Page 1

IDENTIFICATION

About this documentation:

This documentation was originally produced in Dutch by:

Wagenbouw HAPERT

Version name : User documentation/CE/warranty conditions

Fifth edition : January 2019

© Copyright : Wagenbouw HAPERT BV, Hapert, 1998

No part of this documentation may be reproduced in any form whatsoever without the

permission of Wagenbouw HAPERT, except for those chapters that are intended to be

reproduced for use with this documentation, such as summarised instructions and

markings placed on trailers.

About the trailer:

This user documentation is intended for all HAPERT trailers.

For further information, see the type plate on the trailer.

About the manufacturer:

The trailer was manufactured by:

Wagenbouw HAPERT BV (in short: HAPERT)

Handelsweg 13

5527 AL Hapert

The Netherlands

Tel: +31 (0) 497 38 68 68

Fax: +31 (0) 497 38 68 82

Internet: www.hapert.com

E-mail: info@hapert.com

Page 2

CONTENTS:

IDENTIFICATION ................................................................................................... 1

FOREWORD ......................................................................................................... 5

USING THIS DOCUMENTATION ............................................................................... 6

TEXT CONVENTIONS ............................................................................................. 7

WARRANTY AND LIABILITY .................................................................................... 8

1. INTRODUCTION ............................................................................................ 10

1.1 Purpose and function of the trailer…………………………………….10

1.2 Models and accessories………………………………………………..10

2. SAFETY ...................................................................................................... 11

2.1 Introduction………………………………………………………………11

2.2 Safety regulations……………………………………………………….12

2.3 Unauthorised use………………………………………………………..12

2.4 Users……………………………………………………………………...13

2.5 Work area………………………………………………………………..13

2.6 Warnings on the trailer…………………………………………………13

2.7 Substances that are hazardous to humans and the environment…13

2.4.1 Operators ................................................................................ 13

2.4.2 Service personnel ................................................................... 13

2.7.1 General information ................................................................ 13

2.7.2 Storage ................................................................................... 14

2.7.3 Protection of the environment ................................................. 14

2.7.4 Disposal of the trailer .............................................................. 14

3. OPERATING INSTRUCTIONS .......................................................................... 15

3.1 Construction and operating devices…………………………………..15

3.1.1 Remote control system/Hapert remote control (optional) ........ 18

3.1.2 Using the remote control system ............................................. 18

3.1.3 Car2trailer automatic recharging system (optional) ................. 21

3.2 Using the trailer………………………………………………………….22

3.2.1 Connecting and disconnecting the trailer ................................ 22

3.2.2 Loading the trailer ................................................................... 22

3.2.3 Before pulling away ................................................................. 26

3.2.4 Tipping the trailer .................................................................... 27

3.3 Maintenance……………………………………………………………..29

3.4 Cleaning………………………………………………………………….31

4. OTHER MAINTENANCE WORK ........................................................................ 32

4.1 Repair and maintenance……………………………………………….32

4.1.1 Maintenance instructions ........................................................ 32

4.1.2 Repairing/replacing parts ........................................................ 32

Wagenbouw HAPERT 2

Page 3

5. SPECIFICATIONS ......................................................................................... 33

5.1 Trailer and weights………………………………………………………33

5.1.1 Wheels and tyres .................................................................... 33

5.1.1.1 Mounting brake system, axles and drawbar ............................ 33

5.1.2 Electrical system ..................................................................... 34

5.2 Tipping system…………………………………………………………..35

5.2.1 Tipping range .......................................................................... 35

5.2.2 Hydraulic pump ....................................................................... 35

5.3 Physical conditions of use………………………………………………35

5.4 Applicable directives and standards…………………………………...36

6. MARKINGS ON THE TRAILER ......................................................................... 37

6.1 Type/construction plate…………………………………………………37

6.2 Warnings………………………………………………………………….39

6.3 Vehicle details……………………………………………………………40

7. SERVICES ................................................................................................... 41

EU DECLARATION OF CONFORMITY .................................................................... 45

Wagenbouw HAPERT 3

Page 4

Wagenbouw HAPERT 4

Page 5

FOREWORD

This user documentation describes how to use a trailer delivered by HAPERT and how

to perform periodic maintenance. It is applicable to all HAPERT trailers.

It does not include details of work carried out on the trailer by the personnel of HAPERT

or an official HAPERT dealer.

This documentation should be considered an integral part of the trailer!

You should, therefore, store it in a safe place. It contains information that will be

useful or necessary in the future, for example for repairs and maintenance. This

documentation is included as part of the delivery of the trailer.

Besides the provisions stated in this documentation, statutory regulations for the use of

trailers, for example, number plate registration, maximum driving speed, etc. must also

be observed. The statutory regulations may differ per country and may change over

time. Make sure you observe the latest regulations!

Wagenbouw HAPERT 5

Page 6

USING THIS DOCUMENTATION

This documentation describes various trailer models. The descriptions of parts only

apply to the respective types or models on which they are actually fitted.

The instructions in this documentation are categorised according to the type of user.

Chapter 2 contains details of the requirements that different users have to meet.

The following definitions are used in this documentation:

User: The collective name for anyone who works with or on the trailer.

Operator: The daily user of the trailer.

Chapter: Introduction, Safety and Operating Instructions.

Service personnel: People with the training, experience and tools required to carry out

the described work.

Chapter: All

Safety officer: The person who is responsible for safety in the company that

owns the trailer. If nobody is appointed as such, it will be the

employer.

Chapter: Safety and Specifications

Work that is not included in this documentation must be carried out by the personnel of

or in consultation with HAPERT or the official HAPERT dealer.

The figures included in the text of this documentation are purely illustrative.

They are only intended to clarify the respective text sections, for example, to indicate

the location and function of operating mechanisms or components. The actual design

and dimensions may differ.

Wagenbouw HAPERT 6

Page 7

TEXT CONVENTIONS

Except for the text in the “Safety” chapter, text segments that are important for personal

health and safety are printed in bold.

The following warnings may be placed on the trailer:

Attention!

This pictogram warns of possible damage to the load

or the trailer.

Warning!

This pictogram is a warning for the risk of personal injury.

Wagenbouw HAPERT 7

Page 8

WARRANTY AND LIABILITY

WARRANTY

Unless agreed otherwise in writing, the manufacturer issues a warranty to the first user

for a period of 24 months after delivery.

The warranty conditions given below are applicable.

Warranty conditions:

The warranty exclusively applies to faults that occur under normal use of the trailer

and that occur due to defective construction, or due to the use of poor materials or

poor workmanship on the part of the manufacturer.

Any defects or imperfections of the delivered goods must be reported to an official

HAPERT dealer in writing as soon as possible, but no later than eight days after

they have been discovered or could have been discovered.

In order to enable the official HAPERT dealer and the manufacturer to respond

adequately, the report must contain a description of the defect that is as detailed

as possible.

In the event that a defect is reported later, the owner/user will no longer be entitled

to repair, replacement or compensation, unless a longer period ensues from the

nature of the problem or the circumstances of the case.

The warranty comprises of the replacement or repair of the faulty product or parts

free of charge by the manufacturer or the official HAPERT dealer.

The warranty conditions of the respective third parties shall apply to any built-in

components supplied by them. The length of the warranty period may differ from

the period specified above.

No claim can be made under the warranty if:

The warranty certificate is not registered via WWW.HAPERT.COM/REGISTER.

The fault is the result of normal wear, improper use, improper treatment, use of

other consumer items than specified or improper or incorrect maintenance.

The fault occurs after changes or repairs made by the buyer/user or by third

parties on behalf of the buyer/user and if it concerns a fault to the trailer's

support wheel.

The owner/user fails to fulfil all of its obligations towards the manufacturer or the

official HAPERT dealer arising from any agreement whatsoever.

The condition of the trailer on handover cannot be proved (by means of a

handover inspection by the dealer).

It cannot be proved that the trailer has undergone the periodic services (after 6

months, after 1 year, etc.).

Wagenbouw HAPERT 8

Page 9

Liability:

The manufacturer cannot be held liable for unsafe situations, accidents or damage

that are caused by ignoring warnings or regulations placed on the trailer or included in

this documentation, such as:

Incompetent or incorrect use, or poor maintenance.

Using the trailer for purposes or under conditions other than those given in the

documentation.

Using components other than those prescribed in this documentation.

Performing repairs without permission from the manufacturer.

Making changes to the trailer, such as:

Changes to the control system.

Welding, mechanical treatment, etc.

Adding items to the trailer or its control system.

If the buyer of the trailer has not fulfilled all his obligations (financial or otherwise)

to the manufacturer.

For consequential damage caused by defects or the malfunctioning of the trailer

(for example damage to products (to be processed), interruption of work in

progress, delays, etc.).

Wagenbouw HAPERT 9

Page 10

1. INTRODUCTION

1.1 PURPOSE AND FUNCTION OF THE TRAILER

The trailer is intended to be used to transport both bulk goods and individual items. The

trailer consists of a chassis with a single axle, tandem axle or tridem axle on which a

cargo bed is fitted. For types COBALT HB and the INDIGO HT and LT the cargo bed

can be tipped backwards by means of a hydraulic pump and cylinder. For type

COBALT HM and COBALT+, the cargo bed can be tipped to the left, right or

backwards, as desired by the user, by means of a hydraulic pump and cylinder.

1.2 MODELS AND ACCESSORIES

The (technical) specifications of all the HAPERT models and types are available in the

Media section of WWW.HAPERT.COM.

Wagenbouw HAPERT 10

Page 11

2. SAFETY

2.1 INTRODUCTION

The trailer has been designed in such a way so that it is safe to use and maintain. This

applies to the uses, circumstances and guidelines described in this documentation.

Everybody who works with or on the trailer must, therefore, read this documentation

and follow the instructions it contains.

In the case of professional use, it is the employer’s responsibility to ensure that the user

is familiar with the instructions and that they are observed.

Additional safety measures may apply in the company or country in which the trailer is

used. These measures mainly relate to the working conditions. This documentation

does not describe how these measures must be complied with. It does, however,

contain all the information you will need about the trailer. If you have any doubts, ask a

relevant government official or your safety officer.

In this documentation, a distinction is made between normal use (see chapter 3:

Operating Instructions) and other work (see chapter 4) carried out on the trailer. The

reason for this is that service personnel have to meet different requirements than the

operator, particularly with regard to safety.

Simple maintenance work described in the operating instructions can be carried out by

the operators.

Work that is not described in the operating instructions may only be carried out by

people who are qualified to do so. The accessories that are supplied with the trailer to

restrict access to specific sections or functions (such as the key to the main switch) may

not be stored on or near the trailer. These accessories may only be entrusted to people

with the required qualifications.

Wagenbouw HAPERT 11

Page 12

2.2 SAFETY REGULATIONS

Ensure unauthorised people, such as children, cannot operate the tipping

system. The key must be removed from the main switch when the trailer is left

unsupervised.

People may only use the trailer if they have read and understood the operating

instructions.

The tipping system may only be operated when the trailer is stationary, the brake

has been applied and the trailer is connected to a towing vehicle.

Do not climb on the trailer when the tipping system is being used.

Do not climb on the trailer if it is not connected to a vehicle.

When tipping the load off the trailer, make sure nobody is in the area where the

load is to be tipped.

Safety devices may not be removed or put out of operation.

Keep the workplace neat and tidy, and free of obstacles.

Make sure the surroundings are adequately illuminated.

Be aware of the risk of becoming trapped between the cargo bed and the frame

or the front, side and rear flaps.

A trailer must be on a stable surface (not to sink into gravel or sand) during

tipping. Trailer may fall.

Using the tipping system on an incline is dangerous. Trailer may fall.

When using tipping system always use the mounted supports. (For instructions,

see Section 3.2.2)

Do not exceed the maximum permitted load (see name/type plate).

Do not exceed the maximum permitted ball thrust (see name/type plate).

Do not exceed the maximum load of the tie rings

Only use the remote control after reading the operating instructions (see 3.1.2).

2.3 UNAUTHORISED USE

The trailer is especially not suitable for:

Transporting people or animals.

Using the tipping system to unload individual items.

Lifting people or goods.

Wagenbouw HAPERT 12

Page 13

2.4 USERS

2.4.1 OPERATORS

The trailer may be used by any adult who is familiar with and observes the instructions

in the “Safety” and “Operating Instructions” chapters. Special training is not required.

However, a relevant driving licence is required to drive a vehicle while towing a trailer.

2.4.2 SERVICE PERSONNEL

Special knowledge/experience and/or training is required. For the driving section:

knowledge and experience with regard to the maintenance of motorised vehicles. For

the hydraulic section: knowledge and experience with regard to the maintenance of

hydraulic systems.

2.5 WORK AREA

A work area of 100 cm around the trailer must be kept clear in order for the tipping

system to be operated.

2.6 WARNINGS ON THE TRAILER

The warning signs placed on the trailer must be clearly legible. If necessary, replace

them or have somebody else do this for you.

The text of the warning signs placed on the trailer are listed in the “Markings on the

trailer” chapter. The respective hazards are described in further detail in the operating

and maintenance instructions.

2.7 SUBSTANCES THAT ARE HAZARDOUS TO HUMANS AND THE ENVIRONMENT

2.7.1 GENERAL INFORMATION

The following substances that are used when working with the trailer require special

attention:

Hydraulic oil

Battery acid

Wagenbouw HAPERT 13

Page 14

2.7.2 STORAGE

Always store hazardous substances in a location that is not accessible to unauthorised

people. The storage of hazardous substances may be subjected to legal regulations.

Contact the relevant authorities for the applicable regulations and the required permits.

2.7.3 PROTECTION OF THE ENVIRONMENT

Risks of environmental pollution are present in the form of:

Hydraulic oil

The battery (may contain lead)

Battery acid

Battery (the remote control)

Dispose of these substances in accordance with locally applicable regulations and

environmental legislation.

2.7.4 DISPOSAL OF THE TRAILER

If the trailer is dismantled, the local waste disposal regulations applicable at the time of

dismantlement must be observed. The battery unit fitted on the trailer and the oil must

be treated as chemical waste and be processed accordingly. This also applies to the

tyres.

The handbrake is spring-mounted. When disposing of the trailer, the energy stored in

the spring must be released safely.

Apart from this, the trailer only consists of common materials. At the time of

construction, these materials could be disposed of safely without the people carrying

out dismantlement work being exposed to any special or undue risks.

See 2.7.3 “Protection of the environment”.

Wagenbouw HAPERT 14

Page 15

3. OPERATING INSTRUCTIONS

Anyone who wishes to use the trailer must first be familiar with the information in the

“Safety” chapter.

As specified in 2.4.1, this chapter is intended for operators.

Work that is not specified in this chapter may only be carried out by service personnel

(see chapter 4).

3.1 CONSTRUCTION AND OPERATING DEVICES

The operating devices for the electrical tipping system are:

A main switch.

A hold-to-run button on the control panel for raising the cargo bed.

A hold-to-run button on the control panel for lowering the cargo bed.

A hold-to-run button on the remote control for raising the cargo bed (optional).

A hold-to-run button on the remote control for lowering the cargo bed (optional).

The remote control for the tipping system includes:

A valve: a two-position valve for raising and lowering

A pump lever

Main switch

Pump lever

Hand pump

Electric operation switch Hand pump valve

COBALT HM

Wagenbouw HAPERT 15

Page 16

Main switch

Emergency

hand pump

lever

Electric operation switch Emergency hand pump valve

COBALT +

Main switch hand pump valve

COBALT HB

Pump lever

for hand

pump

Electric

operation

Wagenbouw HAPERT 16

Page 17

Hand pump valve Pump lever for hand pump

INDIGO HT

Hand pump valve Pump lever for hand pump

INDIGO LT

Wagenbouw HAPERT 17

Page 18

3.1.1 REMOTE CONTROL SYSTEM/HAPERT REMOTE CONTROL (OPTIONAL)

The remote control system (see figure 3) is fitted during manufacture. The remote

control system works with a hold-to-run system, meaning that raising or lowering stops

as soon as the control button is released.

3.1.2 USING THE REMOTE CONTROL SYSTEM

Observe the safety regulations (see 2.2).

Use the main power switch’s red key to turn on the system. By turning the key

clockwise, the electrical system is switched on. (See figure 1) Before using the remote

control (see figure 3), the on/off button on the control panel (see figure 2) needs to be

pressed 2 times. Now the remote control is ready for use (operation with the control

panel is no longer possible in this position).

Figure 1.

To raise the cargo bed: keep the raise button on the remote control pressed until

the desired height is reached.

To lower the cargo bed: keep the lower button on the remote control pressed

until the cargo bed is back in its rest position.

Use the key of the main power switch to turn off the entire system by turning it

anti-clockwise, then remove the key from the main power switch.

Wagenbouw HAPERT 18

Page 19

RED > Batter

y in

critical voltage

(recharge

)

Control panel

Left LED is green or blue

GREEN > Manual operation

BLUE > Handheld remote

control

On/Off button

Right LED is green, orange or red

GREEN > Battery voltage is good

ORANGE > Battery voltage is weak

Raise button

Lower button

Figure 2.

Wagenbouw HAPERT 19

Page 20

Handheld remote control

On/Off button

Figure 3.

Attention!

When the system is not in use, always turn off the main power

switch and remove the key. Operation via both the control panel

and the remote control is then no longer possible.

Warning!

Using the remote control as a

two-channel on/off switch is not permitted.

Raise button

Lower button

Wagenbouw HAPERT 20

Page 21

3.1.3 CAR2TRAILER AUTOMATIC RECHARGING SYSTEM (OPTIONAL)

The purpose of the automatic recharging system is to supply the correct charging

voltage to the electrically powered tipping system. The system is connected to the

standard lighting cable using a two-pole adapter. The 13-pole connection with the

towing vehicle ensures that the Car2Trailer booster/charger provides the battery system

in the trailer with the correct charging voltage while driving. An acoustic signal is given if

the voltage is too low when using the electric tipping system. See the Media section at

WWW.HAPERT.COM for the installation manual circuit diagram.

Attention!

The Car2Trailer recharging system may only be connected by

competent service personnel who are familiar with the regulations

for working with high-voltage batteries. Always read the installation

manual. Incorrectly connecting the battery (e.g. reversing the plus

and minus terminals) or using the wrong type of connectors can

result in serious damage to the system, for which the manufacturer

cannot be held liable. Make sure the cables are firmly attached.

Always use fuses.

Figure 4.

Wagenbouw HAPERT 21

Page 22

3.2 USING THE TRAILER

3.2.1 CONNECTING AND DISCONNECTING THE TRAILER

Figure 5.

Connecting:

Open the coupling housing by pressing the locking button on the handle H and

moving the handle upwards. Place the opened coupling on the ball of the towing

vehicle’s tow bar and release the handle. The handle should automatically slide back

to the starting position. The coupling is automatically closed and locked in place.

Make sure the coupling is in the right position >>+<< (see figure 5). The tow ball

must not be visible when the trailer is connected. Fasten the safety cable (see figure

11) and insert the plug in the towing vehicle. Raise the support wheel and secure it in

position parallel to the direction of travel (the support wheel must not impede the

movement of the brake rod).

Always check whether the lights work before driving.

Disconnecting:

Lower the support wheel. Disconnect the safety cable and the plug. Open the

coupling housing by pressing the locking button on the handle H and moving the

handle upwards. Lift the coupling off the towing vehicle’s tow bar. Pay particular

attention when disconnecting on an incline (once the towing vehicle is stationary,

apply the handbrake or use the wheel blocker, if fitted)

Only drive in the >>+<< range

3.2.2 LOADING THE TRAILER

Maximum load

The maximum load must not be exceeded. The maximum load is equal to the unladen

weight of the trailer plus the load capacity.

Maximum load: Unladen weight + load capacity

Wagenbouw HAPERT 22

Page 23

Unladen weight: The weight of the trailer when ready to be used, i.e. with spare

parts and tools that are normally included, but without a load.

Load capacity: The maximum permitted load weight.

Weight distribution:

To ensure the brakes work properly and to have good road handling, the centre of

gravity must be as close as possible to the axle.

Heavy objects must be placed as much as possible above the axle.

Lighter objects should be distributed evenly across the cargo bed.

The load should be divided over the right-hand and left-hand halves of the trailer as

evenly as possible.

Avoid point loads.

The load must always be properly secured. Each country has its own regulations.

Make sure the trailer meets the applicable requirements.

When loading and unloading the trailer, it must always be connected to the towing

vehicle.

Figure 6

Maximum support wheel load:

The maximum static load for a sliding support wheel is 150 kg. The maximum static

load for a foldable support wheel is 250 kg. The maximum load must not be exceeded.

Attention!

Wagenbouw HAPERT 23

The trailer has been designed, constructed and tested for the loads

shown in the accompanying documents and on the type

plate/construction plate attached to the front of the trailer. Overloading

the trailer can result in permanent damage, for which the manufacturer

accepts no liability.

Page 24

Tying down/securing the load:

The load must always be tied down and secured properly on the trailer using binders

that are suitable for this specific purpose

The tie rings, which are fitted as standard and are TÜV-certified according to quality

mark DIN EN 75410-1, must be used to secure a load.

Figure 7

For tying down the load, only use reliable ropes that are specifically designed for this

purpose and that comply with standard EN 12195-2.

The maximum load that the tie rings fitted on the sides of the trailer (see figure 7) can

take is 1,000 kg (daN)

Supports

Supports fitted under the chassis can be extended when loading the trailer.

How the supports work: After releasing the locking pin, the supports can be rotated

90°

Rotatable by 90˚ downwards and re-secured in position with the locking pin.

Using the handle supplied with the trailer, the support should

be lowered until it is approx. 5 cm above ground level when

the trailer is empty (see figure 8).

The 5 cm gap is needed to compensate for the spring of the axles. If the supports are

lowered completely, they will take the entire weight of the load and can become

damaged. On soft ground, suitable plate material has to be laid under the supports.

Before driving off, the supports have to be secured in their top position and, if

necessary, rotated 90° so that they lay parallel to the chassis (see figure 9).

Wagenbouw HAPERT 24

Page 25

Figure 8

Figure 9

Ball thrust:

The ball thrust is one of the most important criteria for the road handling of the trailer

and, therefore, the entire vehicle combination.

The maximum permitted ball thrust (see the specifications of your tow bar or vehicle

and the type plate on your trailer) may not be exceeded. The ball thrust can be

increased or reduced by moving the load further forwards or backwards, respectively.

The optimal ball thrust is close to the maximum ball thrust. A negative ball thrust (i.e. an

upwards force applied to the tow bar) is strictly forbidden.

Carelessly loading the trailer may result in a risk of slipping or swerving. Adjust your

speed to the condition of the road surface and the load. This is particularly important in

corners.

Make sure the wheels do not wobble and the tyres are balanced.

Coupling height (with regard to the towing vehicle):

Another important element which influences the vehicle combination’s road handling

(particularly for tandem trailers) is the height of the coupling. The trailer’s coupling

height and that of the towing vehicle must not differ by too much. The vehicle

combination’s road handling is influenced by the difference in coupling height. A

dangerous situation may arise if the towing vehicle’s coupling height is considerably

lower than that of the trailer, because this results in a negative ball thrust.

Wagenbouw HAPERT 25

Page 26

Relationship between load, tyre pressure, ball thrust and coupling height:

Poor road handling is unavoidable if a trailer creates a negative ball thrust because it is

poorly loaded and if it is connected to a towing vehicle with a lower coupling height. If

this is combined with a tyre pressure which is too low (see 5.1.1), then a dangerous

situation may arise. For that reason, all the warnings given above must be observed.

3.2.3 BEFORE PULLING AWAY

Raise the support wheel and secure it in position. The support wheel must always

point in the direction of travel (the support wheel must not impede the movement of

the brake rod).

Check the coupling. The coupling housing must completely enclose the ball and

must be secured. Make sure the coupling is in the right position >>+<< (see figure 5).

Attach the safety cable to the towing vehicle (see figure 11).

Safety cable

Figure 11

Insert the lighting plug.

Regularly check the tyre pressure (see table 5.1).

Make sure the load is evenly distributed and properly secured.

Check the lights: indicators, rear lights, brake lights (the load must never obscure the

view of the lights).

Before driving off, make sure any wheel blockers have been removed and that the

handbrake on a braked trailer has been released.

Check whether the cargo bed is secured to the chassis (only for type INDIGO HT

and LT).

Check whether all the locking pins are fitted and secured in place (only for type

COBALT HM and COBALT+).

Make sure the supports are secured in their top position and, if necessary, rotated

90° so that they lay parallel to the chassis (see figure 9).

The trailer has an auto-reversing mechanism. This means that if you reverse, the

overrun brake does not have to be blocked.

Wagenbouw HAPERT 26

Page 27

3.2.4 TIPPING THE TRAILER

Find out whether the tipping trailer has a hand pump, an electric pump (possibly with a

battery) or both.

Warning!

Only turn on the hydraulic system when you have made

absolutely sure that nobody is in the danger zones around

the trailer. Attention:

Make sure nobody is in the location where the load is to

be tipped.

Make sure nobody is on the trailer.

Pay attention to the risk of becoming trapped between the

cargo bed and the chassis.

Warning!

Do not use the tipping system on a steep incline.

1. Only use the tipping system when the trailer is stationary and connected to the

towing vehicle.

Make sure the trailer’s handbrake has been applied.

2. Lower the support wheel.

3. Make sure the load is no longer secured.

4. To tip backwards:

- Unlock the two locking pins on the two front corners of the trailer (only for type

COBALT HM and COBALT+).

- Unlock the rear flap.

To tip to the left (only for type COBALT HM and COBALT+):

- Fit the two locking pins to the two left-hand corners of the trailer.

- Unlock the left-hand flap.

To tip to the right (only for type COBALT HM and COBALT+):

- Fit the two locking pins to the two right-hand corners of the trailer.

- Unlock the right-hand flap.

Wagenbouw HAPERT 27

Page 28

Warning!

Before tipping, always check that:

- The load is no longer secured.

For type COBALT HM and COBALT+:

- The correct two locking pins are in place.

- The correct side flap or the rear flap is unlocked.

For types COBALT HB and INDIGO HT and INDIGO LT:

- The rear flap is unlocked.

5.0 Tipping using the hand pump:

To tip the cargo bed: place the hand pump’s valve in the “raise” position and use the

pump lever to pump until the desired height is reached.

To lower the cargo bed: place the hand pump’s valve in the “lower” position until the

cargo bed touches the chassis and then place the valve back in the “raise” position.

5.1 Electric tipping:

Use the key of the main power switch to turn on the system. (See figure 1) Turn the key

clockwise to activate the electrical system. The on/off button on the control panel needs

to be pressed 1 time to activate the control panel. To raise the cargo bed: keep the

relevant button on the control panel (see figure 2) pressed until the desired height is

reached.

To lower the cargo bed: keep the relevant button on the control panel pressed until the

cargo bed has returned to its rest position.

Turn the system off using the key in the main switch - turn the key to the left and

remove it!

See 3.1.1 and 3.1.2 for electric tipping using the remote control.

5.2 Electric tipping in combination with an emergency pump:

Electric operation: See “Electric tipping” for additional operating instructions.

Emergency pump operation: To tip the cargo bed: use the pump lever to pump until

the desired height is reached.

To lower the cargo bed: rotate the button until the cargo

bed rests on the chassis.

After the cargo bed has been lowered, place the rotary

button back in the “raise” position.

(Rotate closed/see figure 12)

Wagenbouw HAPERT 28

Page 29

Rotary button

Emergency pump lever

Figure 12

6. Lock the side flap or the rear flap.

Make sure the drive-on ramp is secured (only for type INDIGO HT and

INDIGO LT).

7. Use the two locking pins to secure the cargo bed to the chassis (only for type

COBALT HM and COBALT+) or lock the cargo bed to the chassis (only for type

INDIGO HT and INDIGO LT).

8. Raise the support wheel.

3.3 MAINTENANCE

Warning!

When working under the cargo bed:

Always support the cargo bed!

Maintenance by the user/service personnel

Wheel attachment:

After the first journey, check whether the wheel bolts are still sufficiently tightened. If

necessary, retighten them. Use the tightening torques table in the Specifications

chapter (5.1.1) to find the correct torque. Check the bolts every time a wheel has

been loosened, for example, to change a tyre (tighten the wheel bolts crossways).

Check the plug and the lights (dirt, corrosion and damage).

Check the tyres (tyre pressure, wear and damage).

Ball coupling:

Regularly clean and grease all sliding surfaces and bearing points.

Wagenbouw HAPERT 29

Page 30

Figure 13

Hydraulic pump oil level:

Check the hydraulic oil level and, if necessary, top it up.

For an electric pump: when the cylinders are in the highest position, the level must

be up to 10 cm below the edge of the cover.

For a hand pump: when the cargo bed is down, the level must be up to 1 cm below

the edge of the cover.

Battery, charge it if necessary:

A disconnected battery should be stored in a dry, frost-free location in your

warehouse (this is vital to reduce self-discharge to a minimum).

After a few months, the battery will have discharged itself and its condition should,

therefore, be checked. At 12.2 V (this is 80% of its capacity), the battery needs to be

recharged with a charger that has a capacity equal to at least 10% of the battery’s

capacity (e.g. a 90 Ah battery must be recharged with a charger of at least 8 A and

no more than10 A in order to obtain the best results).

This also applies to batteries that are installed in products in your showroom, so

please check their condition regularly and, if needed, recharge to 12.7 V (100%

battery charge).

If you neglect to do this, battery sulphation will irrevocably occur (lead sulphate that

attaches itself to the plates) and recharging will no longer be possible.

Sulphated batteries are not covered by warranty.

Attention!

You should never charge the battery with a quick charger.

Always use a trickle charger.

Depending on the type of trailer, it may have a plug socket for a battery charger.

Wagenbouw HAPERT 30

Page 31

Lubricating the overrun system:

Lubricate the grease nipples with grease (see figure 14) and the sliding parts with oil.

Handbrake Grease nipples

Ball coupling Safety cable Figure 14

3.4 CLEANING

The trailer may be hosed down with water. We recommend that you do so if the trailer

has been in contact with salt (brine) or acids, as the zinc coating can be permanently

damaged by such substances. For new vehicles of which the zinc coating has not yet

fully hardened, white spots (white rust) or black spots may appear if the trailer is not

cleaned frequently enough. However, the protective effect of the zinc coating is not

reduced by the spots. To try to prevent these spots on hot-dip galvanised components,

you can take measures to ensure there is sufficient air circulation during storage, so no

water film develops between the metal surfaces.

Always make sure the electrical components do not come into contact with water or

other liquids!

Wagenbouw HAPERT 31

Page 32

4. OTHER MAINTENANCE WORK

The work specified here may only be carried out by service personnel, as described in

2.4.2.

4.1 REPAIR AND MAINTENANCE

4.1.1 MAINTENANCE INSTRUCTIONS

The trailer must be inspected at least once a year by an official HAPERT dealer. The

HAPERT dealer will check and repair the trailer in accordance with the “BOVAGAanhangwagenbedrijf” regulations (BOVAG Trailer Company).

If faults arise in the meantime, a dealer must be contacted as soon as possible.

4.1.2 REPAIRING/REPLACING PARTS

During the warranty period, repairs may only be carried out under the supervision of

HAPERT or an official HAPERT dealer.

All replacement parts must always have the same specifications as the originals.

All parts can be ordered from an official HAPERT dealer.

The trailer is built from both standard parts (generally available on the market) and

specific components (especially made for the trailer).

Standard parts:

Only use original parts.

If you have any doubts about the specifications, ask HAPERT or an official HAPERT

dealer.

Specific parts:

Only use replacement parts provided by HAPERT or an official HAPERT dealer.

Warning!

Deviating from the instructions given above may result in

damage to the trailer. HAPERT or an official HAPERT dealer

cannot accept any liability in this respect.

Wagenbouw HAPERT 32

Page 33

5. SPECIFICATIONS

5.1 TRAILER AND WEIGHTS

See the Media section at WWW.HAPERT.COM for all the dimensions and weights.

5.1.1 WHEELS AND TYRES

Wheel bolt specifications:

Screw thread Spanner size Max. tightening moment

mm mm Nm

M 12 x 1,5 17 (19) 80 - 90

M 14 x 1,5 19 110 - 120

Optimal tyre pressure:

The optimal tyre pressure depends on the type of tyre. Any garage can give you this

information. Only use Wagenbouw HAPERT tyres or inquire at Wagenbouw HAPERT

or an official HAPERT dealer.

TYRE SIZE TYRE PRESSURE MAX. LOAD

155/80R13 2,9 42 500

165R13C 4,5 65 710

185/70R13 3 44 650

175R14C 4,5 65 775

185R14C 4,5 65 900

155/70R12C 6,5 95 900

195/50R13C 6,5 95 900

195/55R10C 6,2 90 750

205/70/R15C 3,8 55 900

145/70R13 3 44 425

18.5x8.5-8 3,4 50 425

185/70R13C 6 85 950

BAR PSI KG.

5.1.1.1 MOUNTING BRAKE SYSTEM, AXLES AND DRAWBAR

Screw thread Spanner size Max. tightening moment

mm mm Nm

M 12 Kl. 8.8 17 (19) 80 - 90

M 12 Kl. 10.9 17 (19) 110 - 120

Wagenbouw HAPERT 33

Page 34

5.1.2 ELECTRICAL SYSTEM

13-pole plug connection diagram:

Figure 15

7-pole plug connection diagram:

Figure 16

INDICATION COLOUR NAME

1 Yellow Left indicator

2 Blue Fog lamp

3 White Earth (for poles 1-8)

4 Green Right indicator

5 Brown Right rear light

6 Red Left and right brake lights

7 Black Left rear light

8 Grey Reversing light

9 Brown/blue Continuous current

10 Brown/red Battery charger (plus)

11 White/Red Battery charger earth

12 Free

13 White/black Earth (for poles 9-12)

INDICATION COLOUR

L Yellow Left indicator

54G Blue Fog lamp

31 White Earth

R Green Right indicator

58R Brown Right rear light

54 Red Left and right brake lights

58L Black Left rear light

NAME

Wagenbouw HAPERT 34

Page 35

5.2 TIPPING SYSTEM

5.2.1 TIPPING RANGE

Tipping range, tipping backwards To the end of the cylinder

Tipping range, tipping sideways (only type

COBALT HM and COBALT+)

Until the safety cable is tight or by

means of a stop switch (electric

operation)

5.2.2 HYDRAULIC PUMP

Hand pump COBALT

HB, HM, and COBALT+

Nominal pressure 180 bar 250 bar 170 bar

Pressure relief valve

setting

Oil reservoir

Volume

Effective volume

Hydraulic oil Tellus 46, Shell HM46 or

Battery

Type

Capacity

Electric motor capacity N/A N/A 2 kW

Maximum sound level <70 dB(A) <70 dB(A) <70 dB(A)

220 bar 300 bar 200 bar

5 litres

4.5 litres

similar

N/A N/A

Hand pump INDIGO

HT and INDIGO LT

(double-acting)

1 litre

1 litre

Tellus 46, Shell

HM46 or similar

Electric pump COBALT HB,

HM, COBALT+ and INDIGO

HT

5 litres

4.5 litres

Tellus 46, Shell HM46 or

similar

12 V starter battery

90 Ah

5.3 PHYSICAL CONDITIONS OF USE

Ambient temperature:

* Working

* During transport/storage

Relative humidity (RH) 30% to 95%, non-condensing

Lighting E4 / normal ambient lighting

The trailer is not suitable for use in an explosion-hazardous environment.

-5 to +40 degrees Celsius (with

hydraulic system)

-25 to +40 degrees Celsius

-25 to +55 degrees Celsius

Wagenbouw HAPERT 35

Page 36

5.4 APPLICABLE DIRECTIVES AND STANDARDS

Trailers with a hydraulic tipping system have CE marking. This CE marking concerns

the trailer’s tipping system. The CE marking means that the tipping system meets the

applicable European guidelines concerning health and safety. The "Declaration of

Conformity" (see page 45) specifies the respective directives.

The applicable standards are also specified in the "Declaration of Conformity". The

trailer also complies with the provisions of European Directive 2007/46/EC and the

Netherlands Road Transport Directorate (Rijksdienst voor het Wegverkeer) has issued

the required type approval.

Wagenbouw HAPERT 36

Page 37

6. MARKINGS ON THE TRAILER

6.1 TYPE/CONSTRUCTION PLATE

The trailer complies with the provisions of European Directive 2007/46/EC and the

Netherlands Road Transport Directorate (Rijksdienst voor het Wegverkeer) has issued

the required type approval, which means a type/construction plate has to be fitted on

the trailer. The type/construction plate lists the following information (see figure 17):

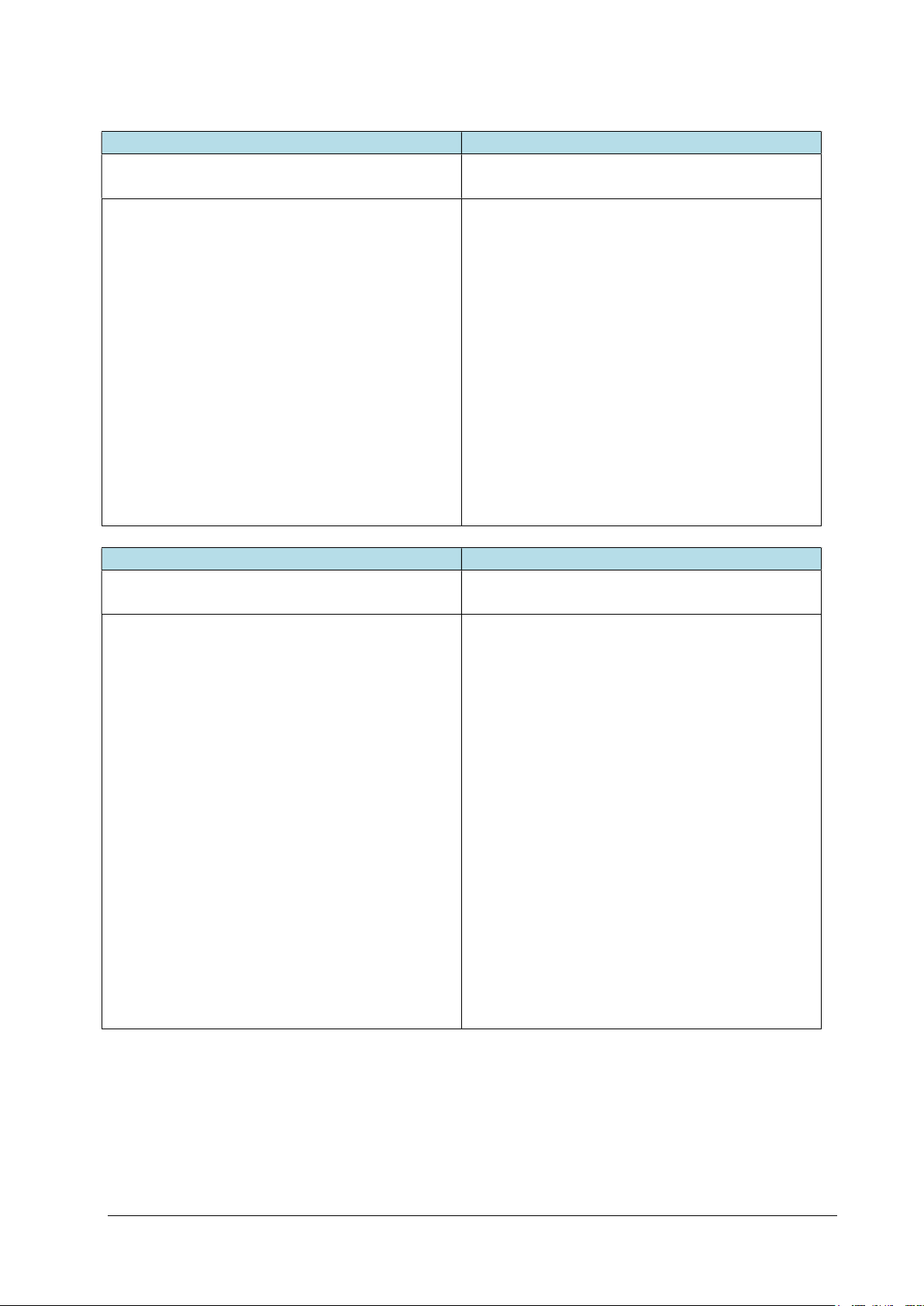

DESCRIPTION TRAILER DETAILS

Name of manufacturer See trailer type plate

Approval no. See trailer type plate

Identification no. See trailer type plate

Max. total weight See trailer type plate

Max. ball thrust See trailer type plate

Max. axle load 1 See trailer type plate

Max. axle load 2 See trailer type plate

Max. axle load 3 See trailer type plate

Max. axle load 4 See trailer type plate

Type See trailer type plate

Manufacturer See trailer type plate

Figure 17

Location of the type/construction plate and chassis number: at the front on the righthand side (see figure 18).

Wagenbouw HAPERT 37

Page 38

Type/construction plate

Identification number

Figure 18

Location of the type plate of an ECE-approved tow pole: against the tow pole

For trailers with a pipe tow shaft, it is located on the shaft.

(See figure 19)

Tow pole type plate

Figure 19

All warning stickers and type plates placed on the trailer must be legible at all

times. Replace stickers and type plates that are damaged or no longer legible.

Wagenbouw HAPERT 38

Page 39

6.2 WARNINGS

The following warnings are placed on the front of a trailer with a hydraulic tipping

system:

The following warning is placed on the rear of a trailer with lights that can be obscured:

Wagenbouw HAPERT 39

Page 40

6.3 VEHICLE DETAILS

Fill in the trailer details below:

Type of trailer

Trailer dimensions

Chassis number

Max. total weight

HAPERT dealer stamp

Wagenbouw HAPERT 40

Page 41

7. SERVICES

This trailer is a road vehicle and has been constructed from parts that require

continuous maintenance. For that reason, this trailer is always delivered with a

handover inspection and a delivery confirmation, which must be completed by the

dealer and the customer. The trailer must undergo its first service after no more than 6

months and then after every 12 months. Observing the service requirement (performing

all the required services for the first 24 months) is compulsory for the warranty to

remain valid. Also see “Warranty and liability” in this manual.

Service on delivery Max. 6 months-after-delivery service

Date

HAPERT dealer stamp

Signature

Date

HAPERT dealer stamp

Signature

Wagenbouw HAPERT 41

Page 42

1st year service 2nd year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the delivery

service

3rd year service 4th year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 2nd service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 2nd service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 3rd service

Wagenbouw HAPERT 42

Page 43

5th year service 6th year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 4th service

7th year service 8th year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 6th service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 5th service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 7th service

Wagenbouw HAPERT 43

Page 44

9th year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 8th service

11th year service 12th year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 10th service

10th year service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 9th service

Date

HAPERT dealer stamp

Signature

At least 1 year after the 11th service

Wagenbouw HAPERT 44

Page 45

EU DECLARATION OF CONFORMITY

We Wagenbouw HAPERT BV

Handelsweg 13

5527 AL Hapert

The Netherlands

Tel: +31 (0) 497 38 68 68

Fax: +31 (0) 497 38 68 82

Internet: www.hapert.com

E-mail: info@hapert.com

Hereby declare under sole responsibility:

1- We are the manufacturer of the following machine to which this declaration

applies: Trailer tipping system

Brand: HAPERT

Types: COBALT HB

COBALT+

COBALT HM

INDIGO LT

INDIGO HT

Function: Tipping a cargo bed with a load.

Serial number: all serial numbers of these types.

2- The machine has been designed and built in accordance with the requirements of

Machinery Directive 2006/42/EC.

3- The machine also complies, when the occasion arises, with the requirements of

the following EU directives: EMC directive 2004/108/EC.

4- The machine has been designed and built in accordance with the requirements of

the (European) standards or normative documents:

NEN EN 1037:1996+A1: 2008 Prevention of unexpected start-up

NEN EN 1853:1999+A1: 2009 Agricultural machinery. Trailers with tipping body. Safety.

NEN EN 4413:2010 Hydraulic fluid power - General rules and safety

requirements for systems and their components

NEN-EN-ISO12100-1:2010 Safety of machinery - General principles for design - Risk

assessment and risk reduction.

Signed in Hapert

Date: September 2013

.....

Signed by: A.J.H. Saris

Position: Director

Wagenbouw HAPERT 45

Loading...

Loading...