK and open the design

you wish to transfer from File… Pattern

Open. You’ll see the dialog box below

appear. Follow the directions.

1. Choose format here

(either DST or TAP –

the machine will read

both.)

2. Browse here to

the folder where

your design is

saved.

Control Panel 2

Design Transfer

Design Transfer

3. Your design will

appear here.

Click once to

highlight it and

click OK.

For USB jump drives, just

plug the drive into any

available USB port on

your PC.

Chapter 2: Machine Setup & Orientation

35

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer by CF card or Jump Drive

How to Use Compact Flash Cards to Transfer Designs

Follow the 9 steps on these pages to transfer designs from a PC into your HAPPY machine

with a Compact Flash card.

3. (optional step) Set the color sequence. Click on

the icon shown below to do so. Or if you choose,

you can set colors in your machine.

4. Save the file to the Flash card or jump drive.

Click on File…Save As. The dialog box shown

below appears. Follow the directions below to

save, then close HAPPYLINK.

Control Panel 2

Design Transfer

Design Transfer

5. Click on Safely Remove Hardware Icon to shut off the card. You’ll

find this icon at the lower-right edge of the screen near the clock.

Continue until the message “It is now safe to remove” appears.

Chapter 2: Machine Setup & Orientation

36

Education Department

Training Workbook: HAPPY HCD-1501 Operat ion an d Maint enance

Machine Setup

Transfer by CF card or Jump Drive

How to Use Compact Flash Cards to Transfer Designs

Follow the 9 steps on these pages to transfer designs from a PC into your HAPPY machine

with a Compact Flash card.

6. Insert the Flash card into the

machine. You’ll need to insert the

card into the PCMCIA adapter sleeve.

Release tab pops

out when the card

is inserted fully.

Insert card

fully into slot

until it snaps

softly into

place.

USB jump drive port

is located behind the

control panel at the end

of the arm.

7. Go to the Read screen in the

control panel to read the card.

From the main (drive) screen press

MENU and click the blue arrow

keys to go to the READ and press

SET.

READ

8. Find your design in the list. Any

DST & TAP designs will show

automatically in a list on the right.

Choose your design with the blue

arrow keys and press SET.

Control Panel 2

Design Transfer

Design Transfer

Your design

will appear in

this list.

2. Press SET

after choosing

your design.

Press ESC to

return to main

menu.

9. Press ESC to return to the main (drive) screen. Once the design is imported from the READ screen, press the ESC

button until you’ve returned to the main Drive screen, where image of your design should now appear. (The next step

will be to set the colors in the Needle screen.)

NEXT: CHAPTER 3: SEWING CHECKLIST, UPPER TENSION TEST

Chapter 2: Machine Setup & Orientation

37

Loading...

Loading...